ASTM D5619-00(2011)

(Test Method)Standard Test Method for Comparing Metal Removal Fluids Using the Tapping Torque Test Machine (Withdrawn 2016)

Standard Test Method for Comparing Metal Removal Fluids Using the Tapping Torque Test Machine (Withdrawn 2016)

SIGNIFICANCE AND USE

The procedures described in this test method can be used to predict more accurately the lubricating properties of a metal removal fluid than previously available laboratory scale tests.

This test method is designed to allow flexibility in the selection of test specimen metal composition, tap alloy or coatings, and machining speeds.

Comparison between various types of fluids can be made, including cutting oils, soluble oils, semi-synthetics, or water soluble synthetics.

SCOPE

1.1 This test method covers a laboratory technique to evaluate the relative performance of metal removal fluids using a non-matrix test protocol using the tapping torque test machine.

1.2 The values stated in SI units are to be regarded as standard. Because the equipment used in this test method is available only in inch-pound units, SI units are omitted when referring to the equipment and the test pieces.

1.3 This test method does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers a laboratory technique to evaluate the relative performance of metal removal fluids using a non-matrix test protocol using the tapping torque test machine.

Formerly under the jurisdiction of Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants, this test method was withdrawn in January 2016. This standard was withdrawn without replacement due to lack of interest in supporting the standard with updated/compliant precision information.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5619 − 00(Reapproved 2011)

Standard Test Method for

Comparing Metal Removal Fluids Using the Tapping Torque

Test Machine

This standard is issued under the fixed designation D5619; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope diameter of the chip curl.Asmall chip curl will flow smoothly

up the flute of the tap and will not affect the torque. However,

1.1 This test method covers a laboratory technique to

a large curl will drag and jam in the flute and will contribute to

evaluatetherelativeperformanceofmetalremovalfluidsusing

the tapping torque.

a non-matrix test protocol using the tapping torque test

If a new tap is utilized, it is necessary to run several tests

machine.

to run-in the tap. This process prepares the cutting edge to

1.2 The values stated in SI units are to be regarded as

receive a characteristic BUE, depending on which cutting

standard. No other units of measurement are included in this

fluid is utilized.

standard.

If a cutting fluid is changed to another cutting fluid during

1.2.1 Exception—Because the equipment used in this test

a test sequence, it is necessary to discard the results from at

method is available only in inch-pound units, SI units are

least the first test of the new fluid since the previous BUE

omitted when referring to the equipment and the test pieces.

must be abraded or modified with the chemistry of the new

1.3 This standard does not purport to address all of the

fluid to form its own characteristic BUE.

safety concerns, if any, associated with its use. It is the The ideal cutting fluid forms a small, stable BUE that

responsibility of the user of this standard to establish appro-

assists in the formation of a small curl.

priate safety and health practices and determine the applica-

3. Summary of Test Method

bility of regulatory limitations prior to use.

3.1 The torque required to tap a thread in a blank specimen

2. Terminology

nutwhilelubricatedwithametalremovalfluidismeasuredand

compared with the torque required to tap a thread in a blank

2.1 Definitions of Terms Specific to This Standard:

specimen nut while lubricated with a reference fluid. See Fig.

2.1.1 build-up edge—a triangular deposit that forms adja-

1. The ratio of the average torque values of the reference oil to

cent to the cutting edge on the face of the tool in a metalwork-

the metal removal fluid tested, when using the same tap, is

ing operation.

expressed as the percent efficiency of the fluid. The efficiency

2.1.1.1 Discussion—The high contact pressure between the

oftwoormorefluidscanbecomparedwhentheaveragetorque

cutting edge of the tap and the specimen material results in a

values of the reference fluid on different taps are considered to

high temperature. The high temperature, the wear debris, the

be statistically equivalent.

high contact pressure, and some of the constituents of the

cutting fluid combine at the cutting edge and form a triangular

4. Significance and Use

deposit, referred to as a built-up edge (BUE). The BUE is

4.1 The procedures described in this test method can be

sustained by the chip curl as it is passed over, and as the BUE

used to predict more accurately the lubricating properties of a

grows, it is abraded by the rubbing of the chip curl. Since the

metal removal fluid than previously available laboratory scale

BUE is located exactly where the curl is generated, it contrib-

tests.

utes to the size of the curl; the larger the BUE, the larger the

4.2 This test method is designed to allow flexibility in the

selection of test specimen metal composition, tap alloy or

This test method is under the jurisdiction of ASTM Committee D02 on

coatings, and machining speeds.

