ASTM D6830-02

(Test Method)Standard Test Method for Characterizing the Pressure Drop and Filtration Performance of Cleanable Filter Media

Standard Test Method for Characterizing the Pressure Drop and Filtration Performance of Cleanable Filter Media

SIGNIFICANCE AND USE

This test method determines the comparative performance of filter media. The results can be used for design, manufacturing, construction and selection of filter media.

Results obtained by this test method should not be used to predict absolute performance on full scale fabric filter (baghouse) facilities, however these results will be useful in selection of proper filter media and identification of recommended operating parameters for these full scale fabric filter facilities.

Dust types vary greatly; therefore, the results obtained using the standard dust should not be extrapolated to other dust types.

SCOPE

1.1 This test method characterizes the operational performance of cleanable filter media under specified laboratory conditions.

1.2 This test method determines the airflow resistance, drag, cleaning requirements, and particulate filtration performance of pulse cleaned filter media.

1.3 This test method determines the comparative performance of cleanable filter media.

1.4 The results obtained from this test method are useful in the design, construction, and selection of filter media.

1.5 The results obtained by this test method should not be used to predict absolute performance of full scale fabric filter (baghouse) facilities, however these results will be useful in selection of proper filter media and identification of recommended operating parameters for these full scale fabric filter facilities.

1.6 The values stated in SI units are to be regarded as standard. The values in parenthesis are for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 6830 – 02

Standard Test Method for

Characterizing the Pressure Drop and Filtration

Performance of Cleanable Filter Media

This standard is issued under the fixed designation D 6830; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Draft Generic Verification Protocol for Baghouse Filtration

Products

1.1 This test method characterizes the operational perfor-

Standard Operating Procedures for Verification Testing of

mance of cleanable filter media under specified laboratory

Baghouse Filtration Products Using LTG/FEMA Test

conditions.

Apparatus, Draft, December

1.2 Thistestmethoddeterminestheairflowresistance,drag,

VDI 3926, Part 2 Testing of Filter Media for Cleanable

cleaningrequirements,andparticulatefiltrationperformanceof

Filters under Operational Conditions

pulse cleaned filter media.

1.3 This test method determines the comparative perfor-

3. Terminology

mance of cleanable filter media.

3.1 Definitions of Terms Specific to This Standard:

1.4 The results obtained from this test method are useful in

3.1.1 fabric conditioning period—the period during which

the design, construction, and selection of filter media.

the fabric specimen is conditioned within the test apparatus by

1.5 The results obtained by this test method should not be

subjecting it to 10 000 rapid compressed air cleaning pulses at

used to predict absolute performance of full scale fabric filter

3-5 seconds between pulses. During the conditioning period

(baghouse) facilities, however these results will be useful in

the specimen is subjected to test method specifications for dust

selection of proper filter media and identification of recom-

and gas flow rates.

mended operating parameters for these full scale fabric filter

3.1.2 fabric recovery period—time period following the

facilities.

conditioning period during which the fabric is allowed to

1.6 The values stated in SI units are to be regarded as

recoverfromrapidpulsing.Thefabricrecoveryperiodrequires

standard. The values in parenthesis are for information only.

30 filtration cycles under normal filtration cycles. During the

1.7 This standard does not purport to address all of the

recovery period the fabric is subjected to test method specifi-

safety concerns, if any, associated with its use. It is the

cations for dust and gas flow rates.

responsibility of the user of this standard to establish appro-

3.1.3 filtration velocity—volumetric is the flow rate per unit

priate safety and health practices and determine the applica-

face area. Also referred to as gas-to-cloth ratio (G/C), or

bility of regulatory limitations prior to use.

air-to-cloth ratio (A/C).

2. Referenced Documents 3.1.4 filtration cycle—a cycle in the filtration process in

which the particulate matter is allowed to form a dust cake on

2.1 ASTM Standards:

the face area of the test specimen with no disturbances from a

D 123 Terminology Relating to Textiles

pulse of compressed air to clean the dust cake from the test

D 461 Test Methods for Felts

specimen. The filtration cycle is the time period between two

D 737 Test Method for Air Permeability of Textile Fabrics

consecutive cleaning or pulse cycles.

E 832 Specification for Laboratory Filter Papers

3.1.5 filtration cycle time—the duration of time, measured

F 740 Terminology Relating to Filtration

in seconds or minutes, defined by one filtration cycle. Also

2.2 Other Standards:

referred to as time between cleaning cycles, or pulse cycles.

