ASTM F2736-13e1

(Specification)Standard Specification for 6 to 30 in. (152 To 762 mm) Polypropylene (PP) Corrugated Single Wall Pipe And Double Wall Pipe (Withdrawn 2018)

Standard Specification for 6 to 30 in. (152 To 762 mm) Polypropylene (PP) Corrugated Single Wall Pipe And Double Wall Pipe (Withdrawn 2018)

SCOPE

1.1 This specification covers requirements and test methods for materials, dimensions, workmanship, elongation, brittleness, pipe stiffness, and markings for single wall corrugated polypropylene (PP) pipe and double wall corrugated polypropylene (PP) pipe. It covers nominal sizes 6 in. through 30 in. (152 mm through 762 mm).

1.2 The corrugated polypropylene pipes governed by this standard are intended for use in non-pressure applications for sanitary sewers, storm sewers and drainage pipes. Single wall corrugated polypropylene pipe shall not be used for sanitary sewer applications.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This specification covers requirements and test methods for materials, dimensions, workmanship, elongation, brittleness, pipe stiffness, and markings for single wall corrugated polypropylene (PP) pipe and double wall corrugated polypropylene (PP) pipe. It covers nominal sizes 6 in. through 30 in. (152 mm through 762 mm).

Formerly under the jurisdiction of Committee F17 on Plastic Piping Systems, this specification was withdrawn in February 2018 and replaced by F3219 Specification for 3 to 30 in. (75 to 750 mm) Polypropylene (PP) Corrugated Single Wall Pipe and Fittings.1

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:F2736 −13 An American National Standard

Standard Specification for

6 to 30 in. (152 To 762 mm) Polypropylene (PP) Corrugated

Single Wall Pipe And Double Wall Pipe

This standard is issued under the fixed designation F2736; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—8.7 was editorially corrected in December 2014.

1. Scope* D792 Test Methods for Density and Specific Gravity (Rela-

tive Density) of Plastics by Displacement

1.1 This specification covers requirements and test methods

D1238 Test Method for Melt Flow Rates of Thermoplastics

for materials, dimensions, workmanship, elongation,

by Extrusion Plastometer

brittleness, pipe stiffness, and markings for single wall corru-

D1505 Test Method for Density of Plastics by the Density-

gated polypropylene (PP) pipe and double wall corrugated

Gradient Technique

polypropylene (PP) pipe. It covers nominal sizes 6 in. through

D1600 Terminology forAbbreviatedTerms Relating to Plas-

30 in. (152 mm through 762 mm).

tics

1.2 The corrugated polypropylene pipes governed by this

D2122 Test Method for Determining Dimensions of Ther-

standard are intended for use in non-pressure applications for

moplastic Pipe and Fittings

sanitary sewers, storm sewers and drainage pipes. Single wall

D2321 PracticeforUndergroundInstallationofThermoplas-

corrugated polypropylene pipe shall not be used for sanitary

tic Pipe for Sewers and Other Gravity-Flow Applications

sewer applications.

D2412 Test Method for Determination of External Loading

1.3 The values stated in inch-pound units are to be regarded

Characteristics of Plastic Pipe by Parallel-Plate Loading

as standard. The values given in parentheses are mathematical

D2444 Test Method for Determination of the Impact Resis-

conversions to SI units that are provided for information only

tance of Thermoplastic Pipe and Fittings by Means of a

and are not considered standard.

Tup (Falling Weight)

1.4 This standard does not purport to address all of the

D2990 Test Methods for Tensile, Compressive, and Flexural

safety concerns, if any, associated with its use. It is the

Creep and Creep-Rupture of Plastics

responsibility of the user of this standard to establish appro-

D3212 Specification for Joints for Drain and Sewer Plastic

priate safety and health practices and determine the applica-

Pipes Using Flexible Elastomeric Seals

bility of regulatory limitations prior to use.

D3895 Test Method for Oxidative-Induction Time of Poly-

olefins by Differential Scanning Calorimetry

2. Referenced Documents

D4101 Specification for Polypropylene Injection and Extru-

2.1 ASTM Standards:

sion Materials

D256 Test Methods for Determining the Izod Pendulum

D6992 Test Method for Accelerated Tensile Creep and

Impact Resistance of Plastics

Creep-Rupture of Geosynthetic Materials Based on Time-

D618 Practice for Conditioning Plastics for Testing

Temperature Superposition Using the Stepped Isothermal

D638 Test Method for Tensile Properties of Plastics

Method

D790 Test Methods for Flexural Properties of Unreinforced

F412 Terminology Relating to Plastic Piping Systems

and Reinforced Plastics and Electrical Insulating Materi-

F477 Specification for Elastomeric Seals (Gaskets) for Join-

als

ing Plastic Pipe

This test method is under the jurisdiction of ASTM Committee F17 on Plastic

2.2 American Association of State Highway and transpor-

Piping Systems and is the direct responsibility of Subcommittee F17.26 on Olefin

tation Offıcials (AASHTO) Standard:

Based Pipe.

