ASTM D5231-92(1998)

(Test Method)Standard Test Method for Determination of the Composition of Unprocessed Municipal Solid Waste

Standard Test Method for Determination of the Composition of Unprocessed Municipal Solid Waste

SCOPE

1.1 This test method describes procedures for measuring the composition of unprocessed municipal solid waste (MSW) by employing manual sorting. This test method applies to determination of the mean composition of MSW based on the collection and manual sorting of a number of samples of waste over a selected time period covering a minimum of one week.

1.2 This test method includes procedures for the collection of a representative sorting sample of unprocessed waste, manual sorting of the waste into individual waste components, data reduction, and reporting of the results.

1.3 This test method may be applied at landfill sites, waste processing and conversion facilities, and transfer stations.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5231 – 92 (Reapproved 1998)

Standard Test Method for

Determination of the Composition of Unprocessed

Municipal Solid Waste

This standard is issued under the fixed designation D 5231; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.1.5 waste component—a category of solid waste, com-

posed of materials of similar physical properties and chemical

1.1 This test method describes procedures for measuring the

composition, which is used to define the composition of solid

composition of unprocessed municipal solid waste (MSW) by

waste, for example, ferrous, glass, newsprint, yard waste,

employing manual sorting. This test method applies to deter-

aluminum, etc.

mination of the mean composition of MSW based on the

collection and manual sorting of a number of samples of waste

3. Summary of Test Method

over a selected time period covering a minimum of one week.

3.1 The number of samples to be sorted is calculated based

1.2 This test method includes procedures for the collection

on statistical criteria selected by the investigators.

of a representative sorting sample of unprocessed waste,

3.2 Vehicle loads of waste are designated for sampling, and

manual sorting of the waste into individual waste components,

a sorting sample is collected from the discharged vehicle load.

data reduction, and reporting of the results.

3.3 The sample is sorted manually into waste components.

1.3 This test method may be applied at landfill sites, waste

The weight fraction of each component in the sorting sample is

processing and conversion facilities, and transfer stations.

calculated from the weights of the components.

1.4 The values stated in inch-pound units are to be regarded

3.4 The mean waste composition is calculated using the

as the standard. The values given in parentheses are for

results of the composition of each of the sorting samples.

information only.

1.5 This standard does not purport to address all of the

4. Significance and Use

safety problems, if any, associated with its use. It is the

4.1 Waste composition information has widespread applica-

responsibility of the user of this standard to establish appro-

tions and can be used for activities such as solid waste

priate safety and health practices and determine the applica-

planning, designing waste management facilities, and estab-

bility of regulatory limitations prior to use. For specific hazard

lishing a reference waste composition for use as a baseline

statements, see Section 6.

standard in both facility contracts and acceptance test plans.

2. Terminology 4.2 The method can be used to define and report the

composition of MSW through the selection and manual sorting

2.1 Definitions:

of waste samples. Where applicable, care should be taken to

2.1.1 composite item—an object in the waste composed of

consider the source and seasonal variation of waste.

multiple waste components or dissimilar materials, such as

4.3 After performing a waste composition analysis, labora-

disposable diapers, bi-metal beverage containers, electrical

tory analyses may be performed on representative samples of

conductors composed of metallic wire encased in plastic

waste components, or mixtures of waste components, for

insulation, etc.

purposes related to the planning, management, design, testing,

2.1.2 solid waste composition or waste composition—the

and operation of resource recovery facilities.

characterization of solid waste as represented by a breakdown

of the mixture into specified waste components on the basis of

5. Apparatus

mass fraction or of weight percent.

5.1 Metal, Plastic, or Fiber Containers, sufficient for stor-

2.1.3 sorting sample—a 200 to 300-lb (91 to 136-kg)

ing and weighing each waste component, labeled accordingly.

portion deemed to represent the characteristics of a vehicle

For components that will have a substantial moisture content

load of MSW.

