ASTM F2548-12(2018)

(Specification)Standard Specification for Expanded Metal Fence Systems for Security Purposes

Standard Specification for Expanded Metal Fence Systems for Security Purposes

ABSTRACT

This specification covers the selection and installation of expanded metal fence systems for applications on new or retrofit fences capable of denying or delaying unwanted access into or out of a commercial, industrial, governmental, or institutional facility as applicable to homeland security, or where the possibility of malevolent incursion is significant. The metal fences can be expanded (Type 1), or expanded and flattened (Type 2); and uncoated (Class 1), hot-dip zinc coated or galvanized (Class 2), or corrosion-resisting steel (Class 3). Fencings shall conform to specified standard sizes and dimensions.

SCOPE

1.1 This specification covers selection and installation of expanded metal fence systems for applications on new or retrofit fences for commercial, industrial, governmental or institutional facilities as applicable to homeland security, or where the possibility of malevolent incursion is significant. See Fig. 1 for typical examples of expanded metal fence applications. This type of fence system is not recommended for residential or public recreational facilities such as pools, schools, and kindergartens.

FIG. 1 Expanded Metal Fencing Applications

1.2 This specification is intended to guide those responsible for or concerned with the design and installation of an expanded metal fence system capable of denying or delaying unwanted access into or out of an area.

1.3 No recommendation is made or implied here as to the merits of the product from any particular manufacturer. Choice of component selection for the expanded metal system should be made by the writer of the project specification based on their own perception of the product’s merit and the consequence of a malevolent incursion.

1.4 The values stated in inch-pound units are to be regarded as standard. Any values given in parentheses are for information only.

1.5 This specification does not purport to address all of the safety and security concerns, if any, associated with homeland security. It is the responsibility of the user of this standard to establish the required and appropriate level of security.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2548 −12 (Reapproved 2018)

Standard Specification for

Expanded Metal Fence Systems for Security Purposes

This standard is issued under the fixed designation F2548; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This specification covers selection and installation of

A123/A123M Specification for Zinc (Hot-Dip Galvanized)

expanded metal fence systems for applications on new or

Coatings on Iron and Steel Products

retrofit fences for commercial, industrial, governmental or

A307 Specification for Carbon Steel Bolts, Studs, and

institutional facilities as applicable to homeland security, or

Threaded Rod 60 000 PSI Tensile Strength

wherethepossibilityofmalevolentincursionissignificant.See

B117 Practice for Operating Salt Spray (Fog) Apparatus

Fig. 1 for typical examples of expanded metal fence applica-

F934 Specification for Standard Colors for Polymer-Coated

tions. This type of fence system is not recommended for

Chain Link Fence Materials

residential or public recreational facilities such as pools,

F1043 Specification for Strength and Protective Coatings on

schools, and kindergartens.

Steel Industrial Fence Framework

F1083 Specification for Pipe, Steel, Hot-Dipped Zinc-

1.2 This specification is intended to guide those responsible

Coated (Galvanized) Welded, for Fence Structures

for or concerned with the design and installation of an

F1267 Specification for Metal, Expanded, Steel

expanded metal fence system capable of denying or delaying

2.2 American Society of Civil Engineers (ASCE):

unwanted access into or out of an area.

ASCE/SEI 7-05 Minimum Design Loads for Buildings and

1.3 No recommendation is made or implied here as to the

Other Structures

merits of the product from any particular manufacturer. Choice

of component selection for the expanded metal system should

3. Terminology

bemadebythewriteroftheprojectspecificationbasedontheir

3.1 Definitions of Terms Specific to This Standard:

own perception of the product’s merit and the consequence of

3.1.1 expanded metal fence system—combines expanded

a malevolent incursion.

metal panels and structural framework posts and rails, if

required with accessories and fasteners, assembled and evalu-

1.4 The values stated in inch-pound units are to be regarded

ated as a complete system. Fig. 1 shows typical applications.

as standard. Any values given in parentheses are for informa-

tion only. 3.1.2 expanded metal panel—element used as filler for the

fence system. The following terms are used to further define

1.5 This specification does not purport to address all of the

characteristics of the expanded metal panels (see Fig. 2 and

safety and security concerns, if any, associated with homeland

Fig. 3).

security. It is the responsibility of the user of this standard to

3.1.3 fitting—any type of formed metal with the intent of

establish the required and appropriate level of security.

securing mesh filler to a framework.

