ASTM E855-90(2000)

(Test Method)Standard Test Methods for Bend Testing of Metallic Flat Materials for Spring Applications Involving Static Loading

Standard Test Methods for Bend Testing of Metallic Flat Materials for Spring Applications Involving Static Loading

SIGNIFICANCE AND USE

Measurements of bending strength and modulus of elasticity in bending should be made for materials whose principal stressing mode is bending. For many materials, the tensile and compressive moduli are somewhat different. Since the bending modulus is a combination of the tensile and compressive moduli, it is often different from each of them.

Precise measurements of the modulus of elasticity in bending and bending strength require due regard for numerous variables that may affect their determination. These include (1) characteristics such as specimen orientation with respect to the rolling direction, grain size, residual stresses, previous strain history, dimensions and specimen preparation, orientation of deformed grains relative to the direction of the normal stress; and (2) test conditions, such as tem-

perature, temperature variations, condition of the test equipment and adherence to the recommended test procedure.

SCOPE

1.1 This standard describes three test methods for determining the modulus of elasticity in bending and the bending strength of metallic strips or sheets intended for the use in flat springs:

1.1.1 Test Method A--a cantilever beam,

1.1.2 Test Method B--a three-point loaded beam (that is, a beam resting on two supports and centrally loaded), and

1.1.3 Test Method Ca four-point loaded beam (that is, a beam resting on two supports and loaded at two points equally spaced from each support).

1.2 Values stated in inch-pound units are to be regarded as the standard. SI units are provided for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E855–90(Reapproved 2000)

Standard Test Methods for

Bend Testing of Metallic Flat Materials for Spring

Applications Involving Static Loading

This standard is issued under the fixed designation E855; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 bend properties—those properties of a material that

2 are associated with elastic and inelastic behavior when a

1.1 This standard describes three test methods for deter-

bending force is applied, or that involve the relationship

mining the modulus of elasticity in bending and the bending

between bending stress and strain.

strength of metallic strips or sheets intended for the use in flat

−2

3.1.3 bending stress at outer fiber (FL )—the nominal

springs:

stressintheouterfibersofabeamresultingfromapplicationof

1.1.1 Test Method A—a cantilever beam,

a bending load.

1.1.2 Test Method B—a three-point loaded beam (that is, a

−2

3.1.4 elastic limit in bending (FL )—the greatest bending

beam resting on two supports and centrally loaded), and

stress that a material is capable of sustaining without perma-

1.1.3 Test Method C—a four-point loaded beam (that is, a

nent strain remaining after complete release of the bending

beam resting on two supports and loaded at two points equally

moment.

spaced from each support).

−2

3.1.5 modulus of elasticity in bending (FL )—the ratio of

1.2 Values stated in inch-pound units are to be regarded as

bendingstresstocorrespondingstrainbelowtheelasticlimitin

the standard. SI units are provided for information only.

bending.

1.3 This standard does not purport to address all of the

3.1.6 span length (L)—the distance between supports.

safety concerns, if any, associated with its use. It is the

3.1.7 uniform bending moment (FL)—a bending moment

responsibility of the user of this standard to establish appro-

thatproducesauniformstrainattheouterfibersthroughoutthe

priate safety and health practices and determine the applica-

gage length of the specimen.

bility of regulatory limitations prior to use.

−2

3.1.8 bending proof strength (FL )—the nominal stress in

2. Referenced Documents the outer fibers of a beam that results in a specific permanent

strain in the outer fibers upon unloading.

2.1 The following documents of the issue in effect on date

−2

3.1.9 cyclic bending yield strength (FL )—the maximum

of use of these test methods form a part of these test methods

nominalstressinuniformcyclicbendingresultingfromagiven

to the extent referenced herein:

plastic deformation in the outer fibers of a beam.

