ASTM A675/A675M-14(2019)

(Specification)Standard Specification for Steel Bars, Carbon, Hot-Wrought, Special Quality, Mechanical Properties

Standard Specification for Steel Bars, Carbon, Hot-Wrought, Special Quality, Mechanical Properties

ABSTRACT

This guide covers standard specification for hot-wrought special quality carbon steel bars and bar size shapes produced to mechanical property requirements and intended for general constructional applications. Heat analysis shall be performed wherein the material shall conform to the required chemical composition for phosphorus, sulfur, copper, and lead. The steel shall meet the required tensile properties such as tensile strength, yield strength, and elongation. The test specimen shall undergo mechanical tests such as tension test and bend test.

SCOPE

1.1 This specification2 covers hot-wrought special quality carbon steel bars and bar size shapes produced to mechanical property requirements and intended for general constructional applications.

1.2 The bars are available in nine strength grades designated 45, 50, 55, 60, 65, 70, 75, 80, and 90 [310, 345, 380, 415, 450, 485, 515, 550, and 620] corresponding to the minimum ultimate tensile strength in ksi [MPa]. The chemical composition is selected by the manufacturer to develop the required mechanical properties.

1.3 Hot-wrought special quality carbon steel bars subject to mechanical property requirements are hot wrought in straight lengths only. Sections and sizes available are covered in Specification A29/A29M.

1.4 Some applications may require one or more of the available designations shown under Supplementary Requirements.

Note 1: Merchant-quality hot-wrought carbon steel bars subject to mechanical property requirements are covered in Specification A663/A663M.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A675/A675M −14 (Reapproved 2019)

Standard Specification for

Steel Bars, Carbon, Hot-Wrought, Special Quality,

Mechanical Properties

This standard is issued under the fixed designationA675/A675M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope mendations issued by the World Trade Organization Technical

2 Barriers to Trade (TBT) Committee.

1.1 This specification covers hot-wrought special quality

carbon steel bars and bar size shapes produced to mechanical

2. Referenced Documents

property requirements and intended for general constructional

2.1 ASTM Standards:

applications.

A29/A29MSpecificationforGeneralRequirementsforSteel

1.2 Thebarsareavailableinninestrengthgradesdesignated

Bars, Carbon and Alloy, Hot-Wrought

45, 50, 55, 60, 65, 70, 75, 80, and 90 [310, 345, 380, 415, 450,

A370Test Methods and Definitions for Mechanical Testing

485, 515, 550, and 620] corresponding to the minimum

of Steel Products

ultimate tensile strength in ksi [MPa]. The chemical composi-

A663/A663MSpecification for Steel Bars, Carbon, Mer-

tion is selected by the manufacturer to develop the required

chant Quality, Mechanical Properties

mechanical properties.

E290Test Methods for Bend Testing of Material for Ductil-

1.3 Hot-wrought special quality carbon steel bars subject to

ity

mechanical property requirements are hot wrought in straight

2.2 ASME Code:

lengths only. Sections and sizes available are covered in

ASMEBoiler and Pressure Vessel Code

Specification A29/A29M.

3. Terminology

1.4 Some applications may require one or more of the

3.1 Definitions of Terms Specific to This Standard:

available designations shown under Supplementary Require-

3.1.1 special quality—special quality bars are used when

ments.

end use, method of fabrication, or subsequent processing

NOTE 1—Merchant-quality hot-wrought carbon steel bars subject to

treatment requires quality characteristics not available in mer-

mechanical property requirements are covered in Specification A663/

chant quality. Typical applications involve bending or machin-

A663M.

ing for general constructional uses. Some end uses or fabricat-

1.5 The values stated in either SI units or inch-pound units

ingprocedurescannecessitateoneormorerequirementswhich

are to be regarded separately as standard. The values stated in

are described in the Supplementary Requirements.

eachsystemarenotnecessarilyexactequivalents;therefore,to

ensure conformance with the standard, each system shall be

4. Ordering Information

used independently of the other, and values from the two

4.1 Orders for material under this specification should

systems shall not be combined.

include the following information:

1.6 This international standard was developed in accor-

4.1.1 Quantity (weight or number of pieces);

dance with internationally recognized principles on standard-

4.1.2 Name of material (hot-wrought special quality bars);

ization established in the Decision on Principles for the

4.1.3 Dimensions, including length;

Development of International Standards, Guides and Recom-

4.1.4 Cross section (round, square, hexagon, equal leg

angle, etc.);

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee For referenced ASTM standards, visit the ASTM website, www.astm.org, or

A01.15 on Bars. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Sept. 1, 2019. Published September 2019. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1972. Last previous edition approved in 2014 as A675/A675M–14. the ASTM website.

