ASTM B267-90(1995)e1

(Specification)Standard Specification for Wire for Use In Wire-Wound Resistors

Standard Specification for Wire for Use In Wire-Wound Resistors

SCOPE

1.1 This specification covers round wire and ribbon with controlled electrical properties for use in wire-wound resistance units and similar applications, but not for use as electrical heating elements.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: B 267 – 90 (Reapproved 1995) An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Wire for Use In Wire-Wound Resistors

This standard is issued under the fixed designation B 267; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Section 18 was added editorially in June 1995.

1. Scope 610 % for Alloy Classes 5 to 11 inclusive.

1.1 This specification covers round wire and ribbon with

7. Nominal Electrical Resistance per Unit Length

controlled electrical properties for use in wire-wound resis-

7.1 The nominal resistance per unit length for round wire

tance units and similar applications, but not for use as electrical

shall be calculated from the nominal resistivity and the nominal

heating elements.

cross-sectional area.

2. Referenced Documents

NOTE 1—When ribbon or flat wire is produced by rolling from round

wire, the cross section departs from that of a true rectangle by an amount

2.1 ASTM Standards:

depending on the width-to-thickness ratio and the specific manufacturing

B 63 Test Method for Resistivity of Metallically Conduct-

practice. The conventional formula for computing ohms per foot and feet

ing Resistance and Contact Materials

per pound is to consider the cross section as 17 % less than a true rectangle

B 77 Test Method for Thermoelectric Power of Electrical-

when width is more than 15 times the thickness and 6 % less than a true

Resistance Alloys

rectangle in other cases. This is not valid in view of modern rolling

equipment and practices, but still is widely used as a basis of description.

B 84 Test Method for Temperature-Resistance Constants of

Ribbon actually is made to a specified resistance per foot, and no tolerance

Alloy Wires for Precision Resistors

is specified for thickness. An alternative and a closer approximation would

be that for ribbon rolled round wire, the electrical resistance would be

3. Significance and Use

calculated on a cross 6 % less than a true rectangle.

3.1 This specification on wire and ribbon contains the

8. Temperature Coefficient of Resistance

generic chemistry and requirements for resistivity, temperature

coefficient of resistance, thermal emf versus copper resistance

8.1 The change in resistance with change in temperature,

tolerances, and mechanical properties of bare wire, as well as

expressed as the mean temperature coefficient of resistance

the wire enamels and insulations of alloys normally used in the

based on the reference temperature of 25°C, shall be within the

manufacture of wound resistors.

limits specified in Table 1, Columns 4 and 6, over the

corresponding temperature ranges specified in Columns 5 and

4. Alloy Classes

7. The mean temperature coefficient of resistance referred to

4.1 Fifteen classes of alloys are covered by this specification

25°C is defined as the slope of a chord of an arc. This slope is

as listed in Table 1.

determined from the following equation:

5. Elongation

a 5 DR/R DT 3 10

~ !

m 25

5.1 The wire shall conform to the requirements for elonga-

tion as prescribed in Table 1, when tested on a 10-in. (254-mm) where:

length. a = mean temperature coefficient of resistance, ppm/°C,

m

Table 1, Columns 4 and 6,

6. Resistivity

DR = change in resistance over temperature range

6.1 The bare wire shall conform to the requirements for

indicated in Table 1, Columns 5 and 7,

nominal resistivity as prescribed in Table 1. R = resistance at 25°C,

DT = temperature range indicated in Table 1, Columns 5

6.2 Actual resistivity shall not vary from nominal resistivity

and 7.

by more than 65 % for Alloy Classes 1 to 4 inclusive, and

8.2 For Alloy Classes 1, 2, and 5, the temperature coefficient

as specified in Table 1 of any 10-ft (3-m) length shall not vary

This specification is under the jurisdiction of ASTM Committee B-4 on more than 3 ppm/°C from that of any other 10-ft length on the

Metallic Materials for Thermostats, Electrical Resistance, Heating and Contacts and

same spool or coil.

is the direct responsibility of Subcommittee B04.01 on Electrical Heating and

Resistance.

