ASTM E784-89(1996)

(Specification)Standard Specification for Clamps, Utility, Laboratory, and Holders, Buret and Clamp

Standard Specification for Clamps, Utility, Laboratory, and Holders, Buret and Clamp

SCOPE

1.1 This specification covers clamps and clamp holders for use in securing laboratory apparatus to support stands.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 784 – 89 (Reapproved 1996)

Standard Specification for

Clamps, Utility, Laboratory, and Holders, Buret and Clamp

This standard is issued under the fixed designation E 784; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.5 Military Standard:

MIL-STD-105 Sampling Procedures and Tables for Inspec-

1.1 This specification covers clamps and clamp holders for

tion by Attributes

use in securing laboratory apparatus to support stands.

1.2 The values stated in SI units are to be regarded as the

3. Classification

standard. The values given in parentheses are for information

3.1 Types, Sizes, and Classes—The clamp and clamp hold-

only.

ers covered by this specification shall be of the types, classes,

2. Referenced Documents and sizes as specified in 3.2-3.6 (see S3.1).

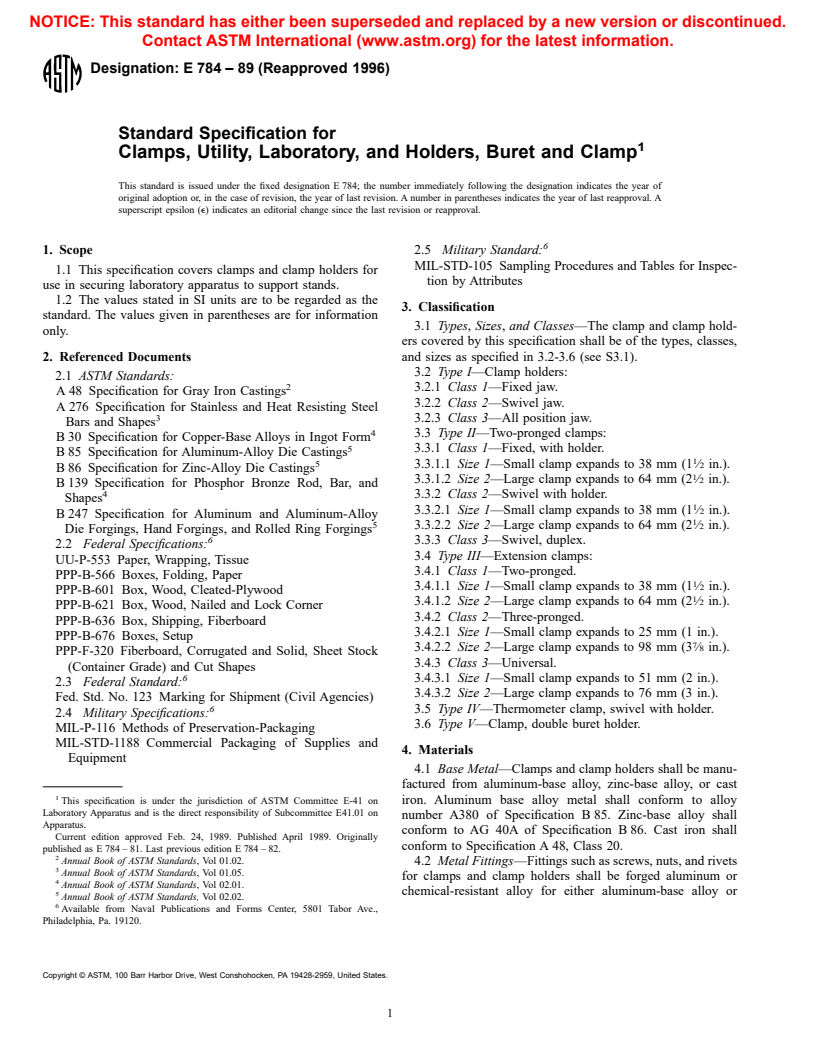

3.2 Type I—Clamp holders:

2.1 ASTM Standards:

3.2.1 Class 1—Fixed jaw.

A 48 Specification for Gray Iron Castings

3.2.2 Class 2—Swivel jaw.

A 276 Specification for Stainless and Heat Resisting Steel

3.2.3 Class 3—All position jaw.

Bars and Shapes

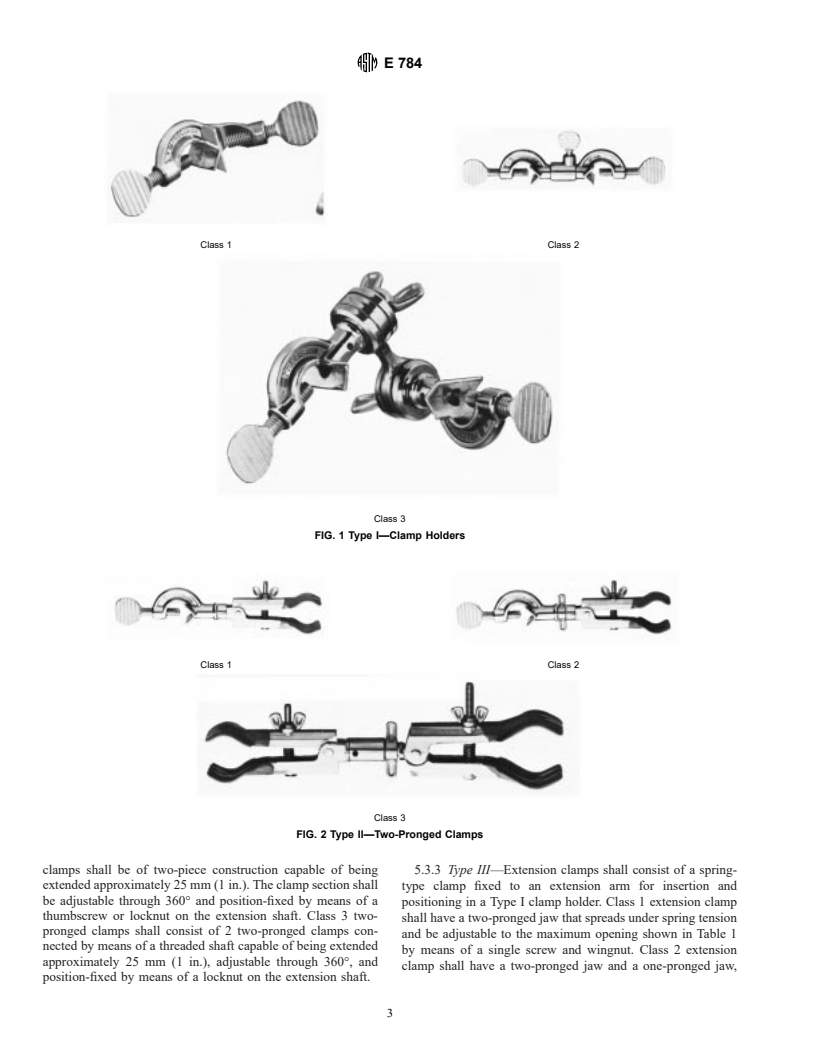

4 3.3 Type II—Two-pronged clamps:

B 30 Specification for Copper-Base Alloys in Ingot Form

3.3.1 Class 1—Fixed, with holder.

B 85 Specification for Aluminum-Alloy Die Castings

5 3.3.1.1 Size 1—Small clamp expands to 38 mm (1 ⁄2 in.).

B 86 Specification for Zinc-Alloy Die Castings

3.3.1.2 Size 2—Large clamp expands to 64 mm (2 ⁄2 in.).

B 139 Specification for Phosphor Bronze Rod, Bar, and

4 3.3.2 Class 2—Swivel with holder.

Shapes

3.3.2.1 Size 1—Small clamp expands to 38 mm (1 ⁄2 in.).

B 247 Specification for Aluminum and Aluminum-Alloy

5 3.3.2.2 Size 2—Large clamp expands to 64 mm (2 ⁄2 in.).