This test method is under the jurisdiction of ASTM Committee D22 on

Sampling and Analysis of Atmospheres and is the direct responsibility of Subcom-

mittee D22.03 on Ambient Atmospheres and Source Emissions. Generic Verification Protocol For Baghouse Filtration Products, RTI, Research

Current edition approved October 10, 2002. Published December 2002. Triangle Park, NC, September 2001.

2 5

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Test/QA Plan For The Verification Testing of Baghouse Filtration Products,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM ETS, Inc., October 2000.

Standards volume information, refer to the standard’s Document Summary page on Verein Deutscher Ingenieure (VDI 3926, Part 2), 9Testing of Filter Media For

the ASTM website. Cleanable Filters under Operational Conditions,9 December, 1994. Availble from

Withdrawn Beuth Verlag GmBH, 10772 Berlin, Germany.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6830–02

3.1.6 normal filtration cycle—a filtration cycle specified for recorded during the performance test period.Table 1 andTable

this test method in which the dust cake is allowed to form on 2 provide test specifications and test conditions respectively.

the test specimen until a differential pressure of 1000 Pa (4 in. Table 3 provides a listing of results that will be obtained from

w.g.) is reached. At this point, the test specimen is cleaned by this test.

a pulse of compressed air from the clean gas side. After the

pulse action is completed the next filtration cycle begins 5. Significance and Use

continuing until the pressure differential reaches 1000 Pa, thus

5.1 This test method determines the comparative perfor-

initiating the next pulse.

mance of filter media. The results can be used for design,

3.1.7 PM- particulate matter—also used interchangeably

manufacturing, construction and selection of filter media.

with “dust” when referring to test dust specifications or inlet

5.2 Results obtained by this test method should not be used

particulate matter flow rates.

to predict absolute performance on full scale fabric filter

3.1.8 PM 2.5—particulate matter nominally 2.5 microme-

(baghouse) facilities, however these results will be useful in

tres and less in equivalent aerodynamic diameter.

selection of proper filter media and identification of recom-

3.1.9 performance test period—a 120 minute test period

mended operating parameters for these full scale fabric filter

following the fabric recovery period (360 minutes minimum

facilities.

for PM 2.5 measurements) during which measurements for

5.3 Dust types vary greatly; therefore, the results obtained

particulate emissions, residual pressure drop, number of filtra-

using the standard dust should not be extrapolated to other dust

tion cycles, and filtration cycle time are monitored and re-

types.

corded. During the performance test period pulse cleaning is

triggered at a differential pressure of 1000 Pa (4 in. w.g.)

6. Interferences

measured across the test specimen. Gas and dust flows are

6.1 Any variations in the test conditions or test apparatus

maintained at test specification flow rates.

that may alter the physical properties of the dispersed test dust

3.1.10 residual pressure drop—the air flow resistance mea-

particles may affect the precision of the test results.

sured across the test specimen, as measured three seconds after

6.1.1 These properties include static charge, cohesion, ef-

cleaning the test specimen with a pulse of compressed air,Also

fective particle size, or any other property that affects the

referred to as residual differential pressure, P, residual delta P,

ability of the dust particles to actually reach the surface of the

or dP,or Dp .

r r

test specimen or that affects the interaction between the dust

3.2 For definitions of other terms used in this test method,

particles and the filtration surface during the filtration or pulse

refer to Terminologies D 123 and F 740, as well as 11.1 of this

cleaning process.

test method.

6.1.2 The test dust is known to have minor differences in

4. Summary of Test Method

particle size from shipment to shipment and lot number to lot

number. It is not fully understood what impact, if any, these

4.1 Afabric filter sample is challenged with a standard dust

deviations have on the test results. With each new shipment

(particulate matter) under simulated baghouse conditions at

and every three months thereafter, the dust particle size should

specified rates for air and dust flow.

be characterized using the handling, preparation, and testing

4.2 The test consists of three test runs. Each run consists of

procedures specified in this test method. In addition the impact

three sequential phases or test periods during which dust and

of the dust on differential pressure and weight gain values of a

gasflowratesarecontinuouslymaintainedtotestspecification.

reference fabric should be established and testing of the dust

4.2.1 The test phases are:

andreferencefabricshouldbeconductedquarterlythereafterto

4.2.1.1 A conditioning period consisting of 10 000 rapid

allow for comparisons with the established values.

pulse filtration cycles to simulate long term operation,

4.2.1.2 A30normalfiltrationcyclerecoveryperiodtoallow 6.1.3 Inadequate dispersion of the test dust may affect the

precision of test results. Any surface with which the dust

the test specimen to recover from rapid pulsing, and

4.2.1.3 A two-hour performance test period, consisting of contacts after it leaves the feeder should be made in strict

accordance with the specification. The use of alternate mate-

normal filtration cycles, during which measurements for par-

ticulate emissions are determined by gravimetric measurement rials for internal surfaces of the raw and clean gas duct may

of the particulate matter which passes through the test speci- cause the charge on the dust particles to be altered triboelec-

trically, which may affect the results.

men.

