ASTM F2257-03

(Specification)Standard Specification for Wrought Seamless or Welded and Drawn 18 Chromium-14Nickel-2.5Molybdenum Stainless Steel Small Diameter Tubing for Surgical Implants (UNS S31673)

Standard Specification for Wrought Seamless or Welded and Drawn 18 Chromium-14Nickel-2.5Molybdenum Stainless Steel Small Diameter Tubing for Surgical Implants (UNS S31673)

ABSTRACT

This specification covers the requirements for wrought seamless or welded and drawn 18chromium-14nickel-2.5molybdenum stainless steel small diameter tubing for surgical implants. Manufacturing method shall be seamless or welded and drawn process. Tubing shall conform to chemical composition, dimensions, and mechanical properties of this specification. Mechanical properties include ultimate tensile strength, yield strength, and elongation. Outside and inside diameter, wall thickness, length and straightness shall conform to the permissible limits of this specification.

SCOPE

1.1 This specification covers the requirements for wrought 18chromium-14nickel-2.5molybdenum stainless steel tubing used for the manufacture of surgical implants. Material shall conform to the applicable requirements of Specification F 138 (for seamless) or Specification F 139 (for welded and drawn). This specification addresses those product variables that differentiate small-diameter medical grade tubing from the bar, wire, sheet, and strip product forms covered in these specifications.

1.2 This specification applies to straight length tubing with 0.125 in. (3.15 mm) and smaller nominal outside diameter (OD) and 0.018 in. (0.46 mm) and thinner nominal wall thickness.

1.3 The values stated in inch-pound units are to be regarded as the standard. The SI units in parentheses are approximate.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 2257 – 03

Standard Specification for

Wrought Seamless or Welded and Drawn 18 Chromium-

14Nickel-2.5Molybdenum Stainless Steel Small Diameter

Tubing for Surgical Implants (UNS S31673)

This standard is issued under the fixed designation F 2257; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope ISO 5832-1 Implants for Surgery—Metallic Materials Part

1: Wrought Stainless Steel

1.1 This specification covers the requirements for wrought

ISO 6892 Metallic Materials—Tensile Testing

18chromium-14nickel-2.5molybdenum stainless steel tubing

2.4 American Society for Quality Standard:

used for the manufacture of surgical implants. Material shall

C1 Specification of General Requirements for a Quality

conform to the applicable requirements of Specification F 138

Program

(for seamless) or Specification F 139 (for welded and drawn).

This specification addresses those product variables that dif-

3. Terminology

ferentiate small-diameter medical grade tubing from the bar,

3.1 Definitions of Terms Specific to This Standard:

wire, sheet, and strip product forms covered in these specifi-

3.1.1 average wall thickness—the arithmetic average of the

cations.

minimum wall thickness and the maximum wall thickness

1.2 This specification applies to straight length tubing with

measured on any one transverse cross section of the tube.

0.125 in. (3.15 mm) and smaller nominal outside diameter

3.1.2 concentricity—two times the offset between the cen-

(OD) and 0.018 in. (0.46 mm) and thinner nominal wall

ters of two circles, representing the outside diameter (OD) and

thickness.

the inside diameter (ID) of the tube. For purposes of this

1.3 The values stated in inch-pound units are to be regarded

specification, the minimum wall and the maximum wall

as the standard. The SI units in parentheses are approximate.

measured on any one transverse cross section shall be used to

2. Referenced Documents calculate concentricity. The percent concentricity shall be

calculated using the equation:

2.1 ASTM Material Standards:

F 138 Specification for Wrought 18Chromium-14Nickel- maximum wall 2 minimum wall

Percent Concentricity 5 2 3 3 100

S D

maximum wall 1 minimum wall

2.5Molybdenum Stainless Steel Bar and Wire for Surgical

Implants (UNS S31673)

3.1.3 nominal outside diameter (OD)—the outside diameter

F 139 Specification for Wrought 18Chromium-14Nickel-

specifiedonthecustomerorderorengineeringdrawingwithout

2.5Molybdenum Stainless Sheet and Strip for Surgical

regard to tolerance.

Implants (UNS S31673)

3.1.4 nominal wall thickness—the wall thickness specified

2.2 ASTM Standards:

onthecustomerorderorengineeringdrawingwithoutregardto

A 632 Specification for Seamless and Welded Austenitic

tolerance.

