ASTM D7971-15

(Guide)Standard Guide for Measuring Roundness of Glass Spheres Using a Flowing Stream Digital Image Analyzer

Standard Guide for Measuring Roundness of Glass Spheres Using a Flowing Stream Digital Image Analyzer

SIGNIFICANCE AND USE

4.1 The roundness of glass beads has a significant influence on the retroreflective efficiency of a pavement marking system.

4.2 The guide is for the characterization of the roundness of glass beads for the purpose of compliance testing against standard specification for glass beads in pavement marking applications.

4.3 While there are potential industrial applications for this guide beyond the measurement of roundness of glass beads for pavement markings, those are beyond the scope of this standard.

SCOPE

1.1 This guide covers the determination of the roundness of glass spheres used in pavement marking systems using a flowing stream digital analyzer. Typical gradations for pavement marking systems are defined in ranges from Type 0 through 5 in AASHTO M247.

1.2 This guide provides for the presentation of roundness data in a variety of formats to the requirement of the agency pavement marking material specification. For most specifications the standard format is to present the roundness data as Percent True Spheres relative to a series of standard ASTM sieve sizes.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7971 − 15

Standard Guide for

Measuring Roundness of Glass Spheres Using a Flowing

1

Stream Digital Image Analyzer

This standard is issued under the fixed designation D7971; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

4

1. Scope 2.3 ISO Standards:

ISO 9276–6 Representation of results of particle size analy-

1.1 This guide covers the determination of the roundness of

sis — Part 6: Descriptive and quantitative representation

glass spheres used in pavement marking systems using a

of particle shape and morphology

flowing stream digital analyzer. Typical gradations for pave-

ISO 13322–1 Particle size analysis — Image analysis meth-

ment marking systems are defined in ranges from Type 0

ods — Part 1: Static image analysis methods

through 5 in AASHTO M247.

3. Terminology

1.2 This guide provides for the presentation of roundness

data in a variety of formats to the requirement of the agency

3.1 Flowing Stream Digital Analyzer:

pavement marking material specification. For most specifica-

3.1.1 A computer controlled particle analyzer employing a

tions the standard format is to present the roundness data as

high resolution digital imaging device and computer image

Percent True Spheres relative to a series of standard ASTM

processingsoftwaretodophotoopticalsingleparticlecounting

sieve sizes.

and particle size analysis.

1.3 The values stated in SI units are to be regarded as 3.2 Roundness of Glass Beads:

standard. No other units of measurement are included in this

3.2.1 Roundness, in the context of this guide, refers to the

standard. percentage of true spheres in a sample as a ratio of the total

number of particles measured.

1.4 This standard does not purport to address all of the

3.2.2 Methods:

safety concerns, if any, associated with its use. It is the

3.2.2.1 These are specific observations and calculations of

responsibility of the user of this standard to establish appro-

the streaming particles that combine to form a protocol for

priate safety and health practices and determine the applica-

measuring the percentage of true spheres within the sample.

bility of regulatory limitations prior to use.

3.3 Aspect Ratio:

2. Referenced Documents

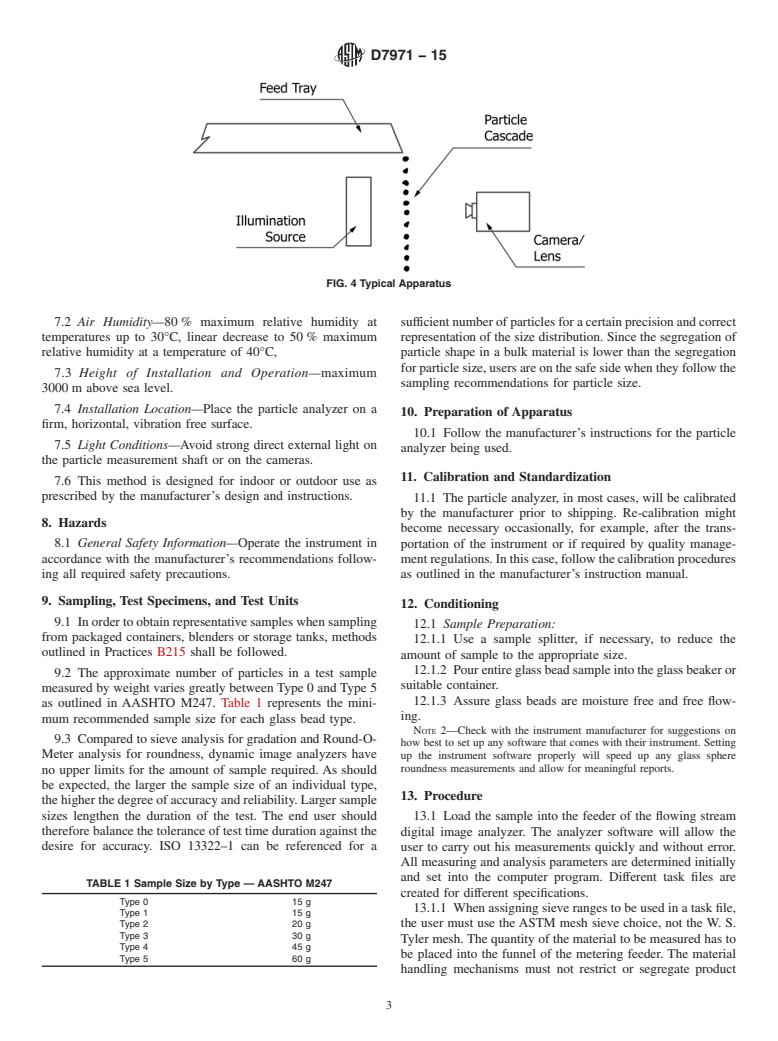

3.3.1 Aspect ratio, often referred to as b/l or w/l, is one of

2

2.1 ASTM Standards: the several methods of determining roundness and is illustrated

B215 Practices for Sampling Metal Powders in Fig. 1.

3

3.3.2 Aspect ratio will be the recommended method for the

2.2 AASHTO Standard:

AASHTO M247 Standard Glass Beads Used in Traffic majority of roundness measurements, especially when there

Markings exists a reasonable expectation that all of the particles being

measured have rounded surfaces and mostly resemble the

shape of a sphere.

1

This guide is under the jurisdiction of ASTM Committee D01 on Paint and

Related Coatings, Materials, and Applications and is the direct responsibility of 3.4 Sphericity (also referred to as circularity):

Subcommittee D01.44 on Traffic Coatings.

3.4.1 Sphericity is one of a number of methods of determin-

Current edition approved April 1, 2015. Published April 2015. DOI: 10.1520/

ing roundness and is illustrated in Fig. 2.

D7971-15.

2

3.4.2 SPHT-value or sphericity is calculated from the mea-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

surements of

Standards volume information, refer to the standard’s Document Summary page on

1. the area* A* of the particle projection (particle image),

the ASTM website.

3

Available from American Association of State Highway and Transportation

4

Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001, Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

http://www.transportation.org. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7971 − 15

3.5.3 The higher the nominal covered area, the more coin-

cidental particles that are captured. With more coincidental

particles measured, the more non-round particles detected.

3.5.4 The task file setting for nominal covered area should

not exceed a certain percentage. Values of nominal covered

area (fld = field density) of 0.8 % for smaller grades (20 to 100

mesh,Type 0 andType 1 outlined inAASHTO M247) and 1 %

for larger grades (10 to 25 mesh, Type 2, Type 3, Type 4 and

Type 5) should not be exceeded. Lower values are possible.

FIG. 1 Aspect Ratio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.