ASTM E580-00

(Practice)Standard Practice for Application of Ceiling Suspension Systems for Acoustical Tile and Lay-in Panels in Areas Requiring Moderate Seismic Restraint

Standard Practice for Application of Ceiling Suspension Systems for Acoustical Tile and Lay-in Panels in Areas Requiring Moderate Seismic Restraint

SCOPE

1.1 This practice covers acoustical ceiling suspension systems and their additional requirements for application in areas subject to seismic disturbance such as Uniform Building Code Seismic Zone 2, the BOCA Basic National Building Code where Av is less than 0.20 but greater than 0.10 and the Standard Building Code (SBC) where Av is less than 0.20 but greater than 0.05. This practice also covers areas subject to moderate to severe seismic disturbance such as Uniform Building Code Seismic Zones 3 and 4, the BOCA Basic Natiuonal Building Code where Av is greater than 0.20, and the SBC where Av is greater than 0.20. The application of this practice is to be determined by local authorities. Current seismic maps published by recognized authorities such as those previously mentioned, should be consulted. Related Material such as Open File 82-1033 and MS-812 Seismicity Map may also be consulted.

1.2 Specification C635 and Practice C636 cover suspension systems and their application, without special regard to seismic restraint needs. They remain applicable and should be followed when this practice is specified.

1.3 This practice is not intended to stifle research and development of new products or methods which may simplify this specified application method. A variation, however, must be substantiated by verifiable engineering data.

1.4 Ceilings of 144 ft (13.4 m ) or less, surrounded by walls that connect directly to the structure above shall be exempt from this practice.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

Designation: E 580 – 00

Standard Practice for

Application of Ceiling Suspension Systems for Acoustical

Tile and Lay-in Panels in Areas Requiring Seismic Restraint

This standard is issued under the fixed designation E 580; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

1.1 This practice covers acoustical ceiling suspension sys- 2.1 ASTM Standards:

tems and their additional requirements for application in areas C 635 Specification for the Manufacture, Performance, and

subject to light to moderate seismic disturbance such as Testing of Metal Suspension Systems for Acoustical Tile

Uniform Building Code Seismic Zone 2, the BOCA Basic and Lay-in Panel Ceilings

National Building Code where A is less than 0.20 but greater C 636 Practice for Installation of Metal Ceiling Suspension

v

than 0.10, and the Standard Building Code (SBC) where A is Systems for Acoustical Tile and Lay-in Panels

v

less than 0.20 but greater than 0.05. This practice also covers 2.2 Other Standards:

areas subject to moderate to severe seismic disturbance such as National Electric Code, 1993

Uniform Building Code Seismic Zones 3 and 4, the BOCA Uniform Building Code, 1994

Basic National Building Code where A is greater than 0.20, BOCA Basic Building Code, 1993

v

and the SBC where A is greater than 0.20. The application of

v

3. Areas Subject to Light to Moderate Seismic

this practice is to be determined by local authorities. Current

Disturbance

seismicmapspublishedbyrecognizedauthoritiessuchasthose

3.1 Suspension System Components:

previously mentioned, should be consulted. Related material

2 3

such as Open File 82-1033 and MS-812 Seismicity Map may 3.1.1 The actual average weight of the ceiling system,

including grid, panel or tile, light fixtures, and air terminals

also be consulted.

2 2

1.2 Specification C 635 and Practice C 636 cover suspen- must be 2.5 lb/ft (12.2 kg/m ) or less. All other services must

be supported independently from the ceiling system. For

sion systems and their application without special regard to

seismic restraint needs. They remain applicable and should be ceilings that have an average weight greater than 2.5 lb/ft , the

followed when this practice is specified. ceiling may be installed as specified in Section 4. Other

deviations or variations must be substantiated by verifiable

1.3 This practice is not intended to stifle research and

development of new products or methods which may simplify engineering data.

3.1.2 The main runners and cross runners of the ceiling

this specified application method. A variation, however, must

be substantiated by verifiable engineering data. system and their splices, intersection connectors, and expan-

2 2

sion devices shall be designed and constructed to carry a mean

1.4 Aceilingareaof144ft (13.4m )orless,surroundedby

walls that connect directly to the structure above shall be ultimate test load of not less than 60 lb (27.2 kg) in tension

with a 5° misalignment of the members in any direction and in

exempt from this practice.

1.5 This standard does not purport to address all of the compression. Instead of a 5° misalignment, the load may be

applied with a 1-in. (25.4-mm) eccentricity on a sample not

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- more than 24 in. (609 mm) long on each side of the splice.

