ASTM D7845-13

(Test Method)Standard Test Method for Determination of Chemical Species in Marine Fuel Oil by Multidimensional Gas Chromatography – Mass Spectrometry

Standard Test Method for Determination of Chemical Species in Marine Fuel Oil by Multidimensional Gas Chromatography – Mass Spectrometry

SIGNIFICANCE AND USE

5.1 The test method allows the quantitation of chemical species at low levels in marine fuel oils and cutter stocks. A great many types and concentrations of chemical species are found in marine fuel oils. A root cause relationship between the presence of such species or their concentration in fuels and any failure modes allegedly induced by the use of these fuels has not been established. This method is necessary to establish test conditions required for future ISO 8217:2010 Petroleum products- Fuels (class F)-Specifications of marine fuel oils as defined in section 5.5 and Annex B item (d). Additional compounds may be determined by using the same conditions and by selecting required mass spectral selected ions, accordingly.

SCOPE

1.1 This test method covers the quantitative determination of a variety of chemical species in marine fuel oil (bunker fuel oil) by gas chromatography – mass spectrometry. By using the same conditions and by selecting required mass spectral selected ions, the test method may be used for the determination of other species than those for which precision statements and limits of detection have been established.

1.2 An example list of chemical species for which a limit of quantification has been determined by means of this test method is given in Table 1.TABLE 1 Component Table

Limit of Quantitation

mg/kg

n-butyl alcohol

10

Cyclohexanol

10

n-butyl ether

10

n-butyl acylate

10

Styrene

10

alpha-pinene

10

Phenol

20

alpha-methyl styrene

10

beta-pinene

10

4-methyl styrene

10

trans-B-methyl styrene

10

3-methyl styrene

10

2-methyl styrene

10

Dicyclopentadiene

10

Limonene

10

Indene

20

1-phenyl ethanol

20

para, alpha-Dimethyl styrene

20

2,5 dimethyl styrene

20

2,4 dimethyl styrene

20

2-phenyl ethanol (phenylethanol)

20

2-Ethyl Phenol

50

2,4 Dimethyl Phenol

20

4-Ethyl Phenol (co elutes with 3-ethylphenol)

20

2-Phenoxy-1-propanol

50

2-Phenoxy ethanol

50

4-isopropylphenol

50

1-Phenoxy-2-Propanol

20

Styrene Glycol

50

1.3 Other refinery hydrocarbon fractions and their mixtures may be tested using the same test method conditions. However, the precision of this test method reflects the compounds in Table 1.

1.4 Results are reported to the nearest 1.0 mg/kg.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7845 − 13

StandardTest Method for

Determination of Chemical Species in Marine Fuel Oil by

Multidimensional Gas Chromatography – Mass

Spectrometry

This standard is issued under the fixed designation D7845; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope and Control Charting Techniques to Evaluate Analytical

Measurement System Performance

1.1 This test method covers the quantitative determination

of a variety of chemical species in marine fuel oil (bunker fuel

3. Terminology

oil) by gas chromatography – mass spectrometry. By using the

same conditions and by selecting required mass spectral

3.1 Definitions:

selected ions, the test method may be used for the determina-

3.1.1 direct or open split interface, n—anyGC/MSinterface

tion of other species than those for which precision statements

used to maintain atmospheric pressure at capillary column

and limits of detection have been established.

outlet.

1.2 An example list of chemical species for which a limit of

3.1.2 reconstructed ion chromatogram (RIC), n—a limited

quantification has been determined by means of this test

mass chromatogram representing the intensities of ion mass

method is given in Table 1.

spectrometric currents for only those ions having particular

1.3 Other refinery hydrocarbon fractions and their mixtures

mass to charge ratios used in this test method to selectively

maybetestedusingthesametestmethodconditions.However, extract and identify components in the presence of a complex

the precision of this test method reflects the compounds in

hydrocarbon matrix.

Table 1.

3.1.3 total ion chromatogram (TIC), n—mass spectrometer

1.4 Results are reported to the nearest 1.0 mg/kg.

computer output representing either the summed intensities of

all scanned ion currents or a sample of the current in the ion

1.5 The values stated in SI units are to be regarded as

beam for each spectrum scan plotted against the corresponding

standard. No other units of measurement are included in this

spectrum number.

standard.

