ASTM D3756-97(2004)

(Test Method)Standard Test Method for Evaluation of Resistance to Electrical Breakdown by Treeing in Solid Dielectric Materials Using Diverging Fields

Standard Test Method for Evaluation of Resistance to Electrical Breakdown by Treeing in Solid Dielectric Materials Using Diverging Fields

SIGNIFICANCE AND USE

This is a laboratory test designed to simulate the effects of (1) the presence of rough interfaces between conductor or semiconductive screen and primary insulation in an insulation system, (2) the presence of foreign particles (contaminants) in an insulation system, and (3) the presence of small voids or cavities within the insulation.

This test method provides comparative data. The degree of correlation with actual performance in service has not been established.

SCOPE

1.1 This test method covers the evaluation and comparison of the resistance of solid organic dielectric materials to the initiation or growth, or both, of tubular tree-like channels resulting from partial discharge (corona) and molecular decomposition that occur in the region of very high, diverging electric fields.

1.2 This test method is primarily for use at a power frequency of 50 or 60 Hz.

1.3 The test may be carried out at room temperature or temperatures above or below room temperature. The temperature should not exceed the softening or melting point of the sample material.

1.4 This test method can be used for any solid material into which needles can be cast, molded, or inserted with heat after molding. The resistance to tree initiation is measured by the double-needle characteristic voltage, which is only applicable to non-opaque materials so that tree can be observed optically. The resistance to tree initiation and growth is reported by the double-needle voltage life, which is applicable to both opaque and non-opaque materials.

1.5 The values stated in SI units are to be regarded as the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D3756–97 (Reapproved 2004)

Standard Test Method for

Evaluation of Resistance to Electrical Breakdown by Treeing

in Solid Dielectric Materials Using Diverging Fields

This standard is issued under the fixed designation D3756; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

When failure occurs in solid organic dielectrics that are subjected to very high, continuous, and

nonuniform electrical gradients, it generally occurs by a mechanism called treeing. Materials of

different molecular structures have different degrees of resistance to failure by treeing, and this

resistance can sometimes be increased by the addition of other materials in low concentration.

Treesthatgrowbyamoleculardegradationmechanismresultingfrompartialdischarge(corona)are

called electrical trees to distinguish them from water and electrochemical trees which are quite

different.

This test method makes use of two opposing thin cylindrical electrodes, one sharpened to a point,

the other with a hemispherical end. They are molded or inserted into blocks of the material to be

tested. Because of the shape of the electrodes this is often called a needle test. This test provides a

statistical estimate of electrical treeing initiation and propagation of solid dielectric materials in high,

diverging electrical fields.

1. Scope 1.4 This test method can be used for any solid material into

which needles can be cast, molded, or inserted with heat after

1.1 This test method covers the evaluation and comparison

molding. The resistance to tree initiation is measured by the

of the resistance of solid organic dielectric materials to the

double-needle characteristic voltage, which is only applicable

initiation or growth, or both, of tubular tree-like channels

to non-opaque materials so that tree can be observed optically.

resultingfrompartialdischarge(corona)andmoleculardecom-

The resistance to tree initiation and growth is reported by the

positionthatoccurintheregionofveryhigh,divergingelectric

3,4

double-needle voltage life, which is applicable to both opaque

fields.

and non-opaque materials.

1.2 This test method is primarily for use at a power

1.5 The values stated in SI units are to be regarded as the

frequency of 50 or 60 Hz.

standard.

1.3 The test may be carried out at room temperature or

1.6 This standard does not purport to address all of the

temperatures above or below room temperature. The tempera-

safety concerns, if any, associated with its use. It is the

ture should not exceed the softening or melting point of the

responsibility of the user of this standard to establish appro-

sample material.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

This test method is under the jurisdiction of ASTM Committee D09 on

Electrical and Electronic Insulating Materials and is the direct responsibility of

2. Referenced Documents

Subcommittee D09.12 on Electrical Tests.

