ASTM D2670-95(2016)

(Test Method)Standard Test Method for Measuring Wear Properties of Fluid Lubricants (Falex Pin and Vee Block Method)

Standard Test Method for Measuring Wear Properties of Fluid Lubricants (Falex Pin and Vee Block Method)

SIGNIFICANCE AND USE

5.1 This test method may be used to determine wear obtained with fluid lubricants under the prescribed test conditions. The user of this test method should determine to his or her own satisfaction whether results of this test procedure correlate with field performance or other bench test machines. If the test conditions are changed, wear values may change and relative ratings of fluids may be different.

SCOPE

1.1 This test method covers a procedure for making a preliminary evaluation of the wear properties of fluid lubricants by means of the Falex Pin and Vee Block Lubricant Test Machine.

Note 1: Certain fluid lubricants may require different test parameters depending upon their performance characteristics.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2670 − 95 (Reapproved 2016)

Standard Test Method for

Measuring Wear Properties of Fluid Lubricants (Falex Pin

and Vee Block Method)

This standard is issued under the fixed designation D2670; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 3.1.2 direct load, n—theloadthatisappliedlinearly,bisect-

ing the angle of the vee block corrected to either the 800lbf or

1.1 This test method covers a procedure for making a

3000lbf gauge reference.

preliminaryevaluationofthewearpropertiesoffluidlubricants

3.1.2.1 Discussion—This load is equivalent to the true load

by means of the Falex Pin and Vee Block Lubricant Test

times the cos 42°.

Machine.

3.1.3 true load, n—the sum of the applied forces normal to

NOTE 1—Certain fluid lubricants may require different test parameters

the tangents of contact between the faces of one vee block and

depending upon their performance characteristics.

the journal pin corrected to the 4500lbf gauge reference line.

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

3.1.4 wear teeth, n—a measurement of wear, which in this

as the standard. The values given in parentheses are for

test, is based on the number of ratchet wheel teeth advanced

information only.

during the test while maintaining load.

1.3 This standard does not purport to address all of the

3.1.4.1 Discussion—The number of teeth is directly related

safety concerns, if any, associated with its use. It is the

to the total wear (inches).

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Summary of Test Method

bility of regulatory limitations prior to use.

4.1 The test consists of running a rotating steel journal

againsttwostationarysteelV-blocksimmersedinthelubricant

2. Referenced Documents

sample. Load is applied to the V-blocks and maintained by a

2.1 ASTM Standards:

ratchet mechanism. Wear is determined and recorded as the

B16/B16MSpecification for Free-Cutting Brass Rod, Bar

numberofteethoftheratchetmechanismadvancedtomaintain

and Shapes for Use in Screw Machines

load constant during the prescribed testing time.

3. Terminology

5. Significance and Use

3.1 Definitions of Terms Specific to This Standard:

5.1 This test method may be used to determine wear

3.1.1 actual gauge load, n—the value obtained from the

obtained with fluid lubricants under the prescribed test condi-

gauge while running the test and before any corrections are

tions. The user of this test method should determine to his or

made.

her own satisfaction whether results of this test procedure

3.1.1.1 Discussion—Thegaugereadingisirrespectiveofthe

correlate with field performance or other bench test machines.

particulargaugeused,andcorrectionsaremadebycomparison

Ifthetestconditionsarechanged,wearvaluesmaychangeand

to a standard reference.

relative ratings of fluids may be different.

This test method is under the jurisdiction of Committee D02 on Petroleum

6. Apparatus

Products, Liquid Fuels, and Lubricantsand is the direct responsibility of Subcom-

