ASTM D6194-08

(Test Method)Standard Test Method for Glow-Wire Ignition of Materials

Standard Test Method for Glow-Wire Ignition of Materials

SIGNIFICANCE AND USE

During operation of electrical equipment, including wires, resistors, and other conductors, it is possible for overheating to occur under certain conditions of operation, or when malfunctions occur. When this happens, a possible result is ignition of the adjacent insulation material.

This test method assesses the susceptibility of electrical insulating materials to ignition as a result of exposure to a glowing wire.

This test method determines the minimum temperature required to ignite a material by the effect of a glowing heat source, under the specified conditions of test.

This method is suitable, subject to the appropriate limitations of an expected precision of ±15 %, to categorize materials.

5.5 In this procedure, the specimens are subjected to one or more specific sets of laboratory conditions. If different test conditions are substituted or the end-use conditions are changed, it is not always possible by or from this test to predict changes in the fire-test-response characteristics measured. Therefore, the results are valid only for the fire test exposure conditions described in this procedure.

SCOPE

1.1 This test method covers the minimum temperature required to ignite insulating materials using a glowing heat source. In a preliminary fashion, this test method differentiates between the susceptibilities of different materials with respect to their resistance to ignition due to an electrically-heated source.

1.2 This test method applies to molded or sheet materials available in thicknesses ranging from 0.25 to 6.4 mm.

1.3 This test method is not valid for determining the ignition behavior of complete electrotechnical equipment, since the design of the electrotechnical product influences the heat transfer between adjacent parts.

1.4 This test method measures and describes the response or materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard. (See IEEE/ASTM SI-10 for further details.)

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 9.

1.7 Fire testing of products and materials is inherently hazardous, and adequate safeguards for personnel and property shall be employed in conducting these tests. Fire testing involves hazardous materials, operations, and equipment.

Note 1—Although this test method and IEC 60695-2-13 differ in approach and in detail, data obtained using either are technically equivalent.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation:D6194–08

Standard Test Method for

1

Glow-Wire Ignition of Materials

This standard is issued under the fixed designation D6194; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

1.1 This test method covers the minimum temperature 2.1 ASTM Standards:

required to ignite insulating materials using a glowing heat D1711 Terminology Relating to Electrical Insulation

source. In a preliminary fashion, this test method differentiates E176 Terminology of Fire Standards

between the susceptibilities of different materials with respect E220 Test Method for Calibration of Thermocouples By

to their resistance to ignition due to an electrically-heated Comparison Techniques

source. E230 Specification and Temperature-Electromotive Force

1.2 This test method applies to molded or sheet materials (EMF) Tables for Standardized Thermocouples

available in thicknesses ranging from 0.25 to 6.4 mm. IEEE/ASTM SI 10 International System of Units (SI), The

1.3 Thistestmethodisnotvalidfordeterminingtheignition Modernized Metric System

behavior of complete electrotechnical equipment, since the 2.2 IEC Standard:

design of the electrotechnical product influences the heat IEC 60695-4 Fire Hazard Testing—Part 4: Terminology

3

transfer between adjacent parts. Concerning Fire Tests

1.4 Thistestmethodmeasuresanddescribestheresponseor IEC 60695-2-12 Fire Hazard Testing—Part 2–12: Glowing/

materials, products, or assemblies to heat and flame under Hot-Wire Based Test Methods—Glow-Wire Flammability

3

controlled conditions, but does not by itself incorporate all Test Method for Materials

factors required for fire hazard or fire risk assessment of the IEC 60695-2-13 Fire Hazard Testing—Section 20:

materials, products, or assemblies under actual fire conditions. Glowing/Hot-WireBasedTestMethods—Glow-WireCoil

3

1.5 The values stated in SI units are to be regarded as Ignitability Test Method for Materials

standard. No other units of measurement are included in this 2.3 ISO Standard:

4

standard. (See IEEE/ASTM SI 10 for further details.) ISO 13943 Fire Safety—Vocabulary

