ASTM F993-86(2006)

(Specification)Standard Specification for Valve Locking Devices

Standard Specification for Valve Locking Devices

ABSTRACT

This specification covers the application, design, and materials for valve locking devices. According to the method of locking, these devices are classified into three types: Type I using a wire rope assembly, Type II using a handwheel latch, and Type III using a locking shield. These devices are also grouped into three grades depending on material composition: Grade A is made of stainless steel, Grade B is made of anodized aluminum, and Grade C is made of carbon steel. Locking devices Types I and II described in this specification are designed to secure the valve in a fully opened or completely closed position. Materials to be used in the manufacture of Type I valve locking device shall consist of pipe clamp, ring link, common wire strand, tiller rope clamp, rigid eye spring hook, and sleeve. As for Type II valve locking device, the materials shall consist of modified pipe clamp, flat head rivet, single-acting quick release pin, lanyard, sleeve, lanyard clip, and lever arm. Type III devices shall consist of plate, single-acting quick release pin, lanyard, sleeve, lanyard clip, and lockbar. The locking device must be able to lock the valve in both the fully opened and completely closed positions.

SCOPE

1.1 This specification covers the application, design, and materials for valve locking devices.

1.2 Locking devices Types I and II described in this specification are designed to secure the valve in a fully opened or completely closed position.

1.3 This specification does not apply to valves equipped with locking devices from the valve manufacturer, unless this standard is invoked in the procurement ordering data for the valve or its locking device, or both.

1.4 This specification is intended to supercede NASEA drawing S4824-1385509. However, cancellation of that drawing and adoption of this specification can only be effected by the navy.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F993 – 86 (Reapproved 2006)

Standard Specification for

Valve Locking Devices

ThisstandardisissuedunderthefixeddesignationF993;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope ANSI B18.1 Small Solid Rivets

2 American Welding Society D1.1 on Steel

1.1 This specification covers the application, design, and

materials for valve locking devices.

3. Classification

1.2 Locking devices Types I and II described in this

3.1 Valve locking devices shall be classified by the follow-

specification are designed to secure the valve in a fully opened

ing types and grades in accordance with the method of locking

or completely closed position.

and material used.

1.3 This specification does not apply to valves equipped

3.2 Types:

with locking devices from the valve manufacturer, unless this

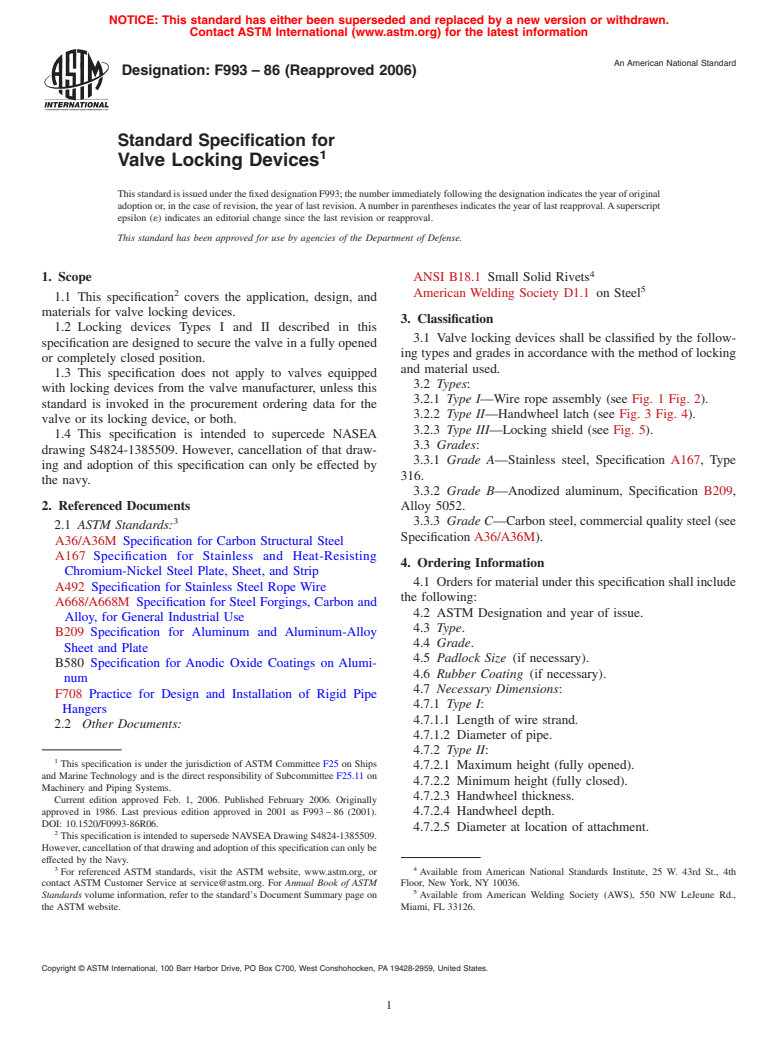

3.2.1 Type I—Wire rope assembly (see Fig. 1 Fig. 2).

standard is invoked in the procurement ordering data for the

3.2.2 Type II—Handwheel latch (see Fig. 3 Fig. 4).

valve or its locking device, or both.

3.2.3 Type III—Locking shield (see Fig. 5).

1.4 This specification is intended to supercede NASEA

3.3 Grades:

drawing S4824-1385509. However, cancellation of that draw-

3.3.1 Grade A—Stainless steel, Specification A167, Type

ing and adoption of this specification can only be effected by

316.

the navy.

3.3.2 Grade B—Anodized aluminum, Specification B209,

2. Referenced Documents Alloy 5052.

3.3.3 Grade C—Carbon steel, commercial quality steel (see

2.1 ASTM Standards:

Specification A36/A36M).

