ASTM G49-85(2005)

(Practice)Standard Practice for Preparation and Use of Direct Tension Stress-Corrosion Test Specimens

Standard Practice for Preparation and Use of Direct Tension Stress-Corrosion Test Specimens

SIGNIFICANCE AND USE

Axially loaded tension specimens provide one of the most versatile methods of performing a stress-corrosion test because of the flexibility permitted in the choice of type and size of test specimen, stressing procedures, and range of stress levels.

The uniaxial stress system is simple; hence, this test method is often used for studies of stress-corrosion mechanisms. This type of test is amenable to the simultaneous exposure of unstressed specimens (no applied load) with stressed specimens and subsequent tension testing to distinguish between the effects of true stress corrosion and mechanical overload (2). Additional considerations in regard to the significance of the test results and their interpretation are given in Sections 6 and 10.

Wide variations in test results may be obtained for a given material and specimen orientation with different specimen sizes and stressing procedures. This consideration is significant especially in the standardization of a test procedure for interlaboratory comparisons or quality control.

SCOPE

1.1 This practice covers procedures for designing, preparing, and using ASTM standard tension test specimens for investigating susceptibility to stress-corrosion cracking. Axially loaded specimens may be stressed quantitatively with equipment for application of either a constant load, constant strain, or with a continuously increasing strain.

1.2 Tension test specimens are adaptable for testing a wide variety of product forms as well as parts joined by welding, riveting, or various other methods.

1.3 The exposure of specimens in a corrosive environment is treated only briefly because other standards are being prepared to deal with this aspect. Meanwhile, the investigator is referred to Practices G 35, G 36, G 37, and G 44, and to ASTM Special Technical Publication 425 ().

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G49–85 (Reapproved2005)

Standard Practice for

Preparation and Use of Direct Tension Stress-Corrosion

Test Specimens

ThisstandardisissuedunderthefixeddesignationG49;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Summary of Practice

1.1 This practice covers procedures for designing, prepar- 3.1 This practice covers the use of axially loaded, quantita-

ing, and using ASTM standard tension test specimens for tively stressed ASTM standard tension test specimens for

investigating susceptibility to stress-corrosion cracking. Axi- investigating the resistance to stress-corrosion cracking of

ally loaded specimens may be stressed quantitatively with metallic materials in all types of product forms. Consideration

equipment for application of either a constant load, constant is given to important factors in the selection of appropriate

strain, or with a continuously increasing strain. specimens, the design of loading equipment, and the effects of

1.2 Tension test specimens are adaptable for testing a wide these factors on the state of stress in the specimen as corrosion

variety of product forms as well as parts joined by welding, occurs.

riveting, or various other methods.

4. Significance and Use

1.3 The exposure of specimens in a corrosive environment

is treated only briefly because other standards are being 4.1 Axially loaded tension specimens provide one of the

most versatile methods of performing a stress-corrosion test

prepared to deal with this aspect. Meanwhile, the investigator

is referred to Practices G35, G36, G37, and G44, and toASTM because of the flexibility permitted in the choice of type and

size of test specimen, stressing procedures, and range of stress

Special Technical Publication 425 (1).

levels.

2. Referenced Documents

4.2 The uniaxial stress system is simple; hence, this test

2.1 ASTM Standards: method is often used for studies of stress-corrosion mecha-

E8 Test Methods for Tension Testing of Metallic Materials nisms. This type of test is amenable to the simultaneous

G35 PracticeforDeterminingtheSusceptibilityofStainless exposure of unstressed specimens (no applied load) with

Steels and Related Nickel-Chromium-Iron Alloys to stressed specimens and subsequent tension testing to distin-

Stress-Corrosion Cracking in Polythionic Acids guish between the effects of true stress corrosion and mechani-

G36 Practice for Evaluating Stress-Corrosion-Cracking Re- cal overload (2). Additional considerations in regard to the

sistance of Metals and Alloys in a Boiling Magnesium significance of the test results and their interpretation are given

Chloride Solution in Sections 6 and 10.