(for example, food waste), metal or plastic containers are

2.1.4 unprocessed municipal solid waste—solid waste in its

recommended in order to avoid absorption of moisture by the

discarded form, that is, waste that has not been size reduced or

container and thus the need for a substantial number of

otherwise processed.

weighings to maintain an accurate tare weight for the container.

5.2 Mechanical or Electronic Weigh Scale, with a capacity

This test method is under the jurisdiction of ASTM Committee D34 on Waste

of at least 200 lb (91 kg) and precision of at least 0.1 lb (0.045

Disposal and is the direct responsibility of Subcommittee D34.01.06 on Analytical

Methods.

kg).

Current edition approved July 31, 1992. Published September 1992.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5231

5.3 Heavy-Duty Tarps, Shovels, Rakes, Push Brooms, Dust Weights of 200 to 300 lb (91 to 136 kg) for sorting samples of

Pans, Hand Brooms, Magnets, Sorting Table, First Aid Kit, unprocessed solid waste are recommended. The number of

Miscellaneous Small Tools, Traffıc Cones, Traffıc Vests, Leather samples is determined using the calculational method de-

Gloves, Hardhats, Safety Glasses, and Leather Boots. scribed in 9.1.

8.5 A comprehensive list of waste components for sorting is

6. Hazards

given in Table 1. A description of some of the waste component

6.1 Review the hazards and procedures with the operating

categories is given in Table 2. Other waste components can be

and sorting personnel prior to conducting the field activities. defined and sorted, depending on the purpose of the waste

6.2 Sharp objects, such as nails, razor blades, hypodermic

composition determination. The list in Table 1 is comprised of

needles, and pieces of glass, are present in solid waste. those components most commonly used to define and report

Personnel should be instructed of this danger, and they should

the composition of solid waste. It is recommended that, at a

brush waste particles aside while sorting rather than projecting minimum, the complement of left-justified categories in Table

their hands with force into the mixture. Personnel handling and

1 be sorted. Similar breakdowns of solid waste composition are

sorting solid waste should wear appropriate protection, such as therefore available for purposes of comparison, if desired.

heavy leather gloves, dust masks, hardhats, safety glasses, and

Label the storage containers accordingly.

safety boots. 8.6 Vehicles for sampling shall be selected at random during

6.3 During the processes of unloading waste from collection

each day of the one-week sampling period, or so as to be

vehicles and handling waste with heavy equipment, projectiles representative of the waste stream as agreed upon by the

may issue from the mass of waste. The projectiles can include

affected parties. With respect to the random selection of

flying glass particles from breaking glass containers and metal

vehicles, any method is acceptable that does not introduce a

lids from plastic and metal containers that burst under pressure bias into the selection. An acceptable method is the use of a

when run over by heavy equipment. The problem is particu-

random number generator. For a weekly sampling period of k

larly severe when the waste handling surface is of high days, the number of vehicles sampled each day shall be

compressive strength, for example, concrete. Personnel should

approximately n/k, where n is the total number of vehicle loads

be informed of this danger and wear eye and head protection if to be selected for the determination of waste composition. A

in the vicinity of either the collection vehicle unloading point

weekly period is defined as 5 to 7 days.

or heavy equipment, or both. 8.7 Direct the designated vehicle containing the load of

6.4 Select a location for the discharge of designated loads,

waste to the area secured for discharge of the load and

manual sorting activities, and weighing operations that is flat, collection of the sorting sample.

level, and away from the normal waste handling and process-

8.8 Collect any required information from the vehicle op-

ing areas. erator before the vehicle leaves the discharge area. Direct the

6.5 Weigh storage containers each day, or more frequently,

vehicle operator to discharge the load onto the clean surface in

if necessary, in order to maintain an accounting of the tare one contiguous pile, that is, to avoid gaps in the discharged

weight.

load in order to facilitate collection of the samples.