Die Forgings, Hand Forgings, and Rolled Ring Forgings

3.3.3 Class 3—Swivel, duplex.

2.2 Federal Specifications:

3.4 Type III—Extension clamps:

UU-P-553 Paper, Wrapping, Tissue

3.4.1 Class 1—Two-pronged.

PPP-B-566 Boxes, Folding, Paper

3.4.1.1 Size 1—Small clamp expands to 38 mm (1 ⁄2 in.).

PPP-B-601 Box, Wood, Cleated-Plywood

3.4.1.2 Size 2—Large clamp expands to 64 mm (2 ⁄2 in.).

PPP-B-621 Box, Wood, Nailed and Lock Corner

3.4.2 Class 2—Three-pronged.

PPP-B-636 Box, Shipping, Fiberboard

3.4.2.1 Size 1—Small clamp expands to 25 mm (1 in.).

PPP-B-676 Boxes, Setup

3.4.2.2 Size 2—Large clamp expands to 98 mm (3 ⁄8 in.).

PPP-F-320 Fiberboard, Corrugated and Solid, Sheet Stock

3.4.3 Class 3—Universal.

(Container Grade) and Cut Shapes

3.4.3.1 Size 1—Small clamp expands to 51 mm (2 in.).

2.3 Federal Standard:

3.4.3.2 Size 2—Large clamp expands to 76 mm (3 in.).

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

3.5 Type IV—Thermometer clamp, swivel with holder.

2.4 Military Specifications:

3.6 Type V—Clamp, double buret holder.

MIL-P-116 Methods of Preservation-Packaging

MIL-STD-1188 Commercial Packaging of Supplies and

4. Materials

Equipment

4.1 Base Metal—Clamps and clamp holders shall be manu-

factured from aluminum-base alloy, zinc-base alloy, or cast

This specification is under the jurisdiction of ASTM Committee E-41 on iron. Aluminum base alloy metal shall conform to alloy

Laboratory Apparatus and is the direct responsibility of Subcommittee E41.01 on

number A380 of Specification B 85. Zinc-base alloy shall

Apparatus.

conform to AG 40A of Specification B 86. Cast iron shall

Current edition approved Feb. 24, 1989. Published April 1989. Originally

conform to Specification A 48, Class 20.

published as E 784 – 81. Last previous edition E 784 – 82.

Annual Book of ASTM Standards, Vol 01.02.

4.2 Metal Fittings—Fittings such as screws, nuts, and rivets

Annual Book of ASTM Standards, Vol 01.05.

for clamps and clamp holders shall be forged aluminum or

Annual Book of ASTM Standards, Vol 02.01.

5 chemical-resistant alloy for either aluminum-base alloy or

Annual Book of ASTM Standards, Vol 02.02.

Available from Naval Publications and Forms Center, 5801 Tabor Ave.,

Philadelphia, Pa. 19120.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 784

zinc-base alloy clamps and clamp holders. In addition zinc- for Federal Services, Unified National Coarse Thread Series.

base alloy clamps and clamp holders may have copper alloy 5.1.1 Metric threads can be used if specified.

fittings. Forged aluminum fittings shall conform in composi- 5.2 Dimensions—The dimensions and tolerances shall be as

tion to 2014 of Specification B 247. Copper alloy fittings shall shown in Table 1.

conform to composition to Specification B 30. 5.3 Construction—The illustrations shown in Figs. 1-5 are

TABLE 1 Dimensions and Tolerances for Clamps and Clamp Holders

Maximum diameter of opening,

Classification Type of Jaw

Overall length, Tolerance,

mm (in.)

mm (in.) 6mm (6 in.)

Type Class Size Clamp Holder Clamp Holder

11 1

I 1 . . ⁄16 (17) 127 (5) 6 ( ⁄4) . V

11 1

I 2 . . ⁄16 152 (6) 6 ( ⁄4) . V

11 1

I 3 . . ⁄16 127 (5) 3 ( ⁄8) . V

1 11 1

II 1 1 38.1 (1 ⁄2) ⁄16 178 (7) 6 ( ⁄4) round V

1 11 1

II 1 2 63.5 (2 ⁄2) ⁄16 178 (7) 6 ( ⁄4) round V

1 11 1

II 2 1 38.1 (1 ⁄2) ⁄16 178 (7) 6 ( ⁄4) round V

1 11 1 1

II 2 2 63.5 (2 ⁄2) ⁄16 191 (7 ⁄2)6( ⁄4) round V

1 1

II 3 . 38.1 and 63.5 . 216 (8 ⁄2)6( ⁄4) round .

