ASTM D1326-94(2000)

(Test Method)Standard Test Methods for Chemical Analysis of Ammoniacal Copper Arsenate and Ammoniacal Copper Zinc Arsenate (Withdrawn 2006)

Standard Test Methods for Chemical Analysis of Ammoniacal Copper Arsenate and Ammoniacal Copper Zinc Arsenate (Withdrawn 2006)

SCOPE

1.1 These test methods cover the determination of the chemical analysis of commercial solutions of ammoniacal copper arsenate.

1.1.1 Test Method D38 covers the sampling of wood preservatives prior to testing.

1.2 The analytical procedures appear in the following order: Sections Ammonia (calculated as anhydrous ammonia) 5 to 7 Arsenic (calculated as As2O5) 8 to 9 Copper (calculated as CuO) 10 to 11

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

These test methods cover the determination of the chemical analysis of commercial solutions of ammoniacal copper arsenate.

Formerly under the jurisdiction of Committee D07 on Wood, these test methods were withdrawn without replacement in July 2006.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1326–94 (Reapproved 2000)

Standard Test Methods for

Chemical Analysis of Ammoniacal Copper Arsenate and

,

1 2

Ammoniacal Copper ZincArsenate

This standard is issued under the fixed designation D 1326; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 AWPA Standard:

AWPA A2 Standard Methods for Analysis of Waterborne

1.1 These test methods cover the determination of the

Preservatives and Fire-Retardant Formulations

chemical analysis of commercial solutions of ammoniacal

copper arsenate.

3. Summary of Test Methods

1.1.1 Test Method D38 covers the sampling of wood

3.1 Ammonia—Ammonia is freed from a caustic solution of

preservatives prior to testing.

thesamplebydistillationandabsorbedinameasuredexcessof

1.2 The analytical procedures appear in the following order:

sulfuric acid solution. The unreacted sulfuric acid solution is

Sections

titrated with standardized NaOH solution to determine the

Ammonium bicarbonate (calculated as carbonate) 20 to 22

Ammonia (calculated as anhydrous ammonia) 6 to 9

ammonia reacted with sulfuric acid.

Arsenic (calculated as arsenic pentoxide) 10 to 11

3.2 Arsenic—A diluted sample is acidified with hydrochlo-

Copper (calculated as copper oxide) 13 to 16

ric and hypophosphorous acid to precipitate the arsenic. The

Zinc (calculated as zinc oxide) 17 to 19

arsenicisvolatilizedbyheatinginthepresenceofsulfuricacid,

1.3 This standard does not purport to address all of the

which is then diluted with water and titrated with a standard

safety concerns, if any, associated with its use. It is the

solution of potassium bromate.Arsenic is calculated asAs O .

2 5

responsibility of the user of this standard to establish appro-

3.3 Copper—Ameasured sample is dissolved in hydrochlo-

priate safety and health practices and determine the applica-

ric acid and reacted with potassium iodide to complex the

bility of regulatory limitations prior to use.

copper ion. The solution is then titrated with a standard

solution of sodium thiosulfate. The copper is calculated as

2. Referenced Documents

CuO.

2.1 ASTM Standards:

3.4 Zinc—A diluted and chemically treated sample is

D38 Test Methods for Sampling Wood Preservatives Prior

treated with a standard solution of potassium ferrocyanide in

to Testing

the presence of an oxidation-reduction indicator (dipheny-

D 1193 Specification for Reagent Water

lamine). The zinc is calculated as ZnO.

D 1325 Specification for Ammoniacal Copper Zinc Arsen-

ate

4. Significance and Use

D 3873 Test Method for Valency State of the Arsenic

4.1 Ammoniacal copper arsenate and ammoniacal copper

Component of Ammoniacal Copper Arsenate Solutions

zinc arsenate for use in the preservative treatment of wood

must conform with Specification D 1325.

