ASTM D7043-17

(Test Method)Standard Test Method for Indicating Wear Characteristics of Non-Petroleum and Petroleum Hydraulic Fluids in a Constant Volume Vane Pump

Standard Test Method for Indicating Wear Characteristics of Non-Petroleum and Petroleum Hydraulic Fluids in a Constant Volume Vane Pump

SIGNIFICANCE AND USE

5.1 This test method is an indicator of the wear characteristics of non-petroleum and petroleum hydraulic fluids operating in a constant volume vane pump. Excessive wear in vane pumps could lead to malfunction of hydraulic systems in critical applications.

SCOPE

1.1 This test method covers a constant volume vane pump test procedure operated at 1200 r/min and 13.8 MPa.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.2.1 Exception—There are no SI equivalents for the inch fasteners and inch O-rings that are used in the apparatus in this test method.

1.2.2 Exception—In some cases English pressure values are given in parentheses as a safety measure.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7043 − 17

Standard Test Method for

Indicating Wear Characteristics of Non-Petroleum and

Petroleum Hydraulic Fluids in a Constant Volume Vane

1

Pump

This standard is issued under the fixed designation D7043; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Data for Use in Test Methods for Petroleum Products and

Lubricants

1.1 This test method covers a constant volume vane pump

E177Practice for Use of the Terms Precision and Bias in

test procedure operated at 1200r⁄min and 13.8MPa.

ASTM Test Methods

1.2 The values stated in SI units are to be regarded as

E691Practice for Conducting an Interlaboratory Study to

standard. No other units of measurement are included in this

Determine the Precision of a Test Method

standard.

1.2.1 Exception—There are no SI equivalents for the inch

3. Terminology

fastenersandinchO-ringsthatareusedintheapparatusinthis

3.1 Definitions of Terms Specific to This Standard:

test method.

3.1.1 flushing, v—process of cleaning the test system before

1.2.2 Exception—In some cases English pressure values are

testing to prevent cross-contamination.

given in parentheses as a safety measure.

3.1.2 torquing, v—processoftighteningthepumpheadbolts

1.3 This standard does not purport to address all of the

to achieve a uniform clamping force.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety and health practices and determine the applica-

4.1 An amount of 18.9L 6 0.5L of a hydraulic fluid are

bility of regulatory limitations prior to use.

circulated through a rotary vane pump system for 100h at a

1.4 This international standard was developed in accor-

pump speed of 1200r⁄min 6 60r⁄min and a pump outlet

dance with internationally recognized principles on standard-

pressure of 13.8MPa 6 0.3MPa (2000psi 6 40psi). Fluid

ization established in the Decision on Principles for the

temperature at the pump inlet is 66°C 6 3°C for all water

Development of International Standards, Guides and Recom-

glycols, emulsions, and other water containing fluids and for

mendations issued by the World Trade Organization Technical

petroleum and synthetic fluids of ISO Grade 46 or lighter. A

Barriers to Trade (TBT) Committee.

temperature of 80°C 6 3°C is used for all other synthetic and

petroleum fluids.

2. Referenced Documents

2

4.2 The result obtained is the total mass loss from the cam

2.1 ASTM Standards:

ringandthetwelvevanesduringthetest.Otherreportedvalues

D2882Test Method for Indicating Wear Characteristics of

are initial flow rate and final flow rate.

Petroleum and Non-Petroleum Hydraulic Fluids in Con-

3

stant Volume Vane Pump (Withdrawn 2003)

4.3 Thetotalquantityoftestoilrequiredforarunis26.5L.

D6300Practice for Determination of Precision and Bias

5. Significance and Use

5.1 This test method is an indicator of the wear character-

1

This test method is under the jurisdiction of ASTM Committee D02 on

istics of non-petroleum and petroleum hydraulic fluids operat-

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

ing in a constant volume vane pump. Excessive wear in vane

Subcommittee D02.N0 on Hydraulic Fluids.

CurrenteditionapprovedJuly1,2017.PublishedJuly2017.Originallyapproved

pumps could lead to malfunction of hydraulic systems in

in 2004. Last previous edition approved in 2012 as D7043–12. DOI: 10.1520/

critical applications.

