ASTM E489-92(1997)

(Test Method)Standard Test Method for Tensile Strength Properties of Metal Connector Plates (Withdrawn 2005)

Standard Test Method for Tensile Strength Properties of Metal Connector Plates (Withdrawn 2005)

SCOPE

1.1 This test method provides a basic procedure for evaluating the tensile strength properties of the net section of finished metal connector plates.

1.2 This test method serves as a basis for determining the comparative performance of different types and sizes of metal connector plates in tension.

1.3 A companion test method, Test Method E767, covers the performances tests on these plates in shear.

1.4 Method D1761 covers the performance of the teeth and nails in wood members during the use of metal connector plates (see Note 1). Note 1-The maximum design load in tension, an indication of the effectiveness of the net cross section of the perforated metal connector plate, is not necessarily a criterion of the effectiveness of the plate in transmitting the load from wood member to wood member, since that property is influenced by a number of factors, including the effectiveness of the nails or that of the integral plate projections, or a combination thereof, used in the wood species under consideration, and tested in accordance with Method D1761.

1.5 This test method does not provide for the corrosion testing of metal connector plates exposed to long-term adverse environmental conditions where plate deterioration occurs as a result of exposure. Under such conditions, special provisions shall be introduced for the testing for corrosion resistance.

1.6 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method provides a basic procedure for evaluating the tensile strength properties of the net section of finished metal connector plates.

Formerly under the jurisdiction of Committee E06 on Performance of Buildings, this test method was withdrawn in March 2005. This standard is being withdrawn due to a lack of support for continued use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E489–92(Reapproved 1997)

Standard Test Method for

Tensile Strength Properties of Metal Connector Plates

This standard is issued under the fixed designation E 489; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The use of prepunched metal connector plates with and without integral projecting teeth as well as

solid metal connector plates, usually fabricated from structural quality sheet coils, such as described

in Specification A 446/A 446M, to fasten wood members together, is a widely accepted practice. In

many applications, these plates must resist tensile forces. During manufacture and subsequent loading

of these plates, stress concentrations develop around holes that were punched (or drilled) during

manufacture or during fabrication of the connection. These stress concentrations limit the accuracy of

strength predictions based solely on metal and net-section properties. This test method provides a

simple alternative to the development of complex analytical models required to deal with these stress

concentrations.

If a section taken through the width of a metal connector plate differs in geometric character from

a section through its length, the strength ratio of this plate is a function of its orientation. If this is the

case,theplateshallbeevaluatedfornetsectionacrossitslengthaswellasitswidthunderthemethods

presented here. However, if a plate is identical in both directions, only testing across its width shall

be necessary and the resulting strength ratio is applicable to both orientations of the plate.

1. Scope * environmental conditions where plate deterioration occurs as a

result of exposure. Under such conditions, special provisions

1.1 This test method provides a basic procedure for evalu-

shall be introduced for the testing for corrosion resistance.

ating the tensile strength properties of the net section of

1.6 This standard does not purport to address all of the

finished metal connector plates.

safety concerns, if any, associated with its use. It is the

1.2 This test method serves as a basis for determining the

responsibility of the user of this standard to establish appro-

comparative performance of different types and sizes of metal

priate safety and health practices and determine the applica-

connector plates in tension.

bility of regulatory limitations prior to use.

1.3 A companion test method, Test Method E 767, covers

the performances tests on these plates in shear.

2. Referenced Documents

1.4 TestMethodsD 1761covertheperformanceoftheteeth

2.1 ASTM Standards:

and nails in wood members during the use of metal connector

A 446/A 446M Specification for Steel Sheet, Zinc-Coated

plates (see Note 1).

