ASTM E2568-07

(Specification)Standard Specification for PB Exterior Insulation and Finish Systems

Standard Specification for PB Exterior Insulation and Finish Systems

ABSTRACT

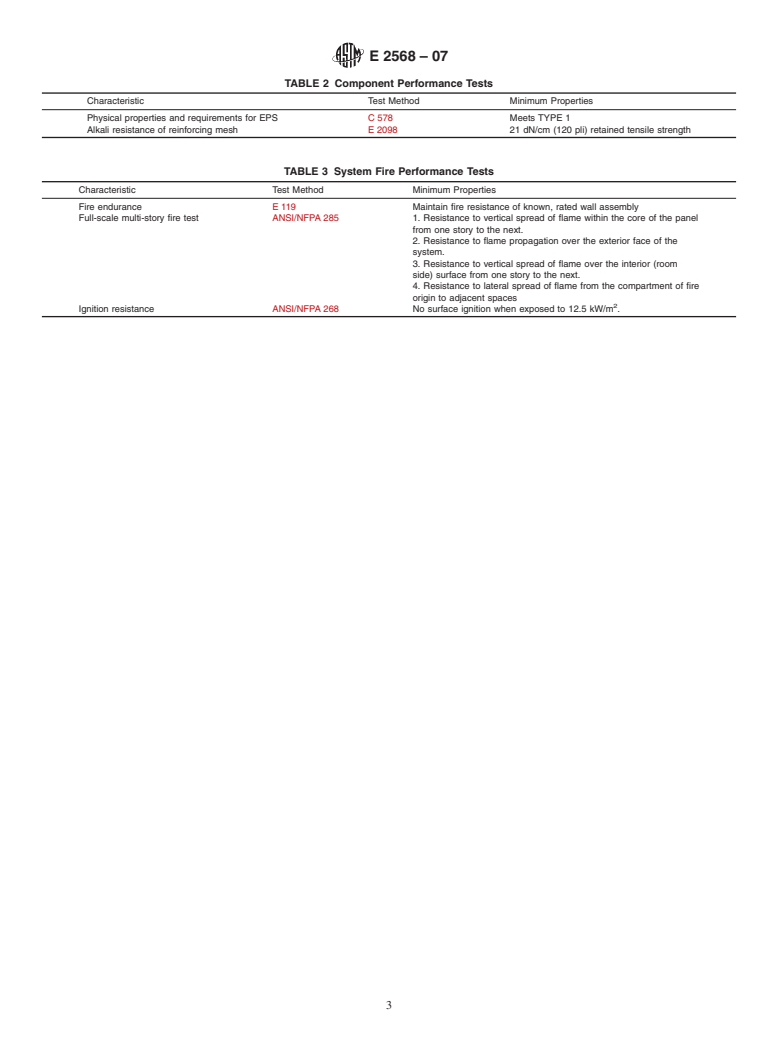

This specification covers PB Exterior Insulation and Finish Systems (EIFS) defined as an exterior, non-bearing wall covering providing a weather-resistant exterior wall envelope on walls required to be combustible or noncombustible, fireresistance-rated or nonfire-resistance-rated. Further, PB EIFS is a system described as being applied over insulation board, an adhesive or mechanical attachment of the insulation board to a substrate, or both, glass fiber reinforcing mesh, a base coat on the face of the insulation board, and a textured protective finish coat. The following tests shall be performed in accordance to the following test methods: accelerated weathering; freeze/thaw; salt spray resistance; tensile bond adhesion; water penetration; water resistance; physical properties and requirements for EPS; alkali resistance of reinforcing mesh; fire endurance; full-scale multi-story fire test; and ignition resistance.

SCOPE

1.1 This specification covers PB Exterior Insulation and Finish Systems (EIFS) defined as an exterior, non-bearing wall covering providing a weather-resistant exterior wall envelope on walls required to be combustible or noncombustible, fire-resistance-rated or nonfire-resistance-rated. Further, PB EIFS is a system described as being applied over insulation board, an adhesive or mechanical attachment of the insulation board to a substrate, or both, glass fiber reinforcing mesh, a base coat on the face of the insulation board, and a textured protective finish coat.

1.2 specification does not cover Class PB EIFS with drainage.