1.6 This standard does not purport to address all of the 3.1.4 wall coated open tubular (WCOT), n—a type of

safety concerns, if any, associated with its use. It is the capillary column prepared by coating or bonding the inside

responsibility of the user of this standard to establish appro- wall of the capillary with a thin film of stationary phase.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 4. Summary of Test Method

4.1 Asuitable internal standard, ethylbenzene d-10 is added

2. Referenced Documents

to the sample, which is then introduced into a gas chromato-

2.1 ASTM Standards:

graph equipped with two columns configured with a Deans

D4307 Practice for Preparation of Liquid Blends for Use as

switching system between the two columns. The sample first

Analytical Standards

passes through the polydimethylsiloxane (WCOT) pre-column

D6299 Practice for Applying Statistical Quality Assurance

which then performs a separation of the light hydrocarbon

fractionandeliminatesthehighboilinghydrocarbonfractionto

vent. The compounds of interest and internal standard are

This test method is under the jurisdiction of ASTM Committee D02 on

transferred to the high resolution polydimethylsiloxane

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

(WCOT) analytical column for chromatographic separation.

Subcommittee D02.04.0M on Mass Spectroscopy.

An auxiliary carrier gas is used to elute higher boiling

Current edition approved April 1, 2013. Published May 2013. DOI: 10.1520/

D7845-13.

hydrocarbons from the pre-column in back flush mode in order

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

to prepare for the next analysis cycle. The resulting chromato-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

gram is then processed by mass spectral analysis based on

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. selected or extracted ion monitoring.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7845 − 13

TABLE 1 Component Table

6.1.2 Pre-Column Column—WCOT Column, 25 m long by

Limit of Quantitation 0.53-mm inside diameter fused silica WCOT column with a

mg/kg

1.0-micron film thickness of polydimethyl siloxane or any

n-butyl alcohol 10

column with suitable chromatographic resolution.

Cyclohexanol 10

n-butyl ether 10 6.1.3 Analytical Column—WCOT Column, 100 m by

n-butyl acylate 10

0.25-mm inside diameter fused silica WCOT column with a

Styrene 10

0.5-micron film thickness of polydimethyl siloxane or any

alpha-pinene 10

Phenol 20

column with suitable chromatographic resolution.

alpha-methyl styrene 10

6.1.4 Purged Packed Injector—Aninjectionportthatallows

beta-pinene 10

controlled injection of the sample at a temperature sufficient to

4-methyl styrene 10

trans-B-methyl styrene 10

pass the high boiling point fraction to the pre-column or any

3-methyl styrene 10

gas chromatographic injector system to perform the same

2-methyl styrene 10

function.

Dicyclopentadiene 10

Limonene 10

6.1.4.1 The injection port liner shall be replaced to remove

Indene 20

non-volatile materials.

1-phenyl ethanol 20

6.1.5 Electronic Pressure Control—Electronic pneumatic

para, alpha-Dimethyl styrene 20

2,5 dimethyl styrene 20

control of carrier gas flows. It can be flow or pressure

2,4 dimethyl styrene 20

programmed to speed up elution of components.

2-phenyl ethanol (phenylethanol) 20

6.1.6 Low-Volume Connector and Tees—A special union or

2-Ethyl Phenol 50

2,4 Dimethyl Phenol 20

tee for connecting two lengths of tubing 1.6-mm inside

4-Ethyl Phenol (co elutes with 3-ethylphenol) 20

diameter and smaller; sometimes referred to as a zero dead-

2-Phenoxy-1-propanol 50

volume union, tee, or an active splitting device.

2-Phenoxy ethanol 50

4-isopropylphenol 50

6.1.7 Pre-Column—ApolydimethylsiloxaneWCOTcolumn

1-Phenoxy-2-Propanol 20

used to isolate the light hydrocarbons to include methane to

Styrene Glycol 50

n-hexadecane from the higher boiling portion of the sample for

transfer to the analytical column for further separation and

quantification.