(Galvanized)bytheHot-DipProcess,Structural(Physical)

NOTE 1—The maximum design load in tension, an indication of the

Quality

effectiveness of the net cross section of the perforated metal connector

A 525 Specification for General Requirements for Steel

plate, is not necessarily a criterion of the effectiveness of the plate in

Sheet, Zinc-Coated (Galvanized) by the Hot-Dip Process

transmitting the load from wood member to wood member, since that

A 591/A 591M Specification for Steel Sheet, Electrolytic

property is influenced by a number of factors, including the effectiveness

Zinc-Coated, for Light Coating Mass Applications

of the nails or that of the integral plate projections, or a combination

thereof, used in the wood species under consideration, and tested in D 1761 Test Methods for Mechanical Fasteners in Wood

accordance with Test Methods D 1761.

E 4 Practices for Force Verification of Testing Machines

E 8 TestMethodsforTensionTestingofMetallicMaterials

1.5 This test method does not provide for the corrosion

E 575 Practice for Reporting Data from Structural Tests of

testing of metal connector plates exposed to long-term adverse

1 2

This test method is under the jurisdiction of ASTM Committee E-6 on Discontinued; see 1994 Annual Book of ASTM Standards, Vol 01.06. Replaced

Performance of Buildings and is the direct responsibility of Subcommittee E06.13 by A653.

on Structural Performance of Connections in Building Construction. Annual Book of ASTM Standards, Vol 01.06.

Current edition approved Oct. 15, 1992. Published December 1992. Originally Annual Book of ASTM Standards, Vol 04.10.

published as E 489 – 73. Last previous edition E 489 – 81 (1987). Annual Book of ASTM Standards, Vol 03.01.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E489

Building Constructions, Elements, Connections, and As-

semblies

E 631 Terminology of Building Constructions

E 767 Test Method for Shear Strength Properties of Metal

Connector Plates

F 680 Test Methods for Nails

3. Terminology

3.1 Definitions—For general definitions of terms used in

this test method, see Terminology E 631.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 gross cross-sectional connector plate area—cross-

sectional area of metal connector plate determined by multi-

plying gross thickness of plate (see 9.3) by gross dimension of

plate perpendicular to direction of load application.

