ASTM E1009-95(2006)

(Practice)Standard Practice for Evaluating an Optical Emission Vacuum Spectrometer to Analyze Carbon and Low-Alloy Steel (Withdrawn 2015)

Standard Practice for Evaluating an Optical Emission Vacuum Spectrometer to Analyze Carbon and Low-Alloy Steel (Withdrawn 2015)

SCOPE

1.1 This practice covers evaluation of an optical emission vacuum spectrometer to analyze carbon and low-alloy steels. It covers instruments used for the analysis of solid samples taken from molten metal for production control or from products to confirm the composition. Both pre-installation and post-installation precision and accuracy are included in the evaluation.

1.2 While are specific for plain carbon and low-alloy steel, they could be supplemented by similar tables for other materials.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This practice covered evaluation of an optical emission vacuum spectrometer to analyze carbon and low-alloy steels.

Formerly under the jurisdiction of Committee E01 on Analytical Chemistry for Metals, Ores, and Related Materials, this practice was withdrawn in January 2015 in accordance with section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1009 − 95(Reapproved 2006)

Standard Practice for

Evaluating an Optical Emission Vacuum Spectrometer to

Analyze Carbon and Low-Alloy Steel

This standard is issued under the fixed designation E1009; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E406 Practice for Using Controlled Atmospheres in Spec-

trochemical Analysis

1.1 This practice covers evaluation of an optical emission

E528 Practice for Grounding Basic Optical Emission Spec-

vacuum spectrometer to analyze carbon and low-alloy steels. It

trochemical Equipment (Withdrawn 1998)

covers instruments used for the analysis of solid samples taken

E876 Practice for Use of Statistics in the Evaluation of

from molten metal for production control or from products to

Spectrometric Data (Withdrawn 2003)

confirm the composition. Both pre-installation and post-

installation precision and accuracy are included in the evalua-

3. Terminology

tion.

3.1 Definitions—For definitions of terms used in this

1.2 While Tables 1–3 are specific for plain carbon and

practice, refer to Terminology E135 and Practice E876.

low-alloy steel, they could be supplemented by similar tables

3.2 Definitions of Terms Specific to This Standard:

for other materials.

3.2.1 accuracy—the closeness of a spectrochemical deter-

1.3 This standard does not purport to address all of the

mination to an accepted reference; it is affected by imprecision

safety concerns, if any, associated with its use. It is the and bias.

