ASTM E2096/E2096M-10

(Practice)Standard Practice for In Situ Examination of Ferromagnetic Heat-Exchanger Tubes Using Remote Field Testing

Standard Practice for In Situ Examination of Ferromagnetic Heat-Exchanger Tubes Using Remote Field Testing

SIGNIFICANCE AND USE

The purpose of RFT is to evaluate the condition of the tubing. The evaluation results may be used to assess the likelihood of tube failure during service, a task which is not covered by this practice.

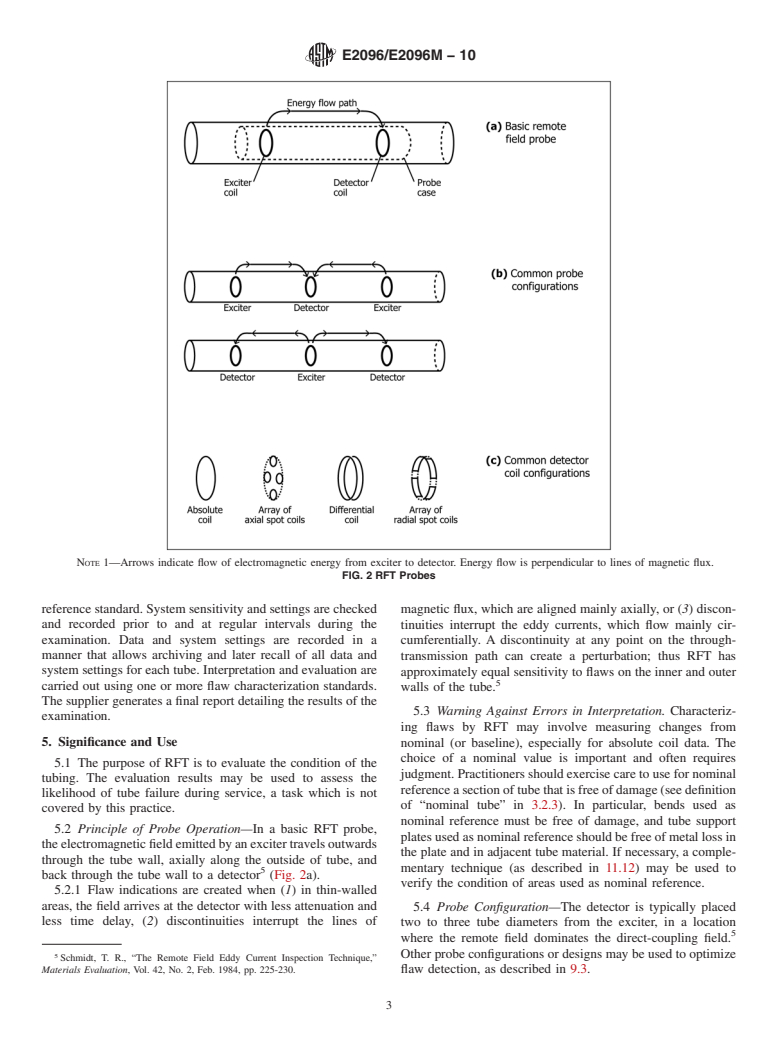

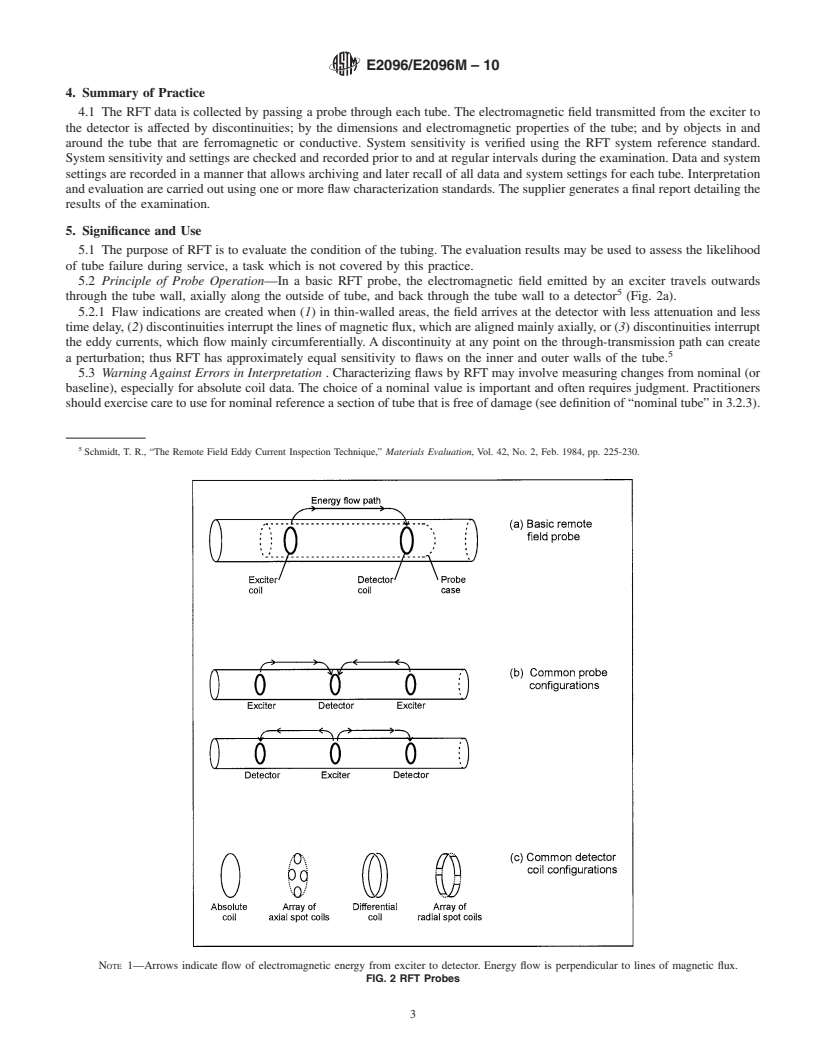

Principle of Probe Operation—In a basic RFT probe, the electromagnetic field emitted by an exciter travels outwards through the tube wall, axially along the outside of tube, and back through the tube wall to a detector (Fig. 2a).

Flaw indications are created when (1) in thin-walled areas, the field arrives at the detector with less attenuation and less time delay, (2) discontinuities interrupt the lines of magnetic flux, which are aligned mainly axially, or (3) discontinuities interrupt the eddy currents, which flow mainly circumferentially. A discontinuity at any point on the through-transmission path can create a perturbation; thus RFT has approximately equal sensitivity to flaws on the inner and outer walls of the tube.

5.3 Warning Against Errors in Interpretation. Characterizing flaws by RFT may involve measuring changes from nominal (or baseline), especially for absolute coil data. The choice of a nominal value is important and often requires judgment. Practitioners should exercise care to use for nominal reference a section of tube that is free of damage (see definition of “nominal tube” in 3.2.3). In particular, bends used as nominal reference must be free of damage, and tube support plates used as nominal reference should be free of metal loss in the plate and in adjacent tube material. If necessary, a complementary technique (as described in 11.12) may be used to verify the condition of areas used as nominal reference.

Probe Configuration—The detector is typically placed two to three tube diameters from the exciter, in a location where the remote field dominates the direct-coupling field. Other probe configurations or designs may be used to optimize flaw detection, as described in 9.3.

Comparison with Conventional Eddy-Current Testing—Conventional e...

SCOPE

1.1 This practice describes procedures to be followed during remote field examination of installed ferromagnetic heat-exchanger tubing for baseline and service-induced discontinuities.