AASHTO LRFD Bridge Design Specifications

Current edition approved Nov. 1, 2013. Published December 2013. Originally

approved in 2010. Last previous edition approved in 2012 as F2736-12. DOI:

10.1520/F2736–13E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Association of State Highway and Transportation

Standards volume information, refer to the standard’s Document Summary page on Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 2001,

the ASTM website. http://www.transportation.org

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F2736−13

2.3 Transportation Research Record: least two years from the date of manufacture without degrada-

TRR No. 2028 , “Guidelines for Interpreting AASHTO tion of the stated properties.

Specifications to Design or Evaluate Buried Structures

4.3 Rework Material—Clean polypropylene rework

with Comprehensive Solution Methods,” 2007.

material, generated from the manufacturer’s own production of

the product and having the same minimum physical properties,

3. Terminology

may be used by the manufacturer, provided that the pipe

3.1 Definitions—Definitions are in accordance with Termi-

produced meets all the requirements of this specification.

nology F412 and abbreviations are accordance with Terminol-

4.4 Rubber Materials—Rubber compounds used in the

ogy D1600, unless otherwise specified.

manufacture of sealing rings or gaskets shall meet the require-

3.2 Definitions of Terms Specific to This Standard:

ments of Specification F477.

3.2.1 double wall pipe, n—corrugated pipe with a coex-

4.5 Lubricant—The lubricant used for assembly of gasketed

truded interior liner.

joints shall have no detrimental effect on the gasket or on the

3.2.2 single wall pipe, n—corrugated pipe without an inte-

pipe.

rior liner.

3.2.3 waterway wall, n—the pipe wall in single wall pipe

5. Joining System

and the interior wall in double wall pipe.

5.1 Bell and Spigot Joint:

5.1.1 The pipe ends shall consist of integrally formed bell

4. Materials

and spigot designed to accommodate a gasket, which when

4.1 Polypropylene—Polypropylene compounds used in the

assembled forms a watertight seal by the radial compression of

manufacture of corrugated single wall and double wall pipe

the gasket between the spigot and the bell ends.

shall have the minimum properties as shown in Table 1.

5.1.2 The joint shall be designed to avoid displacement of

Polypropylene compounds shall be comprised of the base

the gasket when it is assembled in accordance with the

polypropylene virgin material and all additives, colorants, UV

manufacturer’s recommendations.

inhibitors, and stabilizers. Polypropylene compounds can be

5.1.3 The assembly of the joint shall be in accordance with

pre-compounded or made in-situ during pipe extrusion by

the manufacturer’s recommendations.

combining natural polypropylene material with a color master-

5.2 Other Joining Systems—Where these connections are

batch or other additives, or both. Conditioning, sampling,

not practical or undesirable because of space, layout, or other

preparation and testing of molded specimens shall be in

requirements, joining methods such as external snap couplers,

accordance with the requirements in Specification D4101.

split couplers, or other joining methods that are equally

Material for preparation of molded specimens shall be taken

effective are to be used in accordance with the manufacturer’s

from the pipe.

recommendations.

4.2 Color and Ultraviolet (UV) Stabilization— The pipe

shall be colored or black. Black polypropylene compounds

6. Requirements

shall have between 2.0 and 3.0 percent carbon black. Colored

polypropylene compounds shall be protected from Ultraviolet 6.1 Workmanship—The pipe and fittings shall be homoge-

(UV) degradation with UV stabilizers. Colored polypropylene neous throughout and be as uniform as commercially practical

compoundsshallcontainsufficientUVprotectiontoallowpipe in color, opacity, and density. The pipe wall shall be free of

made according to this standard to be stored outdoors for at cracks,holes,blisters,voids,foreigninclusionsorotherdefects

Note-This figure is included for informational purposes only.

