ASTM D6775-02(2011)

(Test Method)Standard Test Method for Breaking Strength and Elongation of Textile Webbing, Tape and Braided Material

Standard Test Method for Breaking Strength and Elongation of Textile Webbing, Tape and Braided Material

SIGNIFICANCE AND USE

This test method can be used for acceptance testing of commercial shipments but comparisons should be made with caution because estimates of between-laboratory precision are incomplete.

If there are differences of practical significance between reported test results for two laboratories (or more), comparative tests should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, use samples for such comparative tests that are as homogeneous as possible, drawn from the same lot of material as the samples that resulted in disparate results during initial testing, and randomly assigned in equal numbers to each laboratory. The test results from the laboratories involved should be compared using a statistical test for unpaired data, at a probability level chosen prior to the testing series. If bias is found, either its cause must be found and corrected, or future test results for that material must be adjusted in consideration of the known bias.

Elongation is an indication of the ability of a fiber to absorb energy. The elongation of textile materials must be great enough to withstand strains experienced in processing and end use, and to absorb the energies of applied forces repeatedly.

SCOPE

1.1 This test method covers the determination of the breaking strength and elongation of textile webbing, tape and braided materials using a split-drum type specimen clamp.

1.2 This test method is limited to materials with a maximum width of 90 mm (3.5 in.) and a maximum breaking strength of no more than 89000N (20000 lb).

1.3 The values stated in either SI units or U.S. Customary units are to be regarded separately as standard. Within the text, the U.S. Customary units are given in parentheses. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6775 − 02(Reapproved 2011)

Standard Test Method for

Breaking Strength and Elongation of Textile Webbing, Tape

and Braided Material

This standard is issued under the fixed designation D6775; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope definitions of other terms related to textiles used in this

standard, refer to Terminology D123, and D4850.

1.1 This test method covers the determination of the break-

ing strength and elongation of textile webbing, tape and

4. Summary of Test Method

braided materials using a split-drum type specimen clamp.

4.1 A specimen is clamped in a tensile testing machine and

1.2 Thistestmethodislimitedtomaterialswithamaximum

extended to rupture. The breaking force is determined from a

width of 90 mm (3.5 in.) and a maximum breaking strength of

force-elongation curve or with an interfaced computer. Elon-

no more than 89000N (20000 lb).

gation is determined by calculating the difference between

1.3 The values stated in either SI units or U.S. Customary

bench marks before the application of a force and at a specified

units are to be regarded separately as standard. Within the text,

force.

the U.S. Customary units are given in parentheses. The values

stated in each system are not exact equivalents; therefore, each

5. Significance and Use

system shall be used independently of the other.

5.1 This test method can be used for acceptance testing of

1.4 This standard does not purport to address all of the

commercial shipments but comparisons should be made with

safety concerns, if any, associated with its use. It is the

caution because estimates of between-laboratory precision are

responsibility of the user of this standard to establish appro-

incomplete.

priate safety and health practices and determine the applica-

5.1.1 If there are differences of practical significance be-

bility of regulatory limitations prior to use.

tween reported test results for two laboratories (or more),

comparative tests should be performed to determine if there is

2. Referenced Documents

a statistical bias between them, using competent statistical

2.1 ASTM Standards:

assistance. As a minimum, use samples for such comparative

D76 Specification for Tensile Testing Machines for Textiles

teststhatareashomogeneousaspossible,drawnfromthesame

D123 Terminology Relating to Textiles

lot of material as the samples that resulted in disparate results

D1776 Practice for Conditioning and Testing Textiles

during initial testing, and randomly assigned in equal numbers

D4848 Terminology Related to Force, Deformation and

to each laboratory. The test results from the laboratories

Related Properties of Textiles

involved should be compared using a statistical test for

D4850 Terminology Relating to Fabrics and Fabric Test

unpaired data, at a probability level chosen prior to the testing

Methods

series. If bias is found, either its cause must be found and

corrected, or future test results for that material must be

3. Terminology

adjusted in consideration of the known bias.

3.1 For definitions of terms related to force and deformation

5.2 Elongation is an indication of the ability of a fiber to

used in this test method, refer to Terminology D4848. For

absorbenergy.Theelongationoftextilematerialsmustbegreat

enough to withstand strains experienced in processing and end

use, and to absorb the energies of applied forces repeatedly.

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods,

6. Apparatus

Specific.