9. Thermal EMF with Respect to Copper

Current edition approved May 25, 1990. Published July 1990. Originally

9.1 The thermal electromotive force (emf) with respect to

published as B 267 – 52 T. Last previous edition B 267 – 83.

Annual Book of ASTM Standards, Vol 03.04. copper shall fall within the limits shown in Table 1, in the

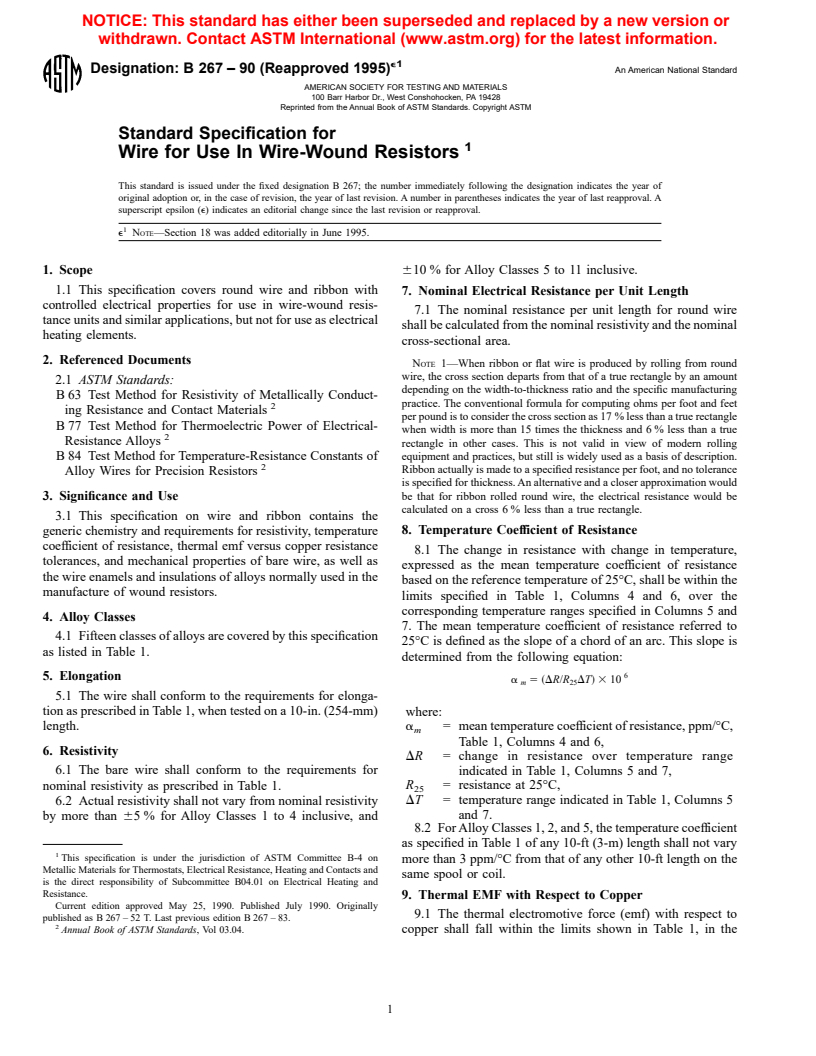

B 267

TABLE 1 Classes of Alloys and Requirements

Mean Temperature Coefficient of Resistance, a ppm for Maximum Thermal emf

m

Elongation in 10 in., min, %

B

° C Over Temperature Range,D T versus Copper, mV/°C

Resistivity,

Alloy Alloy Composition,

Over 0.002 to 0.0009

V·cmil/ft

A

D

Class approximate, %

Temperature 0.002 0.001 in. in

(μV·m)

DT a DT mV/°C

m C D D

Range, DT in. in in. in Diameter

Diameter Diameter and Finer

12 3 4 5 6 7 8 9 10 11 12

1a nickel base, nonmagnetic 800 (1.330) 0, 620 +25 to−55 0, 620 + 25 to + 105 + 0.003 −65 to + 250 10 5 3

1b nickel base, nonmagnetic 800 (1.330) 0, 610 +25 to−55 0, 610 + 25 to + 105 + 0.003 −65 to + 150 10 5 3