1.2 This practice is intended for use on ferromagnetic tubes with outside diameters from 0.500 to 2.000 in. [12.70 to 50.80 mm], with wall thicknesses in the range from 0.028 to 0.134 in. [0.71 to 3.40 mm].

1.3 This practice does not establish tube acceptance criteria; the tube acceptance criteria must be specified by the using parties.

1.4 Units—The values stated in either inch-pound units or SI units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this practice to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2096/E2096M − 10

StandardPractice for

In Situ Examination of Ferromagnetic Heat-Exchanger Tubes

1

Using Remote Field Testing

ThisstandardisissuedunderthefixeddesignationE2096/E2096M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2.2 Other Documents:

ASNT SNT-TC-1A Recommended Practice for Nondestruc-

1.1 Thispracticedescribesprocedurestobefollowedduring

3

tive Testing Personnel Qualification and Certification

remote field examination of installed ferromagnetic heat-

Can CGSB-48.9712-95 Qualification of Nondestructive

exchanger tubing for baseline and service-induced discontinui-

4

Testing Personnel, Natural Resources Canada

ties.

3. Terminology

1.2 This practice is intended for use on ferromagnetic tubes

with outside diameters from 0.500 to 2.000 in. [12.70 to 50.80

3.1 General—Definitions of terms used in this practice can

mm],withwallthicknessesintherangefrom0.028to0.134in.

be found in Terminology E1316, Section A, “Common NDT

[0.71 to 3.40 mm].

Terms,” and Section C, “Electromagnetic Testing.”

1.3 This practice does not establish tube acceptance criteria; 3.2 Definitions:

3.2.1 detector, n—one or more coils or elements used to

the tube acceptance criteria must be specified by the using

parties. sense or measure magnetic field; also known as a receiver.

3.2.2 exciter, n—a device that generates a time-varying

1.4 Units—The values stated in either inch-pound units or

electromagnetic field, usually a coil energized with alternating

SI units are to be regarded separately as standard. The values

current (ac); also known as a transmitter.

stated in each system may not be exact equivalents; therefore,

3.2.3 nominal tube, n—a tube or tube section meeting the

each system shall be used independently of the other. Combin-

tubing manufacturer’s specifications, with relevant properties

ingvaluesfromthetwosystemsmayresultinnonconformance

typical of a tube being examined, used for reference in

with the standard.

interpretation and evaluation.