G37 Practice for Use of Mattsson’s Solution of pH to 4.3 Wide variations in test results may be obtained for a

Evaluate the Stress-Corrosion Cracking Susceptibility of given material and specimen orientation with different speci-

Copper-Zinc Alloys men sizes and stressing procedures. This consideration is

G44 Practice for Exposure of Metals and Alloys by Alter- significant especially in the standardization of a test procedure

nate Immersion in Neutral 3.5 % Sodium Chloride Solu- for interlaboratory comparisons or quality control.

tion

5. Test Specimens

5.1 Whenever possible, tension test specimens used in

This practice is under the jurisdiction of ASTM Committee G01 on Corrosion

evaluating susceptibility to stress-corrosion cracking should

of Metals and is the direct responsibility of Subcommittee G01.06 on Environmen-

conform to the dimensions of standard tension test specimens

tally Assisted Cracking.

Current edition approved Oct. 1, 2005. Published October 2005. Originally

specified in Test Methods E8, which contain details for

approvedin1976.Lastpreviouseditionapprovedin2000asG49 – 85(2000).DOI:

specimens machined from various product forms.

10.1520/G0049-85R05.

5.2 A wide range of sizes for tension test specimens is

The boldface numbers in parentheses refer to the list of references at the end of

this practice. possible, depending primarily upon the dimensions of the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

product to be tested. Because the stress-corrosion test results

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

can be markedly influenced by the cross section of the test

Standards volume information, refer to the standard’s Document Summary page on

specimen, this factor should be given careful consideration

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G49–85 (2005)

with regard to the object of the investigation. Although larger

specimens may be more representative of most actual struc-

tures, they often cannot be machined from product forms to be

evaluated; and they present more difficulties in stressing and

handling in the laboratory. Also, larger specimens of some

materials may require longer exposure periods than smaller

specimens.

5.3 Smaller cross-section specimens are widely used be-

cause they (1) have a greater sensitivity to the initiation of

stress-corrosion cracking, (2) usually give test results more

quickly, and (3) permit greater convenience in testing. On the

other hand, the smaller specimens are more difficult to ma-

chine, and their performance is more likely to be influenced by

extraneous stress concentrations resulting from non-axial load-

ing,corrosionpits,etc.Therefore,specimenslessthanabout10

mm (0.4 in.) in gauge length or 3.0 mm (0.12 in.) in diameter

are not recommended for general use.

5.4 Tension specimens containing machined notches have

been used in studies of stress-corrosion cracking and hydrogen

embrittlement (3). The presence of a notch induces a triaxial

stressstateattherootofthenotchwhereintheactualstresswill

be greater by a concentration factor dependent on the notch

geometry.Advantages of such specimens include the probable

localization of cracking to the notch region and acceleration of

failure. However, unless directly related to practical conditions

of usage, spurious results may ensue.

5.5 Tension specimens containing a machined notch in

NOTE—The behavior shown is generally representative, but the curves

which a mechanical precrack (for example, a fatigue or tension

will vary with specific alloys and tempers.

crack) has been started will be the subject of another ASTM

FIG. 1 Effect of Loading Method and Extent of Cracking or

standard. Various types of precracked specimens are discussed

Corrosion Pattern on Average Net Section Stress

in other publications (2, 4).

6. Stress Considerations

not susceptible to stress-corrosion cracking, or (2) stress-

6.1 There are several factors that may introduce bending corrosion cracking of a material at an unknown stress higher

than the intended nominal test stress. The occurrence of either

moments on specimens, such as a longitudinal curvature,

misalignmentofthreadsonthreaded-endroundspecimens,and of these phenomena would interfere with a valid evaluation of

materials with a relatively high resistance to stress corrosion.

the corners of sheet-type specimens. The significance of these

factors is greater for specimens with smaller cross sections. These considerations must be taken into account in experi-

ments undertaken to determine “threshold” stresses. The sig-

Even though eccentricity in loading can be minimized to equal

the same standards accepted for tension testing machines, nificance of these factors is discussed further in Section 10.