Stainless Steel Tubing (Small Diameter) for General

3.1.5 seamless tubing—tubing made by a process in which

Service

the tube periphery is continuous at all stages of the process.

E 8 Test Methods forTensionTesting of Metallic Materials

3.1.6 welded and drawn tubing—tubing fabricated from

E 112 Test Method for Determining Average Grain Size

strip or sheet using welding, drawing, and annealing opera-

2.3 ISO Standards:

tions. Welding shall be performed using a liquid phase weld

process with no filler metal. Typical weld processes are

1 tungsten inert gas (TIG) and laser. The drawing and annealing

This specification is under the jurisdiction of ASTM Committee F04 on

Medical and Surgical Materials and Devices and is the direct responsibility of

Subcommittee F04.12 on Metallurgical Materials.

Current edition approved Apr. 10, 2003. Published May 2003. Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Annual Book of ASTM Standards, Vol 13.01. 4th Floor, New York, NY 10036.

3 6

Annual Book of ASTM Standards, Vol 01.01. Available from American Society for Quality (ASQ), 600 N. Plankinton Ave.,

Annual Book of ASTM Standards, Vol 03.01. Milwaukee, WI 53203.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2257–03

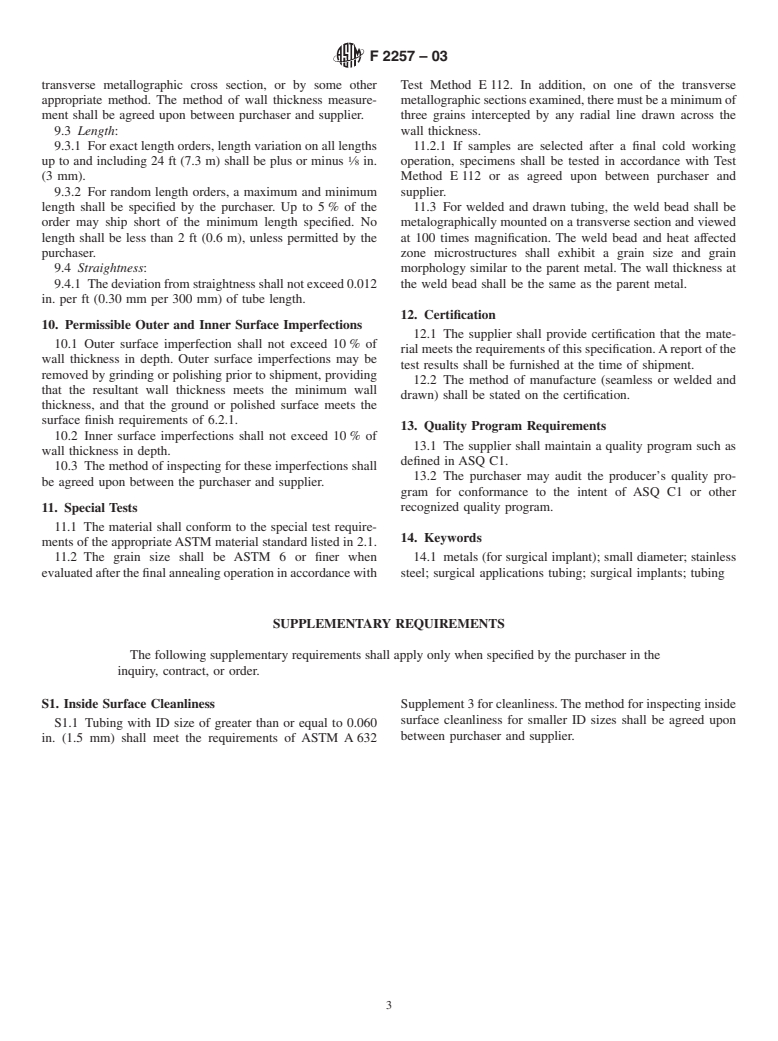

TABLE 1 Mechanical Properties

A

Wall Thickness, Ultimate Tensile Strength, Yield Strength (0.2 % offset), Elongation (% in 2 in. or 4D),

Condition

in. (mm) min, psi (MPa) min psi (MPa) min (%)

