ASTM G182-13

(Test Method)Standard Test Method for Determination of the Breakaway Friction Characteristics of Rolling Element Bearings

Standard Test Method for Determination of the Breakaway Friction Characteristics of Rolling Element Bearings

SIGNIFICANCE AND USE

5.1 This test is a simple, effective way of determining the ability of bearings to roll freely. Most bearing manufacturers do not supply information on the breakaway friction coefficient of their products and if this is a design factor, users often buy candidate bearings and try them until they find one that appears to operate freer than the others. This test allows quantification of the breakaway friction characteristics of bearings. This test assesses the friction of a bearing as a tribosystem which includes its construction and lubrication. It has shown to correlate with use. If a bearing has a low breakaway angle in this test, its breakaway friction will be lower in service than the same size bearings that displayed a higher breakaway angle in this test.

5.2 Breakaway friction of bearings is important in instruments where forces are light and the bearings are used as pivots rather than for continued rotation. Low friction is often imperative for proper device operation.

5.3 Bearings with low breakaway friction are often sought for web handling rollers. Many rollers are driven only by tangential web contact and slippage can often damage the web. Low friction bearings are required.

5.4 This test is useful for screening bearings for any applications where breakaway friction is a design concern.

SCOPE

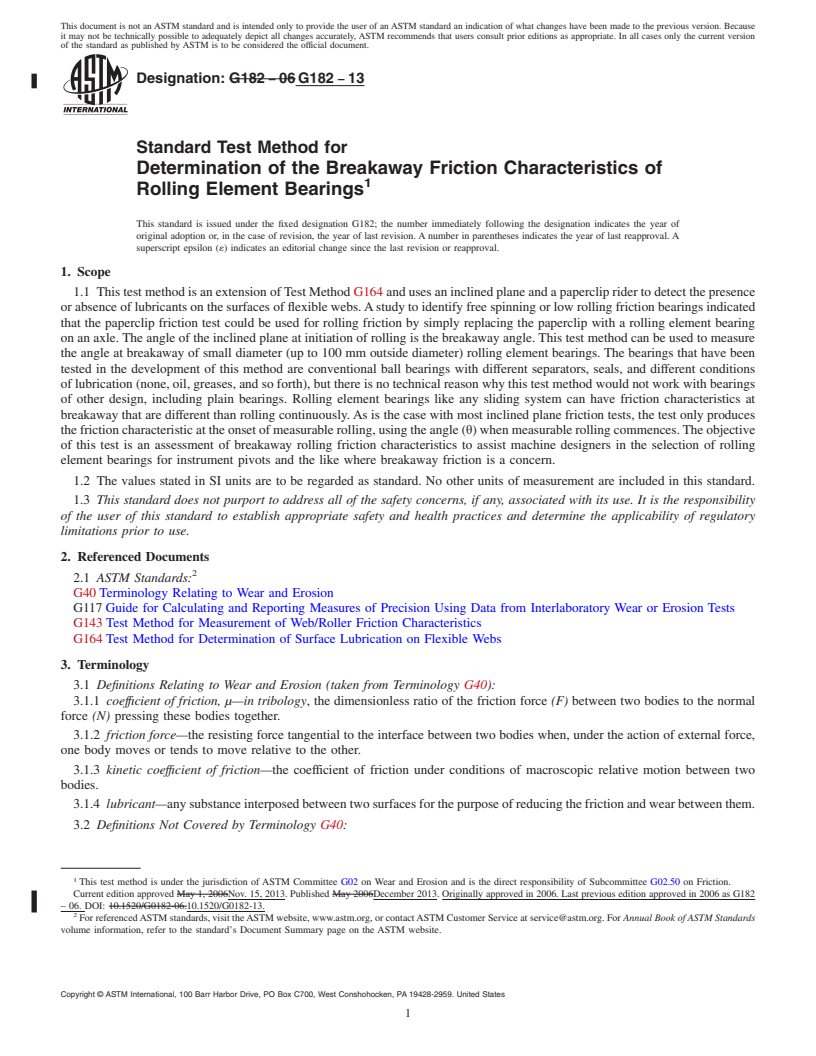

1.1 This test method is an extension of Test Method G164 and uses an inclined plane and a paperclip rider to detect the presence or absence of lubricants on the surfaces of flexible webs. A study to identify free spinning or low rolling friction bearings indicated that the paperclip friction test could be used for rolling friction by simply replacing the paperclip with a rolling element bearing on an axle. The angle of the inclined plane at initiation of rolling is the breakaway angle. This test method can be used to measure the angle at breakaway of small diameter (up to 100 mm outside diameter) rolling element bearings. The bearings that have been tested in the development of this method are conventional ball bearings with different separators, seals, and different conditions of lubrication (none, oil, greases, and so forth), but there is no technical reason why this test method would not work with bearings of other design, including plain bearings. Rolling element bearings like any sliding system can have friction characteristics at breakaway that are different than rolling continuously. As is the case with most inclined plane friction tests, the test only produces the friction characteristic at the onset of measurable rolling, using the angle (θ) when measurable rolling commences. The objective of this test is an assessment of breakaway rolling friction characteristics to assist machine designers in the selection of rolling element bearings for instrument pivots and the like where breakaway friction is a concern.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G182 − 13

Standard Test Method for

Determination of the Breakaway Friction Characteristics of

1

Rolling Element Bearings