3 3

6.6 Loss of mass from the sorting sample can occur through 8.9 Using a front-end loader with at least a 1-yd (0.765-m )

the evaporation of water. Samples should thus be sorted as

bucket, remove the material longitudinally along one entire

soon as possible after collection. side of the discharged load in order to obtain a representative

6.7 Containers of liquids or other potentially dangerous

cross-section of the material. The mass of material shall be

wastes shall be put aside and handled by the crew chief. sufficient to form a mass of material which, on a visual basis,

is at least four times the desired weight of the sorting sample

7. Calibration

(that is, approximately 1000 lb (454 kg)). Mix, cone, and

7.1 All weigh scale equipment shall be calibrated according

quarter the material, and select one quarter to be the sorting

to the manufacturer’s instructions. Take appropriate corrective

sample, using a random method of selection or a sequence

action if the readings are different from those of the calibration

agreed by all affected parties, for the purpose of eliminating or

weights.

minimizing biasing of the sample. If an oversize item (for

8. Procedure

TABLE 1 List of Waste Component Categories

8.1 Secure a flat and level area for discharge of the vehicle

Mixed paper Other organics

load. The surface should be swept clean or covered with a

High-grade paper Ferrous

clean, durable tarp prior to discharge of the load. Computer printout Cans

Other office paper Other ferrous

8.2 Position the scale on a clean, flat, level surface and

Newsprint Aluminum

adjust the level of the scale if necessary. Determine the

Corrugated Cans

accuracy and operation of the scale with a known (that is, Plastic Foil

PET bottles Other aluminum

reference) weight.

HDPE bottles Glass

8.3 Weigh all empty storage containers and record the tare

Film Clear

weights. Other plastic Brown

Yard waste Green

8.4 Determine the number of samples to be sorted. The

Food waste Other inorganics

determination is a function of the waste components to be

Wood

sorted and the desired precision as applied to each component.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5231