Annealed 0.008 (0.20) to 0.018 incl (0.46) 71 000 (490) 27 500 (190) 40

0.002 (0.05) to 0.008 excl (0.20) 80 000 (550) 30 000 (205) 35

Less than 0.002 (0.05) 85 000 (585) 35 000 (240) 20

Cold worked 0.008 (0.20) to 0.018 incl (0.46) 125 000 (860) 100 000 (690) 10

0.002 (0.05) to 0.008 excl (0.20) 125 000 (860) 100 000 (690) 8

Less than 0.002 (0.05) 125 000 (860) 100 000 (690) 4

A

Elongation of material 0.063 in. (1.6 mm) or greater in diameter (D) shall be measured using a gage length of 2 in. (50 mm) or 4D. The gage length must be reported

with the test results. The method for determining elongation of material under 0.063 in. (1.6 mm) shall be agreed upon between purchaser and supplier. Alternatively, a

gauge length corresponding to ISO 6892 (5.65 times the square root of So, where So is the original cross sectional area) may be used when agreed upon between

purchaser and supplier.

operations shall be performed in such a way that the weld bead 6.2.1 The tubing outer surface shall be furnished with a

and heat affected zone are virtually indistinguishable micro- cold-drawn, bright annealed, ground, or polished finish. Outer

structurally and dimensionally from the parent metal when surfaceroughnessshallbeamaximumof25µin.(0.63µm)Ra.

examined per 11.3. 6.2.2 The tubing inner surface shall be furnished with an

as-drawn finish or bright annealed finish. Inner surface rough-

4. General Requirements for Delivery

ness shall be a maximum of 30 µin. (0.75 µm) Ra.

6.2.3 The method used to determine surface roughness shall

4.1 In addition to the requirements of this specification, all

be agreed upon between purchaser and supplier.

applicable requirements of the appropriate ASTM material

standard shall apply.

7. Chemical Composition

4.2 In addition to the requirements of this specification, all

7.1 Forseamlesstubing,theheatanalysislimitsandproduct

applicable requirements of Specification A 632 shall apply.

analysis tolerances of Specification F 138 shall apply. For

welded and drawn tubing, the heat analysis limits and product

5. Ordering Information

analysis tolerances of Specification F 139 shall apply.

5.1 Inquiries and orders for material under this specification

should include the following information:

8. Mechanical Properties

5.1.1 Quantity (weight, total length or number of pieces),

8.1 Material shall meet the appropriate mechanical proper-

5.1.2 This ASTM designation and date of issue,

ties specified in Table 1, when tested in accordance with Test

5.1.3 ASTM material standard (Specification F 138 for

Method E 8. Mechanical properties for material in conditions

seamless or Specification F 139 for welded and drawn) and

other than those in Table 1 shall be agreed upon between

date of issue,

purchaser and supplier.

5.1.4 Method of Manufacture (see 6.1),

8.2 In the event that both tensile properties and hardness are

5.1.5 Condition (see Table 1),

specified on the purchase order, tensile properties will be used

5.1.6 Surface Finish (see 6.2),

to accept or reject. Hardness will be reported for information

5.1.7 Applicable Dimensions, including OD and ID; OD

only.

and wall or ID and wall; length (exact, random, multiples); or

9. Permissible Variation in Dimensions

engineering drawing reference number,

5.1.8 Dimensional Tolerances (see Table 2),

9.1 OD and ID:

5.1.9 Certification requirements, and

9.1.1 Permissible variations of OD and ID from the nominal

5.1.10 Special requirements or supplements, if any.

dimension on the purchase order or engineering drawing are

listed in Table 2.

6. Materials and Manufacture

9.1.2 OD may be measured by hand micrometer, by linear

6.1 Method of Manufacture: variabledifferentialtransducer(LVDT),bylasermicrometeror

6.1.1 Tubing shall be made by the seamless or the welded

by other non-contact method.

and drawn process. 9.2 Wall Thickness:

6.2 Surface Finish: 9.2.1 The range of total wall variation (including concen-

tricity and average wall variation) shall not exceed 14 %

(67 %) of nominal wall thickness.

TABLE 2 Permissible Variation in OD and ID Dimensions

9.2.2 Concentricity shall not exceed 10 % (65 %) of aver-

Nominal OD or ID Permissible Variation

age wall thickness for tubing with nominal wall thickness

A

in. (mm) from Nominal, in. (mm)

greater than or equal to 10 % of the nominal OD dimension.

Less than 0.060 (1.53) 60.0005 (.013)

0.060

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.