This standard is issued under the fixed designation G182; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This test method is an extension of Test Method G164

G40 Terminology Relating to Wear and Erosion

and uses an inclined plane and a paperclip rider to detect the

G117 Guide for Calculating and Reporting Measures of

presence or absence of lubricants on the surfaces of flexible

Precision Using Data from Interlaboratory Wear or Ero-

webs. A study to identify free spinning or low rolling friction

sion Tests

bearings indicated that the paperclip friction test could be used

G143 Test Method for Measurement of Web/Roller Friction

for rolling friction by simply replacing the paperclip with a

Characteristics

rolling element bearing on an axle. The angle of the inclined

G164 Test Method for Determination of Surface Lubrication

plane at initiation of rolling is the breakaway angle. This test

on Flexible Webs

methodcanbeusedtomeasuretheangleatbreakawayofsmall

diameter (up to 100 mm outside diameter) rolling element

3. Terminology

bearings. The bearings that have been tested in the develop-

3.1 Definitions Relating to Wear and Erosion (taken from

ment of this method are conventional ball bearings with

Terminology G40):

different separators, seals, and different conditions of lubrica-

3.1.1 coeffıcient of friction, µ—in tribology, the dimension-

tion (none, oil, greases, and so forth), but there is no technical

less ratio of the friction force (F) between two bodies to the

reason why this test method would not work with bearings of

normal force (N) pressing these bodies together.

other design, including plain bearings. Rolling element bear-

3.1.2 friction force—the resisting force tangential to the

ings like any sliding system can have friction characteristics at

interface between two bodies when, under the action of

breakawaythataredifferentthanrollingcontinuously.Asisthe

external force, one body moves or tends to move relative to the

case with most inclined plane friction tests, the test only

other.

produces the friction characteristic at the onset of measurable

3.1.3 kinetic coeffıcient of friction—the coefficient of fric-

rolling, using the angle (θ) when measurable rolling com-

tion under conditions of macroscopic relative motion between

mences. The objective of this test is an assessment of break-

two bodies.

awayrollingfrictioncharacteristicstoassistmachinedesigners

3.1.4 lubricant—any substance interposed between two sur-

in the selection of rolling element bearings for instrument

pivots and the like where breakaway friction is a concern. facesforthepurposeofreducingthefrictionandwearbetween

them.

1.2 The values stated in SI units are to be regarded as

3.2 Definitions Not Covered by Terminology G40:

standard. No other units of measurement are included in this

3.2.1 breakaway coeffıcient of rolling friction—the force in

standard.

the direction of rolling (F) required to produce rolling of a

1.3 This standard does not purport to address all of the

shape that is capable of rolling on a surface, divided by the

safety concerns, if any, associated with its use. It is the

normal force (N) on the rolling shape:

responsibility of the user of this standard to establish appro-

F

priate safety and health practices and determine the applica- µ rolling 5 (1)

N

bility of regulatory limitations prior to use.

3.2.2 inclined plane—asurfacethatcanberaisedatanangle

to produce motion of an object on the plane.