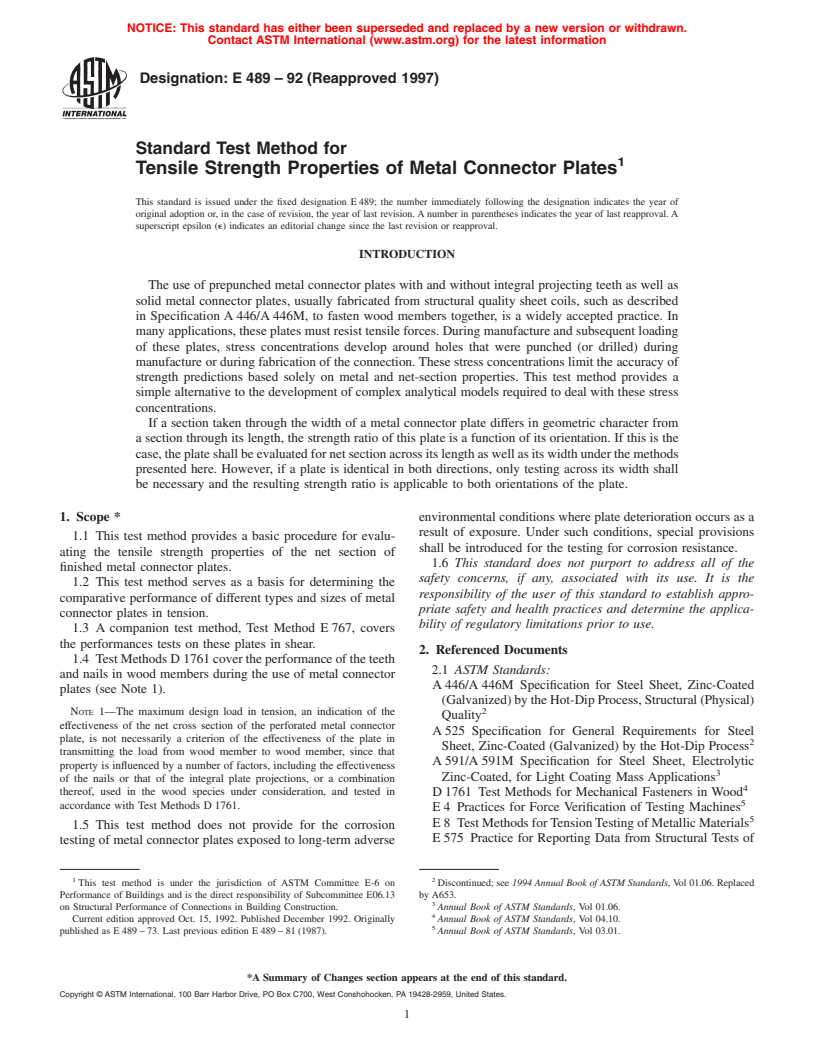

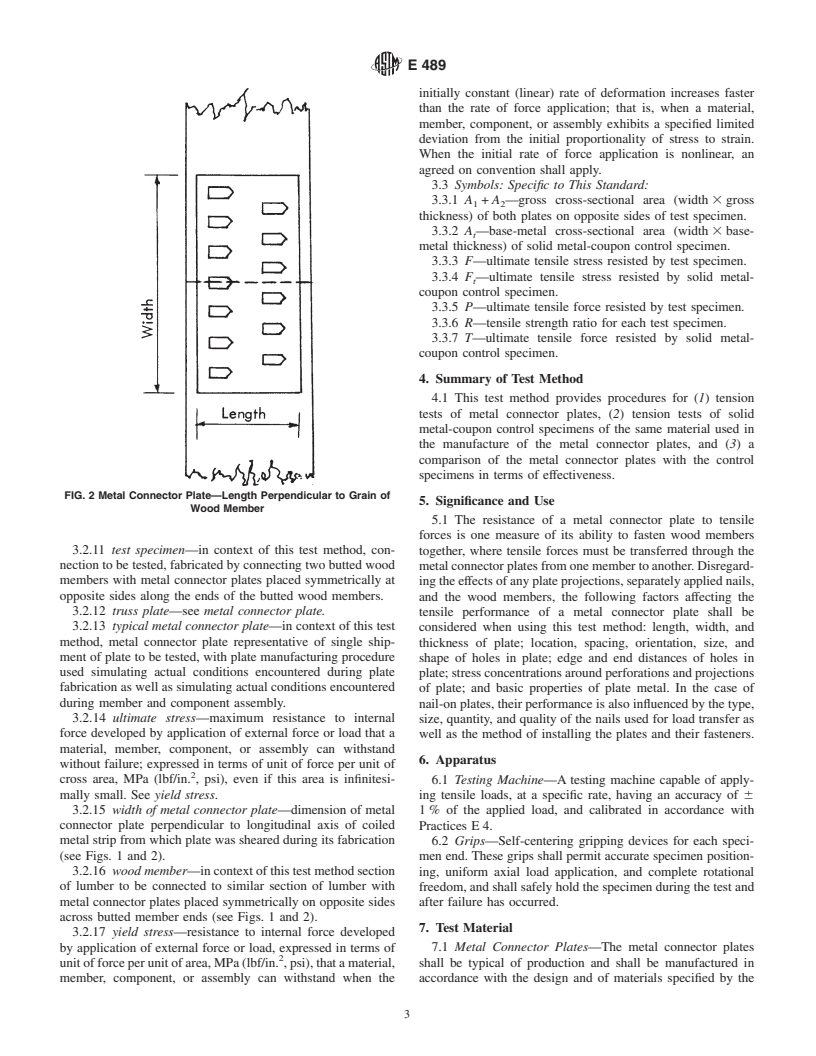

3.2.2 length of metal connector plate—dimension of metal

connector plate parallel to longitudinal axis of coiled metal

stripfromwhichplatewasshearedduringplatefabrication(see

Figs. 1 and 2).

