ASTM F1370-92

(Specification)Standard Specification for Pressure-Reducing Valves for Water Systems, Shipboard

Standard Specification for Pressure-Reducing Valves for Water Systems, Shipboard

SCOPE

1.1 This specification covers self-contained, globe style, pressure-reducing valves for use in water systems of shipboard installations. These valves are limited to discharge pressure settings of 200 psig (1379 kPa) and below.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following precautionary caveat pertains only to the tests portion, Section , of this specification:This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 1370 – 92

Standard Specification for

Pressure-Reducing Valves for Water Systems, Shipboard

This standard is issued under the fixed designation F 1370; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope B 61 Specification for Steam or Valve Bronze Castings

B 62 Specification for Composition Bronze or Ounce Metal

1.1 This specification covers self-contained, globe style,

Castings

pressure-reducing valves for use in water systems of shipboard

B 148 Specification for Aluminum-Bronze Sand Castings

installations. These valves are limited to discharge pressure

B 150 Specification for Aluminum Bronze Rod, Bar, and

settings of 200 psig (1379 kPa) and below.

Shapes

1.2 The values stated in inch-pound units are to be regarded

B 637 Specification for Precipitation Hardening Nickel Al-

as the standard. The values given in parentheses are for

loy Bars, Forgings, and Forging Stock for High-

information only.

Temperature Service

1.3 The following precautionary caveat pertains only to the

B 689 Specification for Electroplated Engineering Nickel

tests portion, Section 8, of this specification: This standard

Coatings

does not purport to address all of the safety concerns, if any,

F 467 Specification for Nonferrous Nuts for General Use

associated with its use. It is the responsibility of the user of this

F 468 Specification for Nonferrous Bolts, Hex Cap Screws,

standard to establish appropriate safety and health practices

and Studs for General Use

and determine the applicability of regulatory limitations prior

F 593 Specification for Stainless Steel Bolts, Hex Cap

to use.

Screws, and Studs

2. Referenced Documents

F 594 Specification for Stainless Steel Nuts

2.2 ANSI Standards:

2.1 ASTM Standards:

ANSI B1.1 Unified Screw Threads

A 125 Specification for Steel Springs, Helical, Heat

ANSI B1.12 Class 5 Interference, Fit Thread

Treated

2.3 ISA Standards:

A 193 Specification for Alloy-Steel and Stainless Steel

S75.01 Flow Equations for Sizing Control Valves

Bolting Materials for High-Temperature Service

S75.02 Control Valve Capacity Test Procedure

A 194 Specification for Carbon and Alloy Steel Nuts for

2.4 Federal Specifications:

Bolts for High-Pressure and High-Temperature Service

QQ-B-637 Brass, Naval: Rod, Wire, Shapes, Forgings, and

A 231 Specification for Chromium-Vanadium Alloy Steel

Flat Products with Finished Edges (Bar, Flat Wire, and

Spring Wire

Strip)

A 276 Specification for Stainless and Heat-Resisting Steel

QQ-C-390 Copper Alloy Casting (Including Cast Bar)

Bars and Shapes

QQ-C-465 Copper-Aluminum Alloys (Aluminum Bronze)

A 313 Specification for Stainless and Heat-Resisting Steel

(CopperAlloy Numbers 606, 6014, 630, 632M, and 642);

Spring Wire

Rod, Flat Products with Finished Edges (Flat Wire, Strip,

A 689 Specification for Carbon and Alloy Steel Bars for

and Bar) Shapes, and Forgings

Springs

QQ-N-281 Nickel-Copper Alloy Bar, Rod, Plate, Sheet,

B 21 Specification for Naval Brass, Rod, Bar, and Shapes

Strip, Wire, Forgings, and Structural and Special Shaped

B 26 Specification for Aluminum-Alloy Sand Castings

Sections

1 7

This specification is under the jurisdiction ofASTM Committee F-25 on Ships Annual Book of ASTM Standards, Vol 02.04.

and Marine Technology and is the direct responsibility of Subcommittee F25.13 on Annual Book of ASTM Standards, Vol 02.05.

Piping Systems. Annual Book of ASTM Standards, Vol 15.08.

Current edition approved Feb. 3, 1992. Published November 1992. Available from American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 01.05. Floor, New York, NY 10036.

3 11

Annual Book of ASTM Standards, Vol 01.01. Available from Instrumentation, Systems, and Automation Society, 67 Alex-

Annual Book of ASTM Standards, Vol 01.03. ander Dr., Research Triangle Park, NC 27709.