2.1 ASTM Standards:

Current edition approved March 1, 2004. Published March 2004. Originally

approved in 1990. Last previous edition approved in 1997 as D3756 – 97. DOI: D149 Test Method for Dielectric Breakdown Voltage and

10.1520/D3756-97R04.

Dielectric Strength of Solid Electrical Insulating Materials

Symposium on Engineering Dielectrics, ASTM STP 783 , ASTM, 1982, and

at Commercial Power Frequencies

Symposium on Engineering Dielectrics, ASTM STP 926, ASTM, 1986.

D1711 Terminology Relating to Electrical Insulation

W. D. Wilkens, Chapter 7, “Statistical Methods for the Evaluation of Electrical

Insulating Systems,” Engineering Dielectrics, Vol IIB, Electrical Properties of Solid

Insulating Materials, Measurement Techniques, R. Bartnikas, Editor, ASTM STP

926 , ASTM, Philadelphia, 1987.

4 5

R. M. Eichorn, Chapter 4, “Treeing in Solid Organic Dielectric Materials,” For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Engineering Dielectrics, Vol IIA, Electrical Properties of Solid Insulating Materi- contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

als: Molecular Structure and Electrical Behavior, R. Bartnikas and R. M. Eichorn, Standards volume information, refer to the standard’s Document Summary page on

Editors, ASTM STP 783, ASTM Philadelphia, 1983. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3756–97 (2004)

D1928 Practice for Preparation of Compression-Molded 6.2 Current—Sensitive Individual Specimen Disconnect—

Polyethylene Test Sheets and Test Specimens When ten specimens are tested to failure for the voltage life

D2275 Test Method for Voltage Endurance of Solid Elec- test, use a disconnect circuit for each.

trical Insulating Materials Subjected to Partial Discharges 6.3 Electrodes—Thecriticalelectrodeisaroundsteelrod,1

(Corona) on the Surface mm in diameter, sharpened at one end to a controlled radius of

2.2 Other Document: 3 6 1 µm and an included angle of 30 6 1 degrees.

ANSI/IEEE 930-1987 IEEE Guide for the Statistical 6.4 Needle-Grinding Lathe,forpreparationofthesharpened

Analysis of Electrical Insulation Voltage Endurance Data electrodes to a controlled-point sharpness and included angle.

A typical lathe and grinder combination are shown in Fig. 1.

3. Terminology 6.5 Specimen Molding Chase, for single-step preparation of

compression molded specimens containing needles. A typical

3.1 Definitions:

chase is shown in Fig. 2.

3.1.1 partial discharge, n—refer to D1711.

