ASTM E1351-96

(Practice)Standard Practice for Production and Evaluation of Field Metallographic Replicas

Standard Practice for Production and Evaluation of Field Metallographic Replicas

SCOPE

1.1 This practice covers recognized methods for the preparation and evaluation of cellulose acetate or plastic film replicas which have been obtained from metallographically prepared surfaces. It is designed for the evaluation of the metallographic replica to ensure that all significant features of a metallographically prepared surface have been duplicated and preserved on the replica with sufficient detail to permit both LM and SEM examination with optimum resolution and sensitivity.

1.2 This practice may be used as a controlling document in commercial situations.

1.3 The values stated in SI units are to be regarded as the standard. Inch-pound units given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1351 – 96

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Practice for

1

Production and Evaluation of Field Metallographic Replicas

This standard is issued under the fixed designation E 1351; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Replication is a nondestructive sampling procedure which records and preserves the topography of

a metallographic specimen as a negative relief on a plastic film. The microstructural replica can be

examined using a light microscope (LM) or scanning electron microscope (SEM) for subsequent

analysis. Specimens examined in the SEM are vacuum coated with vaporized carbon or a suitable

metal to provide contrast and conductivity. The convenience of the replication process makes it

suitable for obtaining microstructures from field locations for subsequent examination and analysis in

a laboratory. The proper preparation of the test surface and of the replica itself is of paramount

importance and must receive careful attention. Because of the diversity of metallographic equipment

available and the wide range of environments in which replication is conducted, the preparation of

replicas of high quality should be viewed as a skilled process for which there exists a variety of

techniques that achieve satisfactory results.

This practice presents some guidelines on the preparation of metallic surfaces and production of

replicas and guidelines on evaluation of replica quality. It does not attempt to limit the variations in

technique developed by skilled metallographers, each of which may produce acceptable replicas.

2

1. Scope Steel Pipe for High-Temperature Service

3

E 3 Methods of Preparation of Metallographic Specimens

1.1 This practice covers recognized methods for the prepa-

3

E 7 Terminology Relating to Metallography

ration and evaluation of cellulose acetate or plastic film

3

E 407 Practice for Microetching Metals and Alloys

replicas which have been obtained from metallographically

prepared surfaces. It is designed for the evaluation of replicas

3. Terminology

to ensure that all significant features of a metallographically

3.1 Definitions—For definitions of terms used in this prac-

prepared surface have been duplicated and preserved on the

tice, refer to Terminology E 7.

replica with sufficient detail to permit both LM and SEM

examination with optimum resolution and sensitivity.

4. Significance and Use

1.2 This practice may be used as a controlling document in

4.1 Replication is a nondestructive sampling procedure that

commercial situations.

records and preserves the topography of a metallographically

1.3 The values stated in SI units are to be regarded as the

prepared surface as a negative relief on a plastic film (replica).

standard. Inch-pound units given in parentheses are for infor-

The replica permits the examination and analysis of the

mation only.

metallographically prepared surface on the LM or SEM.

1.4 This standard does not purport to address all of the

4.2 Enhancement procedures for improving replica contrast

safety concerns, if any, associated with its use. It is the

for microscopic examination are utilized and sometimes nec-

responsibility of the user of this standard to establish appro-

essary (see 8.1).

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

NOTE 1—It is recommended that the purchaser of a field replication

service specify that each replicator demonstrate proficiency by providing

2. Referenced Documents

field prepared replica metallography and direct LM and SEM comparison

to laboratory prepared samples of an identical material by grade and

2.1 ASTM Standards:

service exposure.

A 335/A 335M Specification for Seamless Ferritic Alloy-

5. Evaluation Methods

1

5.1 A suitable replica should accurately reproduce all the

This practice is under the jurisdiction of ASTM Committee E-4 on Metallog-

raphy and is the direct responsibility of Subcommittee E04.01 on Selection and

Preparation of Samples.

2

Current edition approved Oct. 10, 1996. Published December 1996. Originally Annual Book of ASTM Standards, Vol 01.01.

3

published as E 1351 – 90. Last previous edition E 1351 – 90. Annual Book of ASTM Standards, Vol 03.01.