These test methods are under the jurisdiction of ASTM Committee D-7 on

5. Purity of Reagents

Wood and are the direct responsibility of Subcommittee D07.06 on Treatments for

Wood Products.

5.1 Purity of Reagents—Reagent grade chemicals shall be

Current edition approved July 15, 1994. Published September 1994. Originally

used in all tests. Unless otherwise indicated, all reagents shall

published as D 1326 – 54 T. Last previous edition D 1326 – 87.

conform to the specifications of the Committee on Analytical

The analytical methods and sampling procedures are essentially the same as

those given in theAmericanWood-Preservers’Assn. Standard Methods forAnalysis

Reagents of the American Chemical Society, where such

of Water-Borne Preservatives and Fire-Retardant Formulations (A2-91). Acknowl-

edgmentismadetotheAmericanWood-Preservers’Associationforitsdevelopment

of the subject matter covered in this test.

3 5

Annual Book of ASTM Standards, Vol 04.10. Available fromAmerican Wood-Preservers’Association, P.O. Box 286, Wood-

Annual Book of ASTM Standards, Vol 11.01. stock, MD 21163-0286.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1326–94 (2000)

freshly boiled water and 2 drops of phenolphthalein indicator

solution to each flask. Titrate with the NaOH solution to the

appearance of a faint, persistent pink color. The titrations

should agree within 0.1 mL; record the average. Calculate the

normality of the NaOH solution as follows:

Normality of NaOH solution 5 3.920/V (1)

where V = mL of NaOH solution required.

7.4 Sulfuric Acid, Standard (0.1 N)—To 100 mLof water in

a1000-mLvolumetricflask,add3.3mLofH SO (spgr1.84);

2 4

mix and cool to 20°C. Dilute to the mark with water.

Standardizeasfollows:Pipet25mLoftheH SO solutioninto

2 4

a 500-mL Erlenmeyer flask, and add 100 mL of water and 2

dropsofphenolphthaleinindicatorsolution.Titratewiththe0.1

N NaOH solution to the appearance of a faint, persistent pink

color. Calculate the normality of the H SO as follows:

2 4

Normality of H SO 5 VN/25 (2)

2 4

A—Round-bottom flask, 500-mL

B—Distillation trap.

C—Condenser.

where:

D—Delivery tube.

E—Erlenmeyer flask, 500-mL.

V = NaOH solution required, mL, and

FIG. 1 Distillation Apparatus for Determination of Ammonia in

N = normality of the NaOH solution.

Ammoniacal Copper Arsenate and Ammoniacal Copper Zinc

7.5 Sodium Hydroxide Solution (100 g/L)—Dissolve 100 g

Arsenate

of NaOH in water and dilute to 1 L.

specifications are available. Other grades shall only be used

8. Procedure

when it is first ascertained that the reagent is of sufficiently

8.1 Transfer a portion of the sample containing not more

high purity to permit its use without lessening the accuracy of

than 0.15 g of NH (Note 1) to the 500-mL distillation flask.

the determination.

Dilute with water to a volume of about 200 mL. Add a few

5.2 Unless otherwise indicated, references to water shall be

glass beads to prevent bumping.Add 20 mLof NaOH solution

understood to mean reagent water conforming to Specification

(100 g NaOH/L) and immediately close the flask with a rubber

D 1193.

stopperthroughwhichaspraytraphasbeeninserted.Thespray

trap shall previously have been connected to a vertical con-

AMMONIA

denser. Place 100 mL of 0.1 N H SO in a 400-mL beaker.