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.L0.01 on Metal Removal Fluids and Lubricants.

4.3 Comparison between various types of fluids can be

Current edition approved May 1, 2011. Published August 2011. Originally

made, including cutting oils, soluble oils, semi-synthetics, or

approved in 1994. Last previous edition approved in 2005 as D5619–00 (2005).

DOI: 10.1520/D5619-00R11. water soluble synthetics.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5619 − 00 (2011)

FIG. 1 Tapping Torque Curve (insets show position of tap in specimen blank)

FIG. 2 Falex Tapping Torque Test Machine

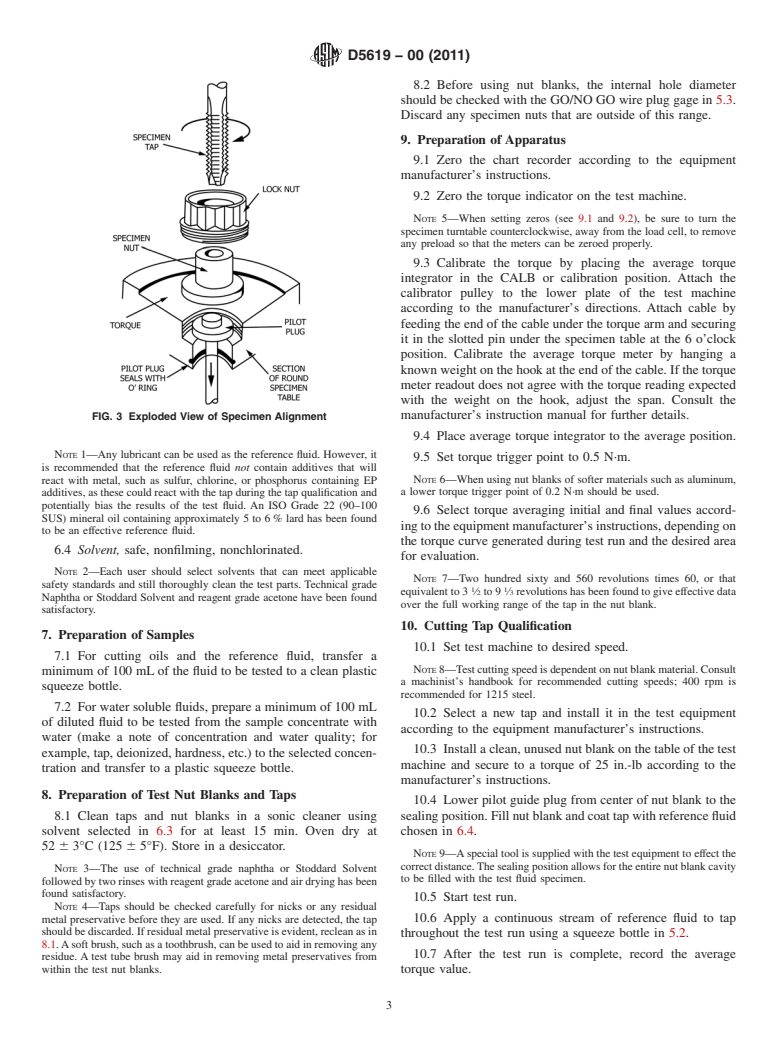

5. Apparatus 5.3 GO/NO GO Wire Plug Gage , 0.3360/0.3363 in.

5.1 Test Machine, the tapping torque test machine as 5.4 Drying Oven, controllable to 52 6 3°C (125 6 5°F).

illustrated in Fig. 2 and Fig. 3.

6. Reagents and Materials

5.2 Plastic Squeeze Bottle, 100 mL or larger.

6.1 Cutting Nut Blanks, inside diameter of 0.33615 6

0.00015 in. material selected by the user of the test method.

This test method was conducted using apparatus and materials available from

1215steelalloyisrecommendedtobeusedforqualifyingtaps.

thesolesourceofsupplyoftheapparatusknowntothecommitteeatthistime,Falex

Corp., 1020 Airpark Dr., Sugar Grove, IL 60554. If you are aware of alternative 6.2 Cutting Tap, 10 by 1.5 mm.

suppliers, please provide this information to ASTM International Headquarters.

6.3 Reference Fluid, a stable fluid that produces minimal

Your comments will receive careful consideration at a meeting of the responsible

technical committee, which you may attend. build-up edge on tap and yields repeatable test results.