1

---------------------- Page: 1 ----------------------

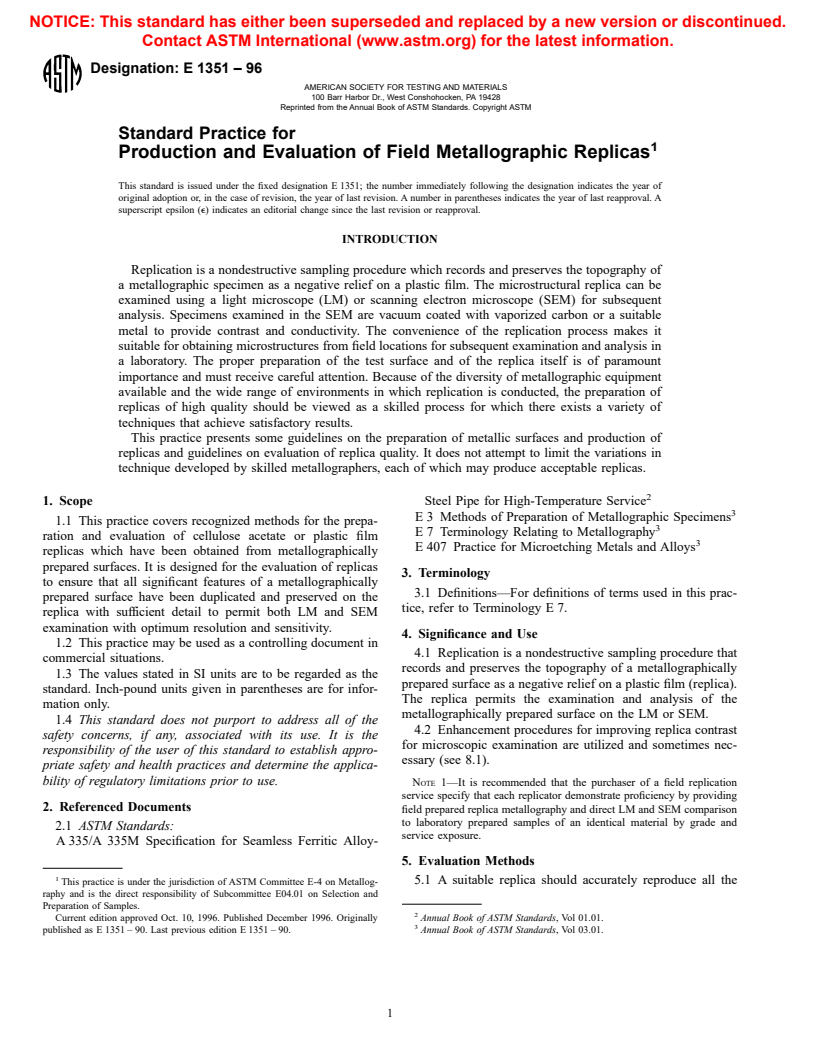

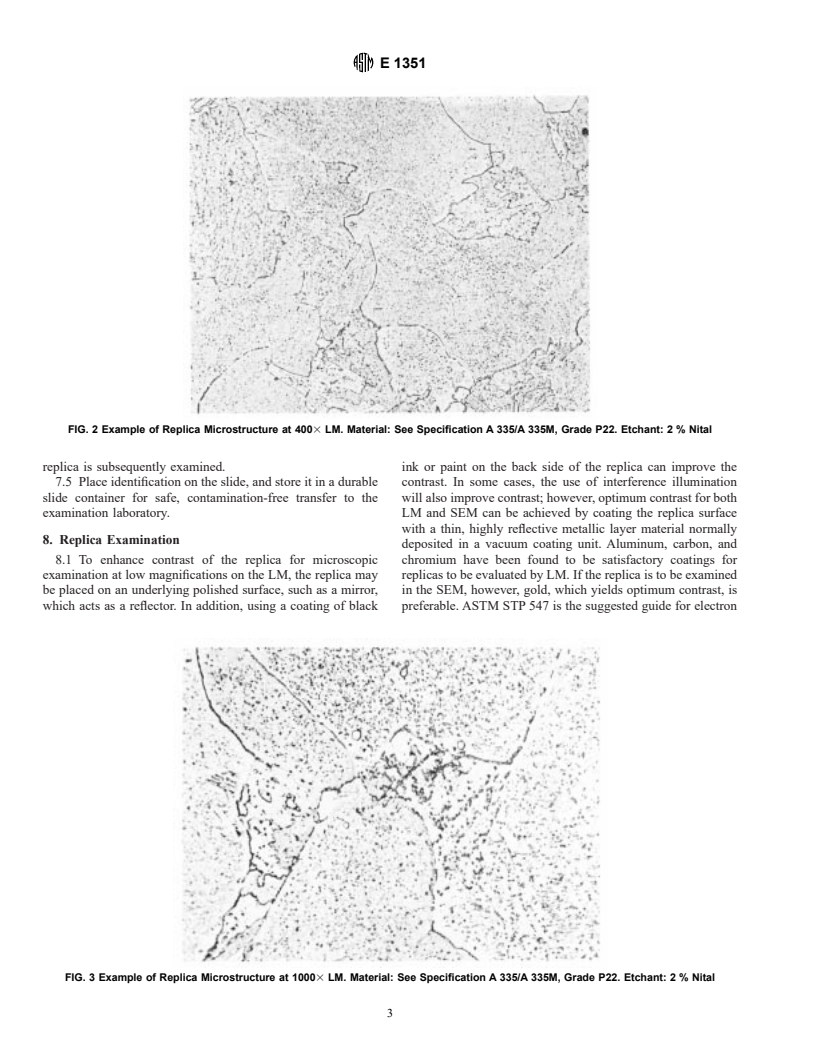

E 1351

microstructural features present on the surface that was repli- 6.7 To prevent possible contamination of any components,

cated. the etched area should be prepared carefully and tho

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.