2 4

Adjust the tip of the condenser so that it just dips into the H

6. Apparatus

SO .Add 4 to 5 drops of methyl purple or methyl red indicator

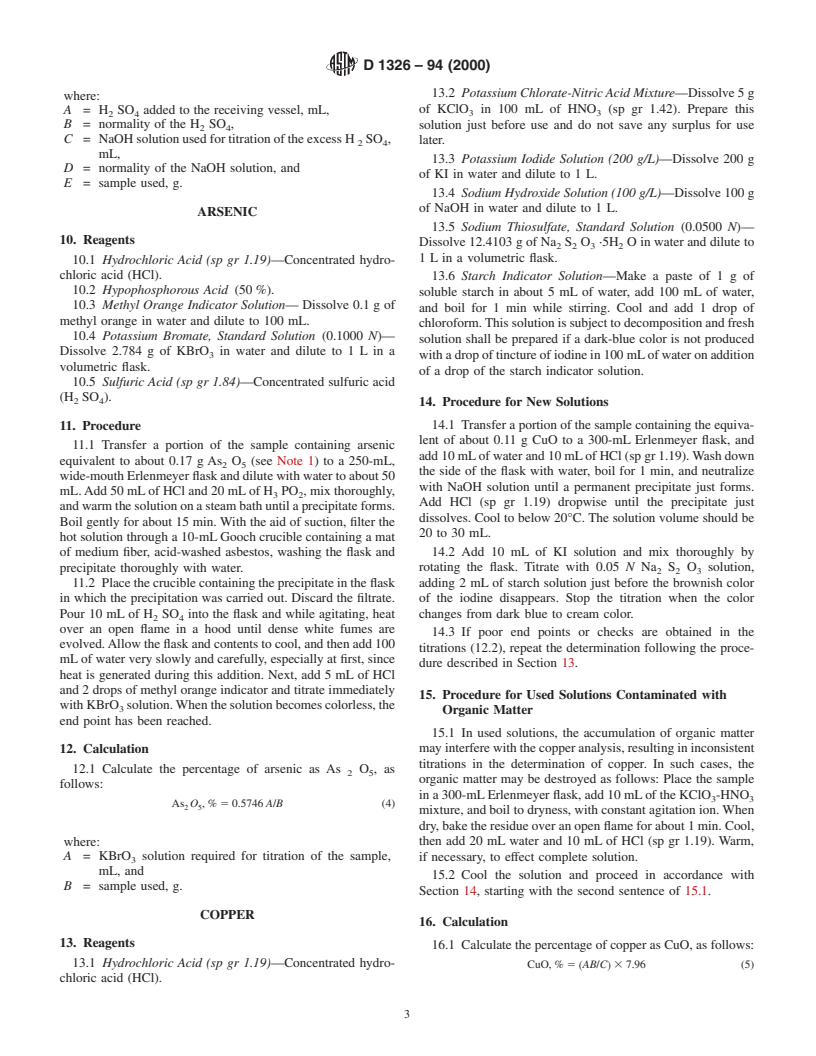

6.1 A typical apparatus for the distillation of ammonia is

solution to the H SO .

2 4

shown in Fig. 1.

NOTE 1—If this procedure is used for testing a solution of treating

7. Reagents

strength, use an accurately measured volume of the filtered solution

equivalent to the appropriate amount of the element to be determined.

7.1 Methyl Purple or Methyl Red Indicator Solution—

Suitable prepared solutions of methyl purple can be purchased.

8.2 After making sure all the connections are airtight,

To prepare the methyl red indicator solution, dissolve 0.1 g of

commence heating the mixture of sample and NaOH solution.

methyl red in 50 mL of alcohol (90 %), dilute to 100 mL with

Distill slowly at first, and finally boil rather vigorously. Distill

water, and filter if necessary.

off about 150 mL of solution. Adjust the height of the beaker

7.2 Phenolphthalein Indicator Solution— Dissolve1gof

throughout the distillation so that the tip of the condenser is

phenolphthalein in 100 mL of alcohol.