D5619 − 00 (2011)

8.2 Before using nut blanks, the internal hole diameter

should be checked with the GO/NO GO wire plug gage in 5.3.

Discard any specimen nuts that are outside of this range.

9. Preparation of Apparatus

9.1 Zero the chart recorder according to the equipment

manufacturer’s instructions.

9.2 Zero the torque indicator on the test machine.

NOTE 5—When setting zeros (see 9.1 and 9.2), be sure to turn the

specimen turntable counterclockwise, away from the load cell, to remove

any preload so that the meters can be zeroed properly.

9.3 Calibrate the torque by placing the average torque

integrator in the CALB or calibration position. Attach the

calibrator pulley to the lower plate of the test machine

according to the manufacturer’s directions. Attach cable by

feeding the end of the cable under the torque arm and securing

it in the slotted pin under the specimen table at the 6 o’clock

position. Calibrate the average torque meter by hanging a

known weight on the hook at the end of the cable. If the torque

meter readout does not agree with the torque reading expected

with the weight on the hook, adjust the span. Consult the

manufacturer’s instruction manual for further details.

FIG. 3 Exploded View of Specimen Alignment

9.4 Place average torque integrator to the average position.

NOTE 1—Any lubricant can be used as the reference fluid. However, it

9.5 Set torque trigger point to 0.5 N·m.

is recommended that the reference fluid not contain additives that will

NOTE 6—When using nut blanks of softer materials such as aluminum,

react with metal, such as sulfur, chlorine, or phosphorus containing EP

a lower torque trigger point of 0.2 N·m should be used.

additives, as these could react with the tap during the tap qualification and

potentially bias the results of the test fluid. An ISO Grade 22 (90–100

9.6 Select torque averaging initial and final values accord-

SUS) mineral oil containing approximately 5 to 6 % lard has been found

ingtotheequipmentmanufacturer’sinstructions,dependingon

to be an effective reference fluid.

the torque curve generated during test run and the desired area

6.4 Solvent, safe, nonfilming, nonchlorinated.

for evaluation.

NOTE 2—Each user should select solvents that can meet applicable

NOTE 7—Two hundred sixty and 560 revolutions times 60, or that

safety standards and still thoroughly clean the test parts. Technical grade

1 1

equivalent to 3 ⁄2 to 9 ⁄3 revolutions has been found to give effective data

Naphtha or Stoddard Solvent and reagent grade acetone have been found

over the full working range of the tap in the nut blank.

satisfactory.

10. Cutting Tap Qualification

7. Preparation of Samples

10.1 Set test machine to desired speed.

7.1 For cutting oils and the reference fluid, transfer a

NOTE 8—Test cutting speed is dependent on nut blank material. Consult

minimum of 100 mL of the fluid to be tested to a clean plastic

a machinist’s handbook for recommended cutting speeds; 400 rpm is

squeeze bottle.

recommended for 1215 steel.

7.2 For water soluble fluids, prepare a minimum of 100 mL

10.2 Select a new tap and install it in the test equipment

of diluted fluid to be tested from the sample concentrate with

according to the equipment manufacturer’s instructions.

water (make a note of concentration and water quality; for

10.3 Install a clean, unused nut blank on the table of the test

example, tap, deionized, hardness, etc.) to the selected concen-

machine and secure to a torque of 25 in.-lb according to the

tration and transfer to a plastic squeeze bottle.

manufacturer’s instructions.

8. Preparation of Test Nut Blanks and Taps

10.4 Lower pilot guide plug from center of nut blank to the

8.1 Clean taps and nut blanks in a sonic cleaner using sealingposition.Fillnutblankandcoattapwithreferencefluid

solvent selected in 6.3 for at least 15 min. Oven dry at chosen in 6.4.

52 6 3°C (125 6 5°F). Store in a desiccator.

NOTE 9—Aspecial tool is supplied with the test equipment to effect the

correctdistance.Thesealingpositionallowsfortheentirenutblankcavity

NOTE 3—The use of technical grade naphtha or Stoddard Solvent

to be filled with the test fluid specimen.

followed by two rinses with reagent grade acetone and air drying has been

found satisfactory.

10.5 Start test run.

NOTE 4—Taps should be checked carefully for nicks or any residual

metal preservative before they are used. If any nicks are detected, the tap 10.6 Apply a continuous stream of reference fluid to tap

should be discarded. If residual metal preservative is evident, reclean as in

throughout the test run using a squeeze bottle in 5.2.

8.1.Asoft brush, such as a toothbrush, can be used to aid in rem

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.