D7043-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6. Apparatus

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

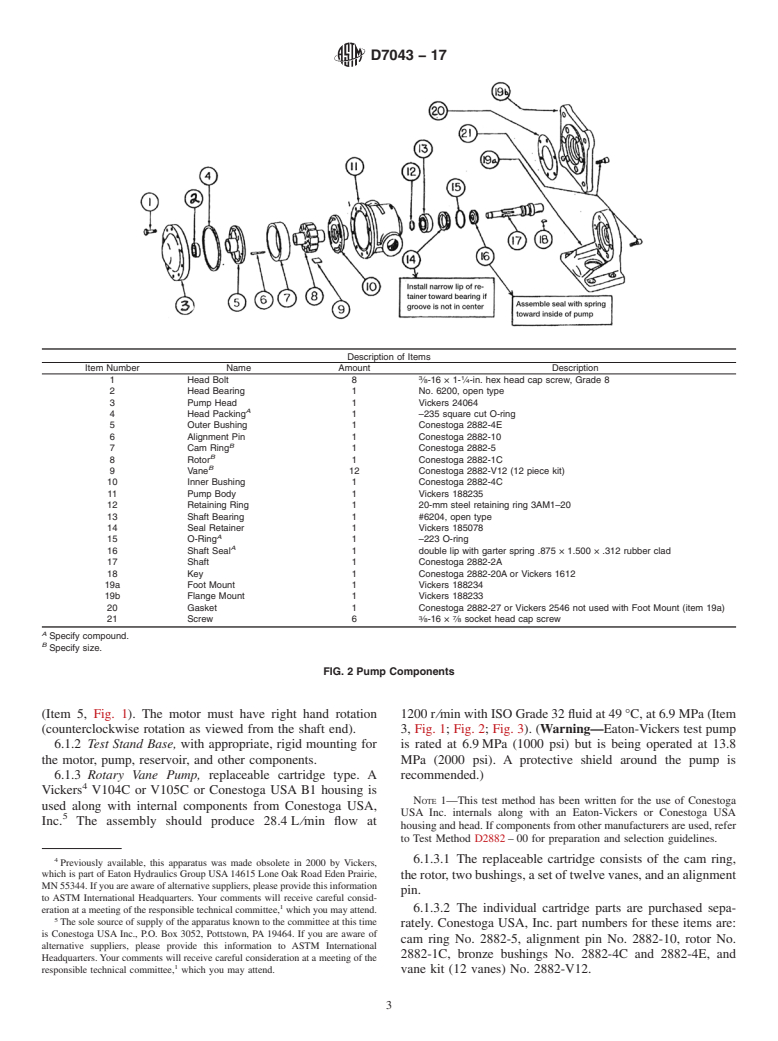

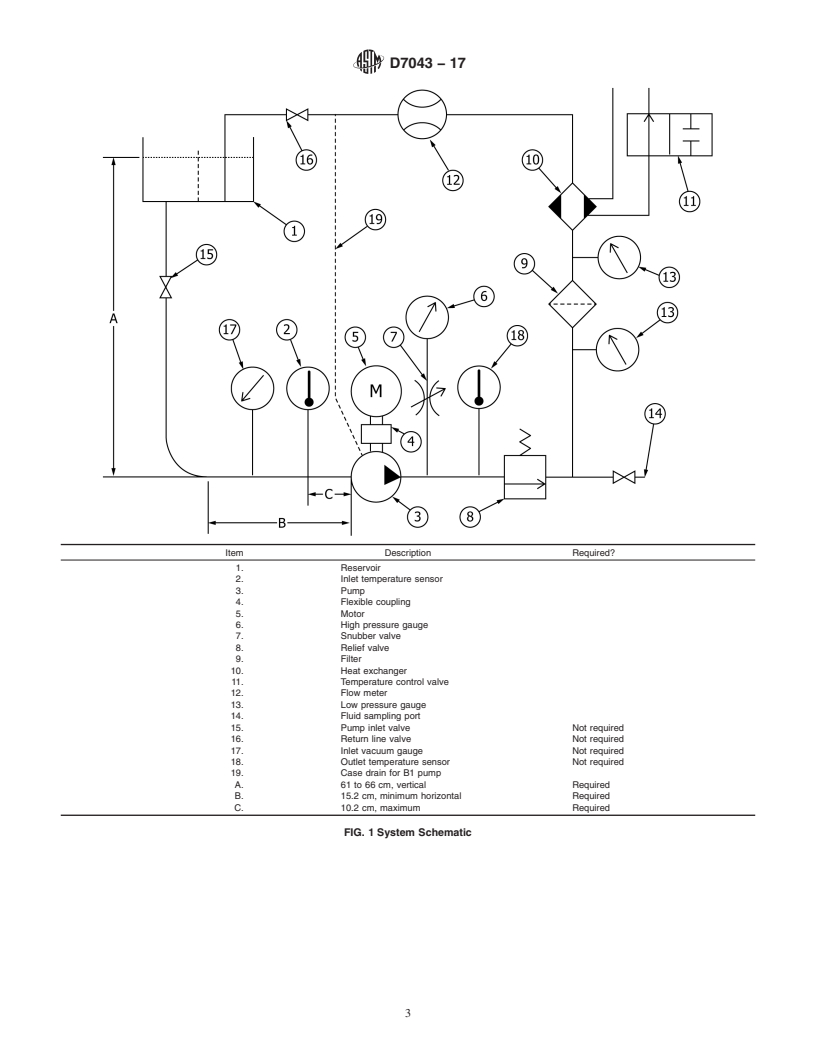

6.1 The basic system consists of the following (see Fig. 1):

the ASTM website.

3

6.1.1 AC Motor, 1200r⁄min, or other suitable drive, with

The last approved version of this historical standard is referenced on

www.astm.org. 11kW (15hp) as suggested minimum power requirement

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7043 − 17

Item Description Required?

1. Reservoir

2. Inlet temperature sensor

3. Pump

4. Flexible coupling

5. Motor

6. High pressure gauge

7. Snubber valve

8. Relief valve

9. Filter

10. Heat exchanger

11. Temperature control valve

12. Flow meter

13. Low pressure gauge

14. Fluid sampling port

15. Pump inlet valve Not required

16. Return line valve Not required

17. Inlet vacuum gau

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7043 − 12 D7043 − 17

Standard Test Method for

Indicating Wear Characteristics of Non-Petroleum and

Petroleum Hydraulic Fluids in a Constant Volume Vane

1

Pump

This standard is issued under the fixed designation D7043; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers a constant volume vane pump test procedure operated at 1200 r ⁄min and 13.8 MPa.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.2.1 Exception—There are no SI equivalents for the inch fasteners and inch O-rings that are used in the apparatus in this test

method.

1.2.2 Exception—In some cases English pressure values are given in parentheses as a safety measure.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D2882 Test Method for Indicating Wear Characteristics of Petroleum and Non-Petroleum Hydraulic Fluids in Constant Volume

3

Vane Pump (Withdrawn 2003)

D6300 Practice for Determination of Precision and Bias Data for Use in Test Methods for Petroleum Products and Lubricants