1

This test method is under the jurisdiction of ASTM Committee G02 on Wear

2

and Erosion and is the direct responsibility of Subcommittee G02.50 on Friction. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 15, 2013. Published December 2013. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2006. Last previous edition approved in 2006 as G182 – 06. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/G0182-13. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G182 − 13

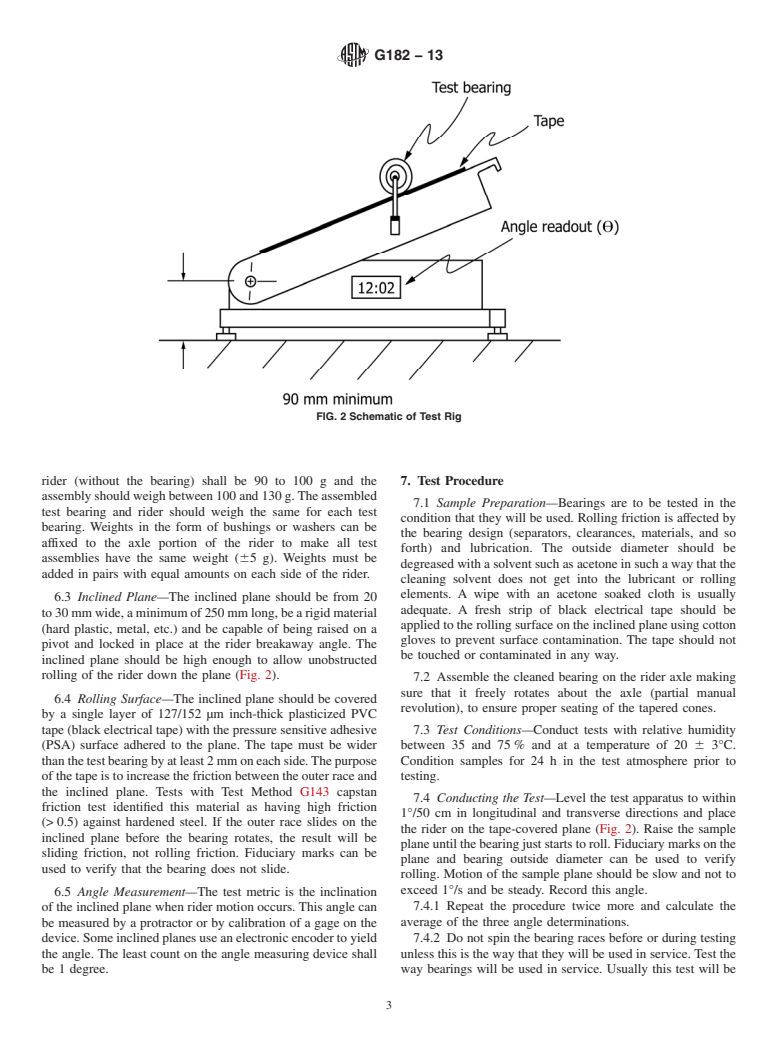

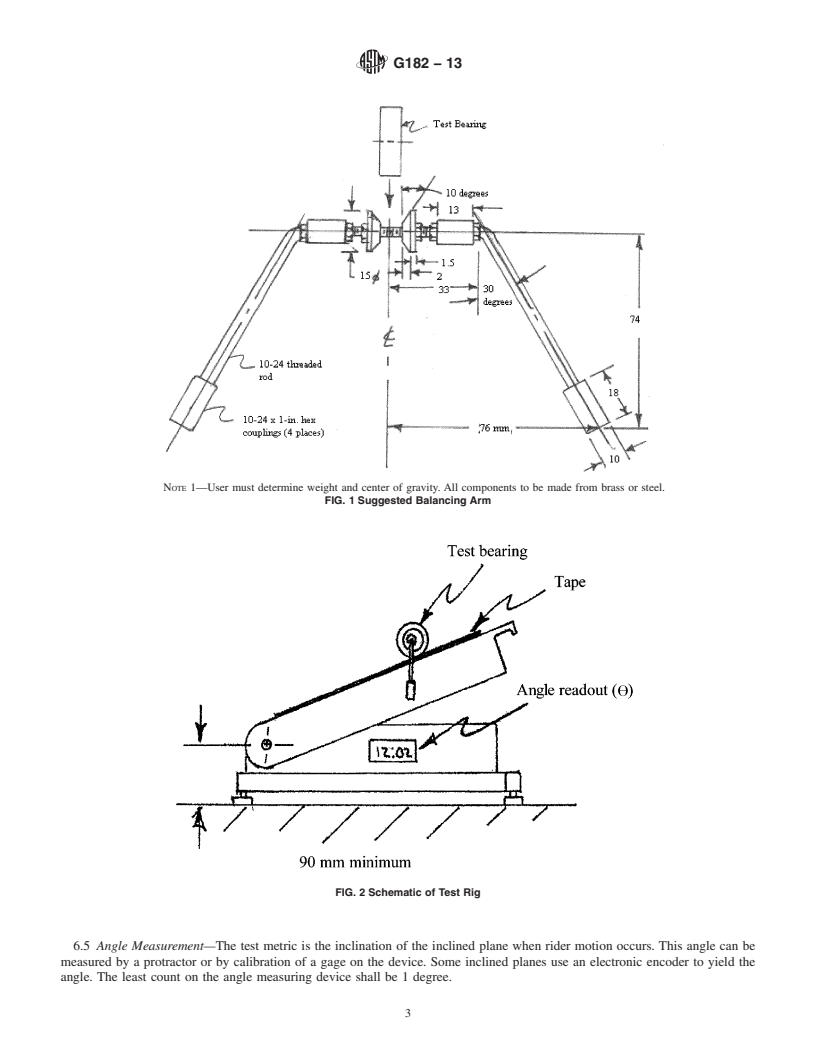

NOTE 1—User must determine weight and center of gravity. All components to be made from brass or steel.

FIG. 1 Suggested Balancing Arm

3.2.3 plain bearings—a cylindrical shape used to s

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G182 − 06 G182 − 13

Standard Test Method for

Determination of the Breakaway Friction Characteristics of

1

Rolling Element Bearings

This standard is issued under the fixed designation G182; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method is an extension of Test Method G164 and uses an inclined plane and a paperclip rider to detect the presence

or absence of lubricants on the surfaces of flexible webs. A study to identify free spinning or low rolling friction bearings indicated

that the paperclip friction test could be used for rolling friction by simply replacing the paperclip with a rolling element bearing

on an axle. The angle of the inclined plane at initiation of rolling is the breakaway angle. This test method can be used to measure

the angle at breakaway of small diameter (up to 100 mm outside diameter) rolling element bearings. The bearings that have been

tested in the development of this method are conventional ball bearings with different separators, seals, and different conditions

of lubrication (none, oil, greases, and so forth), but there is no technical reason why this test method would not work with bearings

of other design, including plain bearings. Rolling element bearings like any sliding system can have friction characteristics at

breakaway that are different than rolling continuously. As is the case with most inclined plane friction tests, the test only produces