FIG. 1Typical Annular Corrugated Profile Wall Polypropylene Pipe with Interior Liner

´1

F2736−13

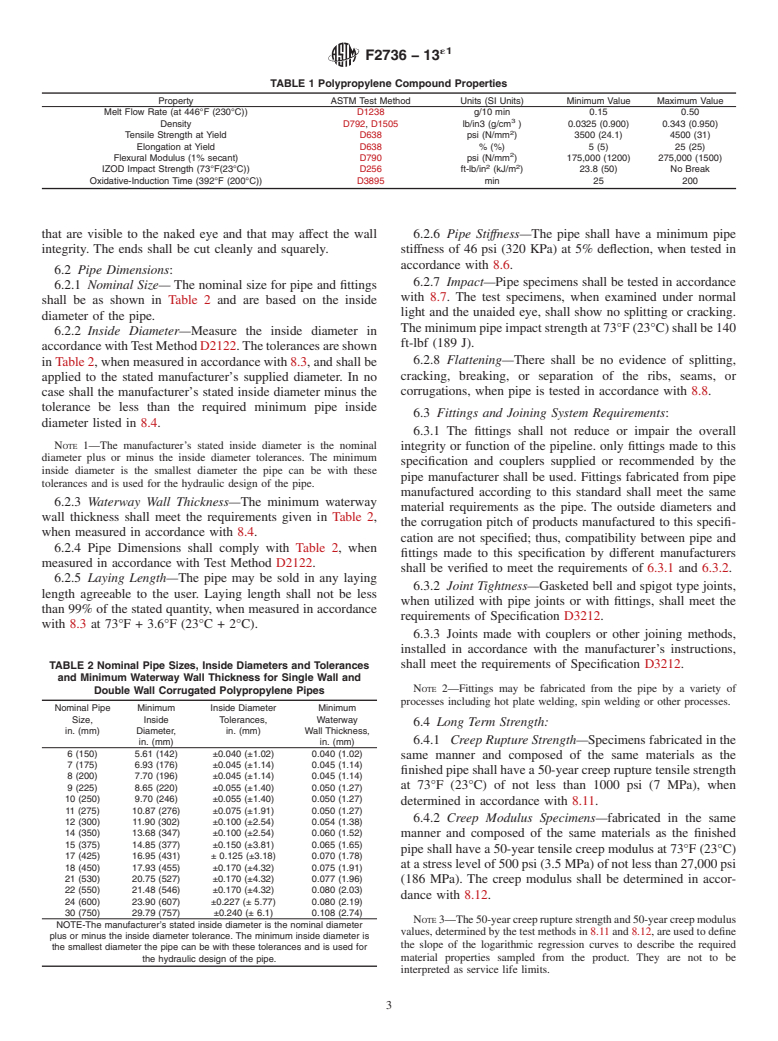

TABLE 1 Polypropylene Compound Properties

Property ASTM Test Method Units (SI Units) Minimum Value Maximum Value

Melt Flow Rate (at 446°F (230°C)) D1238 g/10 min 0.15 0.50

Density D792, D1505 lb/in3 (g/cm ) 0.0325 (0.900) 0.343 (0.950)

Tensile Strength at Yield D638 psi (N/mm ) 3500 (24.1) 4500 (31)

Elongation at Yield D638 % (%) 5 (5) 25 (25)

Flexural Modulus (1% secant) D790 psi (N/mm ) 175,000 (1200) 275,000 (1500)

2 2

IZOD Impact Strength (73°F(23°C)) D256 ft-lb/in (kJ/m ) 23.8 (50) No Break

Oxidative-Induction Time (392°F (200°C)) D3895 min 25 200

that are visible to the naked eye and that may affect the wall 6.2.6 Pipe Stiffness—The pipe shall have a minimum pipe

integrity. The ends shall be cut cleanly and squarely. stiffness of 46 psi (320 KPa) at 5% deflection, when tested in

accordance with 8.6.

6.2 Pipe Dimensions:

6.2.7 Impact—Pipe specimens shall be tested in accordance

6.2.1 Nominal Size— The nominal size for pipe and fittings

with 8.7. The test specimens, when examined under normal

shall be as shown in Table 2 and are based on the inside

light and the unaided eye, shall show no splitting or cracking.

diameter of the pipe.

Theminimumpipeimpactstrengthat73°F(23°C)shallbe140

6.2.2 Inside Diameter—Measure the inside diameter in

ft-lbf (189 J).

accordancewithTestMethodD2122.Thetolerancesareshown

6.2.8 Flattening—There shall be no evidence of splitting,

in Table 2, when measured in accordance with 8.3, and shall be

cracking, breaking, or separation of the ribs, seams, or

applied to the stated manufacturer’s supplied diameter. In no

corrugations, when pipe is tested in accordance with 8.8.

case shall the manufacturer’s stated inside diameter minus the

tolerance be less than the required minimum pipe inside

6.3 Fittings and Joining System Requirements:

diameter listed in 8.4.