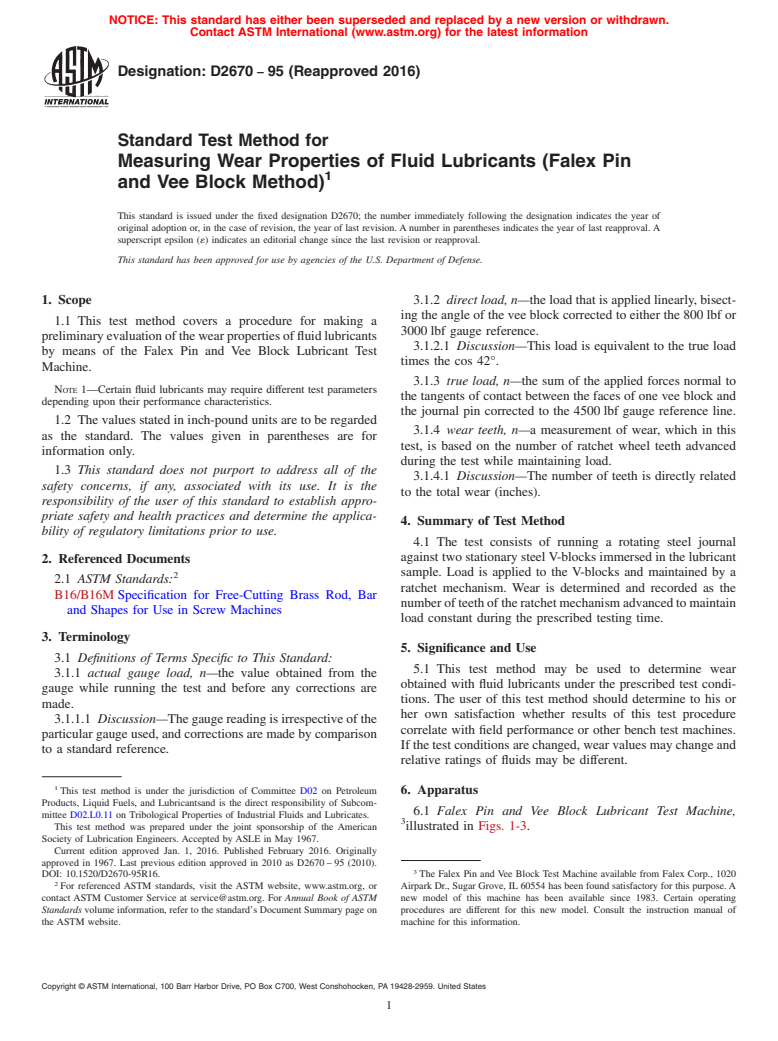

6.1 Falex Pin and Vee Block Lubricant Test Machine,

mittee D02.L0.11 on Tribological Properties of Industrial Fluids and Lubricates.

This test method was prepared under the joint sponsorship of the American

illustrated in Figs. 1-3.

Society of Lubrication Engineers. Accepted by ASLE in May 1967.

Current edition approved Jan. 1, 2016. Published February 2016. Originally

approved in 1967. Last previous edition approved in 2010 as D2670–95 (2010).

DOI: 10.1520/D2670-95R16. The Falex Pin and Vee Block Test Machine available from Falex Corp., 1020

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Airpark Dr., Sugar Grove, IL60554 has been found satisfactory for this purpose.A

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM new model of this machine has been available since 1983. Certain operating

Standards volume information, refer to the standard’s Document Summary page on procedures are different for this new model. Consult the instruction manual of

the ASTM website. machine for this information.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2670 − 95 (2016)

7. Reagents and Materials

7.1 Required for Calibration of Load Gauge:

7.1.1 Allen Screw, with attached 10mm Brinell ball.

7.1.2 Back-Up Plug.

7.1.3 Standard Test Coupon, soft, annealed copper, HB 37

to 39.

7.1.4 Brinell Microscope, or equivalent,

7.1.5 Timer, graduated in seconds and minutes, and

7.1.6 Rule, steel, 6in. (approximately 150mm) long.

7.2 Required for Test:

7.2.1 Standard Coined V-Blocks, 96° 6 1° angle, AISI

C-1137 steel HRC 20 to 24, surface finish 5µin. to 10µin.

−7 −7

(1.3×10 to 2.5×10 m), rms,

7.2.2 Standard Test Journals, ⁄4in. (6.35mm) outside

diameterby1 ⁄4in.(31.75mm)long,AISI3135steel,HRB87

to 91 on a ground flat surface, surface finish 5µin. to 10µin.,

−7 −7

(1.3×10 to 2.5×10 m), rms,

FIG. 1 Falex Pin and Vee Block Test Machine

7.2.3 Locking Pins, ⁄2 H brass, conforming to Specifica-

tion B16/B16M.

7.2.4 Timer, graduated in seconds and minutes.

7.2.5 Solvent, safe, nonfilming, nonchlorinated.

NOTE2—Petroleumdistillateandbenzene,formerlyusedassolventsin

this test method, have been eliminated due to possible toxic effects. Each

user should select a solvent that can meet applicable safety standards and

still thoroughly clean the parts.

8. Calibration of Load Gauges

8.1 Apparatus with 800 lb or 3000 lb Gauge:

8.1.1 RemovetheAllensetscrewand ⁄2in.(12.70mm)ball

from the left jaw socket (Fig. 4).

8.1.2 InsertthespecialAllenscrewwiththeattached10mm

Brinellballintotheworkingfaceoftheleftjaw.Adjustsothat

ballprojectsabout ⁄32(approximately4mm)fromfaceofjaw.

8.1.3 Insert the back-up plug in the counterbore of the

right-hand jaw. Adjust so that the plug projects about ⁄32in.