1.6 This international standard was developed in accor-

3.1.4 flattened expanded metal (F)—expanded metal which

dance with internationally recognized principles on standard-

has been cold rolled leaving a flat, smooth surface.

ization established in the Decision on Principles for the

3.1.5 LWD—long way of diamond, nominal dimension (see

Development of International Standards, Guides and Recom-

Fig. 2).

mendations issued by the World Trade Organization Technical

3.1.6 regular (raised) expanded metal (R) —expandedmetal

Barriers to Trade (TBT) Committee.

as it comes from the press after being simultaneously slit and

1 2

This specification is under the jurisdiction ofASTM Committee F14 on Fences For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and is the direct responsibility of Subcommittee F14.35 on Architectural Metal contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Fence Systems. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved March 1, 2018. Published March 2018. Originally the ASTM website.

approved in 2006. Last previous edition approved in 2012 as F2548–12. DOI: Available from American Society of Civil Engineers (ASCE), 1801 Alexander

10.1520/F2548-12R18. Bell Dr., Reston, VA 20191, http://www.asce.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2548−12 (2018)

FIG. 1Expanded Metal Fencing Applications

FIG. 2Diamond Description—Regular and Flattened

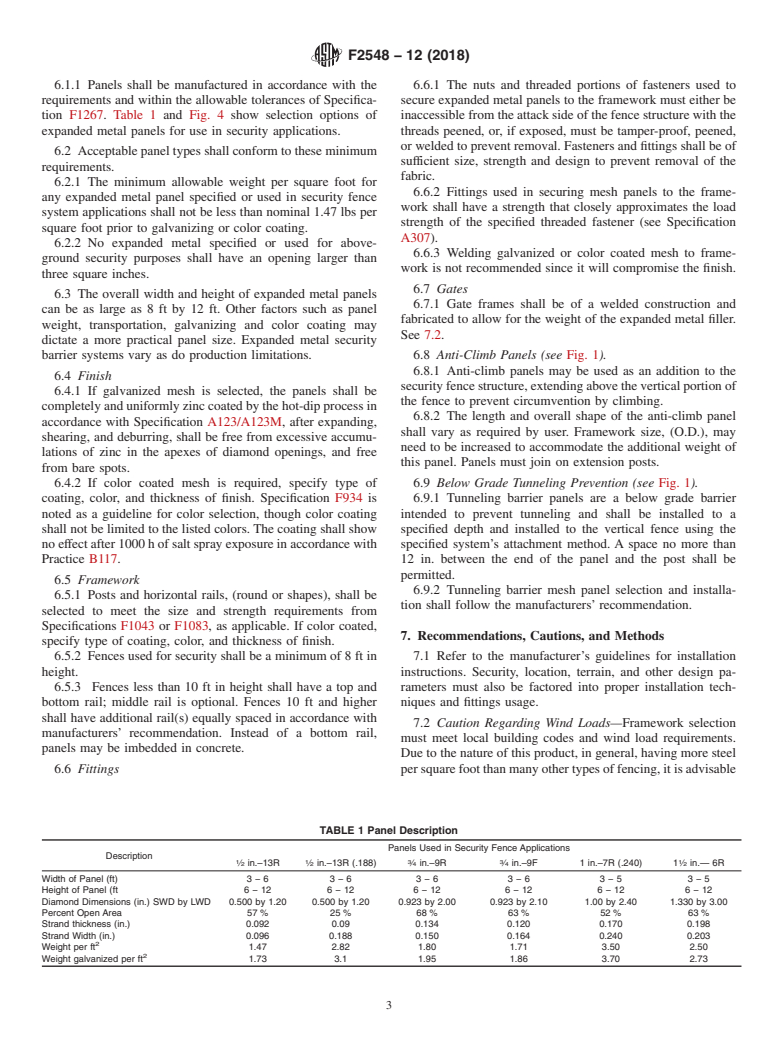

FIG. 3Mesh Description—Standard and Reversed Diamond

process.Constructionofnewexpandedmetalfencesystemsandretrofitof

stretched having the strands and bonds form a uniform angle to

chain link fences historically involved the use of Type 1 expanded metal

the original plane of the solid sheet from which it was formed

panels; retrofit of ornamental picket fences historically involved the use of

creating an open mesh diamond making one continuous panel

Type 2 expanded metal panels.

that cannot unravel.

4.3 Class

3.1.7 SWD—short way of diamond, nominal dimension (see

Fig. 2). 4.3.1 Class 1—Uncoated

4.3.2 Class 2—Hot-dip zinc coated (galvanized)

3.1.8 strand thickness—thickness of base metal.

4.3.3 Class 3—Corrosion-resisting steel

3.1.9 strand width—amount of material fed under the die to

produce one strand.

5. Ordering/Specifying Information

4. Classification

5.1 When ordering or specifying expanded metal fence

4.1 Expanded metal used on fences for security applications

systems for security applications, the appropriate mesh type,

shall meet the material requirements of Specification F1267.

mesh description, fence height, post size, post spacing, allow-

Expanded metal referenced in this specification is classified by

able mesh to framework attachment methods, and finish should

types and classes as follows:

all be defined to ensure that expanded metal panels and all

4.2 Type

associated system components will work compatibly in the

4.2.1 Type 1—Expanded (see Fig. 2 – Type 1)

total system installation.

4.2.2 Type 2—Expanded and flattened (see Fig. 2 – Type 2)

NOTE 1—While it is not the intent of this specification to limit the

6. Materials

selection of expanded metal “Type” to a specific fence application,

historical practice is a relevant factor to consider during the selection 6.1 Expanded Metal Panels

F2548−12 (2018)