the friction characteristic at the onset of measurable rolling, using the angle (θ) when measurable rolling commences. The objective

of this test is an assessment of breakaway rolling friction characteristics to assist machine designers in the selection of rolling

element bearings for instrument pivots and the like where breakaway friction is a concern.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

G40 Terminology Relating to Wear and Erosion

G117 Guide for Calculating and Reporting Measures of Precision Using Data from Interlaboratory Wear or Erosion Tests

G143 Test Method for Measurement of Web/Roller Friction Characteristics

G164 Test Method for Determination of Surface Lubrication on Flexible Webs

3. Terminology

3.1 Definitions Relating to Wear and Erosion (taken from Terminology G40):

3.1.1 coeffıcient of friction, μ—in tribology, the dimensionless ratio of the friction force (F) between two bodies to the normal

force (N) pressing these bodies together.

3.1.2 friction force—the resisting force tangential to the interface between two bodies when, under the action of external force,

one body moves or tends to move relative to the other.

3.1.3 kinetic coeffıcient of friction—the coefficient of friction under conditions of macroscopic relative motion between two

bodies.

3.1.4 lubricant—any substance interposed between two surfaces for the purpose of reducing the friction and wear between them.

3.2 Definitions Not Covered by Terminology G40:

1

This test method is under the jurisdiction of ASTM Committee G02 on Wear and Erosion and is the direct responsibility of Subcommittee G02.50 on Friction.

Current edition approved May 1, 2006Nov. 15, 2013. Published May 2006December 2013. Originally approved in 2006. Last previous edition approved in 2006 as G182

– 06. DOI: 10.1520/G0182-06.10.1520/G0182-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G182 − 13

3.2.1 breakaway coeffıcient of rolling friction—the force in the direction of rolling (F) required to produce rolling of a revolute

shape shape that is capable of rolling on a surface, div

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.