FIG. 2 Falex Digital Pin and Vee Block Test Machine

(approximately 0.8 mm) from the face.

8.1.4 Support the standard test coupon so that the upper

edge of the coupon is about ⁄32in. (approximately 2.5mm)

below the upper surface of the jaws. Place a steel rule across

the face of the jaws. Adjust the Allen screw with the attached

10mm ball until the face of the jaws are parallel to the steel

rule with the test coupon in position for indentation.

8.1.5 With the test coupon in position for the first

impression, place the load gauge assembly on the lever arms.

8.1.6 Placetheloadingarmontheratchetwheelandactuate

themotor.Allowthemotortorununtiltheloadgaugeindicates

a load of 200lb. A slight takeup on the ratchet wheel is

required to hold the load due to the ball sinking into the test

coupon.After a 200lb load is obtained, hold for 1min for the

indentation to form.

8.1.7 Turn off the machine and back off the load until the

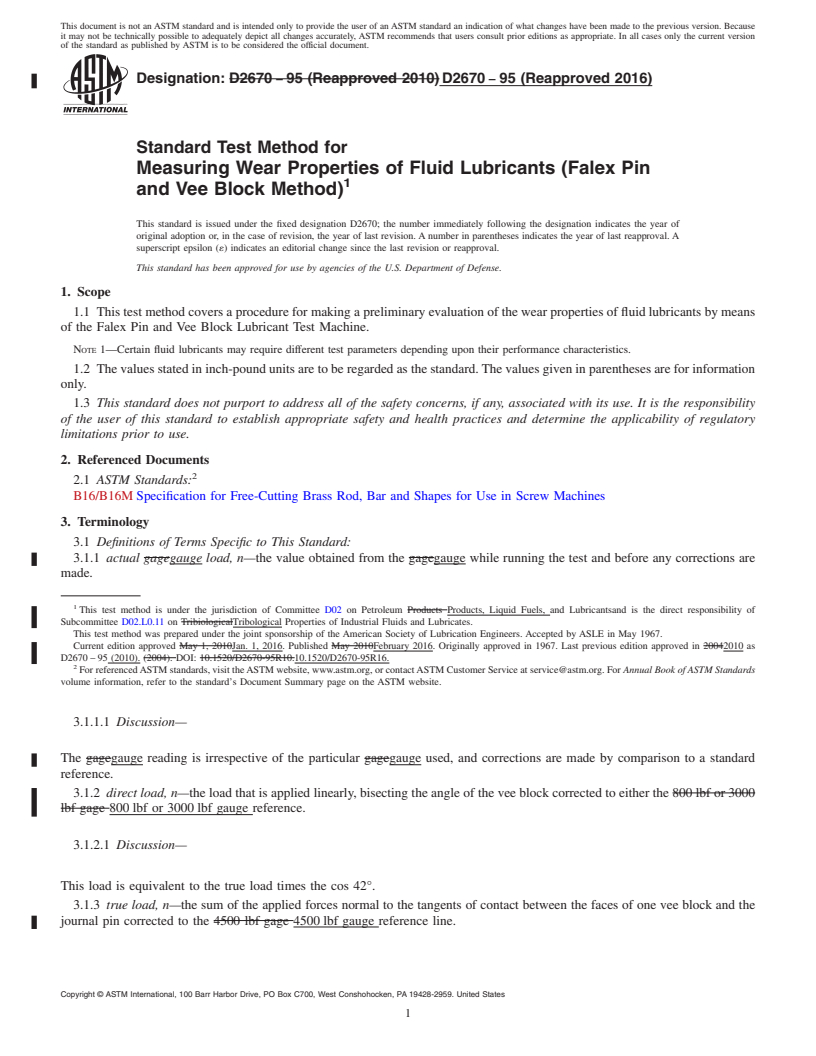

FIG. 3 Exploded View of V-Blocks and Journal Arrangement,

test coupon is free from the jaws. Advance the test coupon

Falex Pin and Vee Block Lubricant Test Machine

approximately ⁄8in. (approximately 9.5mm) (additional in-

dentations should be separated by a minimum distance of

2.5×the diameter of the initial indentation). Check the align-

mentofthejaws,andrepeattheproceduredescribedin8.1.6at

Available from Falex Corp., 1020 Airpark Dr., Sugar Grove, IL 60554.

