ASTM E1640-13

(Test Method)Standard Test Method for Assignment of the Glass Transition Temperature By Dynamic Mechanical Analysis

Standard Test Method for Assignment of the Glass Transition Temperature By Dynamic Mechanical Analysis

SIGNIFICANCE AND USE

5.1 This test method can be used to locate the glass transition region and assign a glass transition temperature of amorphous and semi-crystalline materials.

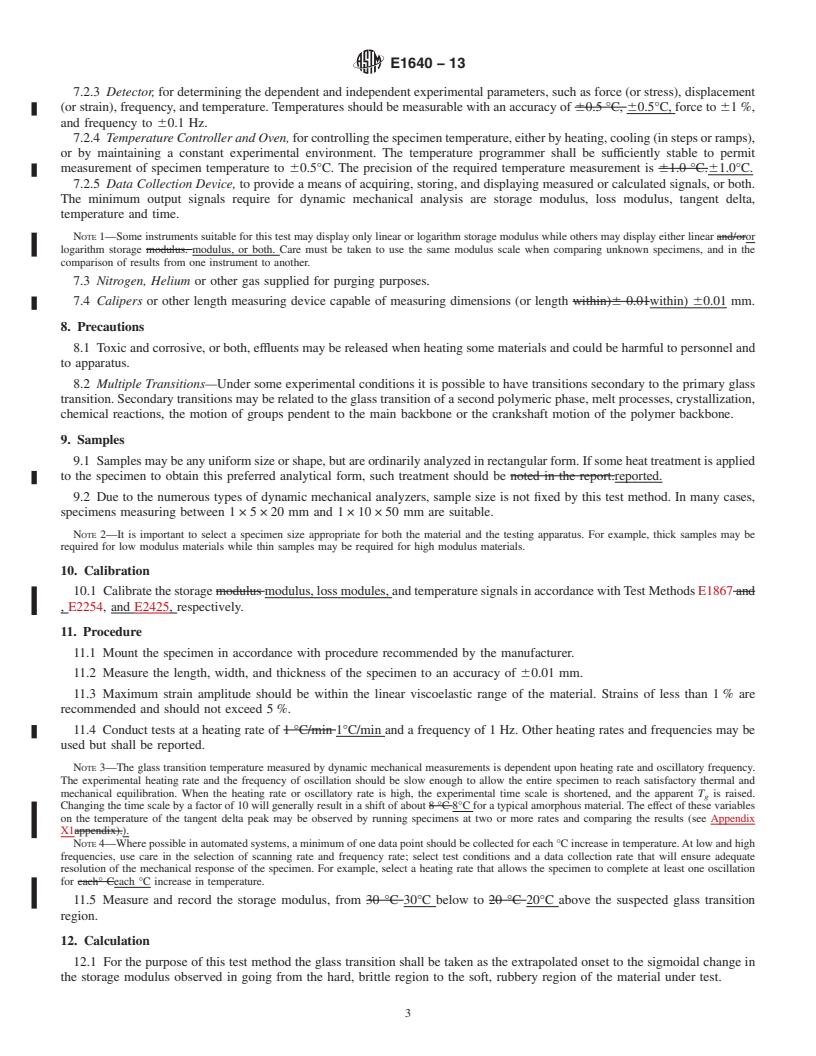

5.2 Dynamic mechanical analyzers monitor changes in the viscoelastic properties of a material as a function of temperature and frequency, providing a means to quantify these changes. In ideal cases, the temperature of the onset of the decrease in storage modulus marks the glass transition.

5.3 A glass transition temperature (Tg) is useful in characterizing many important physical attributes of thermoplastic, thermosets, and semi-crystalline materials including their thermal history, processing conditions, physical stability, progress of chemical reactions, degree of cure, and both mechanical and electrical behavior. Tg may be determined by a variety of techniques and may vary in accordance with the technique.

5.4 This test method is useful for quality control, specification acceptance, and research.

SCOPE

1.1 This test method covers the assignment of a glass transition temperature (Tg) of materials using dynamic mechanical analyzers.

1.2 This test method is applicable to thermoplastic polymers, thermoset polymers, and partially crystalline materials which are thermally stable in the glass transition region.

1.3 The applicable range of temperatures for this test method is dependent upon the instrumentation used, but, in order to encompass all materials, the minimum temperature should be about −150°C.

1.4 This test method is intended for materials having an elastic modulus in the range of 0.5 MPa to 100 GPa.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard is similar to IEC 61006 except that standard uses the peak temperature of the loss modulus peak as the glass transition temperature while this standard uses the extrapolated onset temperature of the storage modulus change.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1640 − 13

Standard Test Method for

Assignment of the Glass Transition Temperature By

1

Dynamic Mechanical Analysis

This standard is issued under the fixed designation E1640; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E691Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers the assignment of a glass

E1142Terminology Relating to Thermophysical Properties

transition temperature (T ) of materials using dynamic me-

g

E1363Test Method forTemperature Calibration ofThermo-

chanical analyzers.

mechanical Analyzers

1.2 This test method is applicable to thermoplastic

E1545Test Method for Assignment of the Glass Transition

polymers, thermoset polymers, and partially crystalline mate-

Temperature by Thermomechanical Analysis

rials which are thermally stable in the glass transition region.