3.2.3 metal connector plate—in the context of this test

method and with reference to coiled strips of structural quality

sheet metal from which metal connector plates are manufac-

tured, finished (coated, galvanized) metal connector plate with

or without integral plate projections or nail holes, or a

combination of both, with projections sheared from a solid

plate during its fabrication and projecting from the plate in a

single direction or both directions perpendicular to the plate

surface area; plate of specified thickness (gage), usually

including the following as well as intermediate thicknesses, to

which appropriate tolerances apply:

Washburn and Specification A 525

Moen (Table 17)

mm in. Steel Gage Galvanized Sheet, in.

0.9 0.035 20 0.0396

1.0 0.041 19 0.0456

NOTE 1—Metal connector plate failure will not necessarily occur along

1.2 0.047 18 0.0516

1.4 0.054 17 0.0575 the dashed line, which indicates the separation of the butted wood

1.6 0.063 16 0.0635

members.

1.8 0.072 15 0.0710

FIG. 1 Metal Connector Plate—Width Perpendicular to Grain of

2.0 0.080 14 0.0785

Wood Member

Produced in various sizes, that is, lengths and widths; and

designedtoconnectwoodmembersandtotransmitforcesfrom

3.2.6 plate—in context of this test method, metal connector

one wood member (or section) to another member (or section).

plate.

Othercommontermsincludeplate,trussplate,andmetalplate,

3.2.7 plate hole—opening in metal connector plate, result-

but preferably termed metal connector plate.

ing from shearing integral plate projections during plate

3.2.4 nail hole—round perforation in metal connector plate

fabrication (see nail hole).

through which a nail can be driven to fasten plate to wood

3.2.8 solid metal-coupon control specimen—solid metal

member (or section) and to transmit shear loads; providing

connector plate sample (see Fig. 3) of same material as metal

predetermined location for appropriately locating nail to be

connector plate under scrutiny; of dimensions meeting the

driven (see plate hole).

requirements of Test Methods E 8; without nail and plate holes

3.2.5 nail-on plate—solid or prepunched (or predrilled)

or integral plate projections.

metal connector plate of specified thickness (gage), manufac-

3.2.9 strength ratio—ratio of ultimate tensile strength of

tured to various sizes, that is, lengths and widths, designed to

metal connector plate to ultimate tensile strength of matched

be fastened with nails (or staples) to wood members and to

solid metal-coupon control specimen of same size; also called

transmit forces from one wood member (or section) to another

effectiveness ratio and efficiency ratio.

member (or section).

3.2.10 tooth—in context of this test method, integral pro-

jection of metal connector plate formed in direction perpen-

dicular to plate surface during stamping process; also called

Annual Book of ASTM Standards, Vol 04.07.

Annual Book of ASTM Standards, Vol 15.08. prong, barb, plug, and nail.

E489

initially constant (linear) rate of deformation increases faster

than the rate of force application; that is, when a material,

member, component, or assembly exhibits a specified limited

deviation from the initial proportionality of stress to strain.

When the initial rate of force application is nonlinear, an

agreed on convention shall apply.

3.3 Symbols: Specific to This Standard:

3.3.1 A + A —gross cross-sectional area (width 3 gross

1 2

thickness) of both plates on opposite sides of test specimen.

3.3.2 A—base-metal cross-sectional area (width 3 base-

t

metal thickness) of solid metal-coupon control specimen.

3.3.3 F—ultimate tensile stress resisted by test specimen.

3.3.4 F—ultimate tensile stress resisted by solid metal-

t

coupon control specimen.

3.3.5 P—ultimate tensile force resisted by test specimen.

3.3.6 R—tensile strength ratio for each test specimen.

3.3.7 T—ultimate tensile force resisted by solid metal-

coupon control specimen.

4. Summary of Test Method

4.1 This test method provides procedures for (1) tension

tests of metal connector plates, (2) tension tests of solid

metal-coupon control specimens of the same material used in

the manufacture of the metal connector plates, and (3)a

comparison of the metal connector plates with the control

specimens in terms of effectiveness.