2.2 ASTM Standards:

−2

3.1.10 offset yield strength in bending (FL )—the nominal

E4 Practices for Force Verification of Testing Machines

stress in the outer fibers of a beam in bending at which a

E6 Terminology Relating to Methods of Mechanical Test-

specified limiting deviation from proportionality of bending

ing

stresstobendingstrainisexhibited.Thedeviationisexpressed

E111 TestMethodforYoung’sModulus,TangentModulus,

in terms of strain.

and Chord Modulus

4. Significance and Use

3. Terminology

4.1 Measurements of bending strength and modulus of

3.1 Definitions of Terms Specific to This Standard:

elasticity in bending should be made for materials whose

3.1.1 In addition to the terms in Terminology E6, the

principal stressing mode is bending. For many materials, the

following descriptions of terms apply in connection with these

tensile and compressive moduli are somewhat different. Since

test methods for determining bend properties:

the bending modulus is a combination of the tensile and

compressive moduli, it is often different from each of them.

These test methods are under the jurisdiction of ASTM Committee E28 on

4.2 Precise measurements of the modulus of elasticity in

Mechanical Testing and are the direct responsibility of Subcommittee E28.02 on

bending and bending strength require due regard for numerous

Ductility and Flexure Testing.

Current edition approved March 30, 1990. Published May 1990. Originally variablesthatmayaffecttheirdetermination.Theseinclude(1)

published as E855–81. Last previous edition E855–84.

characteristics such as specimen orientation with respect to the

MethodD,whichappearedinthelastpreviousedition,wasdroppedbecauseof

rolling direction, grain size, residual stresses, previous strain

the unavailability of commercial testing equipment.

history, dimensions and specimen preparation, orientation of

Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E855

deformed grains relative to the direction of the normal stress; 8.3 Due to necessary approximations in this test method

and (2) test conditions, such as tem- regarding the specimen’s deflection, D, and span, L,itis

perature, temperature variations, condition of the test equip- recommended that a deflection angle of 30° not be exceeded.

ment and adherence to the recommended test procedure. These approximations are explained in Appendix X1.

8.4 Rate of loading is controlled only to the extent that the

5. Fundamental Assumptions

rate of angular change of the rotating jaw is fixed at 58 to

5.1 The test section of the specimen is subjected to uniform

66°/min. Actual rate of stressing will depend on the specimen

bending moment (applies to Test Method C only).

width and thickness and the weight of the pendulum.

5.2 The neutral axis is located at the centerline of the

thickness of the test specimen.

5.3 Transverse cross sections of the beam remain plane and

normal to the longitudinal fibers of the beam during bending.

5.4 The effect of shear stresses is negligible.

TEST METHOD A—CANTILEVER BEAM TEST

6. Scope

6.1 This test method covers the determination of the modu-

lus of elasticity in bending and the offset yield strength in

bending of flat metallic strips or sheets for spring applications.

The test procedure involves measurements of the applied

moment and the corresponding angle of deflection of a

cantileverbeam.Thethicknessrangecoveredis0.015to0.130

in. (0.38 to 3.30 mm). This test method is not applicable for

(Test Method A)

nonlinear elastic materials.