D2670 − 95 (2016)

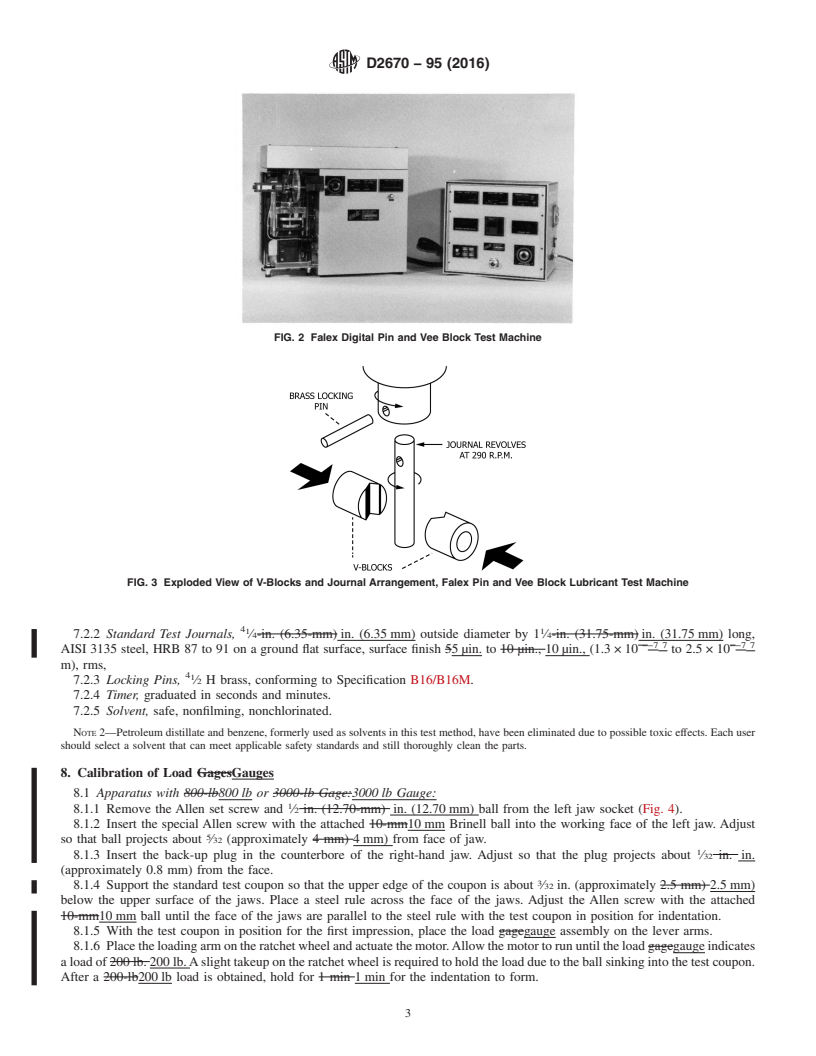

FIG. 4 Schematic Drawing of Calibration Accessories for Falex Pin and Vee Block Lubricant Test Machine

gaugeloadsof400lb,600lb,and800lbwhenusingan800lb mineraloil, USP,havingaviscosityat100°F(37.8°C)of340

gauge.Ifa3000lbgaugeisused,checkat800lb,1500lb,and to390SUS(73.4to84.2cSt).Heattheblend,inaglassbeaker,

2500lb. to 240°F to 250°F (116°C to 121°C) and stir (glass stirrer)

8.1.8 Remove the load gauge assembly and test coupon and for 15min. Designate this mixture as Blend A.

measure the diameter of each indentation to 0.01mm with a

9.2 Prepare, similarly, a blend containing 0.20 weight% of

microscope. Make three measurements of the indentation

sulfur and 99.80 weight% of white mineral oil. Designate this

diameter, rotating the test coupon to ensure that no two

mixture as Blend B.

measurements represent the same points. Average the three

9.3 Refer to Section 8 for recommended use of these

measurements of each impression and record.

standards.

8.1.9 Plot the four impression readings versus gauge load

readings on log-log paper (K and E 467080 or equivalent).

10. Apparatus and Testing Check

From the plot determine the gauge load reading corresponding

10.1 The purpose of this check is to establish that the

to an impression diameter of 3.30mm. Typically, this gauge

apparatus is in satisfactory condition and that the test is being

loadreadingwillbeabout700lb.Thisgaugeloadshallbeused

runinconformancetotheprocedurecoveredinSection13.For

in Section 12. A typical plot of impression diameter versus

such check purposes the fluid standards covered in Section 9

gauge readings is shown in Fig. 5.

should be used (Note 3). The average of triplicate runs on the

8.2 Apparatus with 4500 lb Gauge—Use the same proce-

fluidstandardsshouldfallwithinthefollowinglimits(Note4):

dure as with 800lb gauge, above, except obtain impressions at

Total Teeth Wear, avg.

gauge readings of 300lb, 500lb, 750lb, and 1000lb. Plot the

Blend of triplicate runs

impression readings and determine the gauge load correspond-

A 36to71

ing to an impression diameter of 3.30mm. Typically, this

B 101 to 127

gauge load reading will be about 900lb. This gauge load shall

Repeatability of test data should conform to precision limits

beusedintheprocedure,(Section13).Fig.4includesatypical

set forth in Section 15.

plot of impression diameter versus gauge readings for the

4500lb gauge.