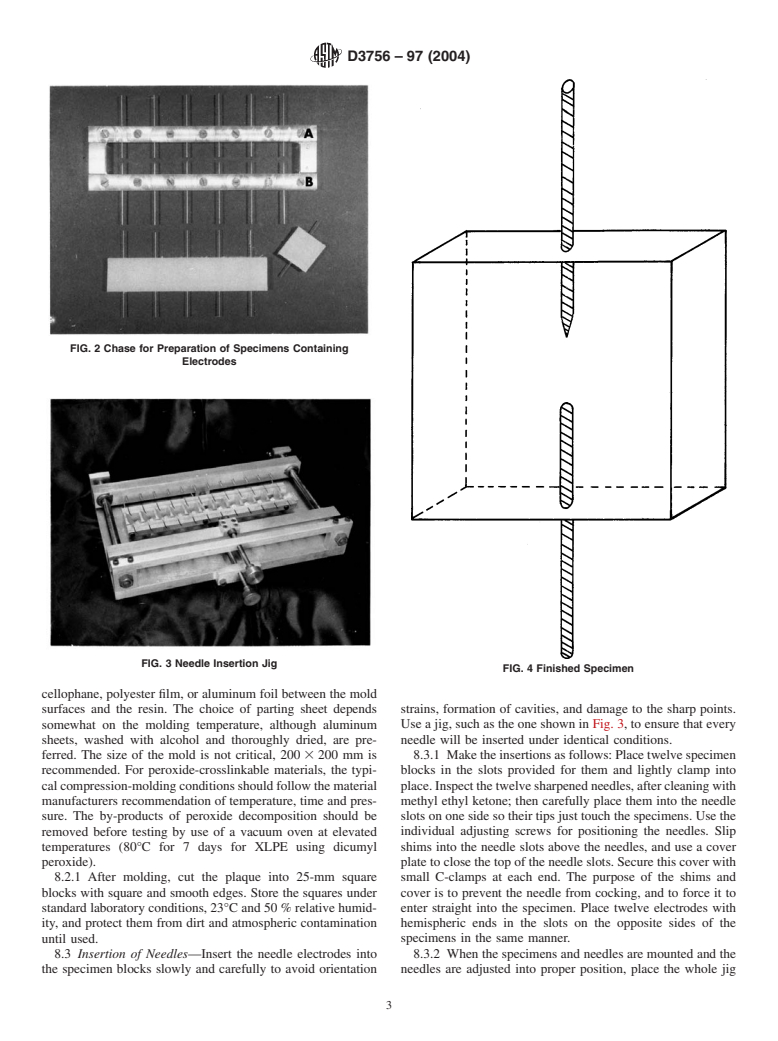

6.6 Needle-Insertion Jig—A jig is required for slow, con-

3.2 Definition of Terms Specific to This Standard:

trolled insertion of electrodes. Fig. 3 shows a specimen

3.2.1 characteristic voltage or DNCV (double-needle char-

insertion jig.

acteristic voltage), n—that voltage which, when applied for 1

6.7 Test Chamber—Any temperature-controlled test cham-

h between the ends of two thin cylindrical electrodes (one

ber or enclosure, which can hold at least ten specimens and

sharpened to a point, the other with a hemispherical end) in a

maintain uniform temperature, is appropriate for this test.

group of replicate specimens, produces observable dielectric

damage at the point of the sharp electrode in half of the

7. Sampling

specimens.

7.1 Sample so that the specimens tested will represent the

3.2.2 median voltage life (t ), n—the time, determined

entire lot.

from a Weibull plot, when 50 % failure occurs from a group of

10 identical specimens subjected to the same voltage stress.

8. Test Specimens

8.1 Testspecimensareapproximately25-mm blocks,6mm

4. Summary of Method

thick, containing two needle-like electrodes as shown in Fig. 4.

4.1 In this test method, specimens are prepared and needles

Prepare by compression molding, extrusion, or cutting from

insertedtoserveaselectrodes.Voltageisappliedtotheneedles

finished pieces.The tips of the electrodes are separated by 12.0

and continued for1hinthe double-needle characteristic

6 0.5 mm for characteristic voltage determination and 6.5 6

voltage test or until electrical breakdown occurs in the double-

0.5 mm for voltage life determination. The number of test

needle voltage life test. Results are expressed as the voltage at

specimensisatleast24forcharacteristicvoltagedetermination

which half of the specimens show dielectric damage in 1 h, or

(i.e. six specimens for each of at least four different testing

the median time to failure of a group of specimens subjected to

voltages) and 10 for voltage life determination.

a given continuous voltage, at a selected or predetermined

8.2 Preparation of Thermoplastic and Crosslinked

temperature.

Specimens—Compression-mold plaques, 6-mm thick, of the

sample material, in a steam or electrically heated hydraulic

5. Significance and Use

press equipped for cold-water cooling of the platens. Use a

5.1 This is a laboratory test designed to simulate the effects

positive pressure mold, which may be of either the picture-

of (1) the presence of rough interfaces between conductor or

frame type or the milled-cavity type. Use parting sheets of

semiconductive screen and primary insulation in an insulation

system, (2) the presence of foreign particles (contaminants) in

an insulation system, and (3) the presence of small voids or

cavities within the insulation.

5.2 This test method provides comparative data. The degree

of correlation with actual performance in service has not been

established.

