ASTM D5566-95(2006)

(Test Method)Standard Test Method for Determination of Inorganic Salt Content of Sulfated and Sulfonated Oils

Standard Test Method for Determination of Inorganic Salt Content of Sulfated and Sulfonated Oils

SIGNIFICANCE AND USE

This test method is intended to be used for the determination of the inorganic salt content of sulfated and sulfonated fats and oils for the purpose of quality control.

SCOPE

1.1 This test method covers the determination of a sample of sulfonated or sulfated oil, or both, the inorganic sulfates, chlorides, and all other salts that are insoluble in a mixture of oleic acid and carbon tetrachloride.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5566–95 (Reapproved 2006)

Standard Test Method for

Determination of Inorganic Salt Content of Sulfated and

1

Sulfonated Oils

This standard is issued under the fixed designation D5566; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Thistestmethodcoversthedeterminationofasampleof

sulfonated or sulfated oil, or both, the inorganic sulfates,

chlorides, and all other salts that are insoluble in a mixture of

oleic acid and carbon tetrachloride.

1.2 The values stated in SI units are to be regarded as the

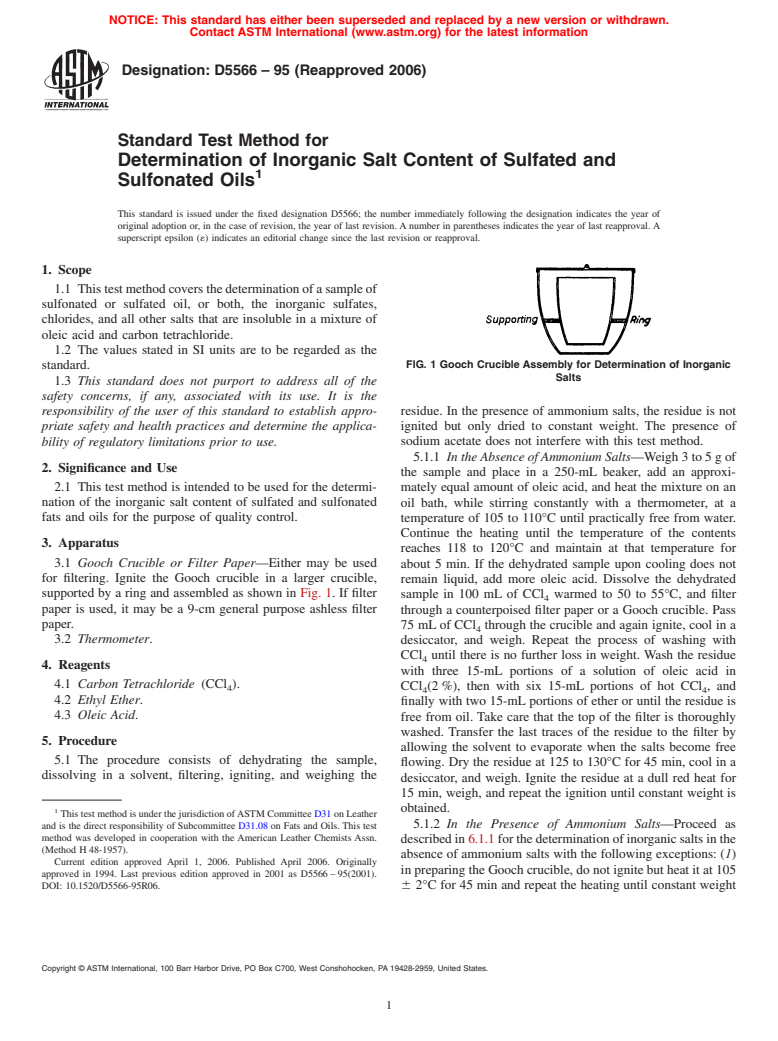

FIG. 1 Gooch Crucible Assembly for Determination of Inorganic

standard.

Salts

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- residue. In the presence of ammonium salts, the residue is not

priate safety and health practices and determine the applica- ignited but only dried to constant weight. The presence of

bility of regulatory limitations prior to use. sodium acetate does not interfere with this test method.

5.1.1 In theAbsence ofAmmonium Salts—Weigh3to5gof

2. Significance and Use

the sample and place in a 250-mL beaker, add an approxi-

2.1 This test method is intended to be used for the determi- mately equal amount of oleic acid, and heat the mixture on an

nation of the inorganic salt content of sulfated and sulfonated oil bath, while stirring constantly with a thermometer, at a

fats and oils for the purpose of quality control. temperature of 105 to 110°C until practically free from water.

Continue the heating until the temperature of the contents

3. Apparatus

reaches 118 to 120°C and maintain at that temperature for

3.1 Gooch Crucible or Filter Paper—Either may be used

about 5 min. If the dehydrated sample upon cooling does not

for filtering. Ignite the Gooch crucible in a larger crucible, remain liquid, add more oleic acid. Dissolve the dehydrated

supported by a ring and assembled as shown in Fig. 1. If filter

sample in 100 mL of CCl warmed to 50 to 55°C, and filter

4

paper is used, it may be a 9-cm general purpose ashless filter

through a counterpoised filter paper or a Gooch crucible. Pass

paper.

75 mL of CCl through the crucible and again ignite, cool in a

4

3.2 Thermometer.

desiccator, and weigh. Repeat the process of washing with

CCl until there is no further loss in weight. Wash the residue

4

4. Reagents

with three 15-mL portions of a solution of oleic acid in

4.1 Carbon Tetrachloride (CCl ).

CCl (2 %), then with six 15-mL portions of hot CCl , and

4

4 4

4.2 Ethyl Ether.

finally with two 15-mL portions of ether or until the residue is

4.3 Oleic Acid.

free from oil. Take care that the top of the filter is thoroughly

washed. Transfer the last traces of the residue to the filter by

5. Procedure

allowing the solvent to evaporate when the salts become free

5.1 The procedure consists of dehydrating the sample,

flowing. Dry the residue at 125 to 130°C for 45 min, cool in a

dissolving in a solvent, filtering, igniting, and weighing the

desiccator, and weigh. Ignite the residue at a dull red heat for

15 min, weigh, and repeat the ignition until constant weight is

obtained.

1

This test method is under the jurisdiction ofASTM Committee D31 on Leather

5.1.2 In the Presenc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.