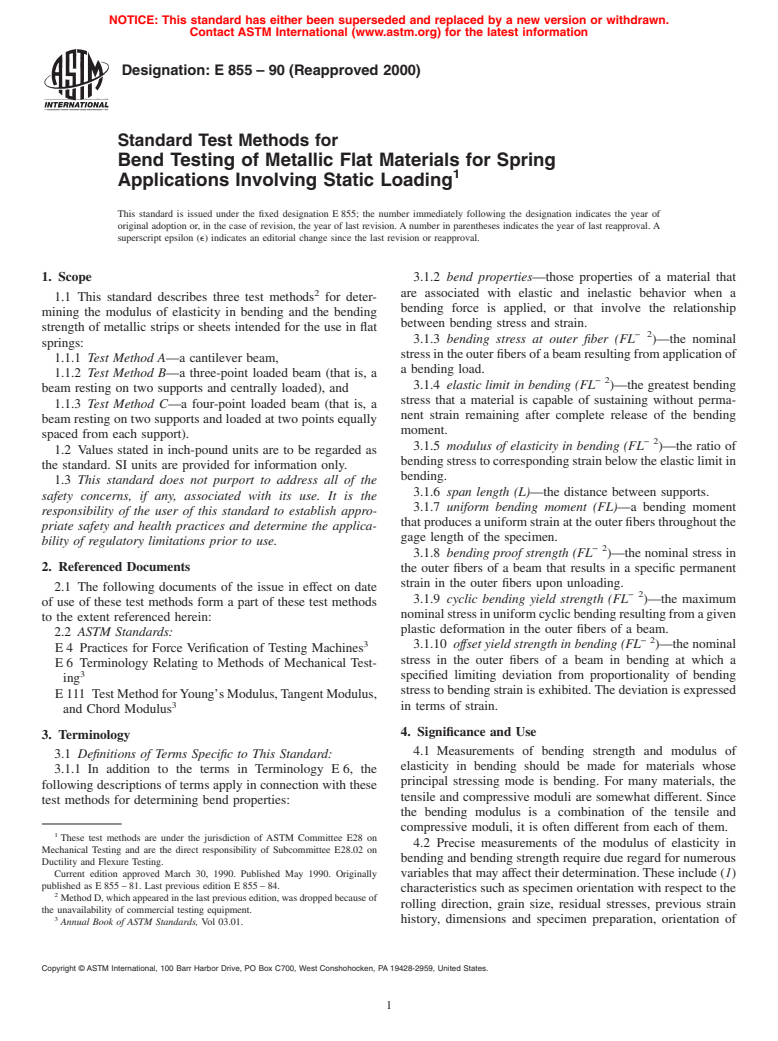

FIG. 1 Cantilever Bend Test Apparatus

7. Summary of Test Method

7.1 Thetestspecimenisloadedasasimplecantileverbeam,

9. Apparatus

and the bending moment is measured at predetermined incre-

ments of angular deflection. When the maximum desired

9.1 The cantilever bend test apparatus shown in Fig. 1

deflection is reached, the bending moment is removed and the

consists of the following components:

permanent set angle resulting from the bend is recorded. All

9.1.1 Specimen Holder, A vise, V, to which an angular

testing is performed under conditions of plane strain (that is,

deflection indicator, I , is attached. The specimen holder is

ratio of specimen width/thickness >10). The bending moment

rotated about point O.

and deflection data obtained are normalized with regard to

9.1.2 Pendulum Weighing System, composed of a set of

specimengeometry.Thesenormalizedtermsarethenplottedto

detachable weights, an angular deflection scale with a moment

produce a stress-strain curve for cantilever bending that is

pointer indicator, I , a loading pin that transmits the bending

similar to a stress-strain curve for tension or compression. The

force of the pendulum system to the free end of the cantilever

modulusofelasticityinbendingandtheoffsetyieldstrengthin

specimen,andaweighttocounter-balancetheloadingpin.The

bending are determined from the bending stress-strain curve

pendulum weighing system pivots about point O. For a

using a procedure similar to that used for tensile stress-strain

pendulumsystem(Fig.2)havingnointernalmoments,thetotal

curves.

bending moment, M, is:

M 5wdsinu (1)

8. Significance and Use

8.1 This test method may be used for obtaining values of

where:

offset yield strength in bending and modulus of elasticity in

M = bending moment at angle u, lbf·in (N·m),

bending. These values are useful to spring designers to

w = total load applied by pendulum system, lbf (N),

determine spring constants and permissible maximum deflec-

d = length of the pendulum arm, in (m), and

tion of flat springs. It should be recognized that the offset yield

u = anglethroughwhichthependulumsystemrotates,rad.

strength in bending as determined by this test method is not

necessarily equal to either the yield strength in tension, the

9.1.3 Angular Deflection Scale,A,isgraduatedindegreesof

cyclic yield strength in bending, or to bending proof strengths

arc and indicates the angle through which the rotating vise has

determined by other methods.

been turned relative to the pendulum system. This is the

8.2 The test method can also serve the following purposes:

difference between the angle through which the vise has been

8.2.1 For research and development to study the effects of

turned and the angle through which the load pendulum has

metallurgical variables, such as composition, heat treatment,

been deflected, and is designated as angle f. The loading pin

fabrication operations and alloy development.

hasadiameterof0.25in.(6.35mm),andthedistancebetween

8.2.2 Forinformationorspecificationpurposes,toprovidea

manufacturing quality control where suitable correlations have

been established with service behavior. The Olsen Stiffness Tester meets the requirements of this test method.

