ASTM F1921/F1921M-12e1

(Test Method)Standard Test Methods for Hot Seal Strength (Hot Tack) of Thermoplastic Polymers and Blends Comprising the Sealing Surfaces of Flexible Webs

Standard Test Methods for Hot Seal Strength (Hot Tack) of Thermoplastic Polymers and Blends Comprising the Sealing Surfaces of Flexible Webs

SIGNIFICANCE AND USE

5.1 In form-fill operations, sealed areas of packages are frequently subject to disruptive forces while still hot. If the hot seals have inadequate resistance to these forces, breakage can occur during the packaging process. These test methods measure hot seal strength and can be used to characterize and rank materials in their ability to perform in commercial applications where this quality is critical. ^SCOPE:

1.1 These two test methods cover laboratory measurement of the strength of heatseals formed between thermoplastic surfaces of flexible webs, immediately after a seal has been made and before it cools to ambient temperature (hot tack strength).

1.2 These test methods are restricted to instrumented hot tack testing, requiring a testing machine that automatically heatseals a specimen and immediately determines strength of the hot seal at a precisely measured time after conclusion of the sealing cycle. An additional prerequisite is that the operator shall have no influence on the test after the sealing sequence has begun. These test methods do not cover non-instrumented manual procedures employing springs, levers, pulleys and weights, where test results can be influenced by operator technique.

1.3 Two variations of the instrumented hot tack test are described in these test methods, differing primarily in two respects: (a) rate of grip separation during testing of the sealed specimen, and (b) whether the testing machine generates the cooling curve of the material under test, or instead makes a measurement of the maximum force observed following a set delay time. Both test methods may be used to test all materials within the scope of these test methods and within the range and capacity of the machine employed. They are described in Section 4.

1.4 SI units are preferred and shall be used in referee decisions. Values stated herein in inch-pound units are to be regarded separately and may not be exact equivalents to SI units. Therefore, each system shall ...

SCOPE

1.1 These two test methods cover laboratory measurement of the strength of heatseals formed between thermoplastic surfaces of flexible webs, immediately after a seal has been made and before it cools to ambient temperature (hot tack strength).

1.2 These test methods are restricted to instrumented hot tack testing, requiring a testing machine that automatically heatseals a specimen and immediately determines strength of the hot seal at a precisely measured time after conclusion of the sealing cycle. An additional prerequisite is that the operator shall have no influence on the test after the sealing sequence has begun. These test methods do not cover non-instrumented manual procedures employing springs, levers, pulleys and weights, where test results can be influenced by operator technique.

1.3 Two variations of the instrumented hot tack test are described in these test methods, differing primarily in two respects: (a) rate of grip separation during testing of the sealed specimen, and (b) whether the testing machine generates the cooling curve of the material under test, or instead makes a measurement of the maximum force observed following a set delay time. Both test methods may be used to test all materials within the scope of these test methods and within the range and capacity of the machine employed. They are described in Section 4.

1.4 SI units are preferred and shall be used in referee decisions. Values stated herein in inch-pound units are to be regarded separately and may not be exact equivalents to SI units. Therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability o...

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F1921/F1921M − 12

Standard Test Methods for

Hot Seal Strength (Hot Tack) of Thermoplastic Polymers and

1

Blends Comprising the Sealing Surfaces of Flexible Webs

ThisstandardisissuedunderthefixeddesignationF1921/F1921M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Designation was corrected editorially in October 2013.

1. Scope 1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 These two test methods cover laboratory measurement

responsibility of the user of this standard to establish appro-

of the strength of heatseals formed between thermoplastic

priate safety and health practices and determine the applica-

surfaces of flexible webs, immediately after a seal has been

bility of regulatory limitations prior to use. The operator of the

made and before it cools to ambient temperature (hot tack

equipment is to be aware of pinch points as the seal jaws come

strength).

together to make a seal, hot surfaces of the jaws, and sharp

1.2 These test methods are restricted to instrumented hot instruments used to cut specimens. It is recommended that the

tack testing, requiring a testing machine that automatically

operator review safety precautions from the equipment sup-

heatseals a specimen and immediately determines strength of plier.

thehotsealatapreciselymeasuredtimeafterconclusionofthe

2. Referenced Documents

sealing cycle. An additional prerequisite is that the operator

2

shall have no influence on the test after the sealing sequence

2.1 ASTM Standards:

has begun. These test methods do not cover non-instrumented

D882 Test Method for Tensile Properties of Thin Plastic

manual procedures employing springs, levers, pulleys and

Sheeting

weights, where test results can be influenced by operator

E171 Practice for Conditioning and Testing Flexible Barrier

technique.