3.1.3 Evaluation of test results shall be made on the basis of

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. the mean values resulting from tests of not fewer than three

identical specimens, provided the deviation of any individual

test result from the mean value does not exceed 610 %.

This practice is under the jurisdiction of ASTM Committee E-33 on Environ-

mental Acoustics and is the direct responsibility of Subcommittee E33.04 on

Application. Annual Book of ASTM Standards, Vol 04.06.

Current edition approved March 10, 2000. Published June 2000. Originally Available from National Fire Protection Association, Batterymarch Park,

published as E 580 – 76. Last previous edition E 580 – 96. Quincy, MA 02269.

2 6

Open File 82-1033 Probabilistic Estimate of Maximum Acceleration in Rock Available from International Conference of Building Officials, 5360 S. Work-

published by United States Geological Survey. man Mill Rd., Whittier, CA 90601.

3 7

MS-8125 Seismicity Map of the Conterminous United States and Adjacent Available from Building Officials and CodeAdministrators International, 4051

Areas, 1965–1974 published by United States Geological Survey. W. Flossmoor Rd., Country Club Hills, IL 60477.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E580–00

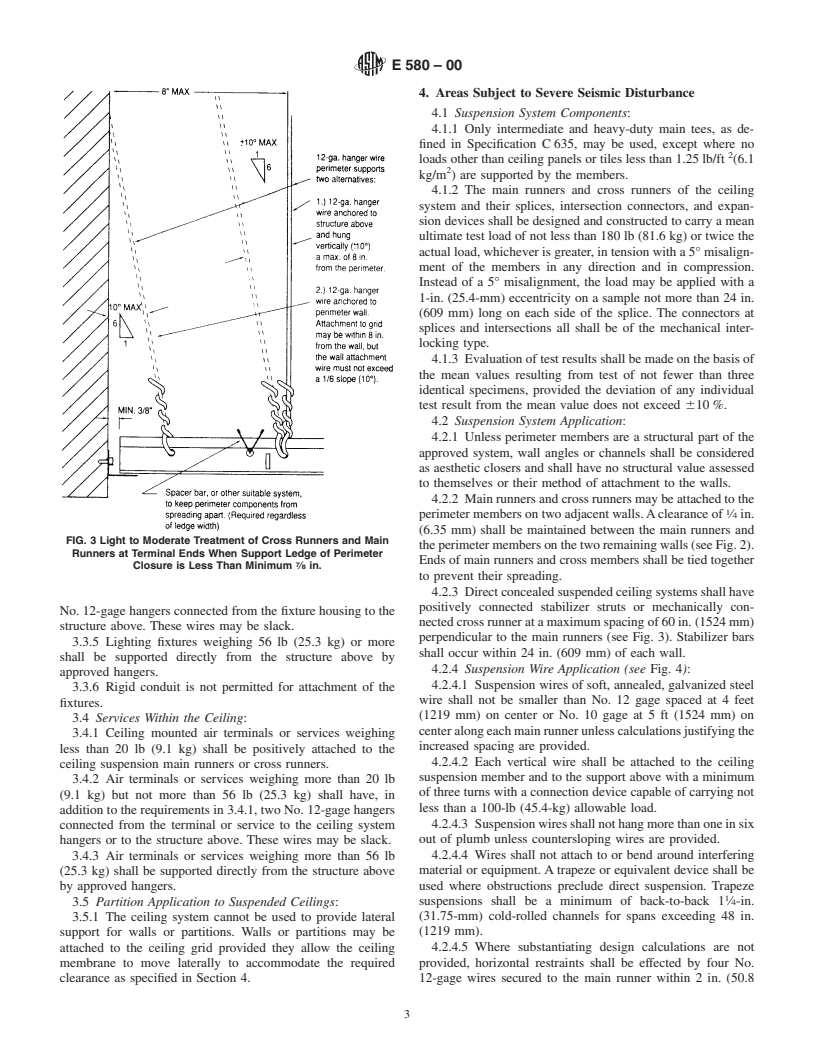

3.2 Suspension System Application:

3.2.1 All perimeter closure angles or channels shall provide

a support ledge of approximately ⁄8 in. (22.2 mm) or greater.

3.2.2 Aterminal end of a grid member (or tile) shall rest on

the ledge or molding with at least ⁄8-in. (9.5-mm) clearance

from an edge or wall as shown in Fig. 1. Reveal (shadow) edge

wall closures should accommodate these clearances as shown

inFig.2.Endsofmainrunnersandcrossmembersshallbetied

together to prevent their spreading.