A36/A36M Specification for Carbon Structural Steel

A167 Specification for Stainless and Heat-Resisting

4. Ordering Information

Chromium-Nickel Steel Plate, Sheet, and Strip

4.1 Ordersformaterialunderthisspecificationshallinclude

A492 Specification for Stainless Steel Rope Wire

the following:

A668/A668M Specification for Steel Forgings, Carbon and

4.2 ASTM Designation and year of issue.

Alloy, for General Industrial Use

4.3 Type.

B209 Specification for Aluminum and Aluminum-Alloy

4.4 Grade.

Sheet and Plate

4.5 Padlock Size (if necessary).

B580 Specification for Anodic Oxide Coatings on Alumi-

4.6 Rubber Coating (if necessary).

num

4.7 Necessary Dimensions:

F708 Practice for Design and Installation of Rigid Pipe

4.7.1 Type I:

Hangers

4.7.1.1 Length of wire strand.

2.2 Other Documents:

4.7.1.2 Diameter of pipe.

4.7.2 Type II:

This specification is under the jurisdiction ofASTM Committee F25 on Ships

4.7.2.1 Maximum height (fully opened).

and Marine Technology and is the direct responsibility of Subcommittee F25.11 on

4.7.2.2 Minimum height (fully closed).

Machinery and Piping Systems.

4.7.2.3 Handwheel thickness.

Current edition approved Feb. 1, 2006. Published February 2006. Originally

approved in 1986. Last previous edition approved in 2001 as F993–86 (2001).

4.7.2.4 Handwheel depth.

DOI: 10.1520/F0993-86R06.

4.7.2.5 Diameter at location of attachment.

ThisspecificationisintendedtosupersedeNAVSEADrawingS4824-1385509.

However,cancellationofthatdrawingandadoptionofthisspecificationcanonlybe

effected by the Navy.

3 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American National Standards Institute, 25 W. 43rd St., 4th

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Floor, New York, NY 10036.

Standards volume information, refer to the standard’s Document Summary page on Available from American Welding Society (AWS), 550 NW LeJeune Rd.,

the ASTM website. Miami, FL 33126.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F993 – 86 (2006)

FIG. 1 Type I—Wire Rope Assembly

FIG. 2 Miscellaneous Type I Details

4.7.3 Type III: 4.7.3.4 Outside diameter (OD) of pipe.

4.7.3.1 Depth.

4.7.3.2 Height.

4.7.3.3 Width.

F993 – 86 (2006)

FIG. 3 Type II—Handwheel Latch

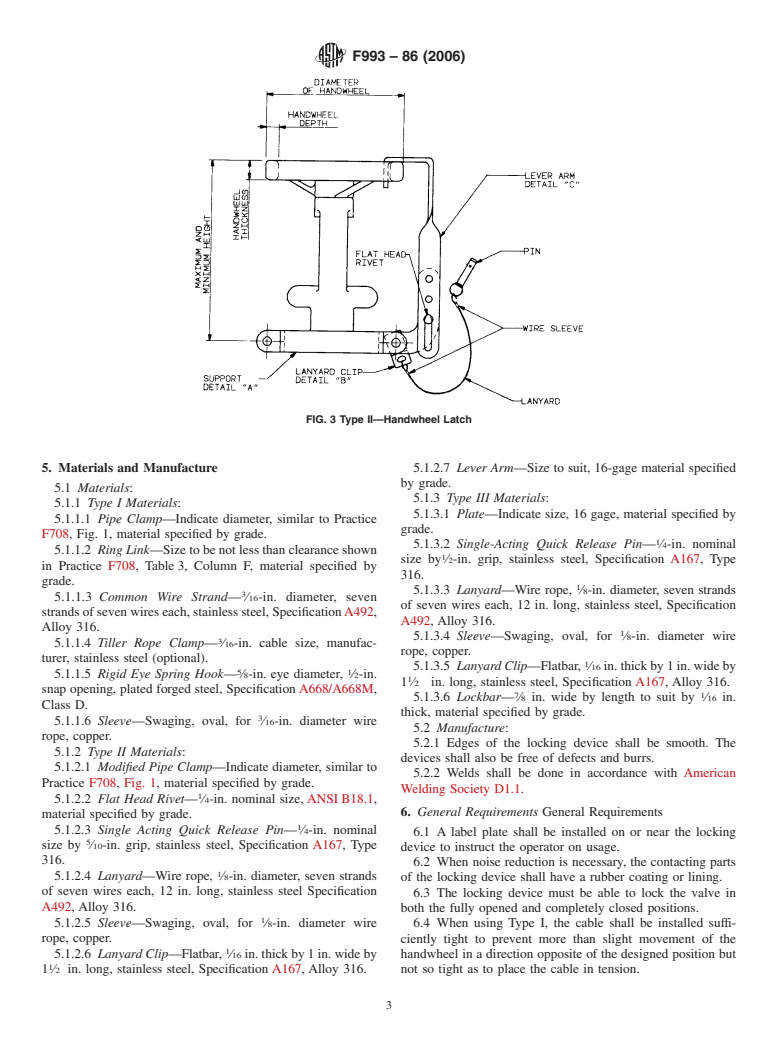

5. Materials and Manufacture 5.1.2.7 Lever Arm—Size to suit, 16-gage material specified

by grade.

5.1 Materials:

5.1.3 Type III Materials:

5.1.1 Type I Materials:

5.1.3.1 Plate—Indicate size, 16 gage, material specified by

5.1.1.1 Pipe Clamp—Indicate diameter, similar to Practice

grade.

F708, Fig. 1, material specified by grade.

5.1.3.2 Single-Acting Quick Release Pin— ⁄4-in. no

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.