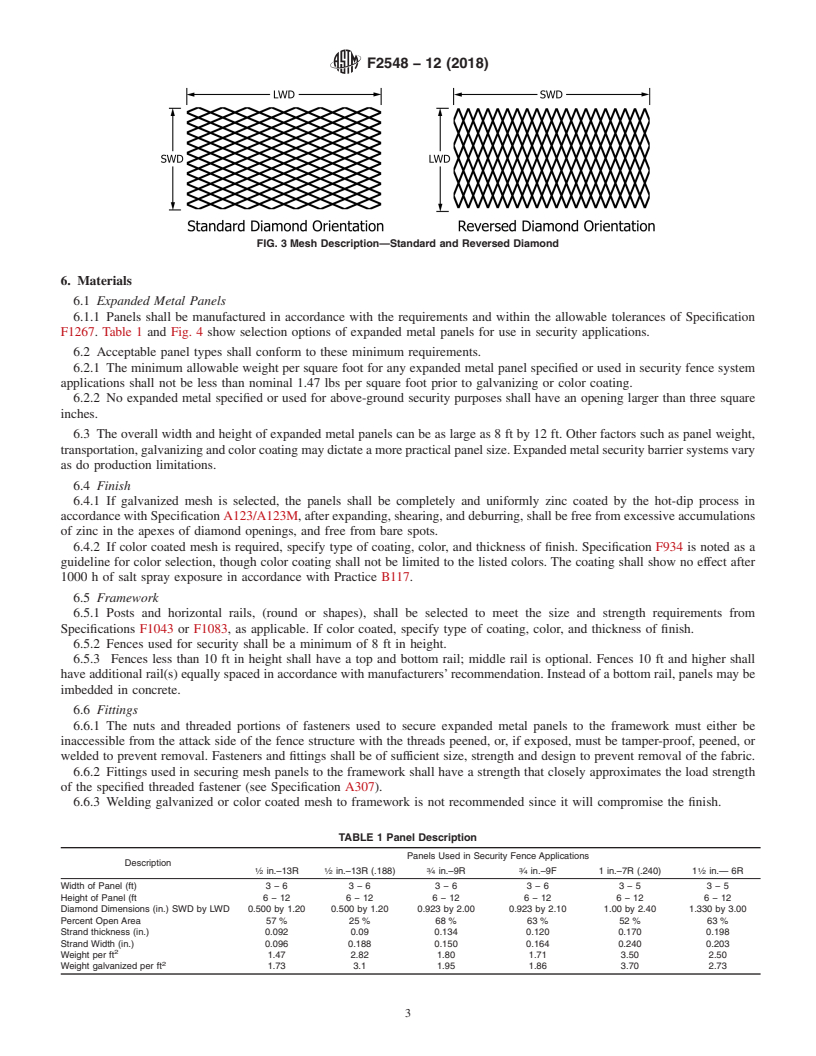

6.1.1 Panels shall be manufactured in accordance with the 6.6.1 The nuts and threaded portions of fasteners used to

requirements and within the allowable tolerances of Specifica- secure expanded metal panels to the framework must either be

tion F1267. Table 1 and Fig. 4 show selection options of inaccessible from the attack side of the fence structure with the

expanded metal panels for use in security applications. threads peened, or, if exposed, must be tamper-proof, peened,

or welded to prevent removal. Fasteners and fittings shall be of

6.2 Acceptable panel types shall conform to these minimum

sufficient size, strength and design to prevent removal of the

requirements.

fabric.

6.2.1 The minimum allowable weight per square foot for

6.6.2 Fittings used in securing mesh panels to the frame-

any expanded metal panel specified or used in security fence

work shall have a strength that closely approximates the load

system applications shall not be less than nominal 1.47 lbs per

strength of the specified threaded fastener (see Specification

square foot prior to galvanizing or color coating.

A307).

6.2.2 No expanded metal specified or used for above-

6.6.3 Welding galvanized or color coated mesh to frame-

ground se

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2548 − 12 F2548 − 12 (Reapproved 2018)

Standard Specification for

Expanded Metal Fence Systems for Security Purposes

This standard is issued under the fixed designation F2548; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers selection and installation of expanded metal fence systems for applications on new or retrofit

fences for commercial, industrial, governmental or institutional facilities as applicable to homeland security, or where the

possibility of malevolent incursion is significant. See Fig. 1 for typical examples of expanded metal fence applications. This type

of fence system is not recommended for residential or public recreational facilities such as pools, schools, and kindergartens.