always near the surface of the liquid in the receiving vessel. If

7.3 Sodium Hydroxide Standard Solution (0.1 N)—Dissolve

the indicator starts to turn color, add a measured amount of

4 g of NaOH in CO -free water and dilute to 1 Lwith CO -free

2 2

additional0.1NH SO .Whendistillationiscomplete,turnout

2 4

water. Standardize as follows: Place 2 0.8000-g portions of

the flame and lower the receiving vessel. Wash down the

potassium acid phthalate (National Bureau of Standards stan-

condenser tube and its tip into the receiver.

dard sample No. 84) in volumetric flasks, and add 100 mL of

8.3 Titrate the excess acid with 0.1 N NaOH solution.

9. Calculation

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not 9.1 Calculate the percentage of ammonia as NH ,as

listed by the American Chemical Society, see Analar Standards for Laboratory

follows:

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

NH,% 5 [~AB 2 CD! 3 1.703]/E (3)

and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville,

MD.

D1326–94 (2000)

13.2 Potassium Chlorate-NitricAcid Mixture—Dissolve 5 g

where:

of KClO in 100 mL of HNO (sp gr 1.42). Prepare this

A =H SO added to the receiving vessel, mL,

3 3

2 4

B = normality of the H SO , solution just before use and do not save any surplus for use

2 4

C = NaOHsolutionusedfortitrationoftheexcessH SO ,

later.

2 4

mL,

13.3 Potassium Iodide Solution (200 g/L)—Dissolve 200 g

D = normality of the NaOH solution, and

of KI in water and dilute to 1 L.

E = sample used, g.

13.4 Sodium Hydroxide Solution (100 g/L)—Dissolve 100 g

of NaOH in water and dilute to 1 L.

ARSENIC

13.5 Sodium Thiosulfate, Standard Solution (0.0500 N)—

10. Reagents

Dissolve 12.4103 g of Na S O ·5H O in water and dilute to

2 2 3 2

1 L in a volumetric flask.

10.1 Hydrochloric Acid (sp gr 1.19)—Concentrated hydro-

chloric acid (HCl).

13.6 Starch Indicator Solution—Make a paste of1gof

10.2 Hypophosphorous Acid (50 %).

soluble starch in about 5 mL of water, add 100 mL of water,

10.3 Methyl Orange Indicator Solution— Dissolve 0.1 g of

and boil for 1 min while stirring. Cool and add 1 drop of

methyl orange in water and dilute to 100 mL.

chloroform.Thissolutionissubjecttodecompositionandfresh

10.4 Potassium Bromate, Standard Solution (0.1000 N)—

solution shall be prepared if a dark-blue color is not produced

Dissolve 2.784 g of KBrO in water and dilute to 1 L in a

withadropoftinctureofiodinein100mLofwateronaddition

volumetric flask.

of a drop of the starch indicator solution.

10.5 Sulfuric Acid (sp gr 1.84)—Concentrated sulfuric acid

(H SO ).

2 4

14. Procedure for New Solutions

14.1 Transfer a portion of the sample containing the equiva-

11. Procedure

lent of about 0.11 g CuO to a 300-mL Erlenmeyer flask, and

11.1 Transfer a portion of the sample containing arsenic

add 10 mLof water and 10 mLof HCl (sp gr 1.19).Wash down

equivalent to about 0.17 g As O (see Note 1) to a 250-mL,

2 5

the side of the flask with water, boil for 1 min, and neutralize

wide-mouthErlenmeyerflaskanddilutewithwatertoabout50

with NaOH solution until a permanent precipitate just forms.

mL.Add 50 mLof HCl and 20 mLof H PO , mix thoroughly,

3 2

Add HCl (sp gr 1.19) dropwise until the precipitate just

andwarmthesolutiononasteambathuntilaprecipitateforms.

dissolves. Cool to below 20°C. The solution volume should be

Boil gently for about 15 min. With the aid of suction, filter the

20 to 30 mL.

hot solution through a 10-mLGooch crucible containing a mat

14.2 Add 10 mL of KI solution and mix thoroughly by

of medium fiber, acid-washed asbestos, washing the flask and

precipitate thoroughly with water. rotating the flask. Titrate with 0.05 N Na S O solution,

2 2 3

11.2 Place the crucible containing the precipitate in the flask adding 2 mL of starch solution just before the brownish color

in which the precipitation was carried out. Discard the filtrate. of the iodine disappears. Stop the titration when the color

Pour 10 mL of H SO into the flask and while agitating, heat changes from dark blue to cream color.