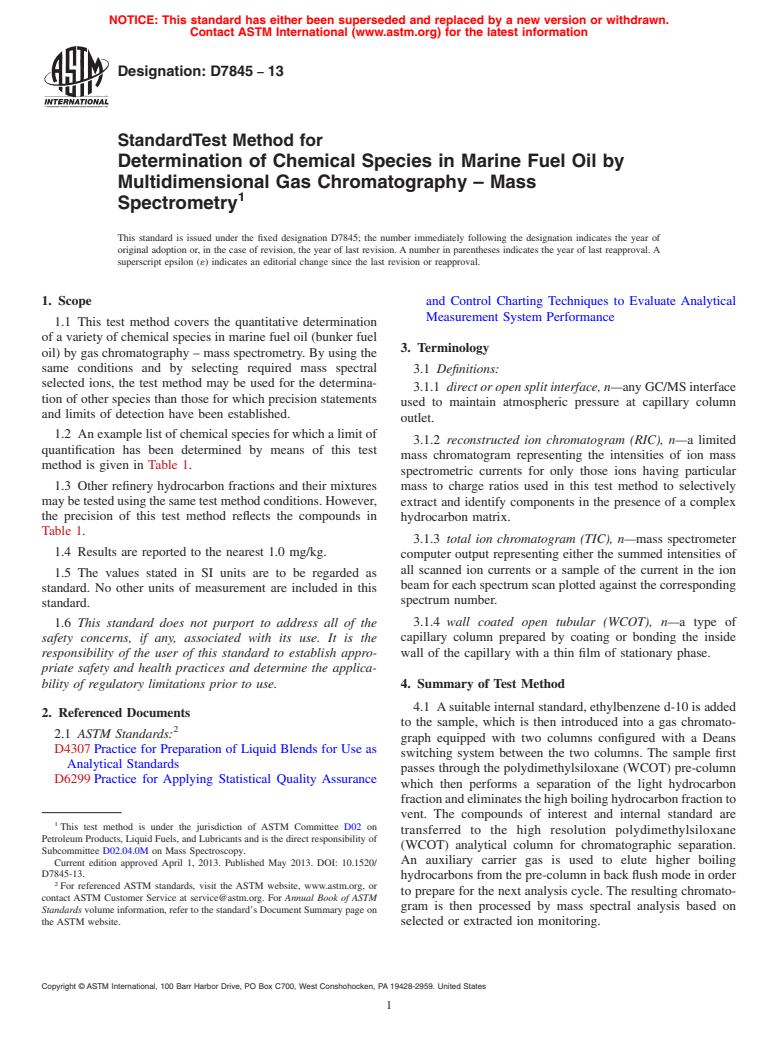

6.1.8 Deans Switching Backflush Configuration (Fig.

1)—Acolumn backflush configuration utilizing dynamic pres-

5. Significance and Use

sure differential which provides suitable means to remove the

5.1 The test method allows the quantitation of chemical

heavier hydrocarbon fraction from the pre-column or any

species at low levels in marine fuel oils and cutter stocks. A

similar configuration that allows for controlled chromato-

great many types and concentrations of chemical species are

graphic separation of components of interest and heavier

foundinmarinefueloils.Arootcauserelationshipbetweenthe

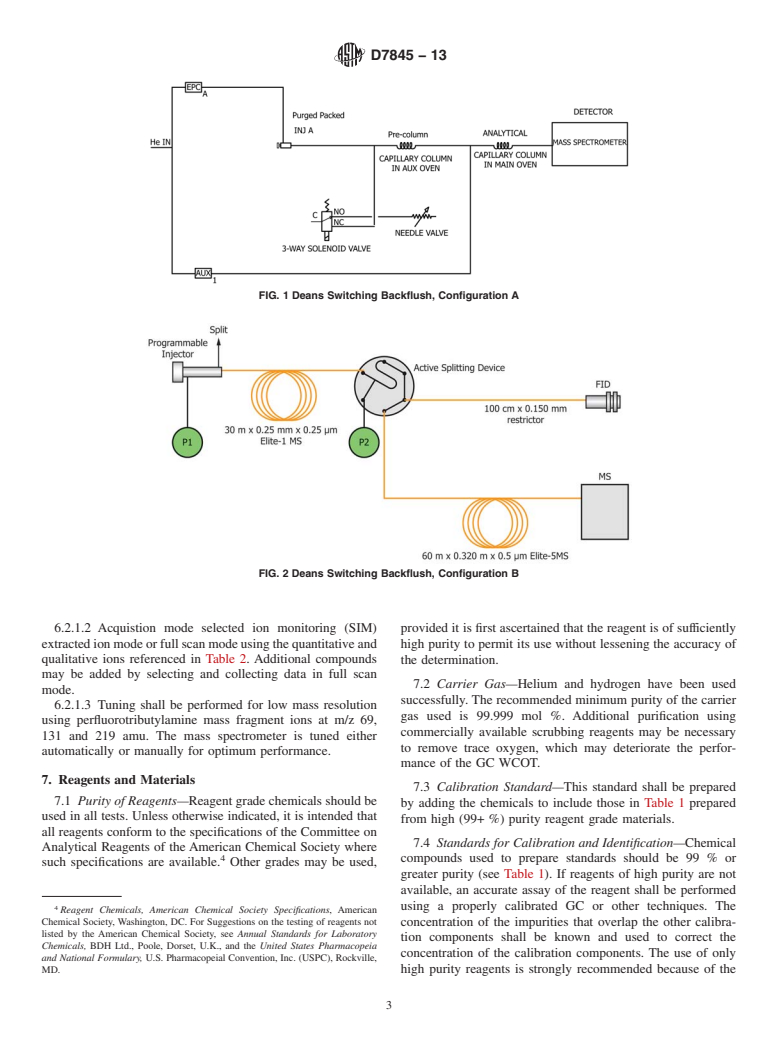

hydrocarbon fraction. An alternative Deans switching back-

presence of such species or their concentration in fuels and any

flush configuration is shown on Fig. 2.

failure modes allegedly induced by the use of these fuels has

6.2 Mass Spectrometry:

not been established. This method is necessary to establish test

conditions required for future ISO 8217:2010 Petroleum 6.2.1 Mass Spectrometer, capable of producing electron

ionization spectra at 70 electron volts or higher, and capable of

products- Fuels (class F)-Specifications of marine fuel oils as

scanning the range of the specified quantitation masses or

defined in section 5.5 and Annex B item (d). Additional

(m/e). The mass scan range shall cover the masses of interest

compounds may be determined by using the same conditions

for quantitation and should yield at least 5 scans across the

and by selecting required mass spectral selected ions, accord-

ingly. peak width at half peak width fora1to3 mg/kg ethylbenzene

d10 peak and cover the masses of interest for quantitation. A

6. Apparatus scan range set for specific ions is defined in Table 2.

6.2.1.1 The mass spectrometer shall be capable of being

6.1 Gas Chromatography:

interfaced to a gas chromatograph and WCOT columns. The

6.1.1 Gas Chromatograph—Any gas chromatograph

interface shall be at a high enough temperature to prevent

equipped with a flame ionization detector (FID) and having