1.3 This specification qualifies EIFS products for use in normal service conditions and is not for evaluating in service EIFS installations.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 2568 – 07

Standard Specification for

PB Exterior Insulation and Finish Systems

This standard is issued under the fixed designation E 2568; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E119 Test Methods for Fire Tests of Building Construction

and Materials

1.1 This specification covers PB Exterior Insulation and

E 330 Test Method for Structural Performance of Exterior

Finish Systems (EIFS) defined as an exterior, non-bearing wall

Windows, Doors, Skylights and Curtain Walls by Uniform

covering providing a weather-resistant exterior wall envelope

Static Air Pressure Difference

on walls required to be combustible or noncombustible, fire-

E 331 Test Method for Water Penetration of Exterior Win-

resistance-rated or nonfire-resistance-rated. Further, PB EIFS

dows, Skylights, Doors, and Curtain Walls by Uniform

isasystemdescribedasbeingappliedoverinsulationboard,an

Static Air Pressure Difference

adhesive or mechanical attachment of the insulation board to a

E 631 Terminology of Building Constructions

substrate, or both, glass fiber reinforcing mesh, a base coat on

E 2098 Test Method for Determining Tensile Breaking

the face of the insulation board, and a textured protective finish

Strength of Glass Fiber Reinforcing Mesh for Use in Class

coat.

PB Exterior Insulation and Finish Systems (EIFS), after

1.2 specification does not cover Class PB EIFS with drain-

Exposure to a Sodium Hydroxide Solution

age.

E2110 Terminology for Exterior Insulation and Finish Sys-

1.3 This specification qualifies EIFS products for use in

tems (EIFS)

normal service conditions and is not for evaluating in service

E 2134 Test Method for Evaluating the Tensile-Adhesion

EIFS installations.

Performance of an Exterior Insulation and Finish System

1.4 The values stated in SI units are to be regarded as the

(EIFS)

standard. The values given in parentheses are for information

E 2485 Test Method for Freeze/Thaw Resistance of Exte-

only.

rior Insulation and Finish Systems (EIFS) and Water

1.5 This standard does not purport to address all of the

Resistive Barrier Coatings

safety concerns, if any, associated with its use. It is the

E 2486 Test Method for Impact Resistance of Class PB and

responsibility of the user of this standard to establish appro-

PI Exterior Insulation and Finish Systems (EIFS)

priate safety and health practices and determine the applica-

G23 Practice for Operating Light-Exposure Apparatus

bility of regulatory limitations prior to use.

(Carbon-Arc Type) With and Without Water for Exposure

2. Referenced Documents

of Nonmetallic Materials (Discontinued 2001)

G26 Practice for Operating Light-Exposure Apparatus

2.1 ASTM Standards:

(Xenon-Arc Type) With and Without Water for Exposure

B117 Practice for Operating Salt Spray (Fog) Apparatus

of Nonmetallic Materials (Discontinued 2001)

C 297/C 297M Test Method for Flatwise Tensile Strength

G 153 Practice for Operating Enclosed Carbon Arc Light

of Sandwich Constructions

Apparatus for Exposure of Nonmetallic Materials

C 578 SpecificationforRigid,CellularPolystyreneThermal

G 155 Practice for Operating Xenon Arc Light Apparatus

Insulation

for Exposure of Non-Metallic Materials

D 2247 PracticeforTestingWaterResistanceofCoatingsin

2.2 NFPA Standards:

100 % Relative Humidity

ANSI/NFPA 268 Standard Test Method for Determining

E84 Test Method for Surface Burning Characteristics of

Ignitability of Exterior Wall Assemblies Using a Radiant

Building Materials

Heat Energy Source

ANSI/NFPA 285 Standard Fire Test Method for the Evalu-

ation of Fire Propagation Characteristics of Exterior,

This test method is under the jurisdiction of ASTM Committee E06 on

Nonload-bearing Wall Assemblies Containing Combus-

Performance of Buildings and is the direct responsibility of Subcommittee E06.58

on Exterior Insulation and Finish Systems (EIFS). tible Components

Current edition approved Sept. 1, 2007. Published September 2007.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Withdrawn.

Standards volume information, refer to the standard’s Document Summary page on Available from National Fire Protection Association (NFPA), 1 Batterymarch

the ASTM website. Park, Quincy, MA 02169-7471, http://www.nfpa.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2568–07

3. Terminology 5.5 Componentfireperformanceshallbeinaccordancewith

Table 4.

3.1 Definitions are in accordance with TerminologyE2110

5.6 Structural performance shall be in conformance with

unless otherwise specified.

Table 5.

3.2 Definitions of Terms Specific to This Standard:

5.7 Impact shall be in conformance with Table 6.

3.3 EIFS-related construction, n—construction that works

in conjunction with the EIFS, but is not part of the EIFS.

3.4 class PB EIFS, n—EIFS where the base coat varies in 6. Inspection

thickness depending upon the number of layers, or thickness of

6.1 Materialssuppliedbythemanufacturershallbesupplied

reinforcing mesh.The reinforcing mesh is glass fiber mesh that

to the site location in original unopened containers with labels

is encapsulated by the base coat per EIFS manufacturer

intact. Upon arrival, the materials shall be inspected for

recommendations. Protective finish coats, of various thick-

damage, and the manufacturer notified of any discrepancies.

nesses in a variety

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.