6.3.1 The fittings shall not reduce or impair the overall

NOTE 1—The manufacturer’s stated inside diameter is the nominal

integrity or function of the pipeline. only fittings made to this

diameter plus or minus the inside diameter tolerances. The minimum

specification and couplers supplied or recommended by the

inside diameter is the smallest diameter the pipe can be with these

pipe manufacturer shall be used. Fittings fabricated from pipe

tolerances and is used for the hydraulic design of the pipe.

manufactured according to this standard shall meet the same

6.2.3 Waterway Wall Thickness—The minimum waterway

material requirements as the pipe. The outside diameters and

wall thickness shall meet the requirements given in Table 2,

the corrugation pitch of products manufactured to this specifi-

when measured in accordance with 8.4.

cation are not specified; thus, compatibility between pipe and

6.2.4 Pipe Dimensions shall comply with Table 2, when

fittings made to this specification by different manufacturers

measured in accordance with Test Method D2122.

shall be verified to meet the requirements of 6.3.1 and 6.3.2.

6.2.5 Laying Length—The pipe may be sold in any laying

6.3.2 Joint Tightness—Gasketed bell and spigot type joints,

length agreeable to the user. Laying length shall not be less

when utilized with pipe joints or with fittings, shall meet the

than 99% of the stated quantity, when measured in accordance

requirements of Specification D3212.

with 8.3 at 73°F + 3.6°F (23°C + 2°C).

6.3.3 Joints made with couplers or other joining methods,

installed in accordance with the manufacturer’s instructions,

shall meet the requirements of Specification D3212.

TABLE 2 Nominal Pipe Sizes, Inside Diameters and Tolerances

and Minimum Waterway Wall Thickness for Single Wall and

NOTE 2—Fittings may be fabricated from the pipe by a variety of

Double Wall Corrugated Polypropylene Pipes

processes including hot plate welding, spin welding or other processes.

Nominal Pipe Minimum Inside Diameter Minimum

Size, Inside Tolerances, Waterway

6.4 Long Term Strength:

in. (mm) Diameter, in. (mm) Wall Thickness,

6.4.1 Creep Rupture Strength—Specimens fabricated in the

in. (mm) in. (mm)

6 (150) 5.61 (142) ±0.040 (±1.02) 0.040 (1.02)

same manner and composed of the same materials as the

7 (175) 6.93 (176) ±0.045 (±1.14) 0.045 (1.14)

finished pipe shall have a 50-year creep rupture tensile strength

8 (200) 7.70 (196) ±0.045 (±1.14) 0.045 (1.14)

at 73°F (23°C) of not less than 1000 psi (7 MPa), when

9 (225) 8.65 (220) ±0.055 (±1.40) 0.050 (1.27)

10 (250) 9.70 (246) ±0.055 (±1.40) 0.050 (1.27)

determined in accordance with 8.11.

11 (275) 10.87 (276) ±0.075 (±1.91) 0.050 (1.27)

6.4.2 Creep Modulus Specimens—fabricated in the same

12 (300) 11.90 (302) ±0.100 (±2.54) 0.054 (1.38)

14 (350) 13.68 (347) ±0.100 (±2.54) 0.060 (1.52)

manner and composed of the same materials as the finished

15 (375) 14.85 (377) ±0.150 (±3.81) 0.065 (1.65)

pipe shall have a 50-year tensile creep modulus at 73°F (23°C)

17 (425) 16.95 (431) ± 0.125 (±3.18) 0.070 (1.78)

atastresslevelof500psi(3.5MPa)ofnotlessthan27,000psi

18 (450) 17.93 (455) ±0.170 (±4.32) 0.075 (1.91)

21 (530) 20.75 (527) ±0.170 (±4.32) 0.077 (1.96)

(186 MPa). The creep modulus shall be determined in accor-

22 (550) 21.48 (546) ±0.170 (±4.32) 0.080 (2.03)

dance with 8.12.

24 (600) 23.90 (607) ±0.227 (± 5.77) 0.080 (2.19)

30 (750) 29.79 (757) ±0.240 (± 6.1) 0.108 (2.74)

NOTE3—The50-yearcreeprupturestrengthand50-yearcreepmodulus

NOTE-The manufacturer’s stated inside diameter is the nominal diameter

values, determined by the test methods in 8.11 and 8.12, are used to define

plus or minus the inside diameter tolerance. The minimum inside diameter is

the slope of the logarithmic regression curves to describe the required

the smallest diameter the pipe can be with these tolerances and is used for

the hydraulic design of the pipe. material properties sampled from the product. They are not to be

interpreted as service life limits.

´1

F2736−13

6.5 Installation Requirements—The pipe manufacturer shall pitch; (2) Locate the first specimen in the loading machine

provide the purchaser with the requirements for the proper eitheralongamoldlineorwiththeimaginarylinebetweentwo

installation of the pipe and the minimum and maximum corrugations described by the mold line and parallel to the

allowable cover height for specific traffic and non-traffic loading plates. The specimen must lay flat on the plate within

loading conditions. The installation requirements shall be ⁄8 in. (3 mm) and may be straightened by hand bending at

based

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.