2 4

over an open flame in a hood until dense white fumes are

14.3 If poor end points or checks are obtained in the

evolved.Allow the flask and contents to cool, and then add 100

titrations (12.2), repeat the determination following the proce-

mLof water very slowly and carefully, especially at first, since

dure described in Section 13.

heat is generated during this addition. Next, add 5 mL of HCl

and 2 drops of methyl orange indicator and titrate immediately

15. Procedure for Used Solutions Contaminated with

withKBrO solution.Whenthesolutionbecomescolorless,the

Organic Matter

end point has been reached.

15.1 In used solutions, the accumulation of organic matter

mayinterferewiththecopperanalysis,resultingininconsistent

12. Calculation

titrations in the determination of copper. In such cases, the

12.1 Calculate the percentage of arsenic as As O,as

2 5

organic matter may be destroyed as follows: Place the sample

follows:

in a 300-mLErlenmeyer flask, add 10 mLof the KClO -HNO

3 3

As O,% 5 0.5746 A/B (4)

2 5

mixture, and boil to dryness, with constant agitation ion.When

dry, bake the residue over an open flame for about 1 min. Cool,

where: then add 20 mL water and 10 mL of HCl (sp gr 1.19). Warm,

A = KBrO solution required for titration of the sample, if necessary, to effect complete solution.

mL, and

15.2 Cool the solution and proceed in accordance with

B = sample used, g.

Section 14, starting with the second sentence of 15.1.

COPPER

16. Calculation

13. Reagents

16.1 Calculate the percentage of copper as CuO, as follows:

13.1 Hydrochloric Acid (sp gr 1.19)—Concentrated hydro-

CuO, % 5 ~AB/C! 3 7.96 (5)

chloric acid (HCl).

D1326–94 (2000)

direction. Match up the burette reading with the last drop in

where:

which the brown color is plainly visible.

A = standard thiosulfate solution required for titration of

18.5 Subtract the mL of ZnCl solution used to back titrate,

the sample, mL,

B = normality of sodium thiosulfate solution, and from the mLof K Fe(CN) and this will give the net mLof K

4 6 2

C = sample used, g. Fe(CN) required by the zinc in the sample.

ZINC

19. Calculations

19.1 Calculate the percentage of active ingredient as fol-

17. Reagents

lows:

17.1 Hydrochloric Acid, concentrated.

mL titration 3 normality of K Fe~CN! 3 factor

4 6

17.2 Hydrochloric Acid 1.20—Add one volume concen-

Percentage 5

sample, g

trated acid to 20 volumes water.

(6)

17.3 Alcohol, ethyl or isopropyl.

17.4 Hydrogen Sulfide Gas.

Active Ingredi- Factor

17.5 Ammonium Hydroxide, concentrated.

ents

17.6 UranylAcetate, ⁄10N,4.3gdissolvedin100mLwater. ZnO 4.068

ZnCl 6.814

17.7 Potassium Ferrocyanide Solution , 0.15 N—Weigh

ZnSO 14.373

accurately 21.12 g of pure K Fe(CN) ·3H O, and dissolve it

4 6 2

NOTE 2—The procedure is based on the assumption that both the

in distilled water. Add 0.2 g sodium carbonate to stabilize the

potassium ferrocyanide and zinc chloride solutions are made up to exactly

solution and make the volume up to 1.000 L.The solution shall

0.15 N. If some different weight (g) of zinc metal is used, calculate the

be kept in a dark bo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.