ASTM F1921/F1921M-12(2023)

(Test Method)Standard Test Methods for Hot Seal Strength (Hot Tack) of Thermoplastic Polymers and Blends Comprising the Sealing Surfaces of Flexible Webs

Standard Test Methods for Hot Seal Strength (Hot Tack) of Thermoplastic Polymers and Blends Comprising the Sealing Surfaces of Flexible Webs

SIGNIFICANCE AND USE

5.1 In form-fill operations, sealed areas of packages are frequently subject to disruptive forces while still hot. If the hot seals have inadequate resistance to these forces, breakage can occur during the packaging process. These test methods measure hot seal strength and can be used to characterize and rank materials in their ability to perform in commercial applications where this quality is critical.

SCOPE

1.1 These two test methods cover laboratory measurement of the strength of heatseals formed between thermoplastic surfaces of flexible webs, immediately after a seal has been made and before it cools to ambient temperature (hot tack strength).

1.2 These test methods are restricted to instrumented hot tack testing, requiring a testing machine that automatically heatseals a specimen and immediately determines strength of the hot seal at a precisely measured time after conclusion of the sealing cycle. An additional prerequisite is that the operator shall have no influence on the test after the sealing sequence has begun. These test methods do not cover non-instrumented manual procedures employing springs, levers, pulleys and weights, where test results can be influenced by operator technique.

1.3 Two variations of the instrumented hot tack test are described in these test methods, differing primarily in two respects: (a) rate of grip separation during testing of the sealed specimen, and (b) whether the testing machine generates the cooling curve of the material under test, or instead makes a measurement of the maximum force observed following a set delay time. Both test methods may be used to test all materials within the scope of these test methods and within the range and capacity of the machine employed. They are described in Section 4.

1.4 SI units are preferred and shall be used in referee decisions. Values stated herein in inch-pound units are to be regarded separately and may not be exact equivalents to SI units. Therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. The operator of the equipment is to be aware of pinch points as the seal jaws come together to make a seal, hot surfaces of the jaws, and sharp instruments used to cut specimens. It is recommended that the operator review safety precautions from the equipment supplier.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1921/F1921M − 12 (Reapproved 2023)

Standard Test Methods for

Hot Seal Strength (Hot Tack) of Thermoplastic Polymers and

Blends Comprising the Sealing Surfaces of Flexible Webs

This standard is issued under the fixed designation F1921/F1921M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

1.1 These two test methods cover laboratory measurement

The operator of the equipment is to be aware of pinch points as

of the strength of heatseals formed between thermoplastic

the seal jaws come together to make a seal, hot surfaces of the

surfaces of flexible webs, immediately after a seal has been

jaws, and sharp instruments used to cut specimens. It is

made and before it cools to ambient temperature (hot tack

recommended that the operator review safety precautions from

strength).

the equipment supplier.

1.2 These test methods are restricted to instrumented hot

1.6 This international standard was developed in accor-

tack testing, requiring a testing machine that automatically

dance with internationally recognized principles on standard-

heatseals a specimen and immediately determines strength of

ization established in the Decision on Principles for the

the hot seal at a precisely measured time after conclusion of the

Development of International Standards, Guides and Recom-

sealing cycle. An additional prerequisite is that the operator

mendations issued by the World Trade Organization Technical

shall have no influence on the test after the sealing sequence

Barriers to Trade (TBT) Committee.

has begun. These test methods do not cover non-instrumented

manual procedures employing springs, levers, pulleys and

2. Referenced Documents

weights, where test results can be influenced by operator

2.1 ASTM Standards:

technique.

D882 Test Method for Tensile Properties of Thin Plastic

1.3 Two variations of the instrumented hot tack test are

Sheeting

described in these test methods, differing primarily in two

E171 Practice for Conditioning and Testing Flexible Barrier

respects: (a) rate of grip separation during testing of the sealed

Packaging

specimen, and (b) whether the testing machine generates the

E691 Practice for Conducting an Interlaboratory Study to

cooling curve of the material under test, or instead makes a

Determine the Precision of a Test Method

measurement of the maximum force observed following a set

F88 Test Method for Seal Strength of Flexible Barrier

delay time. Both test methods may be used to test all materials

Materials

within the scope of these test methods and within the range and

F2029 Practices for Making Laboratory Heat Seals for

capacity of the machine employed. They are described in

Determination of Heat Sealability of Flexible Barrier

Section 4.