3.2.3 Direct concealed suspended ceiling systems shall have

positively connected stabilizer struts or mechanically con-

nected cross runner at a maximum spacing of 60 in. (1524 mm)

perpendicular to the main runners (see Fig. 3). Stabilizer bars

shall occur within 24 in. (609 mm) of each wall.

3.2.4 Suspension Wire Application:

3.2.4.1 Suspension wires of soft, annealed, galvanized steel

wire shall not be smaller than No. 12 gage spaced at 4 ft (1219

mm) on center or No. 10 gage at 5 ft (1524 mm) on center

along each main runner unless calculations justifying the

increased spacing are provided.

3.2.4.2 Each vertical wire shall be attached to the ceiling

suspension member and to the support above with a minimum

of three turns with a connection device capable of carrying not

less than a 100-lb (45.4-kg) allowable load.

3.2.4.3 Suspensionwiresshallnothangmorethanoneinsix

FIG. 2 Light to Moderate Treatment of Cross Runners and Main

out of plumb unless countersloping wires are provided.

Runners at Terminal Ends When Using Reveal (Shadow) Edge

3.2.4.4 Wires shall not attach to or bend around interfering

Wall Closures

material or equipment. A trapeze or equivalent device shall be

ment of the structure during a seismic event. The objective is

used where obstructions preclude direct suspension. Trapeze

to have a free-floating ceiling. Nothing may be installed which

suspensions shall be a minimum of back-to-back 1 ⁄4-in. (31.75

prevents the ceiling system from moving. All ceiling penetra-

mm) cold-rolled channels for spans exceeding 48 in. (1219

tions (columns, sprinklers, etc.) and independently supported

mm).

fixtures or services are to be considered as perimeter closures

3.2.4.5 For perimeter closure angles that provide a support

that also must allow the noted clearances by using suitable

ledge of less than ⁄8 in. (22.2 mm), the terminal ends of each

escutcheons or closure details.

cross runner or main runner shall be independently supported

3.2.6 For essential facilities, perimeter support of each cross

within 8 in. (203 mm) from each wall or ceiling discontinuity

runner and main runner, as mentioned in 4.4, is required. In

as shown in Fig. 3. This support may be a No. 12-gage hanger

addition, a ⁄2-in. (12.7-mm) grid end clearance from a wall

wire or other support that prevents the grid from falling. This

should be maintained.

wire does not need to be vertical but should not have a slope

3.3 Light Fixture Application:

greaterthanoneinsixoutofplumb.A ⁄8-in.(9.5-mm)gridend

3.3.1 All lighting fixtures shall be positively attached to the

clearance from a wall should be maintained.

suspended ceiling system by mechanical means as specified in

3.2.5 The intent of the preceding provisions is to provide an

the National Electrical Code, Section 410-16(c) unless inde-

unrestrained ceiling system that will accommodate the move-

pendently supported. The attachment device, a minimum of

two per fixture, shall have a capacity of 100 % of the lighting

fixture weight acting in any direction.

3.3.2 Surface-mounted lighting fixtures shall be attached to

the ceiling system with positive clamping devices that com-

pletely surround the supporting members. Safety wires shall be

attached between the clamping device and the adjacent ceiling

hanger or to the structure above. In no case shall the fixture

exceed the design carrying capacity of the supporting mem-

bers.

3.3.3 Pendant-hung lighting fixtures shall be supported

directly from the structure above using No. 9-gage wire or an

approved alternate support without using the ceiling suspen-

sion system for direct support.

3.3.4 Lighting fixtures weighing less than 56 lb (25.3 kg)

FIG. 1 Light to Moderate Treatment of Cross Runners, Main

Runners, and Wall Closures at Terminal Ends shall have, in addition to the requirements outlined in 3.3, two

E580–00

4. Areas Subject to Severe Seismic Disturbance

4.1 Suspension System Components:

4.1.1 Only intermediate and heavy-duty main tees, as de-

fined in Specification C 635, may be used, except where no

loads other than ceiling panels or tiles less than 1.25 lb/ft (6.1

kg/m ) are supported by the members.

4.1.2 The main runners and cross runners of the ceiling

system and their splices, intersection connectors, and expan-

sion devices shall be designed and constructed to carry a mean

ultimate test load of not less than 180 lb (81.6 kg) or twice the

actual load, whichever is greater, in tension with a 5° misalign-

ment of the members in any direction and in compression.

Instead of a 5° misalignment, the load may be applied with a

1-in. (25.4-mm) eccentricity on a sample not more than 2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.