ASTM D1826-94(1998)

(Test Method)Standard Test Method for Calorific (Heating) Value of Gases in Natural Gas Range by Continuous Recording Calorimeter

Standard Test Method for Calorific (Heating) Value of Gases in Natural Gas Range by Continuous Recording Calorimeter

SCOPE

1.1 This test method covers the determination with the continuous recording calorimeter (Note 1) of the total calorific (heating) value of fuel gas produced or sold in the natural gas range from 900 to 1200 Btu/standard ft . Note 1-An extensive investigation of the accuracy of the Cutler-Hammer recording gas calorimeter, when used with gases of high heating value, was made by the National Bureau of Standards in 1957 under a research project sponsored by the American Gas Association.

1.2 The subjects covered in this test method appear in the following sections: Sections Air-Gas Ratio Test 11 Apparatus 5 Basis of Measurement 14 Cold Balance Test 10 Compensation of Complicating Factors 13 Condition of Gas Sample 7 Definitions 2 Installation of Apparatus 6 Maintenance, Appendix I X1 Operating Precautions, Appendix II X2 Operation and Checking of Apparatus 9 Precision 15 Scope 1 Significance and Use 4 Standardization of Calorimeter 12 Standardization, Preliminary, of Calorimeter by Hydrogen 8 Summary of Test Method 3

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn

Contact ASTM International (www.astm.org) for the lastest information

Designation:D1826–94 (Reapproved 1998)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Calorific (Heating) Value of Gases in Natural Gas Range by

Continuous Recording Calorimeter

This standard is issued under the fixed designation D1826; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

NOTE 2—The defining relationships are:

1. Scope

−1 −1

(a) 1 Btu·lb 52.326 J·g (exact)

1.1 This test method covers the determination with the

(b) 1 lb5453.59237 g (exact).

continuous recording calorimeter (Note 1) of the total calorific

By these relationships, 1 Btu 5 1 055.05585262 J (exact). For most

(heating) value of fuel gas produced or sold in the natural gas

purposes, the value rounded to 1 Btu 5 1 055.056 J is adequate.

range from 900 to 1200 Btu/standard ft .

2.1.3 combustion air—air used for combustion, a total of

NOTE 1—An extensive investigation of the accuracy of the Cutler- the portion mixed with the gas as primary air and the air

Hammer recording gas calorimeter, when used with gases of high heating

supplied around the burner tube as secondary air (theoretical

value, was made by the National Bureau of Standards in 1957 under a

air plus excess air).

research project sponsored by the American Gas Association.

2.1.4 flue gases—the products, of combustion remaining in

1.2 The subjects covered in this test method appear in the

the gaseous state, together with any excess air.

following sections:

2.1.5 heat-absorbing air—the heat exchange medium used

Sections to absorb the heat of combustion derived from the burning of

Air-Gas Ratio Test 11

gaseous fuel.

Apparatus 5

2.1.6 saturated basis—the expressed total calorific value of

Basis of Measurement 14

Cold Balance Test 10

a gas when it is saturated with water vapor at standard

Compensation of Complicating Factors 13

temperature and pressure; 1 ft of this gas is equivalent in dry

Condition of Gas Sample 7

gascontentto0.9826ft ofdrygasatthestandardtemperature

Definitions 2

Installation of Apparatus 6 of 60°F and standard pressure of 14.73 psia.

Maintenance Appendix X1

NOTE 3—Thedefinitionsgivenin2.1.6and2.1.10arefortotalcalorific

Operating Precautions Appendix X2

Operation and Checking of Apparatus 9

(heating) values per standard cubic foot of gas. The definitions corre-

Precision 15

sponding to any other unit quantity of gas are obtained by substituting the

Scope 1

name of the desired unit in place of the term “standard cubic foot” in the

Significance and Use 4

definitions. Methods of calculating calorific (heating) values per cubic

Standardization of Calorimeter 12

foot of gas under any desired conditions of pressure, temperature, and

Standardization, Preliminary, of Calorimeter by Hydrogen 8

water vapor content are specified in Section 14.

