ASTM D4549-00

(Specification)Standard Specification for Polystyrene and Rubber-Modified Polystyrene Molding and Extrusion Materials (PS)

Standard Specification for Polystyrene and Rubber-Modified Polystyrene Molding and Extrusion Materials (PS)

SCOPE

1.1 This specification covers polystyrene materials, both crystal and rubber modified, suitable for molding and extrusion. Recycled polystyrene products are addressed in Specification D5676.

1.2 This specification is intended to be a means of calling out plastic materials used in the fabrication of end items or parts. Material selection should be made by those having expertise in the plastics field after careful consideration of the design and the performance required of the part, the environment to which it will be exposed, the fabrication process to be employed, the inherent properties of the material other than those covered by this specification, and the economics.

1.3 The properties included in this specification are those required to identify the compositions covered. Other requirements necessary to identify particular characteristics important to specialized applications can be called out using the suffixes as given in Section 5.

Note 1--This standard combines elements from ISO 1622-1-2 and ISO 2897-1-2, but is not equivalent to either ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4549 – 00

Standard Specification for

Polystyrene and Rubber-Modified Polystyrene Molding and

Extrusion Materials (PS)

This standard is issued under the fixed designation D 4549; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 1525 Test Method for Vicat Softening Temperature of

Plastics

1.1 This specification covers polystyrene materials, both

D 1600 Terminology for Abbreviated Terms Relating to

crystal and rubber modified, suitable for molding and extru-

Plastics

sion. Recycled polystyrene products are addressed in Specifi-

D 2584 Test Method for Ignition Loss of Cured Reinforced

cation D 5676.

Resins

1.2 This specification is intended to be a means of calling

D 3892 Practice for Packaging/Packing of Plastics

out plastic materials used in the fabrication of end items or

D 4000 Classification System for Specifying Plastic Mate-

parts. Material selection should be made by those having

rials

expertise in the plastics field after careful consideration of the

D 5676 Specification for Recycled Polystyrene Molding

design and the performance required of the part, the environ-

and Extrusion Materials

ment to which it will be exposed, the fabrication process to be

E 105 Practice for Probability Sampling of Materials

employed, the inherent properties of the material other than

2.2 ISO Standards:

those covered by this specification, and the economics.

ISO 1622-1-2 Polystyrene (PS) Molding and Extrusion Ma-

1.3 The properties included in this specification are those

terials

required to identify the compositions covered. Other require-

ISO 2897-1-2 Impact Resistant Polystyrene (PS-I) Molding

ments necessary to identify particular characteristics important

and Extrusion Materials

to specialized applications can be called out using the suffixes

as given in Section 5.

3. Terminology

NOTE 1—This standard combines elements from ISO 1622-1-2 and ISO

3.1 Definitions — For definitions of technical terms pertain-

2897-1-2, but is not equivalent to either ISO standard.

ing to plastics used in this specification, see Terminology

D 883.

2. Referenced Documents

2.1 ASTM Standards:

4. Classification

D 256 Test Methods for Determining the Izod Pendulum

4.1 Polystyrene materials are classified into groups accord-

Impact Resistance of Plastics

ing to classes and grades as shown in the basic property table

D 618 Practice for Conditioning Plastics for Testing

(Table PS). Injection molded properties are the preferred

D 638 Test Method for Tensile Properties of Plastics

standard and are used for the basis of call out examples.

D 648 Test Method for Deflection Temperature of Plastics

NOTE 2—Since compression molded properties have been removed

Under Flexural Load in the Edgewise Position

from the standard with this publication, refer to previous publications of

D 790 Test Methods for Flexural Properties of Unreinforced

this standard, if interested in these properties.

and Reinforced Plastics and Electrical Insulating Materi-

NOTE 3—An example of this classification system for PS0111 is as

als

follows: The designation PS0111 would indicate: PS = polystyrene as

D 792 Test Methods for Density and Specific Gravity (Rela-

found in Terminology D 1600, 01 (group) = crystal polystyrene, 1 (class)

tive Density) of Plastics by Displacement

= general-purpose, and 1 (grade) = minimum-grade requirements as found

D 883 Terminology Relating to Plastics in Table PS.