condensation of components boiling up to 350°C. Usually,

sensitivity of 0.01 mg/kg. The gas chromatograph must be

20°C above the final column temperature is adequate. Direct

capable of linear temperature control from 50 to 320°C for the

column interface to the mass spectrometer may be used. An

capillary column oven. The gas chromatograph must be ca-

open split interface with computer controlled programmable

pable of controlling multiple valve events. Carrier gas flow

flowcontroller(s)mayalsobeused,tomaintainallcomponents

controllers and or electronic pressure control modules shall be

within the linearity of the mass spectrometer and at the same

capable of precise control where the required flow rates are

time maintain detectability of lower concentration chemical

low. Pressure control devices and gauges shall be capable of

components.

precise control for the typical pressures required.The tempera-

ture program rate must repeat to within 0.1°C and provide

retention time repeatability of 0.05 min throughout the tem-

perature program. Deans, David R., Chromatographia, Vol 1, 18-22, 1968.

D7845 − 13

FIG. 1 Deans Switching Backflush, Configuration A

FIG. 2 Deans Switching Backflush, Configuration B

6.2.1.2 Acquistion mode selected ion monitoring (SIM) provided it is first ascertained that the reagent is of sufficiently

extractedionmodeorfullscanmodeusingthequantitativeand high purity to permit its use without lessening the accuracy of

qualitative ions referenced in Table 2. Additional compounds

the determination.

may be added by selecting and collecting data in full scan

7.2 Carrier Gas—Helium and hydrogen have been used

mode.

successfully. The recommended minimum purity of the carrier

6.2.1.3 Tuning shall be performed for low mass resolution

gas used is 99.999 mol %. Additional purification using

using perfluorotributylamine mass fragment ions at m/z 69,

commercially available scrubbing reagents may be necessary

131 and 219 amu. The mass spectrometer is tuned either

to remove trace oxygen, which may deteriorate the perfor-

automatically or manually for optimum performance.

mance of the GC WCOT.

