ASTM C808-75(2021)

(Guide)Standard Guide for Reporting Friction and Wear Test Results of Manufactured Carbon and Graphite Bearing and Seal Materials

Standard Guide for Reporting Friction and Wear Test Results of Manufactured Carbon and Graphite Bearing and Seal Materials

SIGNIFICANCE AND USE

2.1 The purpose of this guide is twofold. First, it is a research tool that will aid in the analysis and correlation of test results obtained on various test devices by different investigators. Second, it serves to identify important considerations that must be made in testing to make the results easily understood and comparable with the results of other investigators.

SCOPE

1.1 This guide covers the following areas for reporting friction and wear test results of manufactured carbon and graphite bearing and seal materials:

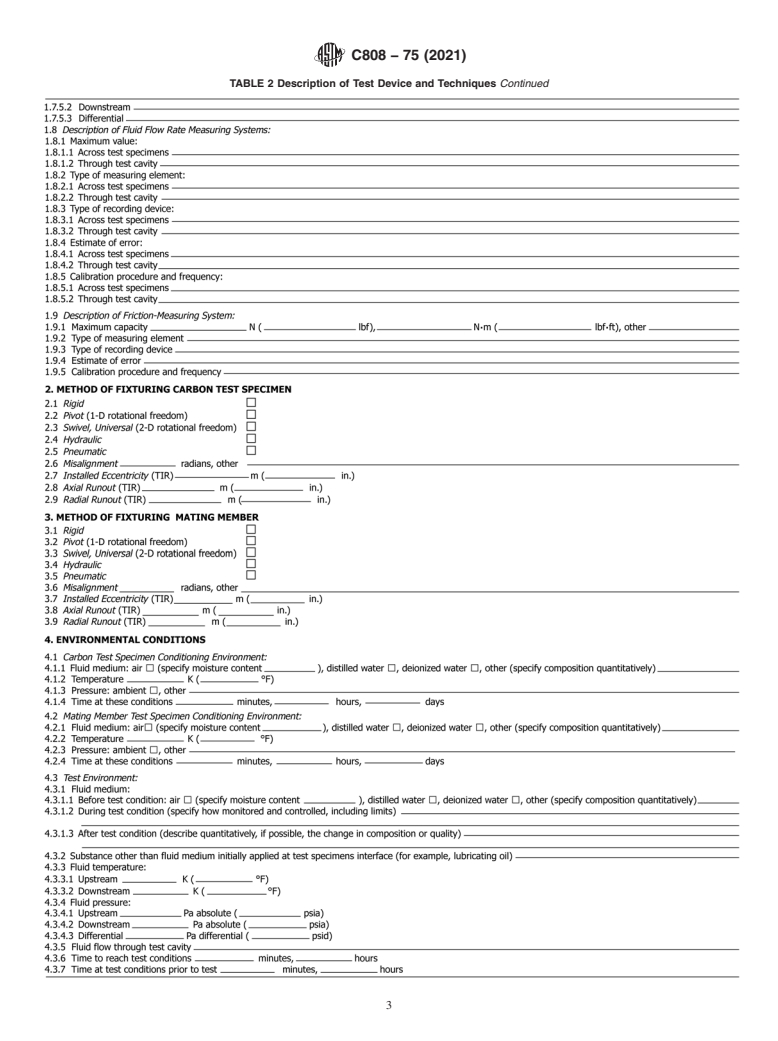

1.1.1 Description of test device and techniques (Table 1 and Table 2.)

1.1.2 Description of carbon and graphite material test specimen (Table 3).

1.1.3 Description of mating member test specimen (Table 4).

1.1.4 Report of friction and wear test results (Table 5).

1.2 Many types of equipment and techniques will yield consistent data characterizing the friction and wear of carbon and graphite materials. However, the ranking of the materials by the various test methods used is not necessarily the same. This guide is an initial effort to promote more complete description of the test methods, whatever they may be. It is the eventual intent to identify one or more specific standard test methods when sufficient information becomes available.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C808 − 75 (Reapproved 2021)

Standard Guide for

Reporting Friction and Wear Test Results of Manufactured

Carbon and Graphite Bearing and Seal Materials

This standard is issued under the fixed designation C808; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope This guide is an initial effort to promote more complete

description of the test methods, whatever they may be. It is the

1.1 This guide covers the following areas for reporting

eventual intent to identify one or more specific standard test

friction and wear test results of manufactured carbon and

methods when sufficient information becomes available.

graphite bearing and seal materials:

1.3 This international standard was developed in accor-

1.1.1 Description of test device and techniques (Table 1 and

dance with internationally recognized principles on standard-

Table 2.)

ization established in the Decision on Principles for the

1.1.2 Description of carbon and graphite material test speci-

Development of International Standards, Guides and Recom-

men (Table 3).

mendations issued by the World Trade Organization Technical

1.1.3 Description of mating member test specimen (Table

Barriers to Trade (TBT) Committee.

4).

1.1.4 Report of friction and wear test results (Table 5).

2. Significance and Use

1.2 Many types of equipment and techniques will yield

2.1 The purpose of this guide is twofold. First, it is a

consistent data characterizing the friction and wear of carbon

research tool that will aid in the analysis and correlation of test

and graphite materials. However, the ranking of the materials

results obtained on various test devices by different investiga-

by the various test methods used is not necessarily the same.

tors. Second, it serves to identify important considerations that

must be made in testing to make the results easily understood

This guide is under the jurisdiction of ASTM Committee D02 on Petroleum

and comparable with the results of other investigators.

Products, Liquid Fuels, and Lubricants and is the direct responsibil

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.