Summary of Test Method 3

2.1.7 standard cubic foot of gas—the quantity of any gas

1.3 This standard does not purport to address all of the

that at standard temperature and under standard pressure will

safety concerns, if any, associated with its use. It is the

fill a space of 1 ft when in equilibrium with liquid water.

responsibility of the user of this standard to establish appro-

2.1.8 standard pressure—is 14.73 psia.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

NOTE 4—This is the pressure base adopted by the American National

Standards Institute in 1969 (Z132.1). According to Dalton’s law, this is

2. Terminology

equivalent to stating that the partial pressure of the gas is:

2.1 Definitions of Terms Specific to This Standard: 14.73−0.25636514.47364 psia

where 0.25636 is the vapor pressure of water in psia at 60°F.

2.1.1 The most important terms used in connection with the

determination of the calorific value of gaseous fuels in record-

2.1.9 standard temperature—60°F, based on the interna-

ing calorimetry are as follows:

tional practical temperature scale of 1968.

2.1.2 British Thermal Unit, or Btu—is the defined Interna-

2.1.10 total calorific value (gross heating value, higher

tional Tables British thermal unit (symbol Btu).

heating value)—of a gas is the number of British thermal units

evolved by the complete combustion at constant pressure of

one standard cubic foot of gas with air, the temperature of the

ThistestmethodisunderthejurisdictionofASTMCommitteeD-3onGaseous

gas, air, and products of combustion being 60°F, and all the

Fuels and is the direct responsibility of Subcommittee D03.03 on Determination of

Heating Value and Relative Density of Gaseous Fuels. water formed by the combustion reaction being condensed to

Current edition approved Feb. 15, 1994. Published April 1994. Originally

the liquid state.

e1

published as D1826–61T. Last previous edition D1826–88(1993) .

--``,`````,,,,`,`,`````,,```,`-`-`,,`,,`,`,,`---

D1826

NOTE 6—Refer to specific manufacturer’s manual for pictures of the

3. Summary of Test Method

recorder or the SMART-CAL, a digital indicating or printing device,

3.1 The heating value is determined by imparting all of the

currently used on new or retrofitted calorimeters.

heat obtained from the combustion of the test gas to a stream

6. Installation of Apparatus

of air and measuring the rise in temperature of the air. The

streams of test gas and heat absorbing air are maintained in 6.1 To secure the precise results that are possible with the

fixed volumetric proportion to each other by metering devices recording calorimeter, it is important that the instrument be

similar to the ordinary wet test meters geared together and installed so that the surrounding conditions will not introduce

drivenfromacommonelectricmotor.Themetersaremounted errors. In general, more precise results will be secured when a

in a tank of water, the level of which is maintained and the narrow range is maintained on the various conditions of the

calorimeter environment.

temperature of which determines the temperature of the enter-

ing gas and air. 6.2 Calorimeter Room—A typical installation of a single

recording calorimeter is shown in Fig. 4. The detailed require-

3.2 The flue gas resulting from combustion of the gas

(combustion products plus excess combustion air) is kept ments for the calorimeter room are given in Table 1.

separate from the heat-absorbing air and is cooled to a few

NOTE 7—Adetailed discussion of these requirements is included in the

degrees above the initial temperature of gas and air. The water

latest edition of the manufacturer’s instruction book covering the record-

formed in the combustion is practically all condensed to the

ing calorimeter. The information can be applied to all models of the

liquidstate.Consequently,thetemperatureriseproducedinthe instrument.

NOTE 8—The dimensions shown in Fig. 4 are for the latest model

heat-absorbing air is directly proportional to the heating value

calorimeter.

of the gas. Since all the heat from the combustion of the test

6.3 Gas Connection—Locatethesamplelinethatbringsthe

gas sample, including the latent heat of vaporization of the

gas to be tested to the calorimeter tank unit so that the heating

water vapor formed in the combustion, is imparted to the

valueisactuallyrepresentativeoftheconditionsexistinginthe

heat-absorbing air, the calorimeter makes a direct determina-

main gas line. Keep the sample line time lag as small as

tionoftotalheatingvalue.Thetemperatureriseismeasuredby

possible by (1) locating the calorimeter tank unit close to the

nickel resistance thermometers and is translated into Btu per

sample point, (2) running the sample line of small size pipe

standard cubic foot.

(Note 9), and (3) operating the sample line at low pressure.

4. Significance and Use

Provideanadditionalpurgeburnerorableedtoalowpressure

4.1 This test method provides an accurate and reliable

point.

method to measure the total calorific value of a fuel gas, on a

NOTE 9—Time lag may be calculated on the basis that the calorimeter

continuous basis, which is used for regulatory compliance,

uses about 1.2 ft /h.

custody transfer, and process control.