inevitably, there is some variation in the tensile stress around

7. Stressing Methods

the circumference of the test specimen which can be of such

7.1 General Considerations:

magnitude that it will introduce considerable error in the

desired stress. Tests should be made on specimens with strain 7.1.1 Tension specimens may be subjected to a wide range

of stress levels associated with either elastic or elastic and

gages affixed to the specimen surface (around the circumfer-

ence in 90° or 120° intervals) to verify strain and stress plastic strain. Because the stress system is intended to be

uniformity and determine if machining practices and stressing essentially uniaxial (except in the case of notched specimens),

jigs are of adequate tolerance and quality. great care must be exercised in the construction of stressing

6.2 Another consideration is the possible increase in net frames so that bending stresses are avoided or minimized.

section stress that will occur when corrosion develops during 7.1.2 Although a number of different stressing frames have

the environmental exposure (1, 5). As shown schematically in been used with tension specimens, three basic types are

Fig. 1, there are two limiting curves: one for zero stiffness considered herein: constant (sustained) load, constant strain

(dead weight) and the other for infinite stiffness (ideal constant (deformation), and continuously increasing strain. A constant

strain). In actual testing with various types of stressing frames, loadcanbeobtainedwithdeadweight,buttrulyconstantstrain

such as those shown in Figs. 2-4, the increase in net section loading is seldom achieved because a stressing frame with

stress will be somewhere in between. When the net section infinitestiffnesswouldberequired.Stress-corrosiontestresults

stress becomes greater than the nominal gross section stress can be influenced by the type of loading in combination with

and increases to the point of fracture, either of two events can the design of the test specimen; therefore, the investigator

occur: (1) fracture by mechanical overload of a material that is shouldselectloadingconditionsmostapplicabletothepurpose

G49–85 (2005)