5 12

Annual Book of ASTM Standards, Vol 02.01. Available from Standardization Documents Order Desk, Bldg. 4 Section D,

Annual Book of ASTM Standards, Vol 02.02. 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1370 – 92

QQ-N-286 Nickel-Copper-Aluminum Alloy, Wrought 3.1.3 hydrostatic proof test pressure—the maximum test

(UNS N05500) pressure that the valve is required to withstand without

QQ-N-288 Nickel-Copper Alloy and Nickel-CopperSilicon damage; valve operation is not required during application of

Alloy, Castings this test pressure, but the valve must meet all performance

QQ-S-763 Steel Bars, Wire, Shapes, and Forgings, Corro- requirements after the pressure has been removed.

sion Resisting 3.1.4 lockup pressure—the outlet pressure delivered by a

QQ-S-766 Steel Corrosion Resisting Plate, Sheet and Strip pressure-reducing valve when the flow is reduced to zero;

QQ-W-390 Wire, Nickel-Chromium-Iron Alloy lockup pressure is always greater than set pressure, and in

TT-P-645 Primer Paint, Zinc Chromate, Alkyd Type actual practice it may vary with the specific valve design,

2.5 Military Standards and Specifications: tolerances,methodofsensingdownstreampressure,andpiping

MIL-V-3 Valves, Fittings, and Flanges (Except for Systems configurations.

Indicated Herein), Packaging of 3.1.5 nominal pressure—the approximate maximum pres-

MIL-S-901 Shock Tests, H.I. (High Impact), Shipboard sure to which the valve will be subjected in service under

Machinery, Equipment and Systems, Requirements for normal conditions.

MIL-F-1183 Fittings, Pipe, Cast Bronze, Silver-Brazing, 3.1.6 set pressure—the downstream pressure that the valve

General Specification for issettomaintainunderagivensetofoperatingconditions(that

DOD-P-15328 Primer (Wash), Pretreatment (Formula No. is, inlet pressure and flow); the valve should ideally be set at

117 for Metals) (Metric) downstream pressure approximately equal to the midpoint of

MIL-F-20042 Flanges, Pipe and Bulkhead, Bronze (Silver the set pressure limits (defined in 3.1.7).

Brazing) 3.1.7 set pressure limits (set pressure adjustable range)—

MIL-C-20159 Copper-Nickel Alloy Casting (UNS No. the range of set pressure over which the valve can be adjusted

C96200 and C96400) while meeting the specified performance requirements.

MIL-F-24227 Fittings and Flanges, Cast Bronze, Silver

4. Classification

Brazing Suitable for Ultrasonic Inspection

4.1 Valves shall be of the following types and pressure

MIL-B-24480 Bronze, Nickel-Aluminum (UNS No.

C95800) Castings for Seawater Service ratings, as specified (see Section 5 and 6.1.21).

4.1.1 Type I—Pressurized spring chamber, and

MIL-S-81733 Sealing and Coating Compound, Corrosion

Inhibitive 4.1.2 Type II—Unpressurized spring chamber.

4.2 Pressure Ratings—Valves shall have nominal inlet pres-

MIL-STD-167-1 Mechanical Vibrations of Shipboard

Equipment (Type I—Environmental, and Type II— sure ratings of 150 or 250 psig (1034 or 1724 kPa), or as

specified (see 6.1.21).

Internally Excited)

MIL-STD-248 Welding and Brazing Procedure and Perfor-

5. Ordering Information

mance Qualification

5.1 Ordering documentation for valves in accordance with

MIL-STD-278 Welding and Casting Standard

this specification shall include the following information, as

MIL-STD-798 Non-destructive Testing, Welding, Quality

required, to describe the equipment adequately.

Control,MaterialControlandIdentification,andHi-shock

5.1.1 ASTM designation and year of issue,

Test Requirements for Piping System Components for

5.1.2 Valve specification code (see 6.1.21),

Naval Shipboard Use

5.1.3 Quantity of valves,

2.6 Other Publications:

5.1.4 Set pressure required,

Naval Sea Systems Command (NAVSEA)

5.1.5 Set pressure limits, if not listed in 7.1.4,

2.7 Drawings:

5.1.6 Face-to-face dimensions for valves, if not listed in

803-1385946 Union Bronze, Silver Brazing WOG for UT

Table 1,

Inspection

5.1.7 Regulation accuracy required, if other than as given in

803-1385947 Flanges, Bronze, 700 PSI WOG for UT In-

7.1.5,

spection

5.1.8 When a choke feature is required (see 6.1.2),

3. Terminology

5.1.9 When tailpieces and nuts are required (see 6.1.15),

3.1 Definitions of Terms Specific to This Standard: Descrip-

5.1.10 Capacity requirement of valves, if not listed in Table

tions of Terms Specific to This Standard:

2 (see 7.1.6), and

3.1.1 accuracy of regulation—the amount by which the

5.1.11 Supplementary requirements, if any (see S1 through

downstream pressure may vary when the valve is set at any

S4).

pressure within the required set pressure limit and is subjected

6. Valve Construction and Coding

to any combination of inlet pressure, flow demand, and

ambient temperature variations within the specified limits. 6.1 Valves shall incorporate the design features specified in

3.1.2 design pressure and temperature—themaximumpres- 6.1.1 through 6.1.21.

sure and temperature the valve should be subjected to under 6.1.1 Materials of Construction—Materials shall be as

any condition; these are the pressure and temperature upon specified in Table 3. All materials shall be selected to prevent

which the strength of the pressure-containing envelope is corrosion, galling, seizing, excessive wear, or erosion where

based. applicable. Cadmium plating is prohibited.

F 1370 – 92

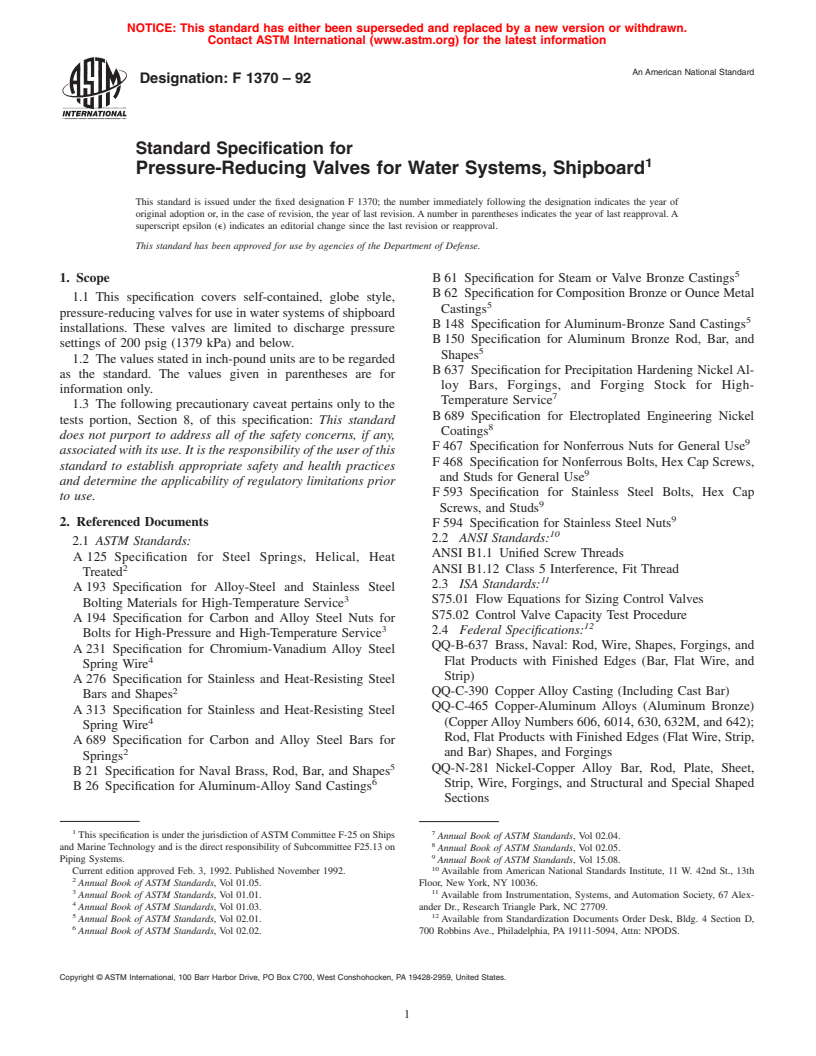

TABLE 1 Face-to-Face Dimensions, in. (mm), 6 ⁄16 (1.59)

Flanged End Union End Flanged End Union End

150 and 250 psig

Size, in. (mm)

150 psig 250 psig 400 psig 700 psig 400 psig 700 psig

(1034 and 1724

(1034 kPa) (1724 kPa) (2758 kPa) (4826 kPa) (2758 kPa) (4826 kPa)

kPa)

1 7 7 7 7

0.25 (6.35) 7 ⁄4 7 ⁄8 7 ⁄32 7 ⁄8 7 ⁄32

1 7 9 9 9

0.37 (9.40) 7 ⁄4 (184) 7 ⁄8 (200) 7 ⁄32 (185) 7 ⁄32 (185) 7 ⁄32(185)

