ASTM D3432-89(1996)e1

(Test Method)Standard Test Method for Unreacted Toluene Diisocyanates in Urethane Prepolymers and Coating Solutions by Gas Chromatography (Withdrawn 2004)

Standard Test Method for Unreacted Toluene Diisocyanates in Urethane Prepolymers and Coating Solutions by Gas Chromatography (Withdrawn 2004)

SCOPE

1.1 This test method covers the determination of free toluene diisocyanates in urethane prepolymers and unpigmented coating solutions.

Note 1-This test method may also be useful for the determination of free isocyanate monomers of other types upon taking precautions to confirm suitability.

1.2 There is no reason to believe this test method would not work for pigmented coatings.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific hazard statement, see Section 8.

WITHDRAWN RATIONALE

This test method covers the determination of free toluene diisocyanates in urethane prepolymers and unpigmented coating solutions.

Formerly under the jurisdiction of Committee D01 on Paint and Related Coatings, Materials, and Applications, this test method was withdrawn in December 2004 in accordance with section 10.6.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:D3432–89(Reapproved 1996)

Standard Test Method for

Unreacted Toluene Diisocyanates in Urethane Prepolymers

and Coating Solutions by Gas Chromatography

This standard is issued under the fixed designation D 3432; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Editorial changes were made throughout in November 1996.

1. Scope internal standard, and a response factor is calculated from the

standard solution. The unreacted diisocyanate content of the

1.1 This test method covers the determination of free

unknown is calculated from the chromatogram of the speci-

toluene diisocyanates in urethane prepolymers and unpig-

men.

mented coating solutions.

NOTE 1—This test method may also be useful for the determination of 4. Significance and Use

free isocyanate monomers of other types upon taking precautions to

4.1 This test method provides a measurement of the unre-

confirm suitability.

acted diisocyanate content of urethane prepolymers and coat-

1.2 There is no reason to believe this test method would not

ing solutions. This measurement is of basic importance to the

work for pigmented coatings.

health of the users.

1.3 The values stated in inch-pound units are to be regarded

5. Interferences

as the standard. The values given in parentheses are for

information only.

5.1 Under the test conditions described in this test method,

1.4 This standard does not purport to address all of the

other diisocyanates or impurities having identical or nearly

safety concerns, if any, associated with its use. It is the

identical elution times may interfere. It is generally necessary

responsibility of the user of this standard to establish appro-

to know the identity of the diisocyanate being used in the

priate safety and health practices and determine the applica-

specimen being tested, either by knowledge of the composition

bility of regulatory limitations prior to use. For a specific

or by a separate analysis.

hazard statement, see Section 8.

