ASTM D4361-10

(Test Method)Standard Test Method for Apparent Tack of Printing Inks and Vehicles by a Three-Roller Tackmeter (Withdrawn 2019)

Standard Test Method for Apparent Tack of Printing Inks and Vehicles by a Three-Roller Tackmeter (Withdrawn 2019)

SIGNIFICANCE AND USE

Tack of printing inks controls their high-speed transfer properties, as manifested by throughput in roll milling, picking of paper during printing, and wet trapping in multicolor printing. Although an apparent tack measurement does not completely predict the transfer performance of an ink or a vehicle, it provides a meaningful parameter for quality control, development, and research.

A number of three-roller tackmeters are available that differ in design features such as roller weight, geometry, and composition of the distribution system. Instruments of different types do not give the same apparent tack readings.

Instruments of the same type will only give apparent tack readings within tolerance, provided that they are maintained and calibrated properly and in the same manner.

SCOPE

1.1 This test method covers the procedure for determining the apparent tack of printing inks using a three-roller tackmeter.

1.2 This test method is applicable to all paste-type printing inks and vehicles that are essentially nonvolatile under ordinary room conditions, provided that any elastomer covered rollers in the tackmeter are resistant to attack by the particular ink or vehicle chemistry. Different elastomers may be required for different ink or vehicle chemistries.

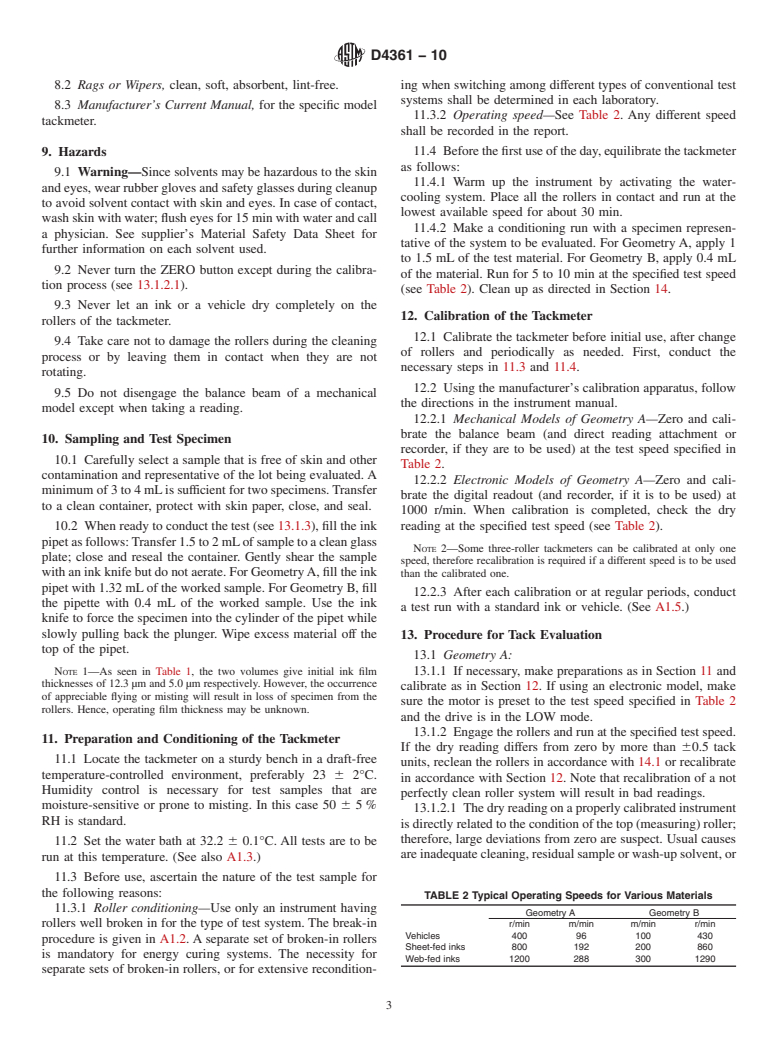

1.3 This test method covers three-roller tackmeters of two different geometries, referred to as Geometry A and Geometry B.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers the procedure for determining the apparent tack of printing inks using a three-roller tackmeter.