responsibility of the user of this standard to establish appro-

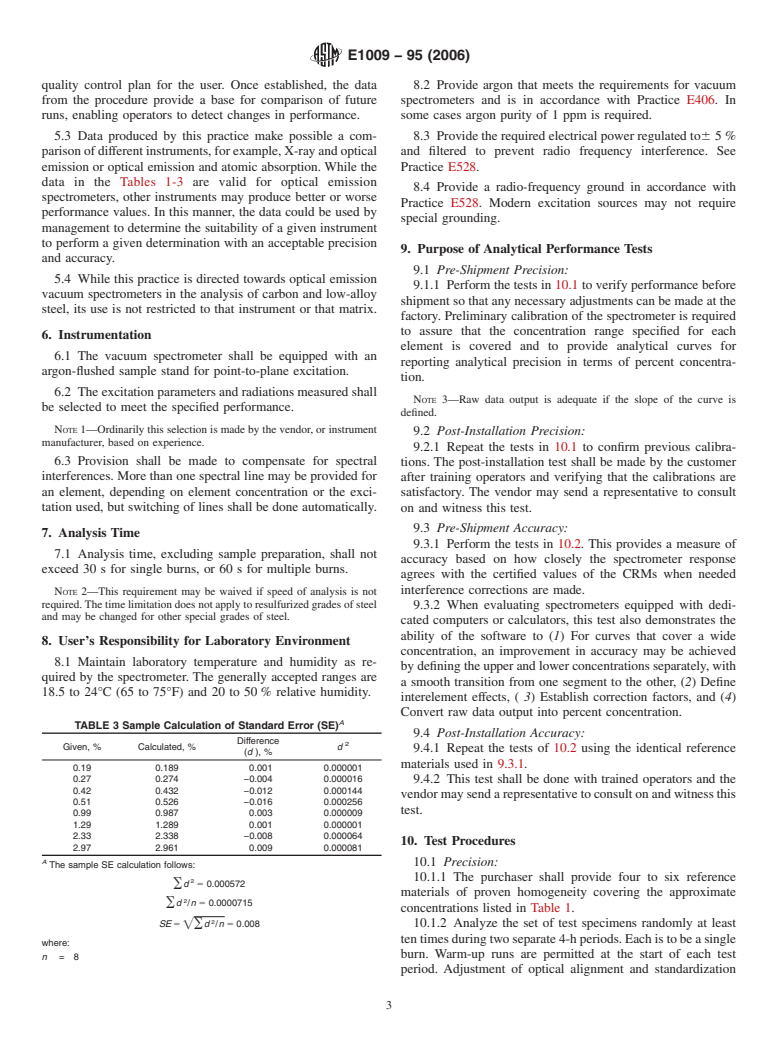

3.2.2 standard error (SE)—although primarily a calculation

priate safety and health practices and determine the applica-

thatmeasureshowwellacalibrationhasbeendefined,standard

bility of regulatory limitations prior to use.

error (SE) is used in this practice as an indicator of accuracy.

It is CRM-dependent and instrument-operator dependent.

2. Referenced Documents

Some expected maximum SE values are listed, but compari-

2.1 ASTM Standards:

sons between instrument calibrations can strictly be done only

E135 Terminology Relating to Analytical Chemistry for

when identical suites of calibrants are used.

Metals, Ores, and Related Materials

E305 Practice for Establishing and Controlling Atomic 4. Summary of Practice

Emission Spectrochemical Analytical Curves

4.1 After the spectrometer is calibrated, use this practice to

evaluate the instrument and its calibration. Certified reference

materials are run as unknowns and precision is compared to

This practice is under the jurisdiction of ASTM Committee E01 on Analytical

Chemistry for Metals, Ores, and Related Materials and is the direct responsibility of

Table 1. Before comparing standard errors to those in Table 2,

Subcommittee E01.01 on Iron, Steel, and Ferroalloys.

ascertain that the calibration does not include unrealistic

Current edition approved June 1, 2006. Published June 2006. Originally

inflections. Values equal to or less than those in Tables 1 and 2

approved in 1990. Last previous edition approved in 2000 as E1009 – 95 (2000).

DOI: 10.1520/E1009-95R06. indicate that the instrument is acceptable.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1009 − 95 (2006)

A

TABLE 1 Recommended Precision Requirements For Steel TABLE 1(a) Revised Data

A

Using An Optical Emission Vacuum Spectrometer

Approximate Standard

Element

Approximate Standard Concentration, % Deviation

Element

Concentration, % Deviation C 0.015 0.0009

C 1.03 0.012

C 0.06 ±0.002

MN 0.067 0.0006

0.15 0.004

Mn 2.00 0.023

0.50 0.010

P 0.0032 0.0007

0.90 0.015

S 0.0024 0.0001

Mn 0.35 0.007

Si 0.01 0.0002

0.60 0.015

Ni 0.021 0.0004

1.00 0.02

Ni 2.00 0.005

1.50 0.03

CR 1.48 0.009

P 0.006 0.0007

Mo 0.005 0.0004

0.04 0.0015

Mo 0.50 0.002

S 0.005 0.0015

Cu 0.015 0.0003

0.04 0.002

Cu 0.30 0.0007

0.06 0.004

Ti 0.0055 0.0004

Si 0.02 0.004

Al 0.004 0.0004

0.30 0.006

Al 0.04 0.0007

0.50 0.010

Nb 0.01 0.0005

Ni 0.03 0.002

Nb 0.1 0.002

0.10 0.003

B 0.001 0.0001

0.70 0.007

B 0.005 0.0001

1.60 0.03

Zr 0.013 0.0007

Cr 0.04 0.002

Pb 0.002 0.0004

0.30 0.007

As 0.01 0.0003

0.80 0.015

As 0.055 0.002

Sn 0.003 0.0006

A

0.02 0.0015

These precisions were generated from data that were collected on newer

0.05 0.002

instruments than the original data.