DOI: 10.1520/A0675_A0675M–14R19. Available from American Society of Mechanical Engineers (ASME), ASME

For ASME Boiler and Pressure Vessel Code applications see related Specifi- International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

cation SA 675 in Section II of that Code. www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A675/A675M−14 (2019)

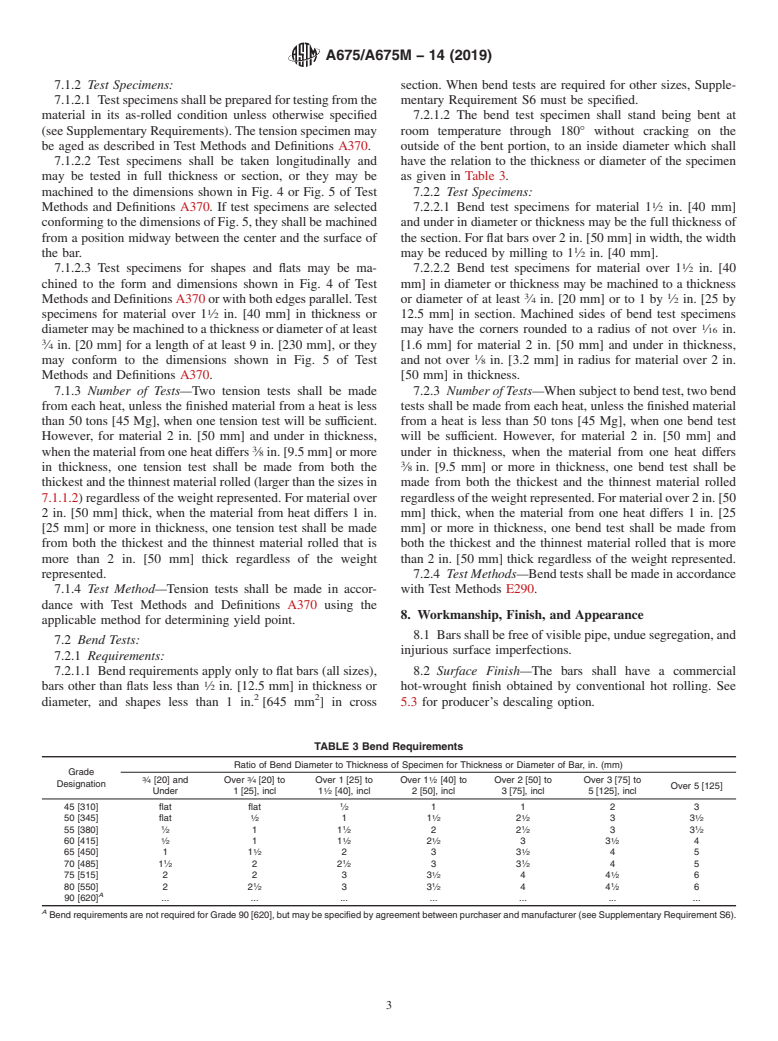

TABLE 1 Tensile Requirements

B C

Tensile Strength Yield Point, min Elongation, min, %

Grade

A ksi [MPa] ksi [MPa] 8 in. or [200 mm] 2 in. or [50 mm]

Designation

Gage Length Gage Length

45 [310] 45 to 55 [310 to 380] 22.5 [155] 27 33

50 [345] 50 to 60 [345 to 415] 25 [170] 25 30

55 [380] 55 to 65 [380 to 450] 27.5 [190] 23 26

60 [415] 60 to 72 [415 to 495] 30 [205] 21 22

65 [450] 65 to 77 [450 to 530] 32.5 [225] 17 20

70 [485] 70 to 85 [485 to 585] 35 [240] 14 18

75 [515] 75 to 90 [515 to 620] 37.5 [260] 14 18

80 [550] 80 min [550 min] 40 [275] 13 17

90 [620] 90 min [620 min] 55 [380] 10 14

A

When lead is required, add the letter “L” after the grade designation, for example, 45L.