1c nickel base, nonmagnetic 800 (1.330) 0, 65 + 25 to − 55 0, 65 + 25 to + 105 + 0.003 −65 to + 150 10 5 3

2a iron base, magnetic 800 (1.330) 0, 620 +25 to−55 0,6 20 + 25 to + 105 −0.004 −65 to + 200 10 5 3

2b iron base, magnetic 800 (1.330) 0, 610 +25 to−55 0, 610 + 25 to + 105 −0.004 −65 to + 150 10 5 3

3a 80 nickel, 20 chromium 650 (1.081) + 80, 620 +25 to−55 +80, 620 + 25 to + 105 + 0.006 −65 to + 250 15 5 3

3b 80 nickel, 20 chromium, 675 (1.122) + 60,6 20 +25 to−55 +60, 620 + 25 to + 105 + 0.006 −65 to + 250 15 5 3

stabilized

4 60 nickel, 16 chromium, 675 (1.122) + 140, 630 + 25 to − 55 + 140, 630 + 25 to + 105 + 0.002 −65 to + 200 15 5 3

balance iron

5a 55 copper, 45 nickel 300 (0.499) 0, 620 +25 to−55 0, 620 + 25 to + 105 −0.045 −65 to + 150 15 5 3

5b 55 copper, 45 nickel 300 (0.499) 0, 640 +25 to−55 0, 640 + 25 to + 105 −0.045 −65 to + 150 15 5 3

EE EE

6 manganin type 290 (0.482) 0, 615 0, 615 −0.003 + 15 to + 35 15 5 3

7 77 copper, 23 nickel 180 (0.299) + 180, 630 + 25 to − 55 + 180,6 30 + 25 to + 105 −0.037 −65 to + 150 15 5 3

8 70 nickel, 30 iron 125 (0.199) + 3600, 6400 + 25 to − 50 + 4300, 6400 + 25 to + 104 −0.040 −50 to + 100 15 5 3

9 90 copper, 10 nickel 90 (0.150) + 450, 650 + 25 to − 55 + 450, 650 + 25 to + 105 −0.026 −65 to + 150 15 5 3

10 94 copper, 6 nickel 60 (0.100) + 700, 6200 + 25 to − 55 + 700,6 200 + 25 to + 105 −0.022 −65 to + 150 15 5 3

11 98 copper, 2 nickel 30 (0.050) + 1400, 6300 + 25 to − 55 + 1400, 6300 + 25 to + 105 0.014 −65 to + 150 15 5 3

A

Alloy Classes 1a to 8 inclusive are designed to provide controlled temperature coefficients. Values shown for other classes are for information only. All values are based

on a reference temperature of 25°C.

B

Alloy Classes 1a, 1b, 1c, 2a, 2b, 3a, 4, and 6 are designed to give a low emf versus copper. Values shown for other classes are for information only. Maximum indicates

the maximum deviation from zero and the plus or minus sign the polarity of the couple.

C

The maximum temperature values listed apply to the alloy wire only. Caution should be exercised pending knowledge of the maximum temperature of use for the

coating material involved.

D

If metric sizes are desired, 1 in. = 25.4 mm.

E

Alloy Class 6 (manganin type for resistors), has a temperature-resistance curve of parabolic shape with the maximum resistance normally located between 25 and

m

30°C. Thus, Columns 5 and 7 cannot indicate 25°C as a limit but a may be expressed as a maximum of + 15 ppm for !5°C to the temperature of maximum resistance

and a maximum of − 15 ppm from the temperature of maximum resistance to 35°C. All of the information included in this note is based on measurements made in

accordance with Test Method B 84.

corresponding temperature ranges. 12. Finish

12.1 The wire shall be as uniform and free from kinks, curls,

10. Permissible Variations in Electrical Resistance

and surface defects such as seams, laminations, scale, and other

10.1 The actual resistance per unit length of any wire

irregularities as the best commercial practice will permit.

furnished under these specifications shall not vary from the

nominal resistance by more than the following amounts:

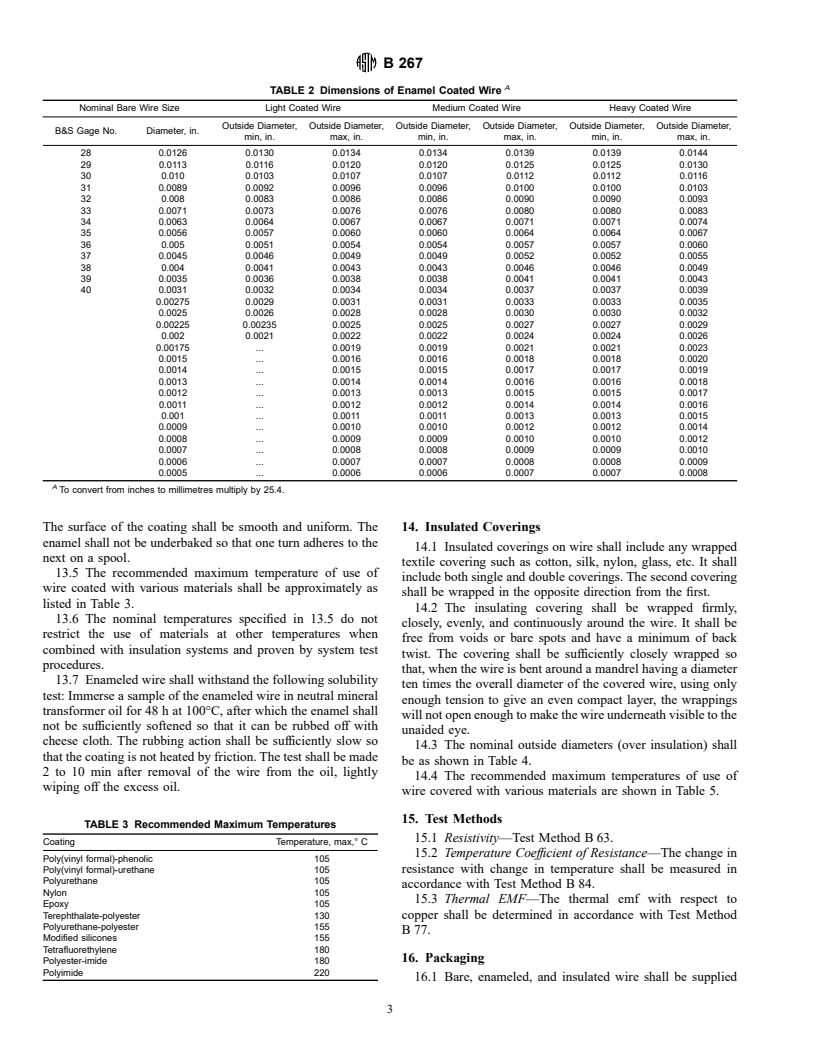

13. Enamel Coatings

Form Permissible

13.1 Enamel coatings shall include any baked-on film of

Variation, 6%

insulating material, such as varnish enamel, polyurethane,

Over 0.005 in. (0.127 mm) in diameter 5

vinyl acetal, etc. and shall conform to the requirements

0.002 to 0.005 in. (0.051 to 0.127 mm) in diameter, incl 8

Under 0.002 in (0.051 mm) in diameter 10

prescribed in 13.2 to 13.7.

Ribbon 5

13.2 The physical dimensions of the enamel film shall

10.2 For Alloy Classes 1 to 4 inclusive, the actual resistance conform to the requirements specified in Table 2.

13.3 The continuity of dielectric strength of medium or

of any 1-ft length of wire in one spool or coil shall not vary by

more than 3 % from the actual resistance of any other 1 ft of heavy enamel shall show a maximum of 10 breaks/100 ft when

tested with a potential of 150 V applied between a single

wire in the same spool or coil.

10.3 For Alloy Classes 5 to 11 inclusive, the actual mercury cup and the bared end of the wire. In the dielectric

strength test, 100 ft of the wire shall be drawn through the

resistance of any 1-ft length of wire in one spool or coil shall

not vary by more than 5 % from the actual resistance of any mercury or equivalent at a speed that will permit the recording

of 600 counts/min. The test circuit shall have a recording

ot

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.