Formerly under the jurisdiction of Committee D01 on Paint and Related Coatings, Materials, and Applications, this test method was withdrawn in July 2019 in accordance with section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4361 − 10

Standard Test Method for

Apparent Tack of Printing Inks and Vehicles by a Three-

1

Roller Tackmeter

This standard is issued under the fixed designation D4361; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3.1.1 tack, n—function of the force required to split a thin

fluid film of a printing ink or vehicle between two rapidly

1.1 This test method covers the procedure for determining

separating surfaces.

the apparent tack of printing inks using a three-roller tackme-

3.1.1.1 Discussion—Tack is a rheological parameter indica-

ter.

tive of internal cohesion of the fluid. It is not a fixed number

1.2 This test method is applicable to all paste-type printing

but varies with operating conditions, primarily separation

inks and vehicles that are essentially nonvolatile under ordi-

velocity, splitting area, force applied by the measuring roller

nary room conditions, provided that any elastomer covered

and film thickness. Tack also varies with changes in the

rollers in the tackmeter are resistant to attack by the particular

rheological properties of the ink or vehicle as a result of time,

ink or vehicle chemistry. Different elastomers may be required

temperature, and interactions with the separating surfaces. In

for different ink or vehicle chemistries.

practice, one or more of these surfaces usually consist of

elastomer rollers that may differ in composition and geometry

1.3 This test method covers three-roller tackmeters of two

and whose properties tend to change with age, nature of

different geometries, referred to as GeometryAand Geometry

previously run fluids, type of wash-up solvent, and mechanical

B.

flaws. Tack readings are also sensitive to the calibration and

1.4 The values stated in SI units are to be regarded as

zero accuracy of the tackmeter used. Different manufacturers’

standard. No other units of measurement are included in this

tackmeters may use different tack scales.

standard.

3.1.2 apparent tack, n—tack reading obtained at a specific

1.5 This standard does not purport to address all of the

set of conditions.

safety concerns, if any, associated with its use. It is the

3.1.3 flying, n—tendency of a printing ink or vehicle to be

responsibility of the user of this standard to establish appro-

ejected as large globules from a roller distribution system.

priate safety and health practices and determine the applica-

3.1.3.1 Discussion—Flying is generally most severe during

bility of regulatory limitations prior to use.

rapid roller acceleration such as occurs when switching imme-

diately from zero or a slow speed to a high operating speed.

2. Referenced Documents

2

3.1.4 misting, n—tendency of a printing ink or vehicle to be

2.1 ASTM Standards:

ejected as a fine aerosol from a roller distribution system.

E691 Practice for Conducting an Interlaboratory Study to

3.1.4.1 Discussion—Misting is generally most severe at

Determine the Precision of a Test Method

high operating speeds and with fluids that produce long

filaments.

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

4. Summary of Test Method

4.1 A thin film of the test printing ink or vehicle is applied

to the three-roller distribution system of the tackmeter, which

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

operates at speeds comparable to those on the roller trains of

and Related Coatings, Materials, andApplications and is the direct responsibility of

production printing presses. Measurement of the frictional

Subcommittee D01.56 on Printing Inks. Subcommittee D01.37 on Ink Vehicles

assisted in the development of the vehicle portion of this test method.

torque induced by drag forces in the splitting film provides a

Current edition approved Dec. 1, 2010. Published February 2011. Originally

value for apparent tack. Readings may vary from instrument

approved in 1984. Last previous edition approved in 2009 as D4361 – 09. DOI:

suppliertoinstrumentsupplierandfromgeometrytogeometry.

10.1520/D4361-10.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.2 The procedures in this test method are designed to give

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

a single value for apparent tack at a specific set of instrument

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. conditions. Typical conditions are as follows: a cooling water

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 194

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.