1 7 9 1 1 9 9

0.50 (12.7) 7 ⁄4 (184) 7 ⁄8 (200) 7 ⁄32 (185) 6 ⁄2 (165) 6 ⁄2(165) 7 ⁄32 (185) 7 ⁄32 (185)

3 7 1 1 1

0.75 (19.05) 7 ⁄8 (187) 7 ⁄8 (200) 7 ⁄2 (191) 7 ⁄2 (191) 7 ⁄2(191) 8 (203) 8 (203)

3 1 1 1 3 3

1.00 (25.4) 7 ⁄8 (187) 8 (203) 7 ⁄2 (191) 8 ⁄2 (216) 8 ⁄2 (216) 8 ⁄4 (222) 8 ⁄4(222)

15 11 5 1 1

1.25 (31.75) 7 ⁄16 (202) 8 ⁄16 (221) 8 ⁄32 (207) 9 (229) 9 (229) 9 ⁄2 (241) 9 ⁄2 (241)

3 1 31 1 1

1.50 (38.1) 8 ⁄4 (222) 9 ⁄2 (241) 8 ⁄32 (228) 9 ⁄2 (241) 9 ⁄2(241) 10 (254) 10 (254)

3 7 1 1 7 7

2.00 (50.8) 10 (254) 10 ⁄4 (273) 10 ⁄32 (260) 11 ⁄2 (292) 11 ⁄2(292) 11 ⁄8 (302) 11 ⁄8 (302)

7 3

2.50 (63.5) 10 ⁄8 (276) 11 ⁄4(298) 13 (330) 13 (330)

5 1

3.00 (76.2) 11 ⁄8 (295) 12 ⁄2(318) 14 (356) 14 (356)

5 5

3.50 (88.9) 11 ⁄8 (295) 12 ⁄8(321)

1 1

4.00 (101.6) 13 ⁄2 (343) 14 ⁄2(368) 16 (406) 17 (432)

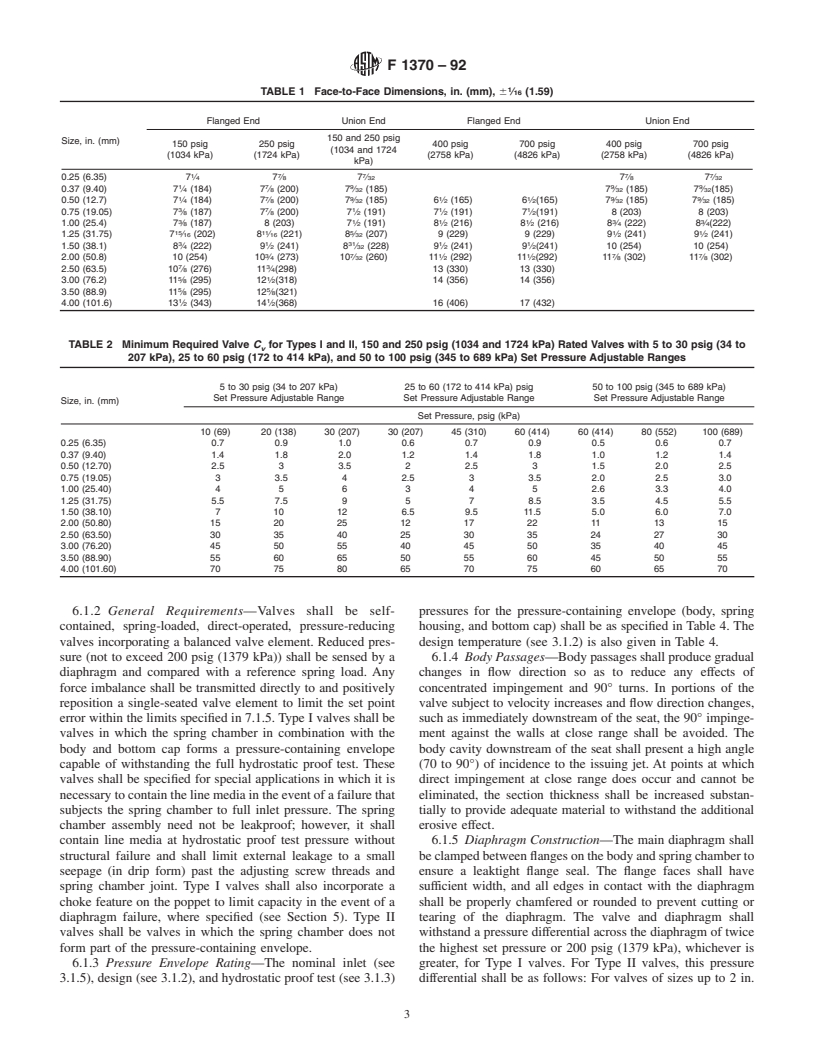

TABLE 2 Minimum Required Valve C for Types I and II, 150 and 250 psig (1034 and 1724 kPa) Rated Valves with 5 to 30 psig (34 to

v

207 kPa), 25 to 60 psig (172 to 414 kPa), and 50 to 100 psig (345 to 689 kPa) Set Pressure Adjustable Ranges