E1867Test Methods for Temperature Calibration of Dy-

1.3 The applicable range of temperatures for this test

namic Mechanical Analyzers

method is dependent upon the instrumentation used, but, in E2254Test Method for Storage Modulus Calibration of

order to encompass all materials, the minimum temperature

Dynamic Mechanical Analyzers

should be about−150°C. E2425Test Method for Loss Modulus Conformance of

Dynamic Mechanical Analyzers

1.4 This test method is intended for materials having an

elastic modulus in the range of 0.5 MPa to 100 GPa. 2.2 Other Standards:

IEC 61006Methods of Test for the Determination of the

1.5 The values stated in SI units are to be regarded as

GlassTransitionTemperature of Electrical Insulating Ma-

standard. No other units of measurement are included in this

3

terials

standard.

1.6 This standard is similar to IEC 61006 except that

3. Terminology

standardusesthepeaktemperatureofthelossmoduluspeakas

3.1 Definitions:

the glass transition temperature while this standard uses the

extrapolated onset temperature of the storage modulus change. 3.1.1 Specific technical terms used in this document are

defined in Terminology D4092 and E1142 including Celsius,

1.7 This standard does not purport to address all of the

dynamic mechanical analyzer, glass transition, glass transition

safety concerns, if any, associated with its use. It is the

temperature,lossmodulus,storagemodulus,tangentdelta,and

responsibility of the user of this standard to establish appro-

viscoelasticity.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Summary of Test Method

2. Referenced Documents

4.1 Aspecimen of known geometry is placed in mechanical

2

2.1 ASTM Standards: oscillationateitherfixedorresonantfrequencyandchangesin

D4092 Terminology for Plastics: Dynamic Mechanical the viscoelastic response of the material are monitored as a

Properties

function of temperature. Under ideal conditions, during

heating, the glass transition region is marked by a rapid

decreaseinthestoragemodulusandarapidincreaseintheloss

1

modulus and tangent delta. The glass transition of the test

ThistestmethodisunderthejurisdictionofASTMCommitteeE37onThermal

Measurements and is the direct responsibility of Subcommittee E37.10 on

specimenisindicatedbytheextrapolatedonsetofthedecrease

Fundamental, Statistical and Mechanical Properties.

instoragemoduluswhichmarksthetransitionfromaglassyto

Current edition approved Aug. 1, 2013. Published August 2013. Originally

a rubbery solid.

approved in 1994. Last previous edition approved in 2009 as E1640–09. DOI:

10.1520/E1640-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1640 − 13

5. Significance and Use 7.2.1 Clamps,aclampingarrangementthatpermitsgripping

ofthespecimen.Samplesmaybemountedbyclampingatboth

5.1 This test method can be used to locate the glass

ends (most systems), one end (for example, torsional

transition region and assign a glass transition temperature of

pendulum), or neither end (free bending between knife edges).

amorphous and semi-crystalline materials.

7.2.2 Oscillatory Stress (Strain), for applying an oscillatory

5.2 Dynamic mechanical analyzers monitor changes i

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1640 − 09 E1640 − 13

Standard Test Method for

Assignment of the Glass Transition Temperature By

1

Dynamic Mechanical Analysis

This standard is issued under the fixed designation E1640; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the assignment of a glass transition temperature (Tg)(T ) of materials using dynamic mechanical

g

analyzers.

1.2 This test method is applicable to thermoplastic polymers, thermoset polymers, and partially crystalline materials which are

thermally stable in the glass transition region.

1.3 The applicable range of temperatures for this test method is dependent upon the instrumentation used, but, in order to

encompass all materials, the minimum temperature should be about −150 °C.about −150°C.

1.4 This test method is intended for materials having an elastic modulus in the range of 0.5 MPa to 100 GPa.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard is similar to IEC 61006 except that standard uses the peak temperature of the loss modulus peak as the glass

transition temperature while this standard uses the extrapolated onset temperature of the storage modulus change.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D4092 Terminology for Plastics: Dynamic Mechanical Properties

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E1142 Terminology Relating to Thermophysical Properties

E1363 Test Method for Temperature Calibration of Thermomechanical Analyzers

E1545 Test Method for Assignment of the Glass Transition Temperature by Thermomechanical Analysis

E1867 Test Method for Temperature Calibration of Dynamic Mechanical Analyzers

E2254 Test Method for Storage Modulus Calibration of Dynamic Mechanical Analyzers

E2425 Test Method for Loss Modulus Conformance of Dynamic Mechanical Analyzers

2.2 Other Standards:

3

IEC 61006 Methods of Test for the Determination of the Glass Transition Temperature of Electrical Insulating Materials

3. Terminology

3.1 Definitions:

3.1.1 Specific technical terms used in this document are defined in Terminology D4092 and E1142 including Celsius, dynamic

mechanical analyzer, glass transition, glass transition temperature, loss modulus, storage modulus, tangent delta, and viscoelas-

ticity.

1

This test method is under the jurisdiction of ASTM Committee E37 on Thermal Measurements and is the direct responsibility of Subcommittee E37.10 on Fundamental,

Statistical and Mechanical Properties.

Current edition approved Sept. 1, 2009Aug. 1, 2013. Published October 2009August 2013. Originally approved in 1994. Last previous edition approved in 20042009 as

E1640 – 04.E1640 – 09. DOI: 10.1520/E1640-09.10.1520/E1640-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1640 − 13

3.1.2 dynamic mechanical analyzer—any of various commercial or experimental devices used to study the viscoelastic response

of a specimen under a forced or free resonant oscillatory load. The force may be applied in torsion, flexure, or a combination of

tension and compression.

4. Summary of Test Method

4.1 A specimen of known geometry is placed in mechanical oscillation at either fixed or resonant frequency and changes in the

viscoelastic response of the material are monitored as a function of temperature. Under ideal conditions, during heating, the glass

transition region is marked by a rapid decrease in the storage modulus and a rapid increase in the los

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.