6.4 Electrical Wiring—The four leads for the resistance

5. Apparatus thermometers between either the recorder or the Smart-Cal

junction box and the tank unit shall be of No. 12 gage,

5.1 The recording calorimeter (Note 5) consists of two

insulated, solid copper wire without joints. Run in a separate

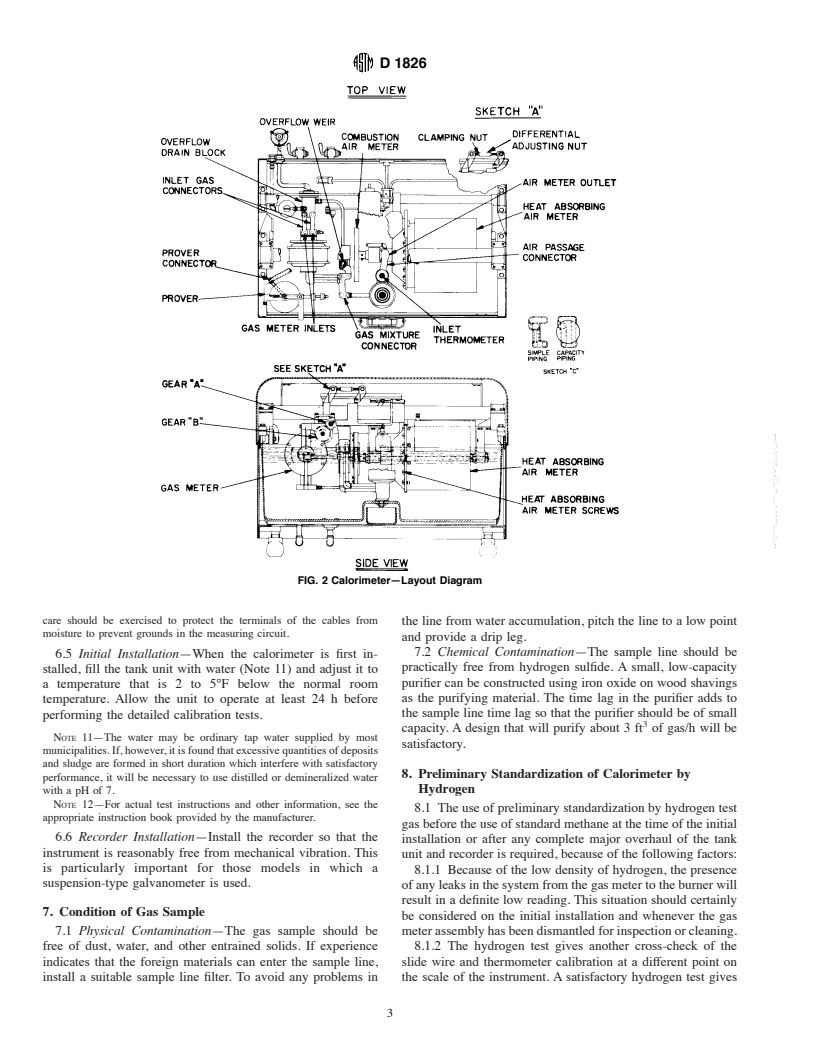

major units; the tank unit or calorimeter proper, Fig. 1, Fig. 2,

rigid metal conduit which is grounded and contains no other

and Fig. 3, in which the heating value of the test gas sample is

leads (Note 10). Power circuit wiring should be No. 14 gage,

measured; and the recording unit which translates the heat

insulated, solid or stranded, copper wire. Provide the supply

measurements into an indication of calorific (heating) value

line with a suitably fused disconnect switch. For the model

and records it graphically on a strip chart recorder or digitally

using an electronic recorder, it is essential that a suitable

if the new SMART-CAL is used (Note 6).

ground connection be made at both the recorder and the tank

NOTE 5—The previous specified pressure base was the absolute pres-

unit. Details are given in the manufacturer’s instructions.

sure of a column of pure mercury 30 in. in height at 32°F and under

standard gravity (32.174 ft/s ). This is equivalent to 14.7346 psia. NOTE 10—Where outdoor or underground wiring must be used, special

FIG. 1 Calorimeter—Schematic Flow Diagram

D1826

FIG. 2 Calorimeter—Layout Diagram

care should be exercised to protect the terminals of the cables from

the line from water accumulation, pitch the line to a low point

moisture to prevent grounds in the measuring circuit.

and provide a drip leg.