NOTE 3—Three commercial cutting oils were initially chosen as

reference fluid standards. These were replaced by the specified white

9. Test Standards Check oil-sulfur blends because of greater availability, uniformity, and purity.

ResultsofthecooperativetestsonthecuttingoilsarecoveredinAppendix

9.1 Prepare a blend containing 0.10 weight% of sulfur,

X1.

precipitated powder, USP, and 99.90 weight percent white

NOTE 4—These limits were derived from data in Appendix X1. The

limits shown for Blend A are the minimum and maximum averages

Sulfur,sospecified,fromJ.T.BakerChemicalCo.hasbeenfoundsatisfactory.

If you are aware of alternative suppliers, please provide this information toASTM Available from most petroleum refining companies. Also available from most

International Headquarters. Your comments will receive careful consideration at a drug stores, typically labeled White Mineral Oil Extra Heavy. See Table X1.1 for

meeting of the responsible technical committee , which you may attend. specific products found satisfactory in cooperative test work.

D2670 − 95 (2016)

FIG. 5 Typical Curves of Gauge Load Readings versus Impression Diameter, Using 800 lb, 3000 lb, and 4500 lb Gauges and BHN 37 to

39 Standard Test Coupons

obtainedintheSeries2tests.Essentiallythesameaverageswereobtained

12.2 After cleaning, handle the test pieces with care to

in the Series 1 and 3 tests.

prevent contamination. Particularly, avoid contact of fingers

ThelimitsshownforBlendBaretheminimumandmaximumaverages

with mating surfaces of V-blocks and test journals.

obtainedintheSeries1tests.Essentiallythesameaverageswereobtained

in the Series 3 tests.

13. Procedure

11. Test Conditions

13.1 Insert the test journal in the test shaft and secure with

11.1 The test shall be conducted under the following con-

a new brass locking pin, as shown in Figs. 1-3.

ditions (Note 5):

13.2 Insert the V-blocks into the recesses of the loading

Oil temperature at start of test 75 °F ± 10 °F (24 °C ± 3 °C)

deviceandswingtheV-blocksinwardtocontactthejournalso

Speed 290 r ⁄ min ± 10 r ⁄ minm

that the V-grooves are aligned with the journal major axis, as

Gauge load corresponding to 3.30 mm diameter

impression on standard test coupon

shown in Fig. 1 and Fig. 2.

Duration of test 15 min ± 5 s

13.3 Place 60mL of test lubricant in the lubricant cup and

NOTE 5—Although the test can be run under other test conditions, the

raise the cup so that the V-blocks are immersed in the test

precision limits described in Section 14 apply only to tests conducted

lubricant.

under the conditions shown above and the procedure specified in Section

13.

13.4 Place the automatic loading device with attached

gauge, on the jaw arms.

12. Preparation of Apparatus

13.5 Remove slack from assembly by moving the ratchet

12.1 Thoroughly clean the V-blocks, test journals, lubricant

wheel by hand. At this setting the torque gauge should read

cup, and supports for V-blocks and test journals by washing

zero, or be adjusted to read zero.

with the solvent selected in 7.2.5. Dry the V-blocks, test

journals,lubricantcup,andsupports,byallowingthesolventto 13.6 Actuate the motor, engage the automatic loading

evaporate in air. ratchet and increase the gauge load to 250lb if the 800lb or

D2670 − 95 (2016)

3000lb gauge is used, or 350lb if the 4500lb gauge is used. 15.1.1 Repeatability—The difference between successive

Disengage the loading ratchet, start the timer, and allow the test results, obtained by the same operator with the same

machine to run at this loading for a 5min break-in period.

apparatus under constant operating conditions on identical test

material would, in the long run, and in the normal and correct

13.7 Re-engage the automatic loading ratchet and leave it

operation of the test method, exceed the following values only

engaged until the gauge load corresponding to 3.30mm

in one case in twenty:

diameter indentation on the standard test coupon (7.1 and 7.2)

is reached (Note 6). When this gauge load is reached, disen-

22%ofthemean

gage the loading device, start the time, and record the gear

15.1.2 Reproducibility—The difference between two, single

toothnumber(Note7).Runthetestfor15min,maintainingthe

load at near constant during the test by taking up the load, by and independent results, obtained by different operators work-

means of the ratchet wheel, whenever wear causes a drop in ing in different laboratories on identical test material would, in

load of 5lb on the 800lb gauge or 50lb on the 4500lb gauge.