D 1238 Test Method for Melt Flow Rates of Thermoplastics

4.1.1 To facilitate the incorporation of future or special

by Extrusion Plastometer

materials, the “other/unspecified” category (0) for group, class,

This specification is under the jurisdiction of ASTM Committee D20 on

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Annual Book of ASTM Standards, Vol 08.02.

Materials. Annual Book of ASTM Standards, Vol 08.03.

Current edition approved Nov. 10, 2000. Published February 2001. Originally Annual Book of ASTM Standards, Vol 14.02.

published as D 4549 – 85. Last previous edition D 4549 – 98. Available from American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 08.01. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 4549

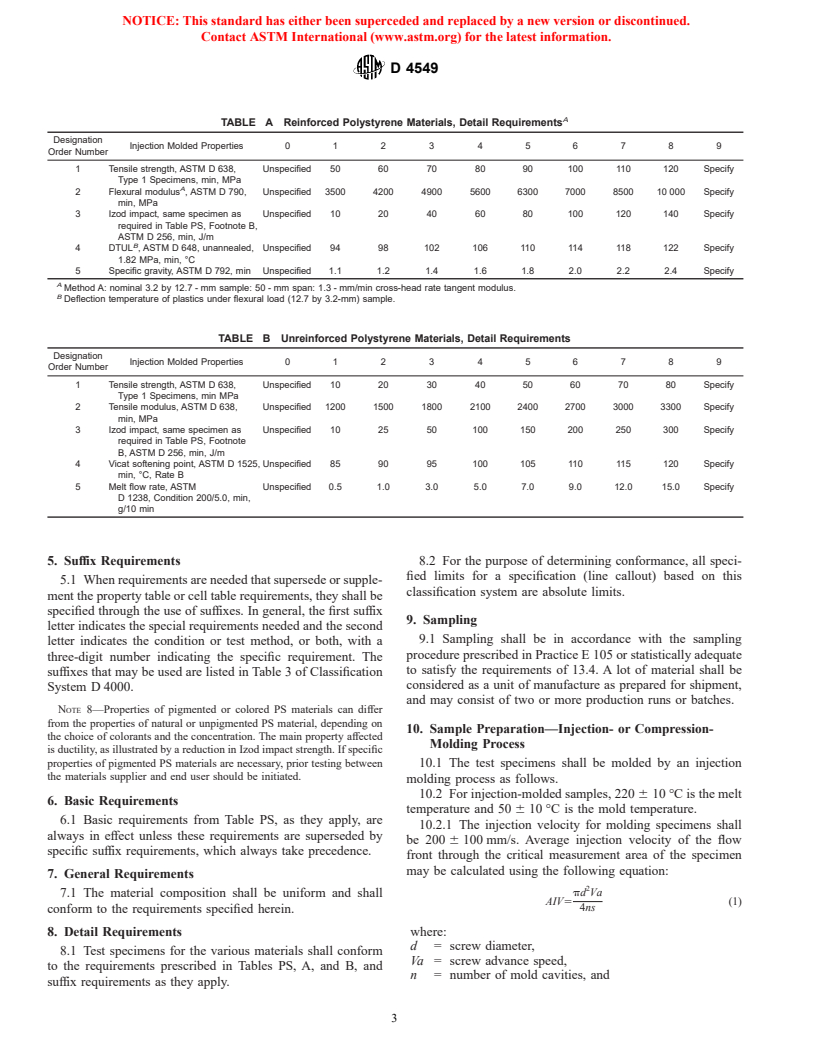

and grade is shown in Table PS. The basic properties can be 4.2.2.1 Although the values listed are necessary to include

obtained from Tables A or B as they apply (see 4.3).

the range of properties available in existing materials, users

4.2 Reinforced and filled polystyrene materials are classi-

should not infer that every possible combination of the

fied in accordance with Table PS and Table A. Table PS

properties exists or can be obtained.