Materials as Measured by Seal Strength

1.4 SI units are preferred and shall be used in referee

decisions. Values stated herein in inch-pound units are to be 3. Terminology

regarded separately and may not be exact equivalents to SI

3.1 Definitions:

units. Therefore, each system shall be used independently of

3.1.1 adhesive failure, n—a failure mode in which the seal

the other. Combining values from the two systems may result

fails at the original interface between the surfaces being sealed.

in non-conformance with the standard.

3.1.2 breadth, n—temperature range over which peel force

1.5 This standard does not purport to address all of the

of a seal is (relatively) constant.

safety concerns, if any, associated with its use. It is the

3.1.3 burnthrough, n—a state or condition of a heatseal

responsibility of the user of this standard to establish appro-

characterized by melted holes and thermal distortion.

These test methods are under the jurisdiction of ASTM Committee F02 on

Primary Barrier Packaging and are the direct responsibility of subcommittee F02.20

on Physical Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2023. Published April 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1998. Last previous edition approved in 2018 as F1921/F1921M – Standards volume information, refer to the standard’s Document Summary page on

12(2018). DOI: 10.1520/F1921-12R23. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1921/F1921M − 12 (2023)

3.1.3.1 Discussion—Burnthrough indicates that the sealing 3.1.12.1 Discussion—This is the basic curve used for com-

conditions (time or temperature, or both) were too high to paring materials for their hot tack performance. It shows not

produce an acceptable seal. only the maximum hot seal strength achievable by each

material and the sealing temperature required, but also the

3.1.4 cohesive failure, n—a failure mode where either or

breadth of the sealing temperature range at any specified level

both of the sealed webs fails by splitting approximately parallel

of hot tack. The portion of the curve at higher sealing

to the seal, and the seal itself remains intact.

temperatures may be affected by failure of the substrate rather

3.1.4.1 Discussion—Refer to Fig. 1. The term may be

than the seal and may not be an accurate representation of hot

defined somewhat differently when applied to sealing systems

tack strength.

involving an adhesive material as a separate component.

3.1.13 seal initiation temperature, n—sealing temperature at

3.1.5 cooling curve, n—the graphical depiction of the in-

which a heatseal of minimum measureable strength is pro-

crease in strength of the seal with time, as it cools during the

duced.

period immediately following conclusion of the sealing cycle

(for example, see Fig. 2). 3.1.14 sealing pressure, n—force required, with transfer of

3.1.5.1 Discussion—The cooling curve is a plot of hot seal heat, to fuse two surfaces together to form a seal. Pressure

strength versus cooling time. The portion of the cooling curve settings may be different than the actual applied pressure and

of greatest practical significance is the first 1000 ms following should be verified as part of instrument calibration.

opening of the heatseal jaws.

3.1.15 sealing temperature, n—maximum temperature

3.1.6 cooling time, n—time in the instrument cycle between reached at the interface between the two web surfaces being

the opening of the seal jaws and the termination of the peel sealed during the dwell time of the sealing cycle.

force measurement. 3.1.15.1 Discussion—Sealing temperature will equal jaw

temperature (both jaws at same temperature) if the dwell time

3.1.7 cycle, n—the combination of instrument mechanical

is long enough for the interface to reach equilibrium with the

and electrical operations automatically performed from initia-

jaws. At this point, seal strength will no longer rise with

tion of sealing through peeling apart a seal and measuring the

increasing dwell time.

hot tack strength. The cycle can be broken down into four

phases: sealing, delay, withdrawal, and peel. 3.1.16 withdrawal time, n—the time interval from the end of

the delay phase to the beginning of the peel of the hot seal.

4. Summary of Test Method

4.1 Two sample strips are sealed by applying pressure from

seal jaws under defined conditions of temperature, contact time

and pressure. The strips may be either the same film or

dissimilar films. Some instrument designs allow the use of a

single strip of film which is cut during the sealing phase to

form two strips. Either one or both of the seal jaws may be

heated. The jaw faces may either be smooth or textured and

may be covered with a material to promote release from the hot

film.