E855

variation is 6%, and the total error attributable to both measurement and

the clamping point (that is, center of rotation of the pendulum

actual variation is 8%. Additional sources of uncertainty are the preci-

system) and the center of the loading pin is 2.0 in. (50.8 mm).

sions of determining the span length, the specimen width, and the beam

The reason for specifying the pin diameter and pin location is

deflection.

explained in Appendix X1.

10.4 The ratio of the specimen span to thickness shall be

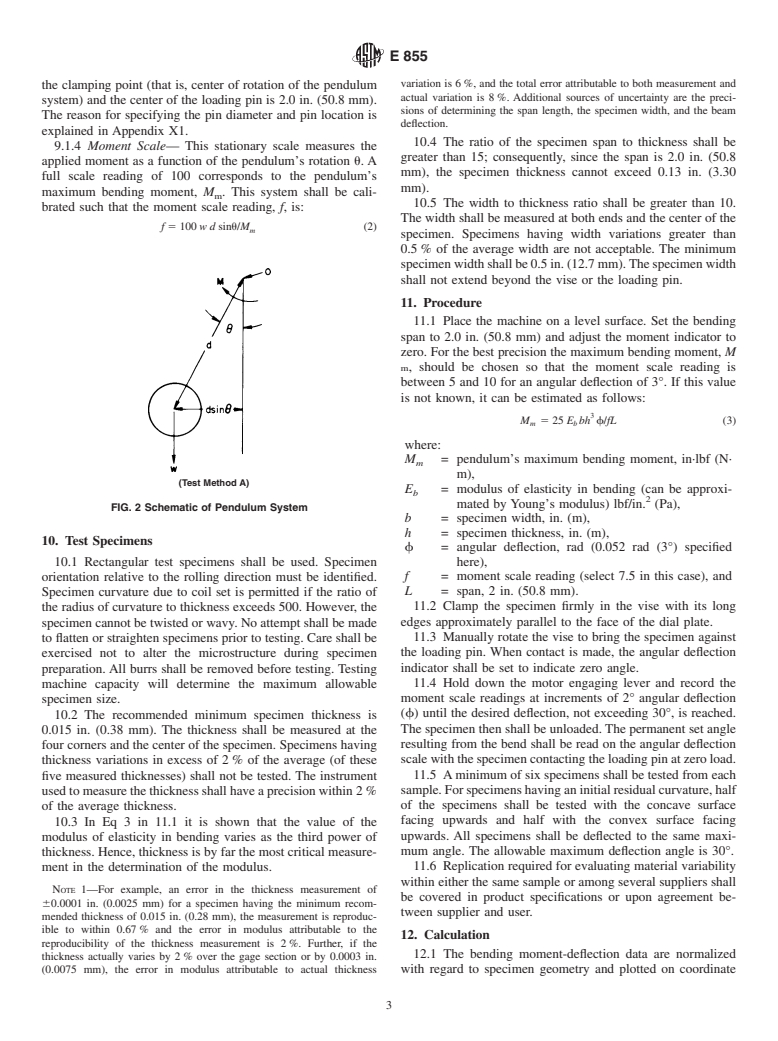

9.1.4 Moment Scale— This stationary scale measures the

greater than 15; consequently, since the span is 2.0 in. (50.8

applied moment as a function of the pendulum’s rotation u.A

mm), the specimen thickness cannot exceed 0.13 in. (3.30

full scale reading of 100 corresponds to the pendulum’s

mm).

maximum bending moment, M . This system shall be cali-

m

10.5 The width to thickness ratio shall be greater than 10.

brated such that the moment scale reading, f, is:

The width shall be measured at both ends and the center of the

f 5100wdsinu/M (2)

m

specimen. Specimens having width variations greater than

0.5% of the average width are not acceptable. The minimum

specimenwidthshallbe0.5in.(12.7mm).Thespecimenwidth

shall not extend beyond the vise or the loading pin.

