ASTM D852-08

(Test Method)Standard Test Method for Solidification Point of Benzene

Standard Test Method for Solidification Point of Benzene

SIGNIFICANCE AND USE

This test method may be used as a criteria for determining the purity of benzene. The closer the solidification point reaches that of pure benzene, the purer the sample.

SCOPE

1.1 This test method covers the determination of the solidification point of benzene.

1.2 In determining the conformance of the test results using this method to applicable specifications, results shall be rounded off in accordance with the rounding-off method of Practice E 29.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D852 −08

StandardTest Method for

1

Solidification Point of Benzene

This standard is issued under the fixed designation D852; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers the determination of the solidi-

2.2 Other Document:

fication point of benzene.

OSHA Regulations, 29 CFR paragraphs 1910.1000 and

1.2 In determining the conformance of the test results using

3

1910.1200

this method to applicable specifications, results shall be

rounded off in accordance with the rounding-off method of

3. Terminology

Practice E29.

3.1 Definitions:

1.3 The values stated in SI units are to be regarded as

3.1.1 solidification point, n—an empirical constant defined

standard. No other units of measurement are included in this

as the temperature at which the liquid phase of a substance is

standard.

in approximate equilibrium with a relatively small portion of

1.4 This standard does not purport to address all of the

the solid phase.

safety concerns, if any, associated with its use. It is the

3.1.1.1 Discussion—Solidification point is distinguished

responsibility of the user of this standard to establish appro-

from freezing point which is described in Test Method D1015.

priate safety and health practices and determine the applica-

An interpretation of mol percent purity in terms of freezing

bility of regulatory limitations prior to use. For specific hazard

point is given in Test Method D1016.

statements, see Section 7.

4. Summary of Test Method

2. Referenced Documents

4.1 Solidification point is measured by noting the maximum

2

2.1 ASTM Standards:

temperature reached during a controlled cooling cycle after the

D1015 Test Method for Freezing Points of High-Purity

appearance of a solid phase.

Hydrocarbons

D1016 Test Method for Purity of Hydrocarbons from Freez-

5. Significance and Use

ing Points

5.1 This test method may be used as a criteria for determin-

D1193 Specification for Reagent Water

ing the purity of benzene. The closer the solidification point

D3437 Practice for Sampling and Handling Liquid Cyclic

reaches that of pure benzene, the purer the sample.

Products

D6809 Guide for Quality Control and Quality Assurance

6. Apparatus

Procedures for Aromatic Hydrocarbons and Related Ma-

6.1 Benzene Container (Air Jacketed):

terials

6.1.1 Inner Container,atesttube15mminoutsidediameter

E1 Specification for ASTM Liquid-in-Glass Thermometers

and 125 mm in length.

E29 Practice for Using Significant Digits in Test Data to

6.1.2 Air Jacket, a standard test tube 25 mm in outside

Determine Conformance with Specifications

diameter and 150 mm in length.

6.1.3 Insulation—Dry absorbent cotton or glass wool.

1

This test method is under the jurisdiction of ASTM Committee D16 on

6.2 Benzene Container (thick walled), a glass test tube 18

Aromatic Hydrocarbons and Related Chemicals and is the direct responsibility of

mminoutsidediameter,14mmininsidediameterand150mm

Subcommittee D16.01 on Benzene, Toluene, Xylenes, Cyclohexane and Their

in length. The thick walled tube is only compatible with the

Derivatives.

Current edition approved July 15, 2008. Published August 2008. Originally

thermistor.

approved in 1945. Last previous edition approved in 2002 as D852 – 02. DOI:

10.1520/D0852-08.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

Standards volume information, refer to the standard’s Document Summary page on 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

the ASTM website. www.access.gpo.gov.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D852−08