3.1.8 delay time, n—the time interval from when the heat-

4.2 When the jaws of the sealing unit open, the sealed strip

seal jaws open after sealing two film surfaces, to the point at

which withdrawal of the sample from between the jaws is is automatically withdrawn from between the jaws by retrac-

tion of the grips holding the unsealed ends of the strips.

initiated.

3.1.9 dwell time, n—the time interval during the seal phase

4.3 As the grips move apart at a set speed and the sealed

when the sealing jaws are in contact with, and exerting

sample is peeled to eventual failure, the force required to peel

pressure on, the material being sealed.

open the seal is measured by the testing machine.

3.1.10 failure mode, n—a visual determination of the man-

4.4 In Method A (machines of the Fixed Delay type) the

ner in which the test strip fails during grip separation.

machine measures and plots hot tack strength versus time after

jaw opening, starting after a manufacturer-set delay and

3.1.11 hot tack strength, n—force per unit width of a seal

withdrawal period, which is part of the cooling curve for the

needed to peel apart a hot seal measured at a specified time

material. The computer then measures the force at various

interval after sealing but prior to the seal cooling to ambient

user-selectable times (minimum of two), and reports the force

temperature.

as hot-tack strength at those cooling times.

3.1.11.1 Discussion—The desired outcome of the test is to

peel apart the seal formed by the test instrument. Other types of

4.5 In Method B (machines of the Variable Delay type) the

film failure in the tensile phase of the instrument test cycle may

computer plots maximum hot tack strength versus time after

not represent hot tack strength.

completion of a user-selected delay time. The maximum force

3.1.12 hot-tack curve, n—a plot of measured hot-tack encountered during grip travel is determined from that plot and

strength versus sealing temperature at fixed dwell time and reported as hot-tack strength for the delay time employed in

sealing pressure (for example, see Fig. 3). that test.

F1921/F1921M − 12 (2023)

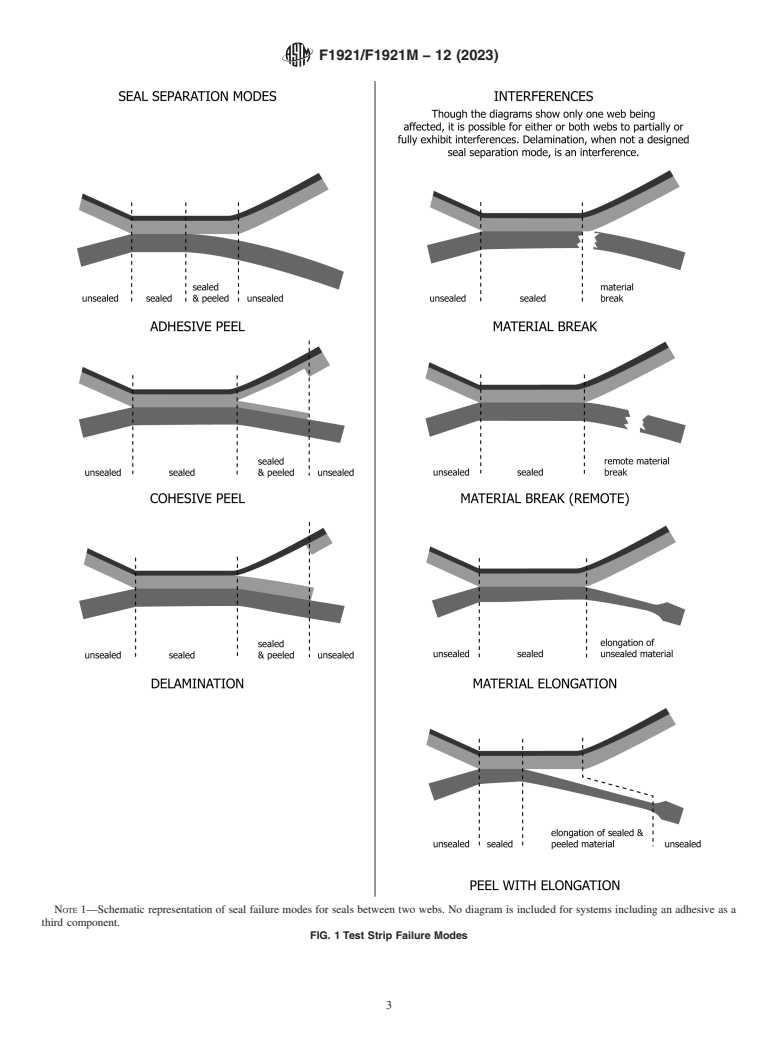

NOTE 1—Schematic representation of seal failure modes for seals between two webs. No diagram is included for systems including an adhesive as a

third component.