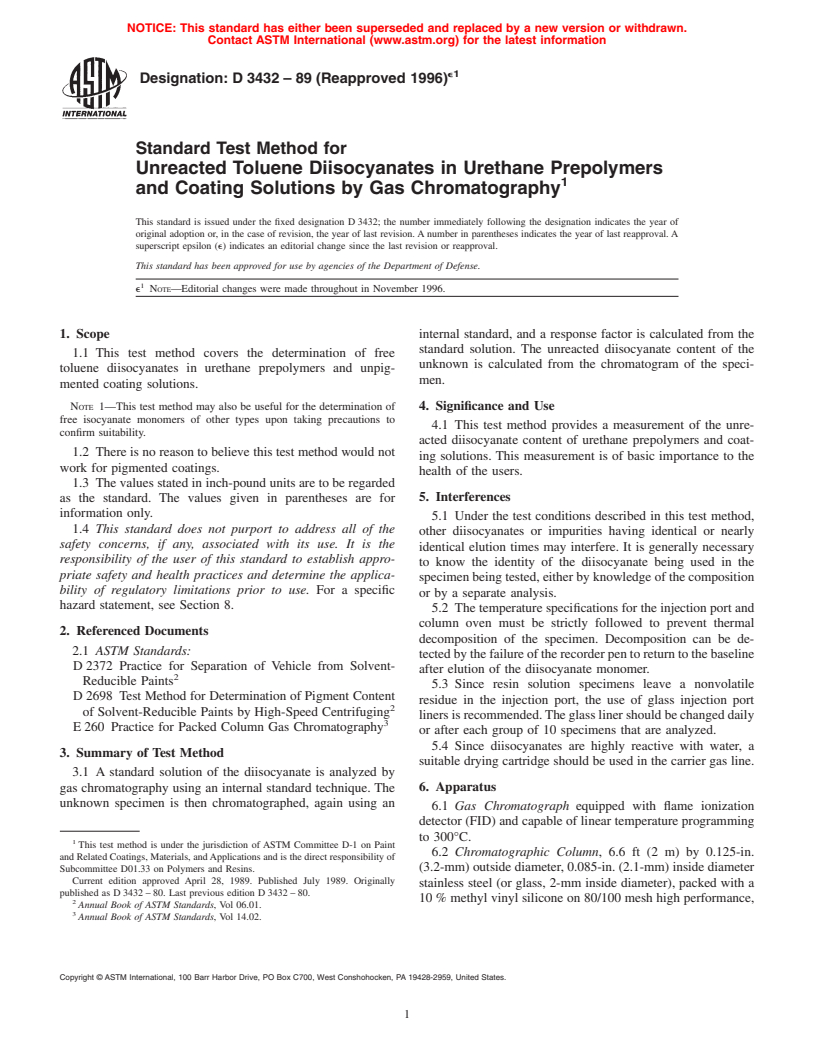

5.2 The temperature specifications for the injection port and

column oven must be strictly followed to prevent thermal

2. Referenced Documents

decomposition of the specimen. Decomposition can be de-

2.1 ASTM Standards:

tectedbythefailureoftherecorderpentoreturntothebaseline

D 2372 Practice for Separation of Vehicle from Solvent-

after elution of the diisocyanate monomer.

Reducible Paints

5.3 Since resin solution specimens leave a nonvolatile

D 2698 Test Method for Determination of Pigment Content

residue in the injection port, the use of glass injection port

of Solvent-Reducible Paints by High-Speed Centrifuging

linersisrecommended.Theglasslinershouldbechangeddaily

E 260 Practice for Packed Column Gas Chromatography

or after each group of 10 specimens that are analyzed.

5.4 Since diisocyanates are highly reactive with water, a

3. Summary of Test Method

suitable drying cartridge should be used in the carrier gas line.

3.1 A standard solution of the diisocyanate is analyzed by

gas chromatography using an internal standard technique. The 6. Apparatus

unknown specimen is then chromatographed, again using an

6.1 Gas Chromatograph equipped with flame ionization

detector (FID) and capable of linear temperature programming

to 300°C.

This test method is under the jurisdiction of ASTM Committee D-1 on Paint

6.2 Chromatographic Column, 6.6 ft (2 m) by 0.125-in.

and Related Coatings, Materials, andApplications and is the direct responsibility of

(3.2-mm) outside diameter, 0.085-in. (2.1-mm) inside diameter

Subcommittee D01.33 on Polymers and Resins.

Current edition approved April 28, 1989. Published July 1989. Originally

stainless steel (or glass, 2-mm inside diameter), packed with a

published as D 3432 – 80. Last previous edition D 3432 – 80.

10 % methyl vinyl silicone on 80/100 mesh high performance,

Annual Book of ASTM Standards, Vol 06.01.

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3432

white, flux-calcined diatomaceous earth. The packing is pre- impermeable gloves (for example, rubber, polyethylene, etc.)

pared by dissolving 1.0 g of the methyl vinyl silicone in 50 mL when handling these materials. Consult the manufacturer’s

of methylene chloride. This solution is placed in an evaporat- Material Safety Data Sheet (MSDS) before handling any of

ing dish and9gofthe diatomaceous earth is added with gentle these materials.

stirring. The evaporating dish may be gently heated on a steam

bathorevaporatedatroomtemperature.Thepackingshouldbe 9. Procedure

gently stirred, periodically, until dry and free-flowing.Anewly

9.1 Prepare the gas chromatograph (refer to Practice E 260)

packed column should be conditioned overnight at 200°C with

as follows:

a flow of dry carrier gas.

9.1.1 Injection Port Temperature—150°C. When first using

the method, it may be desirable to experiment with slightly

NOTE 2—Any other column, either packed or capillary, may be substi-

tuted if the required separation is obtained. higherandlowertemperaturestodetermineiftheinjectionport

NOTE 3—Other methods of packing preparation may be used, provided

temperature is high enough for complete volatilization of the

a free-flowing, uniformly coated packing results.

monomer, but low enough to avoid decomposition of the

polymer (see 5.2).

6.3 Chromatographic Syringe,10µL.

9.1.2 Oven Temperature—150°C (for TDI). For other iso-

6.4 Analytical Balance, accurate to 0.1 mg.

6.5 Glassware—All glassware used should be oven-dried to cyanates, isothermal or temperature programmed analysis may

be necessary.

eliminate moisture.

6.6 Recorder, Recording Integrator or Computer with ap- 9.1.3 Detector Temperature—300°C.

9.1.4 Carrier Gas—Dry helium or nitrogen (see 5.4), flow

propriate software.

rate adjusted to obtain proper elution time (3.7 min) of the

7. Reagents and Materials

internal standard (30 mL/min nominal).

7.1 Purity of Reagents—Reagent grade chemicals shall be 9.2 Separation may be required for products containing

used in all tests. Unless otherwise indicated, it is intended that pigments.Pigmentsmayberemovedusingproceduresgivenin

all reagents shall conform to t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.