4.3 PM 2.5 emission determinations can also be conducted 6.1.4 The relative humidity and temperature at which the

by employing a cascade impactor and modifying the clean gas test is conducted is known to have an effect on the test results.

duct of the test apparatus to insure that isokinetic sampling As there are no quantitative relationship that have been

rates through the impactor are maintained. established that would allow the correction of test results for

4.3.1 If measuring for PM 2.5 it is advised that the perfor- variations in these parameters, it is recommended that the test

mancetestperiodbeincreasedfrom120minutestoatleast360 be conducted in a conditioned room with a relative humidity

minutes to allow for adequate weight gains on each collection between 40 and 65 % and at a temperature between 23 and

stage of the impactor. 27°C ( 73.4 to 80.6°F). In the absence of a conditioned room,

4.4 Initial residual pressure drop, average residual pressure the relative humidity and temperature should be as tightly

drop, residual pressure drop increase, number of filtration controlled as possible and their levels recorded throughout the

cycles, and average filtration cycle time are monitored and test.

D6830–02

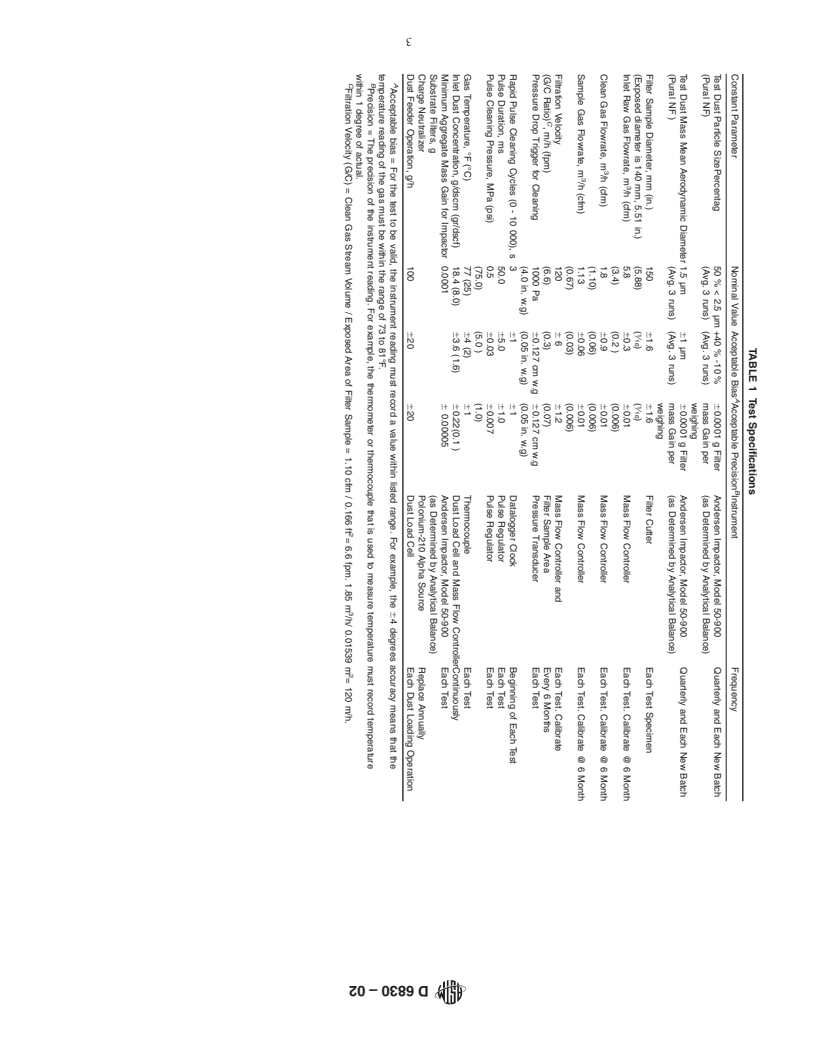

TABLE 1 Test Specifications

A B

Constant Parameter Nominal Value Acceptable Bias Acceptable Precision Instrument Frequency

Test Dust Particle SizePercentag 50 % < 2.5 µm +40 % -10 % 60.0001 g Filter Andersen Impactor, Model 50-900 Quarterly and Each New Batch