6. Apparatus

6.1 Power Supply—Ahigh voltage supply having a sinusoi-

dal voltage output at a power frequency equipped with con-

tinuous voltage control and an adjustable protective automatic

circuit-breaking device that operates at a controllable current

level. See Test Method D149.

Withdrawn. The last approved version of this historical standard is referenced

on www.astm.org.

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036. FIG. 1 Machine Setup for Needle Sharpening

D3756–97 (2004)

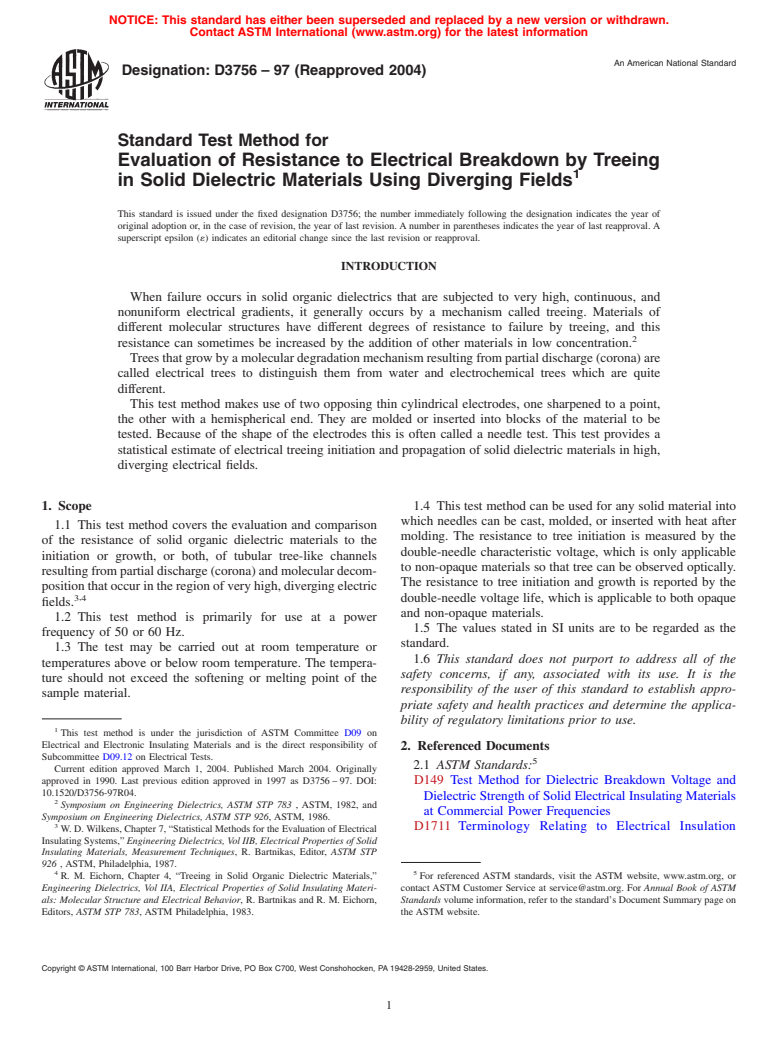

FIG. 2 Chase for Preparation of Specimens Containing

Electrodes

FIG. 3 Needle Insertion Jig

FIG. 4 Finished Specimen

cellophane, polyester film, or aluminum foil between the mold

surfaces and the resin. The choice of parting sheet depends strains, formation of cavities, and damage to the sharp points.