FIG. 1 Test Strip Failure Modes

F1921/F1921M − 12 (2023)

FIG. 2 Cooling Curve

FIG. 3 Hot Tack Curve

4.6 In both methods the operator cannot influence the test 6.2.2 User-selectable and precise control of jaw

once the sealing cycle is initiated. temperatures, dwell time and pressure,

6.2.3 User-selectable constant rate of grip separation,

4.7 Hot-tack strength at various sealing temperatures is

6.2.4 Automatic activation of the withdrawal and pull

plotted as the hot-tack curve of the material tested (see Fig. 3).

cycles when seal jaws open,

4.8 The type of seal failure is noted for each determination.

6.2.5 Measures the force required to cause failure in the

sealed specimen, and

5. Significance and Use

6.2.6 Displays measurements in SI, inch-pound, or mixed

5.1 In form-fill operations, sealed areas of packages are

units.

frequently subject to disruptive forces while still hot. If the hot

7. Instrument Calibration

seals have inadequate resistance to these forces, breakage can

occur during the packaging process. These test methods

7.1 Calibration of the hot tack tester should be in accor-

measure hot seal strength and can be used to characterize and

dance with manufacturer’s instructions and should include, as

rank materials in their ability to perform in commercial

a minimum, seal bar temperature, seal bar pressure, phase

applications where this quality is critical.

times, transducer, and withdrawal rate.

7.2 The interval between calibrations may be determined

6. Apparatus

locally based on frequency of use and stability of calibration.

6.1 Specimen Cutter—Sized to cut specimens to a width of

8. Test Specimen

either 25 mm (0.984 in.), 15 mm (0.591 in.), or 1.00 in.

(25.4 mm). Tolerance shall be 60.5 %. Cutter shall conform to

8.1 Conditioning of samples or specimens prior to hot-tack

requirements specified in Test Method D882.

testing is commonly omitted. The atmospheric conditions of

Specification E171 are recommended when it is desired to

6.2 Testing Machine —An automated sealing and tensile

precondition materials to be tested.

testing instrument having the following minimum capabilities:

6.2.1 Equipped with two heated jaws for making seals,

8.2 The number of test specimens shall be chosen to permit

an adequate determination of representative performance.

When hot tack strength is being measured at a series of sealing

For further information on machines, users of these test methods are referred to

internet web sites of the various manufacturers. temperatures, a minimum of three replicates shall be used to

F1921/F1921M − 12 (2023)

determine the mean value at each temperature. When the

Delay time (user-selectable): 100 ms

Clamp separation rate: 1200 cm/min

measurements are not part of a series where an identifiable

trend is expected, a minimum of five replicates shall be

9.4 Start the machine. It will progress through the seal,

employed. delay, withdrawal, and hot tack strength-testing phases of the

test cycle, and automatically record numerical test data.

8.3 Specimens may be prepared by cutting test material in

either the machine direction (MD) or the transverse direction 9.5 Remove strip from grips. Observe and record mode of

(TD). If the direction of seal stress is of concern, the direction

specimen failure. For meaningful evaluation and comparison

in which the samples are cut should be noted in the final report. of materials, in all test methods and with all types of testing

machines, this step is essential. The mode of failure shall be

8.4 Specimen width may be either 25 mm, 15 mm, or 1.00

determined visually for each specimen tested, in accordance

in. Test results shall identify the width used. Specimen length

with the following or a similar classification, and the results

must be adequate for the testing machine (range of 25 cm to

included in the test report:

35 cm; 10 in. to 14 in.).

Failure Mode, see Fig. 1 (equivalent to Test

8.5 A typical hot tack curve may require 25 to 50 specimens

Method F88, Fig. 4)

of each material. Adhesive failure of the seal; peel

Cohesive failure of the material

8.6 Specimens that fail at some obvious film flaw such as a

Delaminat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.