1.2 This specification is intended to guide those responsible for or concerned with the design and installation of an expanded

metal fence system capable of denying or delaying unwanted access into or out of an area.

1.3 No recommendation is made or implied here as to the merits of the product from any particular manufacturer. Choice of

component selection for the expanded metal system should be made by the writer of the project specification based on their own

perception of the product’s merit and the consequence of a malevolent incursion.

1.4 The values stated in inch-pound units are to be regarded as standard. Any values given in parentheses are for information

only.

1.5 This specification does not purport to address all of the safety and security concerns, if any, associated with homeland

security. It is the responsibility of the user of this standard to establish the required and appropriate level of security.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

A123/A123M Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products

A307 Specification for Carbon Steel Bolts, Studs, and Threaded Rod 60 000 PSI Tensile Strength

B117 Practice for Operating Salt Spray (Fog) Apparatus

F934 Specification for Standard Colors for Polymer-Coated Chain Link Fence Materials

F1267 Specification for Metal, Expanded, Steel

F1043 Specification for Strength and Protective Coatings on Steel Industrial Fence Framework

F1083 Specification for Pipe, Steel, Hot-Dipped Zinc-Coated (Galvanized) Welded, for Fence Structures

F1267 Specification for Metal, Expanded, Steel

2.2 American Society of Civil Engineers (ASCE):

ASCE/SEI 7-05 Minimum Design Loads for Buildings and Other Structures

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 expanded metal fence system—combines expanded metal panels and structural framework posts and rails, if required with

accessories and fasteners, assembled and evaluated as a complete system. Fig. 1 shows typical applications.