V 0.01 0.0015

TABLE 2 Elements, Concentration Ranges, and Recommended

0.03 0.002

Acceptable Standard Error (SE) for Steel

0.25 0.007

Approximate Concentration

Mo 0.03 0.003

Max Allowable Standard

Element Range, %, as Covered by the

0.30 0.008 A

Error, %

Certified Standards

Cu 0.02 0.0007

0.15 0.003

C 0.02 to 1.00 0.009

Ti 0.02 0.002

Mn 0.01 to 1.50 0.012

0.20 0.008

P 0.001 to 0.07 0.002

Al 0.006 0.002

S 0.003 to 0.06 0.002

0.02 0.003

Si 0.005 to 1.00 0.012

0.07 0.004

Ni 0.01 to 2.00 0.014

Nb 0.02 0.0015

Cr 0.01 to 1.00 0.012

0.07 0.003

Sn 0.002 to 0.10 0.002

B 0.001 0.00015

V 0.002 to 0.50 0.005

0.07 0.003

Mo 0.003 to 0.50 0.005

Zr 0.05 0.002

Cu 0.005 to 0.50 0.007

Pb 0.01 0.0015

Ti 0.003 to 0.25 0.005

Se 0.02 0.002

Al 0.005 to 0.25 0.005

B

A Nb 0.002 to 0.30

These precisions were generated from actual data in one laboratory; as such,

B 0.0001 to 0.04 0.001

they represent what has been done with proven, homogeneous materials.

B

Zr 0.01 to 1.00

B

Pb 0.001 to 0.03

B

Se 0.001 to 0.05

A

These values will depend on the standards used and the distribution of their

compositions throughout the range of calibration.

B

Accuracy will not be assessed for these elements due to lack of CRM’s.

5. Significance and Use

5.1 Periodically throughout the useful life of an optical

emission spectrometer it becomes necessary to evaluate its

performance. This is especially true at manufacture and during

installation. The objective at this time is to establish whether

the instrument meets design specifications and performs to

customer specifications. A manufacturer’s objective may be to

compare production line instruments. With data on many

instruments, such an evaluation procedure would be a valuable

contribution to the manufacturer’s quality control plan.

5.2 Use of this procedure at installation can tell the manu-

facturer or user whether there has been a significant change in

performance due to faulty shipping or handling of the instru-

ment. At this time, the procedure could be the beginning of a

E1009 − 95 (2006)

quality control plan for the user. Once established, the data 8.2 Provide argon that meets the requirements for vacuum

from the procedure provide a base for comparison of future spectrometers and is in accordance with Practice E406.In

runs, enabling operators to detect changes in performance. some cases argon purity of 1 ppm is required.

5.3 Data produced by this practice make possible a com- 8.3 Provide the required electrical power regulated to65%

parisonofdifferentinstruments,forexample,X-rayandoptical and filtered to prevent radio frequency interference. See

emission or optical emission and atomic absorption. While the Practice E528.

data in the Tables 1-3 are valid for optical emission

8.4 Provide a radio-frequency ground in accordance with

spectrometers, other instruments may produce better or worse

Practice E528. Modern excitation sources may not require

performance values. In this manner, the data could be used by

special grounding.

management to determine the suitability of a given instrument

to perform a given determination with an acceptable precision

9. Purpose of Analytical Performance Tests

and accuracy.

9.1 Pre-Shipment Precision:

5.4 While this practice is directed towards optical emission

9.1.1 Perform the tests in 10.1 to verify performance before

vacuum spectrometers in the analysis of carbon and low-alloy

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.