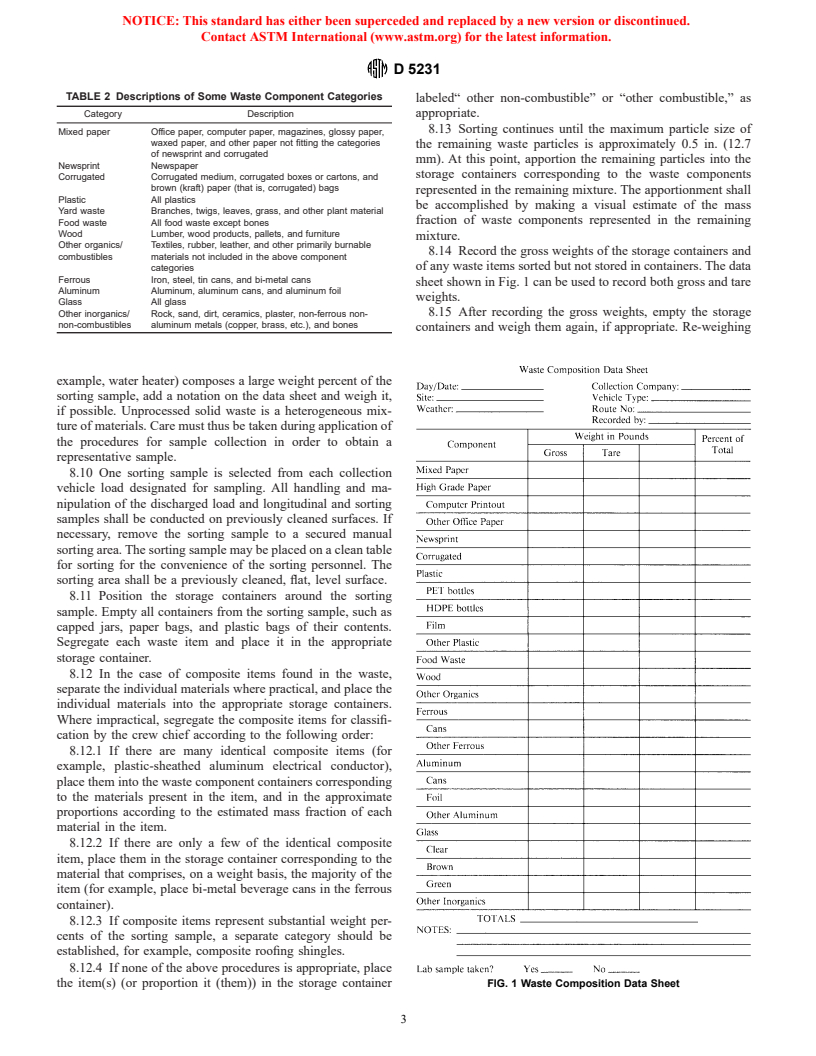

TABLE 2 Descriptions of Some Waste Component Categories

labeled“ other non-combustible” or “other combustible,” as

Category Description appropriate.

8.13 Sorting continues until the maximum particle size of

Mixed paper Office paper, computer paper, magazines, glossy paper,

waxed paper, and other paper not fitting the categories

the remaining waste particles is approximately 0.5 in. (12.7

of newsprint and corrugated

mm). At this point, apportion the remaining particles into the

Newsprint Newspaper

storage containers corresponding to the waste components

Corrugated Corrugated medium, corrugated boxes or cartons, and

brown (kraft) paper (that is, corrugated) bags

represented in the remaining mixture. The apportionment shall

Plastic All plastics

be accomplished by making a visual estimate of the mass

Yard waste Branches, twigs, leaves, grass, and other plant material

fraction of waste components represented in the remaining

Food waste All food waste except bones

Wood Lumber, wood products, pallets, and furniture

mixture.

Other organics/ Textiles, rubber, leather, and other primarily burnable

8.14 Record the gross weights of the storage containers and

combustibles materials not included in the above component

of any waste items sorted but not stored in containers. The data

categories

Ferrous Iron, steel, tin cans, and bi-metal cans

sheet shown in Fig. 1 can be used to record both gross and tare

Aluminum Aluminum, aluminum cans, and aluminum foil

weights.

Glass All glass

Other inorganics/ Rock, sand, dirt, ceramics, plaster, non-ferrous non- 8.15 After recording the gross weights, empty the storage

non-combustibles aluminum metals (copper, brass, etc.), and bones

containers and weigh them again, if appropriate. Re-weighing

example, water heater) composes a large weight percent of the

sorting sample, add a notation on the data sheet and weigh it,

if possible. Unprocessed solid waste is a heterogeneous mix-

ture of materials. Care must thus be taken during application of

the procedures for sample collection in order to obtain a

representative sample.

8.10 One sorting sample is selected from each collection

vehicle load designated for sampling. All handling and ma-

nipulation of the discharged load and longitudinal and sorting

samples shall be conducted on previously cleaned surfaces. If

necessary, remove the sorting sample to a secured manual

sorting area. The sorting sample may be placed on a clean table

for sorting for the convenience of the sorting personnel. The

sorting area shall be a previously cleaned, flat, level surface.

8.11 Position the storage containers around the sorting

sample. Empty all containers from the sorting sample, such as

capped jars, paper bags, and plastic bags of their contents.

Segregate each waste item and place it in the appropriate

storage container.

8.12 In the case of composite items found in the waste,

separate the individual materials where practical, and place the

individual materials into the appropriate storage containers.

Where impractical, segregate the composite items for classifi-

cation by the crew chief according to the following order:

8.12.1 If there are many identical composite items (for

example, plastic-sheathed aluminum electrical conductor),

place them into the waste component containers corresponding

to the materials present in the item, and in the approximate

proportions according to the estimated mass fraction of each

material in the item.

8.12.2 If there are only a few of the identical composite

item, place them in the storage container corresponding to the

material that

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.