This specification is under the jurisdiction of ASTM Committee F14 on Fences and is the direct responsibility of Subcommittee F14.35 on Architectural Metal Fence

Systems.

Current edition approved July 1, 2012March 1, 2018. Published September 2012March 2018. Originally approved in 2006. Last previous edition approved in 20062012

as F2548 - 06. DOI: 10.1520/F2548-12.–12. DOI: 10.1520/F2548-12R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American Society of Civil Engineers (ASCE), 1801 Alexander Bell Dr., Reston, VA 20191, http://www.asce.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2548 − 12 (2018)

FIG. 1 Expanded Metal Fencing Applications

3.1.2 expanded metal panel—element used as filler for the fence system. The following terms are used to further define

characteristics of the expanded metal panels (see Fig. 2 and Fig. 3).

3.1.3 fitting—any type of formed metal with the intent of securing mesh filler to a framework.

3.1.4 flattened expanded metal (F)—Expandedexpanded metal which has been cold rolled leaving a flat, smooth surface.

3.1.5 LWD—long way of diamond, nominal dimension (see Fig. 2).

3.1.6 regular (raised) expanded metal (R) —Expandedexpanded metal as it comes from the press after being simultaneously slit

and stretched having the strands and bonds form a uniform angle to the original plane of the solid sheet from which it was formed

creating an open mesh diamond making one continuous panel that cannot unravel.

3.1.7 SWD—short way of diamond, nominal dimension (see Fig. 2).

3.1.8 strand thickness—thickness of base metal.

3.1.9 strand width—amount of material fed under the die to produce one strand.

4. Classification

4.1 Expanded metal used on fences for security applications shall meet the material requirements of Specification F1267.

Expanded metal referenced in this specification is classified by types and classes as follows:

4.2 Type

4.2.1 Type 1—Expanded (see Fig. 2 – Type 1)

4.2.2 Type 2—Expanded and flattened (see Fig. 2 – Type 2)

NOTE 1—While it is not the intent of this specification to limit the selection of expanded metal “Type” to a specific fence application, historical practice

is a relevant factor to consider during the selection process. Construction of new expanded metal fence systems and retrofit of chain link fences historically

involved the use of Type 1 expanded metal panels; retrofit of ornamental picket fences historically involved the use of Type 2 expanded metal panels.

4.3 Class

4.3.1 Class 1—Uncoated

4.3.2 Class 2—Hot-dip zinc coated (galvanized)

4.3.3 Class 3—Corrosion-resisting steel

5. Ordering/Specifying Information

5.1 When ordering or specifying expanded metal fence systems for security applications, the appropriate mesh type, mesh

description, fence height, post size, post spacing, allowable mesh to framework attachment methods, and finish should all be

defined to ensure that expanded metal panels and all associated system components will work compatibly in the total system

installation.

FIG. 2 Diamond Description—Regular and Flattened

F2548 − 12 (2018)

FIG. 3 Mesh Description—Standard and Reversed Diamond

6. Materials

6.1 Expanded Metal Panels

6.1.1 Panels shall be manufactured in accordance with the requirements and within the allowable tolerances of Specification

F1267. Table 1 and Fig. 4 show selection options of expanded metal panels for use in security applications.

6.2 Acceptable panel types shall conform to these minimum requirements.

6.2.1 The minimum allowable weight per square foot for any expanded metal panel specified or used in security fence system

applications shall not be less than nominal 1.47 lbs per square foot prior to galvanizing or color coating.

6.2.2 No expanded metal specified or used for above-ground security purposes shall have an opening larger than three square

inches.

6.3 The overall width and height of expanded metal panels can be as large as 8 ft by 12 ft. Other factors such as panel weight,

transportation, galvanizing and color coating may dictate a more practical panel size. Expanded metal security barrier systems vary

as do production limitations.

6.4 Finish

6.4.1 If galvanized mesh is selected, the panels shall be compl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.