ASTM B660-08

(Practice)Standard Practices for Packaging/Packing of Aluminum and Magnesium Products

Standard Practices for Packaging/Packing of Aluminum and Magnesium Products

ABSTRACT

These practices describe methods of packaging/packing aluminum and magnesium products, in preparation for storage or shipment, both foreign and domestic. These practices are designed to deliver the products to their destination in good condition. Aluminum and magnesium products must be preserved and packed so as to be adequately protected from possible damage during shipment and storage. Major damage type are: mechanical and corrosion or water stain. These practices are classified according to levels of protection: Level A and commercial packaging.

SCOPE

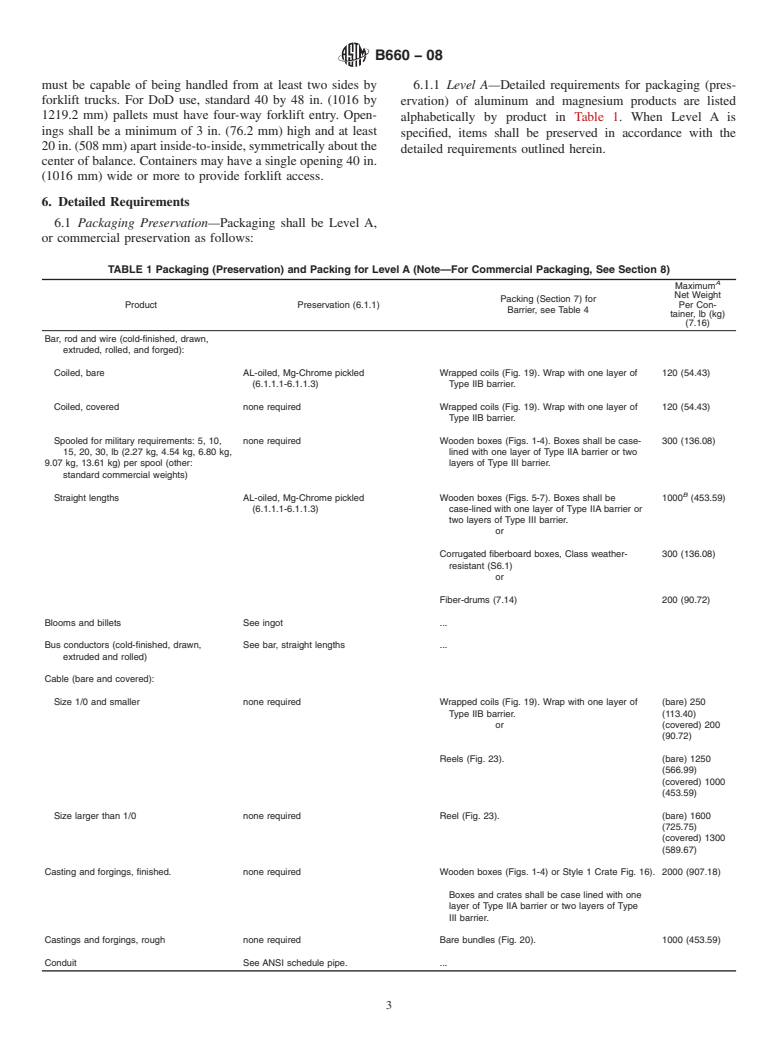

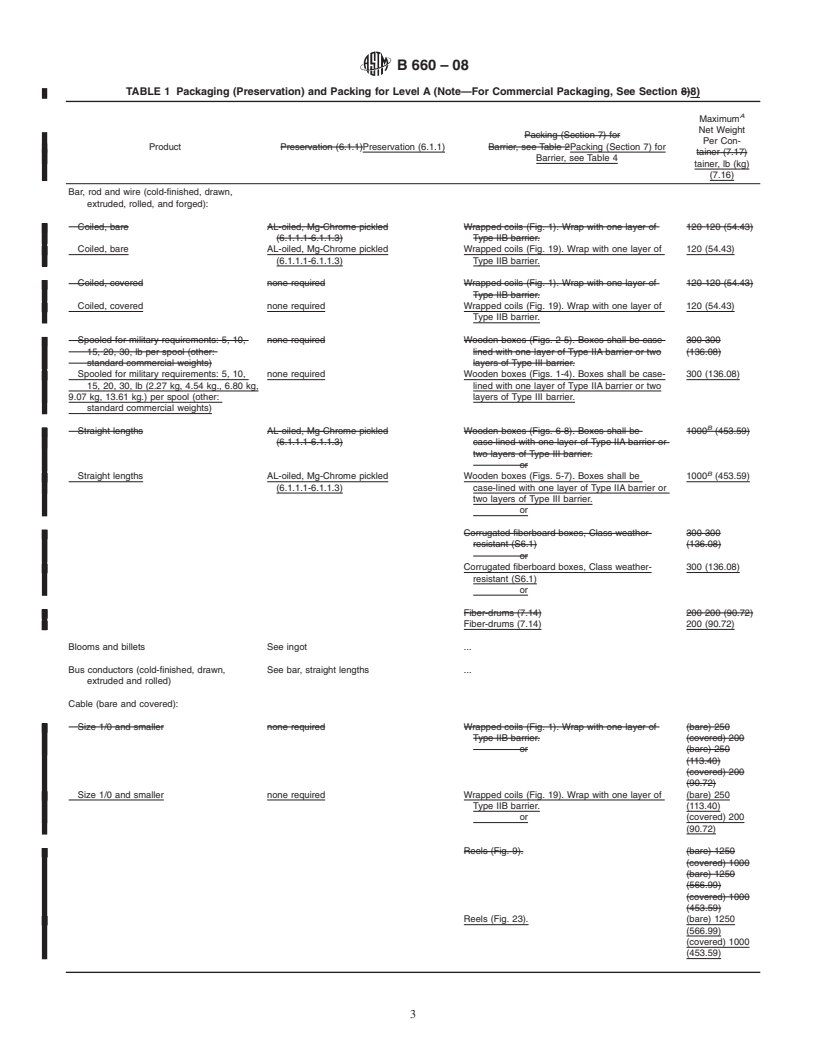

1.1 These practices describe methods of packaging/packing aluminum and magnesium products, in preparation for storage or shipment, both foreign and domestic. Assuming proper and normal handling in transit, these practices are designed to deliver the products to their destination in good condition. For DoD redistribution, see Supplementary Requirements.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 Aluminum and magnesium products must be preserved and packed so as to be adequately protected from possible damage during shipment and storage. Major damage types are:

1.3.1 Mechanical, including bending, crushing, denting, scratching, or gouging during handling and storage; and abrasions resulting from vibration during transport of the material.

1.3.2 Corrosion, or water stain, resulting from exposure of packed material to water, either externally applied, or as condensate caused by temperature variations in a humid atmosphere.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B660 − 08

StandardPractices for

1

Packaging/Packing of Aluminum and Magnesium Products

This standard is issued under the fixed designation B660; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

3

1. Scope* cator Method (Withdrawn 2011)

D1732 Practices for Preparation of Magnesium Alloy Sur-

1.1 These practices describe methods of packaging/packing

faces for Painting

aluminum and magnesium products, in preparation for storage