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 flushing, v—process of cleaning the test system before testing to prevent cross-contamination.

3.1.2 torquing, v—process of tightening the pump head bolts to achieve a uniform clamping force.

4. Summary of Test Method

4.1 An amount of 18.9 L 6 0.5 L of a hydraulic fluid are circulated through a rotary vane pump system for 100 h at a pump

speed of 1200 r ⁄min 6 60 r ⁄min and a pump outlet pressure of 13.8 MPa 6 0.3 MPa (2000 psi 6 40 psi). Fluid temperature at

the pump inlet is 66 °C 6 3 °C for all water glycols, emulsions, and other water containing fluids and for petroleum and synthetic

fluids of ISO Grade 46 or lighter. A temperature of 80 °C 6 3 °C is used for all other synthetic and petroleum fluids.

4.2 The result obtained is the total mass loss from the cam ring and the twelve vanes during the test. Other reported values are

initial flow rate and final flow rate.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.N0 on Hydraulic Fluids.

Current edition approved June 1, 2012July 1, 2017. Published October 2012July 2017. Originally approved in 2004. Last previous edition approved in 20102012 as

D7043D7043 – 12.–10. DOI: 10.1520/D7043-12.10.1520/D7043-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7043 − 17

4.3 The total quantity of test oil required for a run is 26.5 L.

5. Significance and Use

5.1 This test method is an indicator of the wear characteristics of non-petroleum and petroleum hydraulic fluids operating in a

constant volume vane pump. Excessive wear in vane pumps could lead to malfunction of hydraulic systems in critical applications.

6. Apparatus

6.1 The basic system consists of the following (see Fig. 1):

6.1.1 AC Motor, 1200 r ⁄min, or other suitable drive, with 11 kw11 kW (15 hp)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.