thelongrun,andinthenormalandcorrectoperationofthetest

After15minrunningatthetestload,reducetheloadby100lb

met

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2670 − 95 (Reapproved 2010) D2670 − 95 (Reapproved 2016)

Standard Test Method for

Measuring Wear Properties of Fluid Lubricants (Falex Pin

and Vee Block Method)

This standard is issued under the fixed designation D2670; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This test method covers a procedure for making a preliminary evaluation of the wear properties of fluid lubricants by means

of the Falex Pin and Vee Block Lubricant Test Machine.

NOTE 1—Certain fluid lubricants may require different test parameters depending upon their performance characteristics.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

B16/B16M Specification for Free-Cutting Brass Rod, Bar and Shapes for Use in Screw Machines

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 actual gagegauge load, n—the value obtained from the gagegauge while running the test and before any corrections are

made.

This test method is under the jurisdiction of Committee D02 on Petroleum Products Products, Liquid Fuels, and Lubricantsand is the direct responsibility of

Subcommittee D02.L0.11 on TribiologicalTribological Properties of Industrial Fluids and Lubricates.

This test method was prepared under the joint sponsorship of the American Society of Lubrication Engineers. Accepted by ASLE in May 1967.

Current edition approved May 1, 2010Jan. 1, 2016. Published May 2010February 2016. Originally approved in 1967. Last previous edition approved in 20042010 as

D2670 – 95 (2010). (2004). DOI: 10.1520/D2670-95R10.10.1520/D2670-95R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3.1.1.1 Discussion—

The gagegauge reading is irrespective of the particular gagegauge used, and corrections are made by comparison to a standard

reference.

3.1.2 direct load, n—the load that is applied linearly, bisecting the angle of the vee block corrected to either the 800 lbf or 3000

lbf gage 800 lbf or 3000 lbf gauge reference.

3.1.2.1 Discussion—

This load is equivalent to the true load times the cos 42°.

3.1.3 true load, n—the sum of the applied forces normal to the tangents of contact between the faces of one vee block and the

journal pin corrected to the 4500 lbf gage 4500 lbf gauge reference line.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2670 − 95 (2016)

3.1.4 wear teeth, n—a measurement of wear, which in this test, is based on the number of ratchet wheel teeth advanced during

the test while maintaining load.

3.1.4.1 Discussion—

The number of teeth is directly related to the total wear (inches).

4. Summary of Test Method

4.1 The test consists of running a rotating steel journal against two stationary steel V-blocks immersed in the lubricant sample.

Load is applied to the V-blocks and maintained by a ratchet mechanism. Wear is determined and recorded as the number of teeth

of the ratchet mechanism advanced to maintain load constant during the prescribed testing time.

5. Significance and Use

5.1 This test method may be used to determine wear obtained with fluid lubricants under the prescribed test conditions. The user

of this test method should determine to his or her own satisfaction whether results of this test procedure correlate with field

performance or other bench test machines. If the test conditions are changed, wear values may change and relative ratings of fluids

may be different.

6. Apparatus

6.1 Falex Pin and Vee Block Lubricant Test Machine, illustrated in Figs. 1-3.

7. Reagents and Materials

7.1 Required for Calibration of Load Gage:Gauge:

7.1.1 Allen Screw, with attached 10-mm10 mm Brinell ball.

7.1.2 Back-Up Plug.

7.1.3 Standard Test Coupon, soft, annealed copper, HB 37 to 39.

7.1.4 Brinell Microscope, or equivalent,

7.1.5 Timer, graduated in seconds and minutes, and

7.1.6 Rule, steel, 6-in.6 in. (approximately 150-mm)150 mm) long.

7.2 Required for Test:

7.2.1 Standard Coined V-Blocks, 9696° 6 1° angle, AISI C-1137 steel HRC 20 to 24, surface finish 55 μin. to 10 μin. 10 μin.

−−77 −−7 7

(1.3 × 10 to 2.5 × 10 m), rms,

The Falex Pin and Vee Block Test Machine available from Falex Corp., 1020 Airpark Dr., Sugar Grove, IL 60554 has been found satisfactory for this purpose. A new

model of this machine has been available since 1983. Certain operating procedures are different for this new model. Consult the instruction manual of machine for this

information.

Available from Falex Corp., 1020 Airpark Dr., Sugar Grove, IL 60554.