1.6 This standard does not purport to address all of the

3. Terminology

safety concerns, if any, associated with its use. It is the

3.1 Definitions:

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 3.1.1 Use Terminology E176, ISO 13943, and IEC 60695-4

for definitions of terms used in this test method and associated

bility of regulatory limitations prior to use. For specific

precautionary statements, see Section 9. with fire issues. Where differences exist in definitions, those

contained in Terminology E176 shall be used. Use Terminol-

1.7 Fire testing of products and materials is inherently

hazardous, and adequate safeguards for personnel and property ogy D1711 for definitions of terms used in this test method and

associated with electrical insulation materials.

shall be employed in conducting these tests. Fire testing

involves hazardous materials, operations, and equipment. 3.2 Definitions of Terms Specific to This Standard:

3.2.1 glow wire, n—a wire of specified dimensions that can

NOTE 1—Although this test method and IEC 60695-2-13 differ in

becontrollably-heatedelectricallytodetermineignitabilityofa

approach and in detail, data obtained using either are technically equiva-

material.

lent.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This test method is under the jurisdiction of ASTM Committee D09 on Standards volume information, refer to the standard’s Document Summary page on

Electrical and Electronic Insulating Materials and is the direct responsibility of the ASTM website.

3

Subcommittee D09.21 on Fire Performance Standards. Available from International Electrotechnical Commission (IEC), 3 Rue de

CurrenteditionapprovedJune1,2008.PublishedJuly2008.Originallyapproved Varembe, Geneva, Switzerland.

4

in 1997. Last previous edition approved in 2004 as D6194 – 04. DOI: 10.1520/ Use undyed, soft, strong, lightweight tissue paper weighing between 12 and 30

2

D6194-08. g/m .