FIG. 2 Metal Connector Plate—Length Perpendicular to Grain of

5. Significance and Use

Wood Member

5.1 The resistance of a metal connector plate to tensile

forces is one measure of its ability to fasten wood members

3.2.11 test specimen—in context of this test method, con-

together, where tensile forces must be transferred through the

nection to be tested, fabricated by connecting two butted wood

metalconnectorplatesfromonemembertoanother.Disregard-

members with metal connector plates placed symmetrically at

ingtheeffectsofanyplateprojections,separatelyappliednails,

opposite sides along the ends of the butted wood members.

and the wood members, the following factors affecting the

3.2.12 truss plate—see metal connector plate. tensile performance of a metal connector plate shall be

3.2.13 typical metal connector plate—in context of this test

considered when using this test method: length, width, and

method, metal connector plate representative of single ship- thickness of plate; location, spacing, orientation, size, and

ment of plate to be tested, with plate manufacturing procedure

shape of holes in plate; edge and end distances of holes in

used simulating actual conditions encountered during plate plate;stressconcentrationsaroundperforationsandprojections

fabrication as well as simulating actual conditions encountered

of plate; and basic properties of plate metal. In the case of

during member and component assembly. nail-on plates, their performance is also influenced by the type,

3.2.14 ultimate stress—maximum resistance to internal

size, quantity, and quality of the nails used for load transfer as

force developed by application of external force or load that a well as the method of installing the plates and their fasteners.

material, member, component, or assembly can withstand

6. Apparatus

without failure; expressed in terms of unit of force per unit of

cross area, MPa (lbf/in. , psi), even if this area is infinitesi- 6.1 Testing Machine—A testing machine capable of apply-

mally small. See yield stress.

ing tensile loads, at a specific rate, having an accuracy of 6

3.2.15 width of metal connector plate—dimension of metal 1 % of the applied load, and calibrated in accordance with

connector plate perpendicular to longitudinal axis of coiled

Practices E 4.

metal strip from which plate was sheared during its fabrication 6.2 Grips—Self-centering gripping devices for each speci-

(see Figs. 1 and 2).

men end. These grips shall permit accurate specimen position-

3.2.16 wood member—incontextofthistestmethodsection ing, uniform axial load application, and complete rotational

of lumber to be connected to similar section of lumber with

freedom, and shall safely hold the specimen during the test and

metal connector plates placed symmetrically on opposite sides after failure has occurred.

across butted member ends (see Figs. 1 and 2).

7. Test Material

3.2.17 yield stress—resistance to internal force developed

by application of external force or load, expressed in terms of 7.1 Metal Connector Plates—The metal connector plates

unitofforceperunitofarea,MPa(lbf/in. ,psi),thatamaterial, shall be typical of production and shall be manufactured in

member, component, or assembly can withstand when the accordance with the design and of materials specified by the

E489

FIG. 3 Solid Metal-Coupon Control Specimen (for Dimensions, see Test Methods E8)

platemanufacturer.Thecoilmetalusedforproductionofmetal 9. Test Specimen

connector plates shall meet minimum specified grade proper-

9.1 Plates—Theplatesshallbeofsufficientlengthtoinduce

ties, including the elongation for a 50-mm (2.0-in.) gage length

a tearing or tensile failure in the plates, rather than a with-

to be at least 16 % for specified Grade C steel with minimum

drawal failure of the teeth in the plate-wood interface. Alter-

275-MPa (40-ksi) yield point and a minimum 380-MPa (55-

natively,clamptheplatesaminimumof50mm(2in.)fromthe

ksi) ultimate tensile stress in accordance with Specification

member ends, or otherwise firmly fasten, to prevent tooth

A 446/A 446M.

withdrawal, provided such clamping or fastening does not

7.2 Solid Metal-Coupon Control Specimens—The solid

affect the tensile resistance of the plates. The connection

metal-coupon control specimens shall originate from the same

dimensions shall be sufficient in size for the plates not to

coil from which the metal connector plates were fabricated.

extendbeyondthesidesofthewoodmembers,andofsuchsize

7.3 Wood Members—The wood members of the connection

not to result in failure of the wood members.

shall be of such density and moisture content to ensure that

9.1.1 Net Section Normal to Plate Length—Firmly embed

failure occurs in the metal connector plates

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.