CurrenteditionapprovedMay1,2011.PublishedJuly2011.Originallyapproved

6.1 Tensile Testing Machine, CRE-type, conforming to

in 2002. Last previous edition approved in 2007 as D6775 – 02(2007). DOI:

Specification D76 with respect to force indication, working

10.1520/D6775-02R11.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Apparatus and clamps are commercially available.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6775 − 02 (2011)

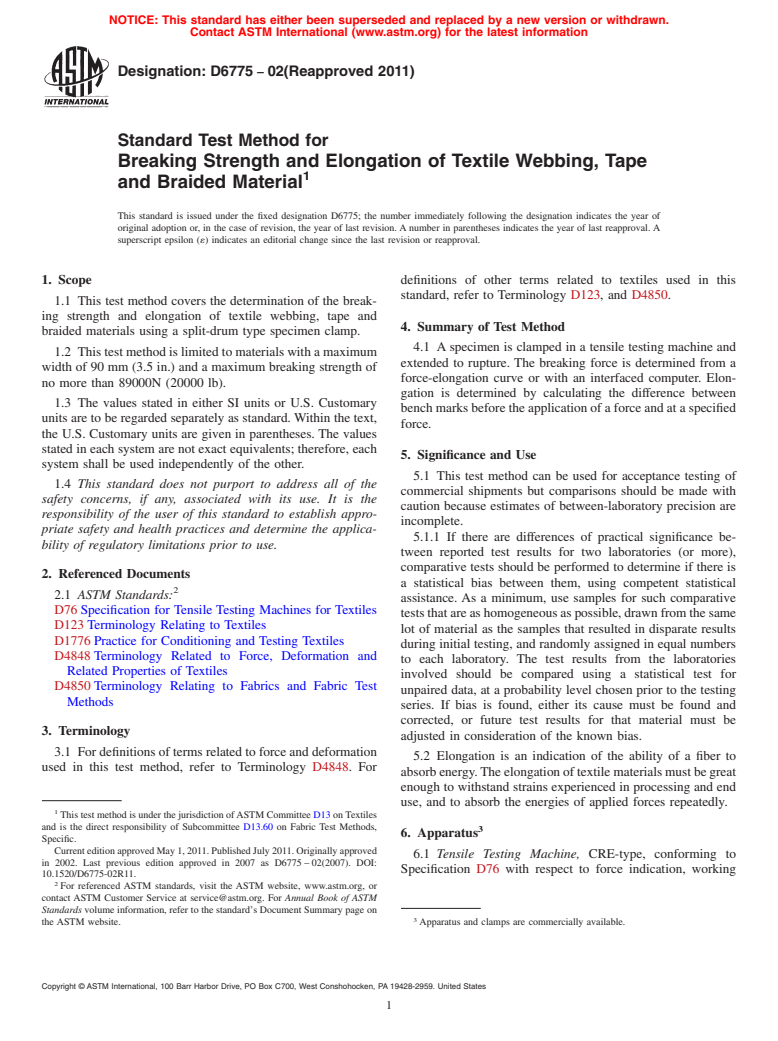

FIG. 1 Side View of Clamping Assembly

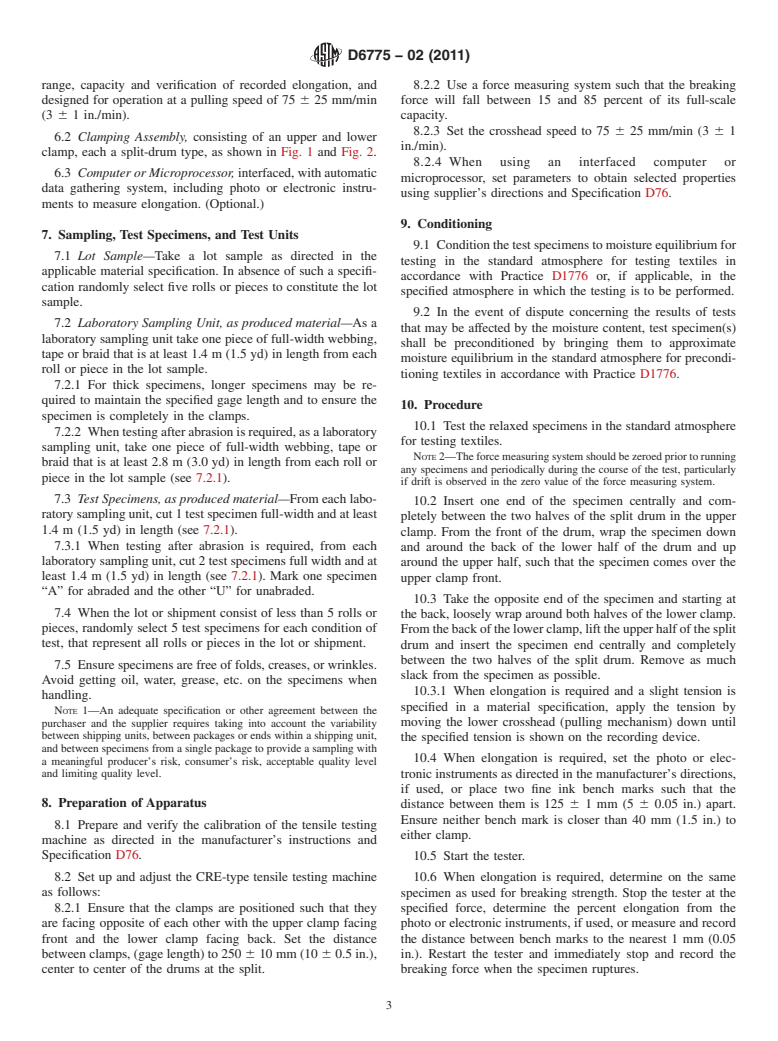

FIG. 2 Example of Clamping Assembly

D6775 − 02 (2011)

range, capacity and verification of recorded elongation, and 8.2.2 Use a force measuring system such that the breaking

designed for operation at a pulling speed of 75 6 25 mm/min force will fall between 15 and 85 percent of its full-scale

(3 6 1 in./min). capacity.

8.2.3 Set the crosshead speed to 75 6 25 mm/min (3 6 1

6.2 Clamping Assembly, consisting of an upper and lower

in./min).

clamp, each a split-drum type, as shown in Fig. 1 and Fig. 2.

8.2.4 When using an interfaced computer or

6.3 ComputerorMicroprocessor, interfaced, with automatic

microprocessor, set parameters to obtain selected properties

data gathering system, including photo or electronic instru-

using supplier’s directions and Specification D76.

ments to measure elongation. (Optional.)

9. Conditioning

7. Sampling, Test Specimens, and Test Units

9.1 Conditionthetestspecimenstomoistureequilibriumfor

7.1 Lot Sample—Take a lot sample as directed in the

testing in the standard atmosphere for testing textiles in

applicable material specification. In absence of such a specifi-

accordance with Practice D1776 or, if applicable, in the

cation randomly select five rolls or pieces to constitute the lot

specified atmosphere in which the testing is to be performed.

sample.

9.2 In the event of dispute concerning the results of tests

7.2 Laboratory Sampling Unit, as produced material—As a

that may be affected by the moisture content, test specimen(s)

laboratory sampling unit take one piece of full-width webbing,

shall be preconditioned by bringing them to approximate

tape or braid that is at least 1.4 m (1.5 yd) in length from each

moisture equilibrium in the standard atmosphere for precondi-

roll or piece in the lot sample.

tioning textiles in accordance with Practice D1776.