D1974 Practice for Methods of Closing, Sealing, and Rein-

or shipment, both foreign and domestic. Assuming proper and

forcing Fiberboard Boxes

normal handling in transit, these practices are designed to

D3950 Specification for Strapping, Nonmetallic (and Join-

deliver the products to their destination in good condition. For

ing Methods)

DoD redistribution, see Supplementary Requirements.

D3951 Practice for Commercial Packaging

1.2 The values stated in inch-pound units are to be regarded

D3953 Specification for Strapping, Flat Steel and Seals

as standard. The values given in parentheses are mathematical

D4727/D4727M Specification for Corrugated and Solid Fi-

conversions to SI units that are provided for information only

berboard Sheet Stock (Container Grade) and Cut Shapes

and are not considered standard.

D5168 Practice for Fabrication and Closure of Triple-Wall

1.3 Aluminum and magnesium products must be preserved

Corrugated Fiberboard Containers

and packed so as to be adequately protected from possible D5486/D5486M Specification for Pressure-Sensitive Tape

damage during shipment and storage. Major damage types are:

for Packaging, Box Closure, and Sealing

1.3.1 Mechanical, including bending, crushing, denting,

F1667 Specification for Driven Fasteners: Nails, Spikes, and

scratching, or gouging during handling and storage; and

Staples

abrasions resulting from vibration during transport of the

2.2 ANSI Standard:

material.

4

ANSI/AHAA135.4 Basic Hardboard

1.3.2 Corrosion, or water stain, resulting from exposure of

5

2.3 Federal Specifications:

packed material to water, either externally applied, or as

A-A-1249 Paper, Wrapping, Tissue

condensate caused by temperature variations in a humid

A-A-1671 Tape, Gummed (Paper, Reinforced, Asphalt

atmosphere.

Laminated)

1.4 This standard does not purport to address all of the

A-A-55057 Panels, Wood/Wood-Based; Construction and

safety concerns, if any, associated with its use. It is the

Decorative

responsibility of the user of this standard to establish appro-

PPP-B-566 Box, Folding, Paperboard

priate safety and health practices and determine the applica-

PPP-C-96 Can, Metal, 28 Gage and Lighter

bility of regulatory limitations prior to use.