A

1 1

(1 ⁄2 and 2 ⁄2)

1 1

III 1 1 38.1 (1 ⁄2) . 203 (8) 6 ( ⁄4) round .

1 1

III 1 2 63.5 (2 ⁄2) . 228 (9) 6 ( ⁄4) round .

III 2 1 25.4 (1) . 152 (6) 6 ( ⁄4) prong .

7 1 1

III 2 2 (3 ⁄8) . 267 (10 ⁄2)13( ⁄2) prong .

III 3 1 50.8 (2) . 203 (8) 6 ( ⁄4) prong .

1 1

III 3 2 76.2 (3) . 242 (9 ⁄2)6( ⁄4) prong .

1 1 11 1

IV . . 3 ( ⁄8)to13( ⁄2) ⁄16 152 (6) 6 ( ⁄4) clip V

B

11 1

V . . ⁄16 254 (10) 6 ( ⁄4) finger V

A

Clamp on each end, one small and one large sized.

B

Clamp shall be capable of holding micro to 100-mL size burets, 5 to 20 mm in diameter.

4.3 Springs—Component springs of clamps shall be phos- for the convenience of identification and shall not preclude

clamps and clamp holders otherwise in accordance with this

phor bronze or corrosion-resistant steel. Phosphor bronze shall

conform to Composition C51000 of Specification B 139. specification.

5.3.1 Type I—Class 1 clamp holders shall be of one-piece

Corrosion-resistant steel shall conform to Class 202 or 302 of

construction, consisting of 2 V-grooved areas at right angles to

Specification A 276.

each other. Class 2 clamp holders shall consist of 2 separate

4.4 Sleeves—Component sleeves of clamps may be rubber,

V-grooved sections freely movable through an angle of 360° in

plastic, fiber glass, non-hazardous minerals, or replaceable

parallel planes and position fixed by means of a set screw.

plastic. Unless otherwise specified by the procuring agency,

Class 3 clamp holders shall consist of 2 V-grooved areas

rubber sleeves shall be supplied with clamps (see S2.1).

connected to each other by a double plate joint which keeps the

4.4.1 Rubber—Rubber for sleeves shall conform to Type R,

V-grooved areas in planes permanently set at 90° to each other.

class optional of MIL-STD-147.

The plate joints have friction disks which allow each

4.4.2 Plastic—When plastic sleeves are specified, they shall V-grooved area full movement through an angle of 360° within

be bonded firmly to the clamp jaw. The plastic sleeve shall be each plane. The V-grooved areas of each class are fitted with

thumbscrews for attachment to support rods or anchoring

formed by hot dipping the clamp jaw in a vinyl plastisol

clamp shafts. All clamp holders shall be capable of direct

conforming to Type II of MIL-P-20689.

attachment to rods up to 13 mm ( ⁄2 in.) in diameter without the

4.4.3 Mineral—When mineral sleeves are specified, they

necessity of passing the clamp holders over the ends of the

shall be nonraveling and woven from high-quality mineral

rods. All clamp holders shall be capable of attachment to rods

yarn.

up to 17 mm ( ⁄16 in.) in diameter by passing the clamp holder

4.4.4 Fiber Glass—When fiber glass sleeves are specified,

over the ends of the rods.

they shall be nonraveling and woven.

5.3.2 Type II—Class 1 and Class 2 two-pronged clamps

4.4.5 Replaceable Plastic—When replaceable plastic

shall consist of a V-grooved holder fitted with thumbscrews for

sleeves are specified, they shall be durable enough not to break attachment to support rods and a spring type clamp. The clamp

down in sand blasting, shot blasting, painting or coating shall have two jaws that spread under spring tension and shall

be adjustable to the maximum opening shown in Table 1 by

operations. Application should be quick and the resulting fit be

means of a single screw and wingnut. Class 1 two-pronged

snug and conforming.

clamps shall be of one-piece construction. Class 2 t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.