(Pural NF) (Avg. 3 runs) (Avg. 3 runs) mass Gain per (as Determined by Analytical Balance)

weighing

Test Dust Mass Mean Aerodynamic Diameter 1.5 µm 61µm 60.0001 g Filter Andersen Impactor, Model 50-900 Quarterly and Each New Batch

(Pural NF ) (Avg. 3 runs) (Avg. 3 runs) mass Gain per (as Determined by Analytical Balance)

weighing

Filter Sample Diameter, mm (in.) 150 61.6 61.6 Filter Cutter Each Test Specimen

1 1

(Exposed diameter is 140 mm, 5.51 in.) (5.88) ( ⁄16) ( ⁄16)

Inlet Raw Gas Flowrate, m /h (cfm) 5.8 60.3 60.01 Mass Flow Controller Each Test. Calibrate @ 6 Month

(3.4) (0.2 ) (0.006)

Clean Gas Flowrate, m /h (cfm) 1.8 60.9 60.01 Mass Flow Controller Each Test. Calibrate @ 6 Month

(1.10) (0.06) (0.006)

Sample Gas Flowrate, m /h (cfm) 1.13 60.06 60.01 Mass Flow Controller Each Test. Calibrate @ 6 Month

(0.67) (0.03) (0.006)

Filtration Velocity 120 6 6 61.2 Mass Flow Controller and Each Test. Calibrate

C

(G/C Ratio) , m/h (fpm) (6.6) (0.3) (0.07) Filter Sample Area Every 6 Months

Pressure Drop Trigger for Cleaning 1000 Pa 60.127 cm w.g 60.127 cm w.g Pressure Transducer Each Test

(4.0 in. w.g) (0.05 in. w.g) (0.05 in. w.g)

Rapid Pulse Cleaning Cycles (0 - 10 000), s 3 61 61 Datalogger Clock Beginning of Each Test

Pulse Duration, ms 50.0 65.0 61.0 Pulse Regulator Each Test

Pulse Cleaning Pressure, MPa (psi) 0.5 60.03 60.007 Pulse Regulator Each Test

(75.0) (5.0 ) (1.0)

Gas Temperature, °F (°C) 77 (25) 64(2) 61 Thermocouple Each Test

Inlet Dust Concentration, g/dscm (gr/dscf) 18.4 (8.0) 63.6 (1.6) 60.22(0.1 ) Dust Load Cell and Mass Flow ControllerContinuously

Minimum Aggregate Mass Gain for Impactor 0.0001 6 0.00005 Andersen Impactor, Model 50-900 Each Test

Substrate Filters, g (as Determined by Analytical Balance)

Charge Neutralizer Polonium-210 Alpha Source Replace Annually

Dust Feeder Operation, g/h 100 620 620 Dust Load Cell Each Dust Loading Operation

A

Acceptable bias = For the test to be valid, the instrument reading must record a value within listed range. For example, the 64 degrees accuracy means that the

temperature reading of the gas must be within the range of 73 to 81°F.

B

Precision = The precision of the instrument reading. For example, the thermometer or thermocouple that is used to measure temperature must record temperature

within 1 degree of actual.

C 2 3 2

Filtration Velocity (G/C) = Clean Gas Stream Volume / Exposed Area of Filter Sample = 1.10 cfm / 0.166 ft = 6.6 fpm. 1.85 m /h/ 0.01539 m = 120 m/h.

D6830–02

TABLE 2 Test Conditions

Fig. 1 provides a schematic of the test apparatus. The test

Test parameter Value apparatus consists of the following components.

7.1.1 A continuous dust feeding system capable of provid-

Dust concentration 18.4 6 3.6 g/dscm

(8.0 6 1.6 gr/dscf)

ing dust feed rates ranging from 80 to 120 grams per hour.

Filtration velocity (G/C) (G/C) 120 66m/h

7.1.2 APolonium-210 alpha source for neutralizing the test

(6.6 6 0.5 fpm)

Pressure loss before cleaning 1,000 6 12 Pa dusts that have been electrostatically charged by dispersion

(4 6 0.05 in. w.g.)

(dust charge neutralizer).

Tank pressure 0.5 6 0.03 MPa

7.1.3 A dust feed hopper with a minimum capacity of 2.0

(75 6 5 psi)

Valve opening time 50 65ms

kilogram of aluminum oxide test dust.

Air temperature 25 6 2°C

7.1.4 Ascalebeneaththedustfeedmechanismincludingthe

(78 6 4°F)

dust feed hopper with a continuos readout capable of measure-

Relative humidity 50 6 10 %

Raw gas stream flow rate 5.8 m /h

ment

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.