7.2.1 For thick specimens, longer specimens may be re-

quired to maintain the specified gage length and to ensure the

10. Procedure

specimen is completely in the clamps.

10.1 Test the relaxed specimens in the standard atmosphere

7.2.2 Whentestingafterabrasionisrequired,asalaboratory

for testing textiles.

sampling unit, take one piece of full-width webbing, tape or

NOTE2—Theforcemeasuringsystemshouldbezeroedpriortorunning

braid that is at least 2.8 m (3.0 yd) in length from each roll or

any specimens and periodically during the course of the test, particularly

piece in the lot sample (see 7.2.1).

if drift is observed in the zero value of the force measuring system.

7.3 TestSpecimens,asproducedmaterial—From each labo-

10.2 Insert one end of the specimen centrally and com-

ratory sampling unit, cut 1 test specimen full-width and at least

pletely between the two halves of the split drum in the upper

1.4 m (1.5 yd) in length (see 7.2.1).

clamp. From the front of the drum, wrap the specimen down

7.3.1 When testing after abrasion is required, from each

and around the back of the lower half of the drum and up

laboratory sampling unit, cut 2 test specimens full width and at

around the upper half, such that the specimen comes over the

least 1.4 m (1.5 yd) in length (see 7.2.1). Mark one specimen

upper clamp front.

“A” for abraded and the other “U” for unabraded.

10.3 Take the opposite end of the specimen and starting at

7.4 When the lot or shipment consist of less than 5 rolls or

the back, loosely wrap around both halves of the lower clamp.

pieces, randomly select 5 test specimens for each condition of

Fromthebackofthelowerclamp,lifttheupperhalfofthesplit

test, that represent all rolls or pieces in the lot or shipment.

drum and insert the specimen end centrally and completely

between the two halves of the split drum. Remove as much

7.5 Ensure specimens are free of folds, creases, or wrinkles.

slack from the specimen as possible.

Avoid getting oil, water, grease, etc. on the specimens when

10.3.1 When elongation is required and a slight tension is

handling.

specified in a material specification, apply the tension by

NOTE 1—An adequate specification or other agreement between the

purchaser and the supplier requires taking into account the variability moving the lower crosshead (pulling mechanism) down until

between shipping

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.