PPP-D-705 Drum, Shipping and Storage: Steel 16 and 30

Gallon Capacity

2. Referenced Documents

PPP-D-723 Drum, Fiber (inactive for new design)

2

2.1 ASTM Standards:

PPP-D-729 Drum, Shipping and Storage: Steel, 55 Gallon

D779 Test Method for Water Resistance of Paper,

PPP-P-704 Pails, Metal: (Shipping, Steel, 1 through 12,

Paperboard, and Other Sheet Materials by the Dry Indi-

Gallons)

PPP-T-495 Tubes, Mailing, and Filing

1

These practices are under the jurisdiction of ASTM Committee B07 on Light

Metals and Alloys and are the direct responsibilities of Subcommittee B07.03 on

Aluminum Alloy Wrought Products.

3

Current edition approved Oct. 15, 2008. Published December 2008. Originally The last approved version of this historical standard is referenced on

approved in 1979. Last previous edition approved in 2002 as B660 – 02. DOI: www.astm.org.

4

10.1520/B0660-08. Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 4th Floor, New York, NY 10036, http://www.ansi.org.

5

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Standards volume information, refer to the standard’s Document Summary page on Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

the ASTM website. www.dodssp.daps.mil.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B660 − 08

5

2.4 Federal Standards: 4.1.7 interleaving—placement of a sheet of protective ma-

APA-PS1 U.S. Product Standard (For Construction and In- terial between two adjacent pieces of metal.

dustrial

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B660–02 Designation: B 660 – 08

Standard Practices for

1

Packaging/Packing of Aluminum and Magnesium Products

This standard is issued under the fixed designation B 660; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 These practices describe methods of packaging/packing aluminum and magnesium products, in preparation for storage or

shipment, both foreign and domestic.Assuming proper and normal handling in transit, these practices are designed to deliver the

products to their destination in good condition. For DoD redistribution, see Supplementary Requirements.

1.2Aluminum and magnesium products must be preserved and packed so as to be adequately protected from possible damage

during shipment and storage. Major damage types are:

1.2.1Mechanical, including bending, crushing, denting, scratching, or gouging during handling and storage; and abrasions

resulting from vibration during transport of the material.

1.2.2Corrosion, or water stain, resulting from exposure of packed material to water, either externally applied, or as condensate

caused by temperature variations in a humid atmosphere.

NOTE1—AcompletemetriccompaniontoPracticesB660isbeingdeveloped—PracticesB660M;therefore,nometricequivalentsarepresentedinthese

practices.

1.3

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 Aluminum and magnesium products must be preserved and packed so as to be adequately protected from possible damage

during shipment and storage. Major damage types are:

1.3.1 Mechanical, including bending, crushing, denting, scratching, or gouging during handling and storage; and abrasions

resulting from vibration during transport of the material.

1.3.2 Corrosion, or water stain, resulting from exposure of packed material to water, either externally applied, or as condensate

caused by temperature variations in a humid atmosphere.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 779 Test Method for Water Resistance of Paper, Paperboard, and Other Sheet Materials by the Dry- Indicator Method

D 1732 Practices for Preparation of Magnesium Alloy Surfaces for Painting

D 1974 Practice for Methods of Closing, Sealing, and Reinforcing Fiberboard Boxes

D 3950 Specification for Strapping, Nonmetallic (and Joining Methods)

D 3951 Practice for Commercial Packaging

D 3953 Specification for Strapping, Flat Steel and Seals

D 4727/D 4727M Specification for Corrugated and Solid Fiberboard Sheet Stock (Container Grade) and Cut Shapes

D 5168 Practice for Fabrication and Closure of Triple-Wall Corrugated Fiberboard Containers

D 5486/D 5486M Specification for Pressure-Sensitive Tape for Packaging, Box Closure, and Sealing

F 1667 Specification for Driven Fasteners: Nails, Spikes, and Staples

2.2 ANSI Standard:

1

These practices are under the jurisdiction ofASTM Committee B07 on Light Metals andAlloys and are the direct responsibilities of Subcommittee B07.03 onAluminum

Alloy Wrought Products.

Current edition approved Oct. 10, 2002. Published January 2003. Originally published as B660–79. Last previous edition B660–96 (2002).

Current edition approved Oct. 15, 2008. Published November 2008. Originally approved in 1979. Last previous edition approved in 2002 as B 660 – 02.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 15.09.volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B660–08

3

ANSI/AHAA135.4 Basic Hardboard

4

2.3 Federal Specifications:

A

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.