1.5 This standard does not purport to address all of the

3.2.4 remote field, n— as applied to nondestructive testing,

safety concerns, if any, associated with its use. It is the

the electromagnetic field which has been transmitted through

responsibility of the user of this practice to establish appro-

the test object and is observable beyond the direct coupling

priate safety and health practices and determine the applica-

field of the exciter.

bility of regulatory limitations prior to use.

3.2.5 remote field testing, n—a nondestructive test method

that measures changes in the remote field to detect and

2. Referenced Documents

characterize discontinuities.

2

2.1 ASTM Standards:

3.2.6 using parties, n—the supplier and purchaser.

E543 Specification for Agencies Performing Nondestructive

3.2.6.1 Discussion—The party carrying out the examination

Testing

is referred to as the “supplier,” and the party requesting the

E1316 Terminology for Nondestructive Examinations

examination is referred to as the “purchaser,” as required in

Form and Style for ASTM Standards, April 2004. In common

usage outside this practice, these parties are often referred to as

1

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

the “operator” and “customer,” respectively.

structive Testing and is the direct responsibility of Subcommittee E07.07 on

3.3 Definitions of Terms Specific to This Standard:

Electromagnetic Method.

Current edition approved Sept. 1, 2010. Published October 2010. Originally

approved in 2000. Last previous edition approved in 2005 as E2096 - 05. DOI:

10.1520/E2096_E2096M-10.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available from CGSB Sales Centre; Place du Portage, Phase 3, 6B1; 11 Laurier

the ASTM website. Street, Hull QC, Canada K1A 1G6.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2096/E2096M − 10

FIG. 1 A and B: Typical Phase-Amplitude Diagrams Used in RFT; C: Generic Strip Chart With Flaw

3.3.1 flaw characterization standard, n—a standard used in 3.3.6 sample rate—the rate at which data is digitized for

additiontotheRFTsystemreferencestandard

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E2096–05 Designation: E2096/E2096M – 10

Standard Practice for

In Situ Examination of Ferromagnetic Heat-Exchanger Tubes

1

Using Remote Field Testing

ThisstandardisissuedunderthefixeddesignationE2096/E2096M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 Thispracticedescribesprocedurestobefollowedduringremotefieldexaminationofinstalledferromagneticheat-exchanger

tubing for baseline and service-induced discontinuities.

1.2 Thispracticeisintendedforuseonferromagnetictubeswithoutsidediametersfrom0.500to2.000in.[12.70to50.80mm],

with wall thicknesses in the range from 0.028 to 0.134 in. [0.71 to 3.40 mm].

1.3 This practice does not establish tube acceptance criteria; the tube acceptance criteria must be specified by the using parties.

1.4 Units—The values stated in either inch-pound units or SI units are to be regarded separately as standard. The values stated

in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values

from the two systems may result in nonconformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this practice to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E543 Specification for Agencies Performing Nondestructive Testing

E1316 Terminology for Nondestructive Examinations

2.2 Other Documents:

3

ASNT SNT-TC-1A Recommended Practice for Nondestructive Testing Personnel Qualification and Certification

4

Can CGSB-48.9712-95 Qualification of Nondestructive Testing Personnel, Natural Resources Canada

3. Terminology

3.1 General—DefinitionsoftermsusedinthispracticecanbefoundinTerminologyE1316,SectionA,“CommonNDTTerms,”

and Section C, “Electromagnetic Testing.”

3.2 Definitions:

3.2.1 detector, n—one or more coils or elements used to sense or measure magnetic field; also known as a receiver.

3.2.2 exciter, n—a device that generates a time-varying electromagnetic field, usually a coil energized with alternating current

(ac); also known as a transmitter.

3.2.3 nominal tube, n—a tube or tube section meeting the tubing manufacturer’s specifications, with relevant properties typical

of a tube being examined, used for reference in interpretation and evaluation.

3.2.4 remote field, n— as applied to nondestructive testing, the electromagnetic field which has been transmitted through the

test object and is observable beyond the direct coupling field of the exciter.

3.2.5 remote field testing, n—a nondestructive test method that measures changes in the remote field to detect and characterize

discontinuities.

3.2.6 using parties, n—the supplier and purchaser.

3.2.6.1 Discussion—The party carrying out the examination is referred to as the “supplier,” and the party requesting the

examination is referred to as the “purchaser,” as required in Form and Style for ASTM Standards, April 2004. In common usage

1

This practice is under the jurisdiction ofASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.07 on Electromagnetic

Methods.Method.

Current edition approved JanuarySept. 1, 2005.2010. Published January 2005.October 2010. Originally approved in 2000. Last previous edition approved in 20002005

as E2096 - 005. DOI: 10.1520/E2096_E2096M-105.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from TheAmerican Society for Nondestructive Testing (ASNT), P.O. Box 28518, 1711Arlingate Lane,Ln., Columbus, OH 43228-0518, http://www.asnt.org.

4

Available from CGSB Sales Centre; Place du Portage, Phase 3, 6B1; 11 Laurier Street, Hull QC, Canada K1A 1G6.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E2096/E2096M – 10

outside this practice, these parties are often referred to as the “operator” and “customer,”

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.