FIG. 1 Falex Pin and Vee Block Test Machine

D2670 − 95 (2016)

FIG. 2 Falex Digital Pin and Vee Block Test Machine

FIG. 3 Exploded View of V-Blocks and Journal Arrangement, Falex Pin and Vee Block Lubricant Test Machine

1 1

7.2.2 Standard Test Journals, ⁄4-in. (6.35-mm) in. (6.35 mm) outside diameter by 1 ⁄4-in. (31.75-mm) in. (31.75 mm) long,

−−7 7 −−7 7

AISI 3135 steel, HRB 87 to 91 on a ground flat surface, surface finish 55 μin. to 10 μin., 10 μin., (1.3 × 10 to 2.5 × 10

m), rms,

7.2.3 Locking Pins, ⁄2 H brass, conforming to Specification B16/B16M.

7.2.4 Timer, graduated in seconds and minutes.

7.2.5 Solvent, safe, nonfilming, nonchlorinated.

NOTE 2—Petroleum distillate and benzene, formerly used as solvents in this test method, have been eliminated due to possible toxic effects. Each user

should select a solvent that can meet applicable safety standards and still thoroughly clean the parts.

8. Calibration of Load GagesGauges

8.1 Apparatus with 800-lb800 lb or 3000-lb Gage:3000 lb Gauge:

8.1.1 Remove the Allen set screw and ⁄2 in. (12.70-mm) in. (12.70 mm) ball from the left jaw socket (Fig. 4).

8.1.2 Insert the special Allen screw with the attached 10-mm10 mm Brinell ball into the working face of the left jaw. Adjust

so that ball projects about ⁄32 (approximately 4 mm) 4 mm) from face of jaw.

8.1.3 Insert the back-up plug in the counterbore of the right-hand jaw. Adjust so that the plug projects about ⁄32 in. in.

(approximately 0.8 mm) from the face.

8.1.4 Support the standard test coupon so that the upper edge of the coupon is about ⁄32 in. (approximately 2.5 mm) 2.5 mm)

below the upper surface of the jaws. Place a steel rule across the face of the jaws. Adjust the Allen screw with the attached

10-mm10 mm ball until the face of the jaws are parallel to the steel rule with the test coupon in position for indentation.

8.1.5 With the test coupon in position for the first impression, place the load gagegauge assembly on the lever arms.

8.1.6 Place the loading arm on the ratchet wheel and actuate the motor. Allow the motor to run until the load gagegauge indicates

a load of 200 lb. 200 lb. A slight takeup on the ratchet wheel is required to hold the load due to the ball sinking into the test coupon.

After a 200-lb200 lb load is obtained, hold for 1 min 1 min for the indentation to form.

D2670 − 95 (2016)

FIG. 4 Schematic Drawing of Calibration Accessories for Falex Pin and Vee Block Lubricant Test Machine

8.1.7 Turn off the machine and back off the load until the test coupon is free from the jaws. Advance the test coupon

approximately ⁄8 in. (approximately 9.5 mm) in. (approximately 9.5 mm) (additional indentations should be separated by a

minimum distance of 2.5 × the2.5× the diameter of the initial indentation). Check the alignment of the jaws, and repeat the

procedure described in 8.1.6 at gagegauge loads of 400, 600, and 800 lb 400 lb, 600 lb, and 800 lb when using an 800-lb

gage.800 lb gauge. If a 3000-lb gage3000 lb gauge is used, check at 800, 1500, and 2500 lb.800 lb, 1500 lb, and 2500 lb.

8.1.8 Remove the load gagegauge assembly and test coupon and measure the diameter of each indentation to 0.01 mm 0.01 mm

with a microscope. Make three measurements of the indentation diameter, rotating the test coupon to ensure that no two

measurements represent the same points. Average the three measurements of each impression and record.

8.1.9 Plot the four impression readings versus gagegauge load readings on log-log paper (K and E 467080 or equivalent). From

the plot determine the gagegauge load reading corresponding to an impression diameter of 3.30 mm. 3.30 mm. Typically, this

gagegauge load reading will be about 700 lb. 700 lb. This gagegauge load shall be used in Section 12. A typical plot of impression

diameter versus gagegauge readings is shown in Fig. 5.

8.2 Apparatus with 4500-lb Gage—4500 lb Gauge—Use the same procedure as with 800-lb gage,800 lb gauge, above, except

obtain impressions at gagegauge readings of 300, 500, 750, and 1000 lb. 300 lb, 500 lb, 750 lb, and 1000 lb. Plot the impression

readings and determine the gagegauge load corresponding to an impression diameter of 3.30 mm. 3.30 mm. Typically, this

gagegauge load reading will be about 900 lb. 900 lb. This gagegauge load shall be used in the procedure, (Section 13). Fig. 4

includes a typical plot of impression diameter versus gagegauge readings for the 4500-lb gage.4500 lb gauge.