7.2 Chemical Contamination—The sample line should be

6.5 Initial Installation—When the calorimeter is first in-

practically free from hydrogen sulfide. A small, low-capacity

stalled, fill the tank unit with water (Note 11) and adjust it to

purifier can be constructed using iron oxide on wood shavings

a temperature that is 2 to 5°F below the normal room

as the purifying material. The time lag in the purifier adds to

temperature. Allow the unit to operate at least 24 h before

the sample line time lag so that the purifier should be of small

performing the detailed calibration tests.

capacity. A design that will purify about 3 ft of gas/h will be

NOTE 11—The water may be ordinary tap water supplied by most

satisfactory.

municipalities.If,however,itisfoundthatexcessivequantitiesofdeposits

and sludge are formed in short duration which interfere with satisfactory

8. Preliminary Standardization of Calorimeter by

performance, it will be necessary to use distilled or demineralized water

Hydrogen

with a pH of 7.

NOTE 12—For actual test instructions and other information, see the

8.1 The use of preliminary standardization by hydrogen test

appropriate instruction book provided by the manufacturer.

gasbeforetheuseofstandardmethaneatthetimeoftheinitial

6.6 Recorder Installation—Install the recorder so that the

installation or after any complete major overhaul of the tank

instrument is reasonably free from mechanical vibration. This

unit and recorder is required, because of the following factors:

is particularly important for those models in which a

8.1.1 Because of the low density of hydrogen, the presence

suspension-type galvanometer is used.

ofanyleaksinthesystemfromthegasmetertotheburnerwill

result in a definite low reading. This situation should certainly

7. Condition of Gas Sample

be considered on the initial installation and whenever the gas

7.1 Physical Contamination—The gas sample should be meterassemblyhasbeendismantledforinspectionorcleaning.

free of dust, water, and other entrained solids. If experience 8.1.2 The hydrogen test gives another cross-check of the

indicates that the foreign materials can enter the sample line, slide wire and thermometer calibration at a different point on

install a suitable sample line filter. To avoid any problems in the scale of the instrument. A satisfactory hydrogen test gives

--``,`````,,,,`,`,`````,,```,`-`-`,,`,,`,`,,`---

D1826

FIG. 3 Calorimeter Combustion Chamber

additional assurance that no error exists in this part of the following points should be checked periodically:

instrument. 9.1.1 Recorder—Check the operation of the recorder at

8.1.3 There is practically no possibility of incomplete com-

regular intervals to be sure that the chart is set at the proper

bustion on the hydrogen test. Therefore, a satisfactory hydro- time and that the pen is making a satisfactory line. Examina-

gen result gives assurance that, with the proper heat input, the

tions of the chart record will aid in avoiding certain operating

correct calorific value reading will be secured. If a satisfactory problems since the record will show if undesirable conditions

hydrogen test has been secured and a low reading has been develop. For example, an irregular chart may be the result of

obtained on the standard gas, the possibility of incomplete depositsintheburnerpartsoronorificecaps.Gradualchanges

combustion could be suspected. Without the hydrogen test, in the record from normal values may indicate a failure to

there might be some tendency to make adjustments to com- replenish the water in the reserve tank or may show the

pensate in another way for the low reading. This is obviously existence of obstructions on the overflow weir.

undesirable. 9.1.1.1 SMART-CAL—The paper in the printer should be

checked weekly. It may be necessary to correct the time. If

NOTE 13—Use the manufacturer’s instruction manual for the hydrogen

alarm lights such as “high,” “low,” “max deviation,” or “flame

test. This test is considered satisfactory if the reading agrees with the

out” are activated, the operator will check the tank unit for

theoretical value within 0.3%.

water level, flame out, dirty overflow weir, restricted combus-

9. Operation and Checking of Apparatus

tion air flow, defective burner parts, and so forth.

9.1 The recording calorimeter is designed for continuous 9.1.2 Tank Unit—To avoid contamination of the air in the

operation and, as a precision instrument, it should receive roomwithcombustiblegas,takecaretoen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.