Use a jig, such as the one shown in Fig. 3, to ensure that every

somewhat on the molding temperature, although aluminum

sheets, washed with alcohol and thoroughly dried, are pre- needle will be inserted under identical conditions.

ferred. The size of the mold is not critical, 200 3 200 mm is 8.3.1 Maketheinsertionsasfollows:Placetwelvespecimen

recommended. For peroxide-crosslinkable materials, the typi- blocks in the slots provided for them and lightly clamp into

calcompression-moldingconditionsshouldfollowthematerial place.Inspectthetwelvesharpenedneedles,aftercleaningwith

manufacturers recommendation of temperature, time and pres- methyl ethyl ketone; then carefully place them into the needle

sure. The by-products of peroxide decomposition should be slots on one side so their tips just touch the specimens. Use the

removed before testing by use of a vacuum oven at elevated individual adjusting screws for positioning the needles. Slip

temperatures (80°C for 7 days for XLPE using dicumyl shims into the needle slots above the needles, and use a cover

peroxide). plate to close the top of the needle slots. Secure this cover with

8.2.1 After molding, cut the plaque into 25-mm square small C-clamps at each end. The purpose of the shims and

blocks with square and smooth edges. Store the squares under cover is to prevent the needle from cocking, and to force it to

standard laboratory conditions, 23°C and 50 % relative humid- enter straight into the specimen. Place twelve electrodes with

ity, and protect them from dirt and atmospheric contamination hemispheric ends in the slots on the opposite sides of the

until used. specimens in the same manner.

8.3 Insertion of Needles—Insert the needle electrodes into 8.3.2 When the specimens and needles are mounted and the

the specimen blocks slowly and carefully to avoid orientation needles are adjusted into proper position, place the whole jig

D3756–97 (2004)

into a circulating air oven at 105°C, for low-density polyeth- 8.4.8 Check each specimen under a microscope with an

ylene or crosslinked materials, for a 1-h preheating period. For optical scale and use only if the electrode spacing is found to

other partially crystalline polymeric materials use a tempera- be correct. If any contamination or voids are found within the

ture approximately 10°C below the thermodynamic first-order test region, reject the specimen.

transition point. After preheating, simultaneously advance the

9. Conditioning

needles 1.30 mm by making one full turn of the large lead

screw. Repeat at 5-min intervals. Make sufficient turns to

9.1 After specimen preparation is complete, store all speci-

accomplish the insertion. Five turns are normally required for

mens for approximately 24 h at 23°C and 50 % relative

thecharacteristicvoltagetestandsevenforthevoltagelifetest.

humidity before testing.

An electrode gap of 12.0 6 0.5 mm is commonly used for

characteristic voltage determination and 6.5 6 0.5 mm is 10. Procedure

preferred for voltage life tests. Use constant gaps for compari-

10.1 Warning—Lethal voltages are a potential hazard dur-

son of materials by this test.

ing the performance of this test. It is essential that the test

8.3.3 When the insertions are complete, leave the jigs

apparatus and all associated equipment that may be electrically

untouched for at least 30 min in the oven for stress relief or

connected to it be properly designed and installed for safe

annealing. Remove the jigs from the oven and cool naturally to

operation. Solidly ground all electrically conductive parts

room temperature. Examine each specimen with a microscope,

which are possible for a person to contact during the test.

if possible, to ensure that the needle point was not damaged

Provide means for use at the completion of any test to ground

during insertion.

anypartswhichwereathighvoltageduringthetestorhavethe

8.4 Preparation of Specimens with Molded-In Electrodes—

potential for acquiring an induced charge during the test or

Condition as specified in Section 9.

retaining a charge even after disconnection of the voltage

8.4.1 The molding is 150 3 25 3 6 mm thick and contains source. Thoroughly instruct all operators as to the correct

six pointed and six hemispherical electrodes. Cut six square procedures for performing tests safely. When making high-

specimens from this block. See Fig. 2. voltage tests, particularly in compressed gas, oil, water or

aqueous solution, it is possible for the energy released at

8.4.2 A compression mold that can be used for preparation

breakdown to be sufficient to result in fire, explosion, or

of the six specimen plaques consists of a chase, in two layers,

rupture of the test chamber. Design test equipment, test

grooved to clamp the electrodes during molding. It is sur-

chambers, and test specimens so as to minimize the possibility

rounded laterally by a steel backup plate to prevent distortion

of such occurrences and to eliminate the possibility of personal

of the chase. Slits cut in the backup plate accommodate the

injury. If the potential for fire exists, have fire suppression

ends of the needle

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.