11. Procedure

11.1 Place the machine on a level surface. Set the bending

span to 2.0 in. (50.8 mm) and adjust the moment indicator to

zero. For the best precision the maximum bending moment, M

m, should be chosen so that the moment scale reading is

between 5 and 10 for an angular deflection of 3°. If this value

is not known, it can be estimated as follows:

M 525 E bh f/fL (3)

m b

where:

M = pendulum’s maximum bending moment, in·lbf (N·

m

m),

(Test Method A)

E = modulus of elasticity in bending (can be approxi-

b

mated by Young’s modulus) lbf/in. (Pa),

FIG. 2 Schematic of Pendulum System

b = specimen width, in. (m),

h = specimen thickness, in. (m),

10. Test Specimens

f = angular deflection, rad (0.052 rad (3°) specified

10.1 Rectangular test specimens shall be used. Specimen

here),

f = moment scale reading (select 7.5 in this case), and

orientation relative to the rolling direction must be identified.

L = span, 2 in. (50.8 mm).

Specimen curvature due to coil set is permitted if the ratio of

11.2 Clamp the specimen firmly in the vise with its long

the radius of curvature to thickness exceeds 500. However, the

edges approximately parallel to the face of the dial plate.

specimencannotbetwistedorwavy.Noattemptshallbemade

11.3 Manually rotate the vise to bring the specimen against

to flatten or straighten specimens prior to testing. Care shall be

the loading pin. When contact is made, the angular deflection

exercised not to alter the microstructure during specimen

indicator shall be set to indicate zero angle.

preparation.All burrs shall be removed before testing. Testing

11.4 Hold down the motor engaging lever and record the

machine capacity will determine the maximum allowable

moment scale readings at increments of 2° angular deflection

specimen size.

(f) until the desired deflection, not exceeding 30°, is reached.

10.2 The recommended minimum specimen thickness is

0.015 in. (0.38 mm). The thickness shall be measured at the The specimen then shall be unloaded.The permanent set angle

resulting from the bend shall be read on the angular deflection

four corners and the center of the specimen. Specimens having

thickness variations in excess of 2% of the average (of these scalewiththespecimencontactingtheloadingpinatzeroload.

11.5 Aminimum of six specimens shall be tested from each

five measured thicknesses) shall not be tested. The instrument

usedtomeasurethethicknessshallhaveaprecisionwithin2% sample.Forspecimenshavinganinitialresidualcurvature,half

of the specimens shall be tested with the concave surface

of the average thickness.

facing upwards and half with the convex surface facing

10.3 In Eq 3 in 11.1 it is shown that the value of the

upwards. All specimens shall be deflected to the same maxi-

modulus of elasticity in bending varies as the third power of

mum angle. The allowable maximum deflection angle is 30°.

thickness. Hence, thickness is by far the most critical measure-

11.6 Replication required for evaluating material variability

ment in the determination of the modulus.

within either the same sample or among several suppliers shall

NOTE 1—For example, an error in the thickness measurement of

be covered in product specifications or upon agreement be-

60.0001 in. (0.0025 mm) for a specimen having the minimum recom-

tween supplier and user.

mended thickness of 0.015 in. (0.28 mm), the measurement is reproduc-

ible to within 0.67% and the error in modulus attributable to the

12. Calculation

reproducibility of the thickness measurement is 2%. Further, if the

12.1 The bending moment-deflection data are normalized

thickness actually varies by 2% over the gage section or by 0.0003 in.

(0.0075 mm), the error in modulus attributable to actual thickness with regard to specimen geometry and plotted on coordinate

E855

paper with the bending stress having (3M f/50bh )asthe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.