B

When the tension test does not show a yield point (drop of the beam, halt of the pointer or sharp-kneed stress-strain diagram), yield strength shall be determined by either

0.5 % extension-under-load or 0.2 % offset. The minimum ksi (MPa) requirement does not change. The test report, if required, shall show yield strength.

C

See 7.1.1.2 through 7.1.1.5 for deduction in elongation due to section size.

TABLE 2 Chemical Requirements (Heat Analysis)

4.1.5 Specification designation and date of issue;

4.1.6 Grade designation (Table 1); Element

4.1.7 Leaded steel, if required (6.2); Phosphorus, max 0.040

Sulfur, max 0.050

4.1.8 Copper bearing steel, if required (6.3);

Copper, when copper steel is specified, min 0.20

4.1.9 Test report, if required (Section 10); A

Lead

4.1.10 Supplementary Requirements or special require-

A

When required, lead may be specified as an added element. See 6.2.

ments if required; and

4.1.11 Application and processing.

NOTE 2—Atypical ordering description is as follows: 10000 lb, [5000

kg]HotWroughtSpecialQualityCarbonSteelBars,1in.diameter×10ft,

6.3 Copper-Bearing Steel—When required copper may be

[25m×3m] Round,ASTMA675/A675M dated ____, Grade 50, [345]

specified as an added element. Copper-bearing steel is identi-

Copper Bearing, Test Report Required, S3 Special Straightness, Boiler

fied by stating “copper-bearing” on the purchase order.

Supports.

5. Materials and Manufacture

7. Mechanical Properties

5.1 Melting Practice—The steel shall be made by one or

7.1 Tension Tests:

more of the following primary processes: basic-oxygen or

7.1.1 Requirements:

electric-furnace.Theprimarymeltingmayincorporateseparate

7.1.1.1 The material as represented by the test specimen

degassing or refining and may be followed by secondary

shall conform to the applicable requirements in Table 1.

melting using electroslag remelting or vacuum-arc remelting.

7.1.1.2 For material over ⁄4 in. [19 mm] in thickness or

Where secondary melting is employed, the heat shall be

diameter, a deduction of 0.25% from the percentage of

definedasalloftheingotsremeltedfromasingleprimaryheat.

elongationin8in.[200mm]specifiedinTable1shallbemade

for each increase of ⁄32in. [0.8 mm] in the specified thickness

5.2 Deoxidation:

or diameter above ⁄4 in. [19 mm].

5.2.1 Unless otherwise specified, the steel shall be killed.

7.1.1.3 For material under ⁄16 in. [8 mm] in thickness or

5.2.2 When required, the purchaser may specify the re-

diameter, a deduction of 2.00% from the percentage of

quired deoxidation practice, dependent upon strength grade

elongationin8in.[200mm]specifiedinTable1shallbemade

specified, purchaser’s methods of fabrication, and end use

for each decrease of ⁄32in. [0.8 mm] in the specified thickness

requirements. Killed steels can be produced to coarse or fine

or diameter below ⁄16 in. [8 mm].

austenitic grain size (Supplementary Requirement S1).

7.1.1.4 For Grades 45, 50, 55, 60, and 65 [310, 345, 380,

5.3 Condition—Unlessotherwisespecified,thebarsshallbe

and 415] for material over 2 in. [50 mm] in thickness or

furnished as-rolled and not pickled, blast cleaned, or oiled.At

diameter, a deduction of 1.00% from the percentage of

the producer’s option, bars may be cleaned for inspection.

elongation in 2 in. [50 mm] specified in Table 1 shall be made

for each 1 in. [25 mm] of specified thickness or diameter or

6. Chemical Composition

fraction thereof over 2 in. [50 mm] in thickness or diameter.

6.1 The steel shall conform to the chemical requirements

7.1.1.5 For Grades 70, 75, 80, and 90 [485, 515, 550 and

specified in Table 2.

620] for material over 2 in. [50 mm] in thickness or diameter,

6.2 Leaded Steel—When required, lead may be specified as a deduction of 1.00% from the percentage of elongation in 2

an added element.When lead is specified as an added element, in. [50 mm] specified in Table 1 shall be made for each 1 in.

a range from 0.15 to 0.35% inclusive shall be furnished. Such [25mm]ofspecifiedthickne

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.