9. Test Standards Check

5 6

9.1 Prepare a blend containing 0.10 weight % of sulfur, precipitated powder, USP, and 99.90 weight percent white mineral oil,

USP, having a viscosity at 100°F (37.8°C)100 °F (37.8 °C) of 340 to 390 SUS (73.4 to 84.2 cSt). 84.2 cSt). Heat the blend, in a

glass beaker, to 240240 °F to 250°F (116250 °F (116 °C to 121°C)121 °C) and stir (glass stirrer) for 15 min. 15 min. Designate

this mixture as Blend A.

9.2 Prepare, similarly, a blend containing 0.20 weight % of sulfur and 99.80 weight % of white mineral oil. Designate this

mixture as Blend B.

9.3 Refer to Section 8 for recommended use of these standards.

10. Apparatus and Testing Check

10.1 The purpose of this check is to establish that the apparatus is in satisfactory condition and that the test is being run in

conformance to the procedure covered in Section 13. For such check purposes the fluid standards covered in Section 9 should be

used (Note 3). The average of triplicate runs on the fluid standards should fall within the following limits (Note 4):

Sulfur, so specified, from J. T. Baker Chemical Co. has been found satisfactory. If you are aware of alternative suppliers, please provide this information to ASTM

International Headquarters. Your comments will receive careful consideration at a meeting of the responsible technical committee , which you may attend.

Available from most petroleum refining companies. Also available from most drug stores, typically labeled White Mineral Oil Extra Heavy. See Table X1.1 for specific

products found satisfactory in cooperative test work.

D2670 − 95 (2016)

FIG. 5 Typical Curves of GageGauge Load Readings versus Impression Diameter, Using 800, 3000 and 4500-lb Gages800 lb, 3000 lb,

and 4500 lb Gauges and BHN 37 to 39 Standard Test Coupons

Total Teeth Wear, avg.

Blend of triplicate runs

A 36 to 71

B 101 to 127

Repeatability of test data should conform to precision limits set forth in Section 15.

NOTE 3—Three commercial cutting oils were initially chosen as reference fluid standards. These were replaced by the specified white oil-sulfur blends

because of greater availability, uniformity, and purity. Results of the cooperative tests on the cutting oils are covered in Appendix X1.

NOTE 4—These limits were derived from data in Appendix X1. The limits shown for Blend A are the minimum and maximum averages obtained in

the Series 2 tests. Essentially the same averages were obtained in the Series 1 and 3 tests.

The limits shown for Blend B are the minimum and maximum averages obtained in the Series 1 tests. Essentially the same averages were obtained

in the Series 3 tests.

11. Test Conditions

11.1 The test shall be conducted under the following conditions (Note 5):

Oil temperature at start of test 75 ± 10°F (24 ± 3°C)

Speed 290 ± 10 rpm

Gage load corresponding to 3.30-mm diameter

impression on standard test coupon

Duration of test 15 min ± 5 s

Oil temperature at start of test 75 °F ± 10 °F (24 °C ± 3 °C)

Speed 290 r ⁄ min ± 10 r ⁄ minm

Gauge load corresponding to 3.30 mm diameter

impression on standard test coupon

Duration of test 15 min ± 5 s

NOTE 5—Although the test can be run under other test conditions, the precision limits described in Section 1414 apply only to tests conducted under

D2670 − 95 (2016)

the conditions shown above and the procedure specified in Section 1313.

12. Preparation of Apparatus

12.1 Thoroughly clean the V-blocks, test journals, lubricant cup, and supports for V-blocks and test journals by washing with

the solvent selected in 7.2.5. Dry the V-blocks, test journals, lubricant cup, and supports, by allowing the solvent to evaporate in

air.

12.2 After cleaning, handle the test pieces with care to prevent contamination. Particularly, avoid contact of fingers with mating

surfaces of V-blocks and test journals.

13. Procedure

13.1 Insert the test journal in the test shaft and secure with a new brass locking pin, as shown in Figs. 1-3.

13.2 Insert the V-blocks into the recesses of the loading device and swing the V-blocks inward to contact the journal so that the

V-grooves are aligned with the journal major axis, as shown in Fig. 1 and Fig. 2.

13.3 Place 60 mL 60 mL of test lubricant in the lubricant cup and raise the cup so that the V-blocks are immersed in the test

lubricant.

13.4 Place the automatic loading device with attached gage,gauge, on the jaw arms.

13.5 Remove

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.