Packaging

E691 Practice for Conducting an Interlaboratory Study to

1.3 Two variations of the instrumented hot tack test are

Determine the Precision of a Test Method

described in these test methods, differing primarily in two

F88 Test Method for Seal Strength of Flexible Barrier

respects: (a) rate of grip separation during testing of the sealed

Materials

specimen, and (b) whether the testing machine generates the

F2029 Practices for Making Heatseals for Determination of

cooling curve of the material under test, or instead makes a

Heatsealability of Flexible Webs as Measured by Seal

measurement of the maximum force observed following a set

Strength

delay time. Both test methods may be used to test all materials

withinthescopeofthesetestmethodsandwithintherangeand

3. Terminology

capacity of the machine employed. They are described in

3.1 Definitions:

Section 4.

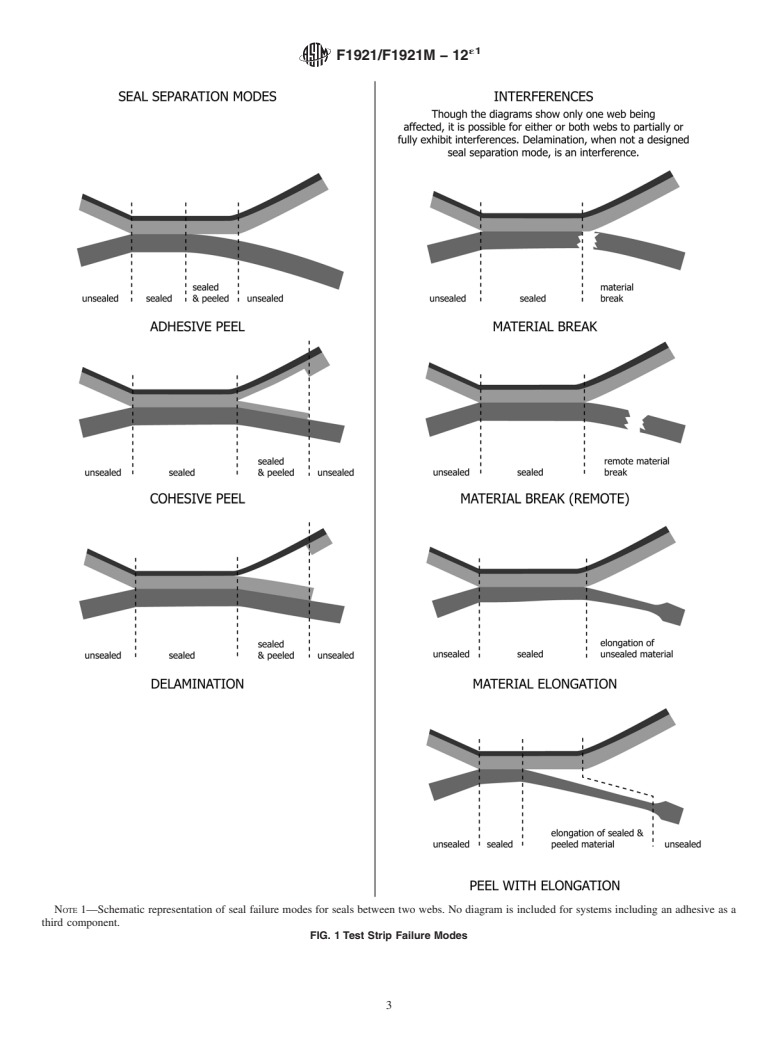

3.1.1 adhesive failure, n—a failure mode in which the seal

1.4 SI units are preferred and shall be used in referee

failsattheoriginalinterfacebetweenthesurfacesbeingsealed.

decisions. Values stated herein in inch-pound units are to be

3.1.2 breadth, n—temperature range over which peel force

regarded separately and may not be exact equivalents to SI

of a seal is (relatively) constant.

units. Therefore, each system shall be used independently of

3.1.3 burnthrough, n—a state or condition of a heatseal

the other. Combining values from the two systems may result

characterized by melted holes and thermal distortion.

in non-conformance with the standard.

3.1.3.1 Discussion—Burnthrough indicates that the sealing

conditions (time or temperature, or both) were too high to

produce an acceptable seal.

1

These test methods are under the jurisdiction of ASTM Committee F02 on

Flexible Barrier Packaging and are the direct responsibility of subcommittee F02.20

2

on Physical Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 1, 2012. Published August 2012. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1998. Last previous edition approved in 2004 as F1921-98(2004). DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F1921-12E01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

F1921/F1921M − 12

3.1.4 cohesive failure, n—a failure mode where either or of hot tack. The portion of the curve at higher sealing

bothofthesealedwebsfailsbysplittingapproximatelyparallel temperatures may be affected by failure of the substrate rather

to the seal,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.