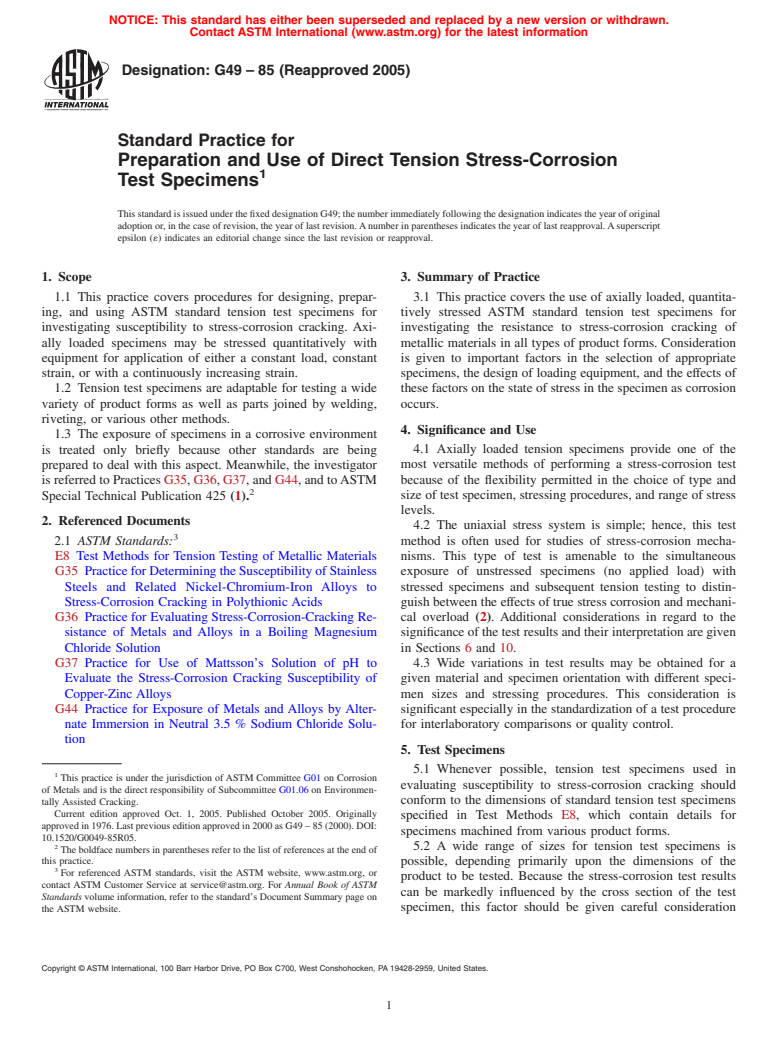

FIG. 2 Spring-Loaded Stressing Frame (7)

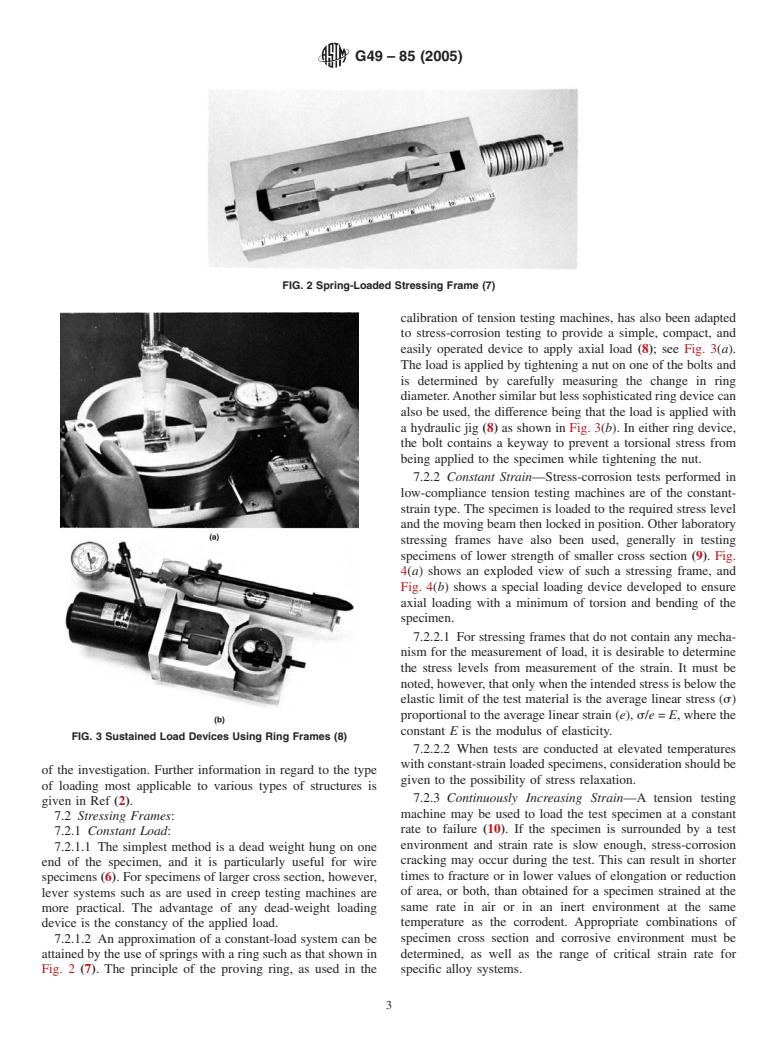

calibration of tension testing machines, has also been adapted

to stress-corrosion testing to provide a simple, compact, and

easily operated device to apply axial load (8); see Fig. 3(a).

The load is applied by tightening a nut on one of the bolts and

is determined by carefully measuring the change in ring

diameter.Anothersimilarbutlesssophisticatedringdevicecan

also be used, the difference being that the load is applied with

a hydraulic jig (8) as shown in Fig. 3(b). In either ring device,

the bolt contains a keyway to prevent a torsional stress from

being applied to the specimen while tightening the nut.

7.2.2 Constant Strain—Stress-co

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.