7. Reagents and Materials

7.3 Calibration Standard—This standard shall be prepared

7.1 Purity of Reagents—Reagent grade chemicals should be

by adding the chemicals to include those in Table 1 prepared

used in all tests. Unless otherwise indicated, it is intended that

from high (99+ %) purity reagent grade materials.

all reagents conform to the specifications of the Committee on

7.4 Standards for Calibration and Identification—Chemical

Analytical Reagents of the American Chemical Society where

compounds used to prepare standards should be 99 % or

such specifications are available. Other grades may be used,

greater purity (see Table 1). If reagents of high purity are not

available, an accurate assay of the reagent shall be performed

using a properly calibrated GC or other techniques. The

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not concentration of the impurities that overlap the other calibra-

listed by the American Chemical Society, see Annual Standards for Laboratory

tion components shall be known and used to correct the

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

concentration of the calibration components. The use of only

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

MD. high purity reagents is strongly recommended because of the

D7845 − 13

TABLE 2 Mass Spectrometer Compound Quantitation Ions (Retention Time Data Based on Configuration A)

Retention Compound CAS # Quantifying Qualifier 1 Qualifier 2 Qualifier 3

Time

21.55 Ethylbenzene-d10 25837-05-2 116 115

13.55 n-butyl alcohol 71-36-3 56 74

22.58 Cyclohexanol 108-93-0 82 100 44

22.61 n-butyl ether 142-96-1 87 101 130

22.78 n-butyl acylate 141-32-2 55 128 73

23.23 Styrene 100-42-5 104

26.03 alpha-pinene 80-56-8 93 136 121

26.66 Phenol 108-95-2 94 66

27.79 alpha-methyl styrene 98-83-9 118 103

28.21 beta-pinene 19902-08-0 93 136 121

28.46 4-methyl styrene 622-97-9 117 118 116 103

28.57 trans-B-methyl styrene 873-66-5 117 118 103 77

28.66 3-methyl styrene 100-80-1 117 118 116 103

29.95 2-methyl styrene 611-15-4 117 118 103 77

30.11 Dicyclopentadiene 77-73-6 66 132

30.43 Limonene 5989-27-5 68 93 136 121

31.11 Indene 95-13-6 116 115 63 89

31.16 1-phenyl ethanol 98-85-1 107 122 79

32.93 para, alpha-Dimethyl styrene 1195-32-0 132 117 102

33.29 2,5 dimethyl styrene 2039-89-6 132 117 77

33.47 2,4 dimethyl styrene 2234-20-0 132 117 77

33.57 2-phenyl ethanol (phenylethanol) 60-12-8 122 103 77

34.05 2-Ethyl Phenol 90-00-6 107 122 77

34.55 2,4 Dimethyl Phenol 105-67-9 122 107 77

35.13 4-Ethyl Phenol (co elutes with 3-ethylphenol) 123-07-9 107 122 77

3-ethylphenol (co elution) 620-17-7

35.86 2-Phenoxy-1-propanol 4169-04-4 105 136 77

37.43 2-Phenoxy ethanol 122-99-6 94 138 77

37.51 4-isopropylphenol 99-89-8 121 136 94 77

38.53 1-Phenoxy-2-Propanol 770-35-4 94 152 108 77

40.53 Styrene Glycol 25779-13-9 107 138 79

error that may be introduced from impurity corrections. Stan- analytical column and potentially interfering with the determi-

dards are used for calibration as well as for establishing the nation of compounds of interest.

identification by retention time in conjunction with mass

8.4 Setting the Backflush Time for Configuration A—The

spectral match.

pre-column connected to the analytical column and the mass

7.5 n-hexadecane—99+ % purity or better. spectrometer as shown in Fig. 1 inject the calibration standard

andrecordthechromatogram.Identifythepeaks.Theretention

7.6 Dilution Solvents—Reagent grade toluene, 99.9 % (or

time data are used to set the valve on time to assure the

suitable dilution solvent).

compound peaks are not backflushed. The retention times

7.7 Internal Standards—Deuteratedanalogofethylbenzene,

should be incorporated into the software timed events before

as specified, shall be used as internal standard because of the

continuing with sample analysis. Assure all of the compounds

similar chromatographic characteristics as the components

of interest are

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.