5 to 30 psig (34 to 207 kPa) 25 to 60 (172 to 414 kPa) psig 50 to 100 psig (345 to 689 kPa)

Set Pressure Adjustable Range Set Pressure Adjustable Range Set Pressure Adjustable Range

Size, in. (mm)

Set Pressure, psig (kPa)

10 (69) 20 (138) 30 (207) 30 (207) 45 (310) 60 (414) 60 (414) 80 (552) 100 (689)

0.25 (6.35) 0.7 0.9 1.0 0.6 0.7 0.9 0.5 0.6 0.7

0.37 (9.40) 1.4 1.8 2.0 1.2 1.4 1.8 1.0 1.2 1.4

0.50 (12.70) 2.5 3 3.5 2 2.5 3 1.5 2.0 2.5

0.75 (19.05) 3 3.5 4 2.5 3 3.5 2.0 2.5 3.0

1.00(25.40) 456345 2.6 3.3 4.0

1.25 (31.75) 5.5 7.5 9 5 7 8.5 3.5 4.5 5.5

1.50 (38.10) 7 10 12 6.5 9.5 11.5 5.0 6.0 7.0

2.00 (50.80) 15 20 25 12 17 22 11 13 15

2.50 (63.50) 30 35 40 25 30 35 24 27 30

3.00 (76.20) 45 50 55 40 45 50 35 40 45

3.50 (88.90) 55 60 65 50 55 60 45 50 55

4.00 (101.60) 70 75 80 65 70 75 60 65 70

6.1.2 General Requirements—Valves shall be self- pressures for the pressure-containing envelope (body, spring

contained, spring-loaded, direct-operated, pressure-reducing housing, and bottom cap) shall be as specified in Table 4. The

valves incorporating a balanced valve element. Reduced pres- design temperature (see 3.1.2) is also given in Table 4.

sure (not to exceed 200 psig (1379 kPa)) shall be sensed by a 6.1.4 Body Passages—Body passages shall produce gradual

diaphragm and compared with a reference spring load. Any changes in flow direction so as to reduce any effects of

force imbalance shall be transmitted directly to and positively concentrated impingement and 90° turns. In portions of the

reposition a single-seated valve element to limit the set point valve subject to velocity increases and flow direction changes,

error within the limits specified in 7.1.5. Type I valves shall be such as immediately downstream of the seat, the 90° impinge-

valves in which the spring chamber in combination with the ment against the walls at close range shall be avoided. The

body and bottom cap forms a pressure-containing envelope body cavity downstream of the seat shall present a high angle

capable of withstanding the full hydrostatic proof test. These (70 to 90°) of incidence to the issuing jet. At points at which

valves shall be specified for special applications in which it is direct impingement at close range does occur and cannot be

necessary to contain the line media in the event of a failure that eliminated, the section thickness shall be increased substan-

subjects the spring chamber to full inlet pressure. The spring tially to provide adequate material to withstand the additional

chamber assembly need not be leakproof; however, it shall erosive effect.

contain line media at hydrostatic proof test pressure without 6.1.5 Diaphragm Construction—The main diaphragm shall

structural failure and shall limit external leakage to a small beclampedbetweenflangesonthebodyandspringchamberto

seepage (in drip form) past the adjusting screw threads and ensure a leaktight flange seal. The flange faces shall have

spring chamber joint. Type I valves shall also incorporate a sufficient width, and all edges in contact with the diaphragm

choke feature on the poppet to limit capacity in the event of a shall be properly chamfered or rounded to prevent cutting or

diaphragm failure, where specified (see Section 5). Type II tearing of the diaphragm. The valve and diaphragm shall

valves shall be valves in which the spring chamber does not withstand a pressure differential across the diaphragm of twice

form part of the pressure-containing envelope. the highest set pressure or 200 psig (1379 kPa), whichever is

6.1.3 Pressure Envelope Rating—The nominal inlet (see greater, for Type I valves. For Type II valves, this pressure

3.1.5), design (see 3.1.2), and hydrostatic proof te

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.