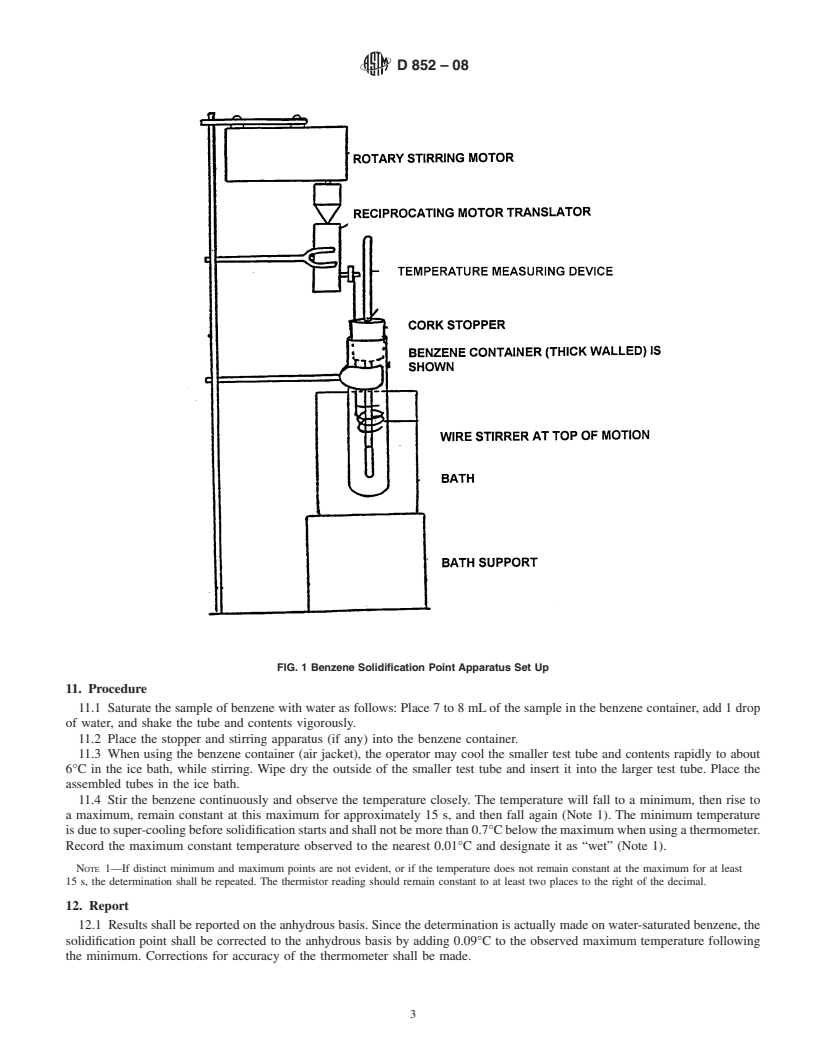

FIG. 1Benzene Solidification Point Apparatus Set Up

6.3 Ice Bath, a 1-L beaker, or similar suitable container, 6.5.2 Thermistor, in stainless steel housing with resistance

having an effective depth of at least 127 mm and filled with greater than 2K ohms at 25°C. Calibration accuracy 0.01°C.

chipped or shaved ice. Drift in resistance equivalent to less than 60.01°C/year.

4

Thermistor shall be calibrated to cover the range it is used.

6.4 Stirrer, consisting of a 1-mm wire (copper or stainless

steel) or a 2-mm glass rod with one end bent into a circular

6.6 Stirring Apparatus (Optional), th

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D852–02 Designation: D 852 – 08

Standard Test Method for

1

Solidification Point of Benzene

This standard is issued under the fixed designation D 852; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of the solidification point of benzene.

1.2 In determining the conformance of the test results using this method to applicable specifications, results shall be rounded

off in accordance with the rounding-off method of Practice E 29.

1.3

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard statements, see Section 7.

2. Referenced Documents

2

2.1 ASTM Standards:

D 1015 Test Method for Freezing Points of High-Purity Hydrocarbons

D 1016 Test Method for Purity of Hydrocarbons from Freezing Points

D 1193 Specification for Reagent Water

D 3437 Practice for Sampling and Handling Liquid Cyclic Products

D 6809 Guide for Quality Control and Quality Assurance Procedures for Aromatic Hydrocarbons and Related Materials

E 1 Specification for ASTM Liquid-in-Glass Thermometers

E 29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

2.2 Other Document:

OSHA Regulations, 29CFR,Other Document:

3

OSHA Regulations, 29CFR paragraphs 1910.1000 and 1910.1200

3. Terminology

3.1 Definitions:

3.1.1 solidification pointsolidification point, n—an empirical constant defined as the temperature at which the liquid phase of

a substance is in approximate equilibrium with a relatively small portion of the solid phase.

3.1.1.1 Discussion—Solidification point is distinguished from freezing point which is described in Test Method D 1015. An

interpretation of mol percent purity in terms of freezing point is given in Test Method D 1016.

4. Summary of Test Method

4.1 Solidification point is measured by noting the maximum temperature reached during a controlled cooling cycle after the

appearance of a solid phase.

5. Significance and Use

5.1 This test method may be used as a criteria for determining the purity of benzene. The closer the solidification point reaches

that of pure benzene, the purer the sample.

1

This test method is under the jurisdiction ofASTM Committee D16 onAromatic Hydrocarbons and Related Chemicals and is the direct responsibility of Subcommittee

D16.01 on Benzene, Toluene, Xylenes, Cyclohexane, and Their Derivatives.

Current edition approved Aug. 10, 2002.July 15, 2008. Published October 2002.August 2008. Originally published as D852–45.approved in 1945. Last previous edition

´1

D852–00 . approved in 2002 as D 852 – 02.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 05.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Annual Book of ASTM Standards, Vol 11.01.

3

Available from U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

www.access.gpo.gov.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D852–08

6. Apparatus

6.1 Benzene Container (Air Jacketed):

6.1.1 Inner Container, a test tube 15 mm in outside diameter and 125 mm in length.

6.1.2 Air Jacket, a standard test tube 25 mm in outside diameter and 150 mm in length.

6.1.3 Insulation—Dry absorbent cotton or glass wool.

6.2 Benzene Container (thick walled) , a glass test tube 18 mm in outside diameter, 14 mm in inside diameter and 150 mm in

length. The thick walled tube is only compatible with the thermistor.

6.3 Ice Bath, a 1-L beaker, or similar suitable container, having an effective depth of at least 127 mm and fi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.