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6194–08

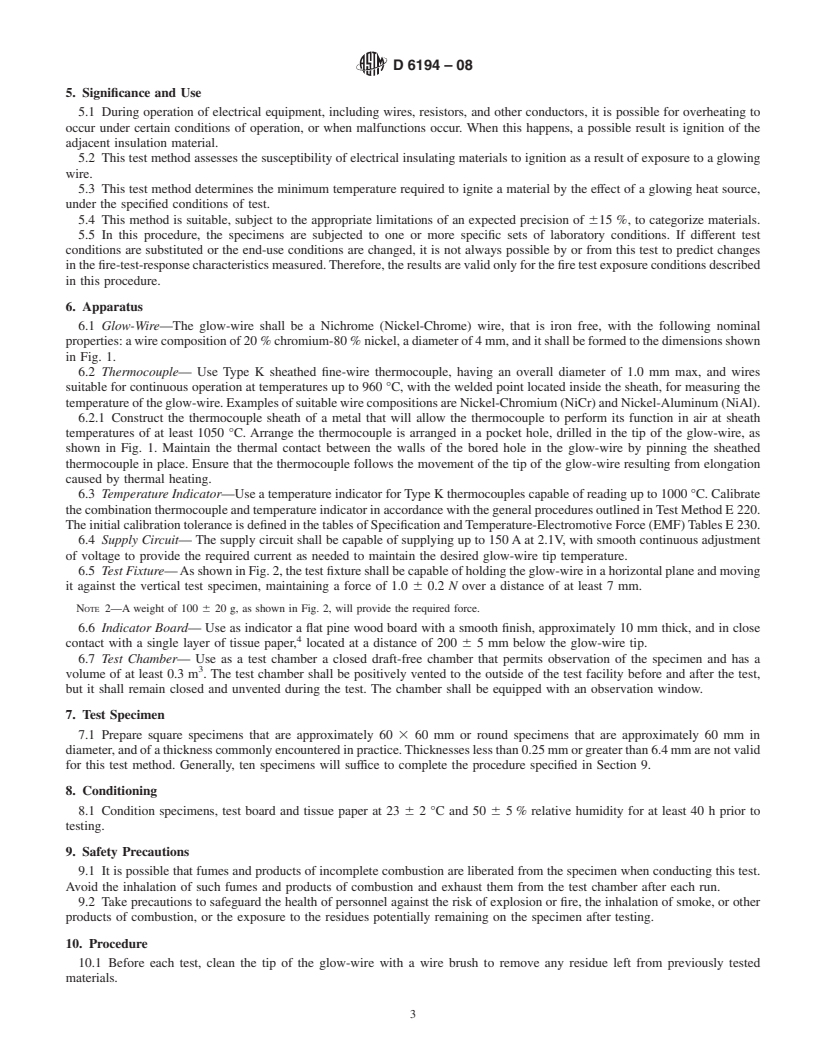

3.2.1.1 Discussion—Fig. 1 shows a glow wire and its 5. Significance and Use

positioning.

5.1 During operation of electric

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D6194–04 Designation: D 6194 – 08

Standard Test Method for

1

Glow-Wire Ignition of Materials

This standard is issued under the fixed designation D 6194; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the minimum temperature required to ignite insulating materials using a glowing heat source. In

a preliminary fashion, this test method differentiates between the susceptibilities of different materials with respect to their

resistance to ignition due to an electrically-heated source.

1.2 This test method applies to molded or sheet materials available in thicknesses ranging from 0.25 to 6.4 mm.

1.3 This test method is not valid for determining the ignition behavior of complete electrotechnical equipment, since the design

of the electrotechnical product influences the heat transfer between adjacent parts.

1.4 This test method measures and describes the response or materials, products, or assemblies to heat and flame under

controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials,

products, or assemblies under actual fire conditions.

1.5The values stated in SI units are to be regarded as the standard. (See IEEE/ASTM SI-10

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

(See IEEE/ASTM SI-10 for further details.)

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific precautionary statements, see Section 9.

1.7 Fire testing of products and materials is inherently hazardous, and adequate safeguards for personnel and property shall be

employed in conducting these tests. Fire testing involves hazardous materials, operations, and equipment.

NOTE 1—Although this test method and IEC 60695-2-13 differ in approach and in detail, data obtained using either are technically equivalent.

2. Referenced Documents

2

2.1 ASTM Standards:

D 1711 Terminology Relating to Electrical Insulation

E 176 Terminology of Fire Standards

E 220 Test Method for Calibration of Thermocouples byBy Comparison Techniques

E 230 Specification and Temperature-Electromotive Force (EMF) Tables for Standardized Thermocouples

IEEE/ASTM SI-10 International System of Units (SI), The Modernized Metric System

2.2 IEC Standard: IEC 60695-2-13:Fire Hazard Testing—Section 20: Glowing/Hot-Wire Based Test Methods—Glow-Wire Coil

Ignitability Test Method for Materials

3

IEC 60695-4:Fire Hazard Testing—Part 4: Terminology Concerning Fire Tests IEC 60695-4 Fire Hazard Testing—Part 4:

3

Terminology Concerning Fire Tests

IEC 60695-2-12 Fire Hazard Testing—Part 2–12: Glowing/Hot-Wire Based Test Methods—Glow-Wire Flammability Test

3

Method for Materials

IEC 60695-2-13 Fire Hazard Testing—Section 20: Glowing/Hot-Wire Based Test Methods—Glow-Wire Coil Ignitability Test

3

Method for Materials

2.3 ISO Standard:

4

ISO 13943:ISO 13943 Fire Safety—Vocabulary

1

This test method is under the jurisdiction of ASTM Committee D09 on Electrical and Electronic Insulating Materials and is the direct responsibility of Subcommittee

D09.21 on Fire Performance Standards.

Current edition approved Sept.June 1, 2004.2008. Published September 2004.July 2008. Originally approved in 1997. Last previous edition approved in 20032004 as

D 6194 – 034.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from International Electrotechnical Commission (IEC), 3 Rue de Varembe, Geneva, Switzerland.

4 2

Use undyed, soft, strong, lightweight tissue paper weighing between 12 and 30 g/m .

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6194–08

3. Terminology

3.1 Definitions:

3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.