specifies unreinforced material and Table A the properties after

NOTE 6—An example of a reinforced polystyrene of this classification

addition of reinforcements or lubricants at the normal levels

system is as follows: The designation PS0110G15A12332 would indicate

indicated (see 4.2.1).

the following material requirements from Table A:

4.2.1 Reinforcements and Additive Materials—A single let-

0110 = Polystyrene, crystal, from Table PS,

ter will be used for the major reinforcement or combination, or

G15 = Glass-reinforced at 15 % nominal (see 4.2.1),

both, along with two digits that indicate the percentage of

A = Table A for property requirements,

1 = Tensile strength, 50 MPa, min,

addition by mass with the tolerances tabulated as follows:

2 = Flexural modulus, 4200 MPa, min,

Symbol Material Tolerance

3 = Izod impact, 40 J/m, min,

(Based on Total Mass)

3 = Deflection temperature, 102°C, min, and

2 = Specific gravity, 1.2, min.

C Carbon and graphite fiber-rein- 6 2%

If no properties are specified, the designation would be PS0110G15-A00000.

forced

G Glass 6 2%

M Mineral-reinforced 6 2%

L Lubricants Depends upon material

4.3 Table B has been incorporated into this specification to

and process to be

facilitate the classification of special materials where Table PS

specified

R Combination of reinforcement 6 2%

or Table A does not reflect the required properties. Tables shall

or fillers, or both

be used in the same manner as Table A.

NOTE 7—An example of a special material using this classification

NOTE 4—This part of the system uses the type and percentages of

system is as follows: The designation PS0110B76013 would indicate the

additive to designate the modification of the basic material. Percentage of

following, with the material requirements from Table B:

additives can be shown on the supplier’s Technical Data Sheet unless it is

PS0110 = Polystyrene, crystal, from Table PS,

proprietary. If necessary, additional requirements shall be indicated by the

B = Cell Table B for property requirements,

use of the suffix part of the system, as given in Section 5.

7 = Tensile strength, 70 MPa, min,

6 = Tensile modulus, 2700 MPa, min,

NOTE 5—Ash content of filled or reinforced materials may be deter-

0 = Unspecified Izod impact

mined using Test Method D 2584 where applicable.

I = Vicat softening temperature, 85°C, min, and

3 = Flow rate, 3.0, min.

4.2.2 Table A, Detail Requirements—An identifying num-

ber is made up of the letter A and five digits comprising the cell

numbers for the new requirements in the designated order as

they appear in Table A.

TABLE PS Polystyrene Materials, Detail Requirements, Natural Color Only

Melt Flow Rate, Vicat Softening

Izod Impact, (12.7 Tensile Strength at Tensile Modulus,

ASTM D 1238, Point, ASTM

by 3.2 mm) ASTM Yield, ASTM D 638, ASTM D 638, min,

Descrip-

Condition 200/5.0 D 1525, Rate B, °C,

B C,D D

Group Description Class Description Grade

D 256, min, J/m min, MPa MPa

A

tion

g/10 min, min min 1000-g load

Injection molded Injection molded Injection molded Injection molded Injection molded

01 Crystal 1 General- 1 1.0 45 3100 100

Purpose 2 5.0 40 3000 95

3 10.0 35 2900 85

0 Other 0 Other Unspecified Unspecified

02 Rubber- 1 Medium- 1 1.0 40 34 2500 95

modified impact 2 5.0 40 28 2300 90

3 10.0 40 22 2000 85

0 Other Unspecified Unspecified

2 High-impact 1 1.0 80 20 2000 95

2 5.0 80 18 1800 90

3 10.0 80 16 1600 85

0 Other Unspecified Unspecified

3 Super-high- 1 1.0 120 14 1400 90

impact 2 5.0 120 12 1200 85

0 Other 0 Other Unspecified Unspecified

00 Other 0 0

A

Specimen may be pellets, powder, or parts cut into pieces that can fit into the barrel.

B

Method A, specimen are nominal 3.2-mm thick injection-molded and taken from the center of Type I

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.