ASTM B870-08

(Specification)Standard Specification for Copper-Beryllium Alloy Forgings and Extrusions Alloys (UNS Nos. C17500 and C17510)

Standard Specification for Copper-Beryllium Alloy Forgings and Extrusions Alloys (UNS Nos. C17500 and C17510)

ABSTRACT

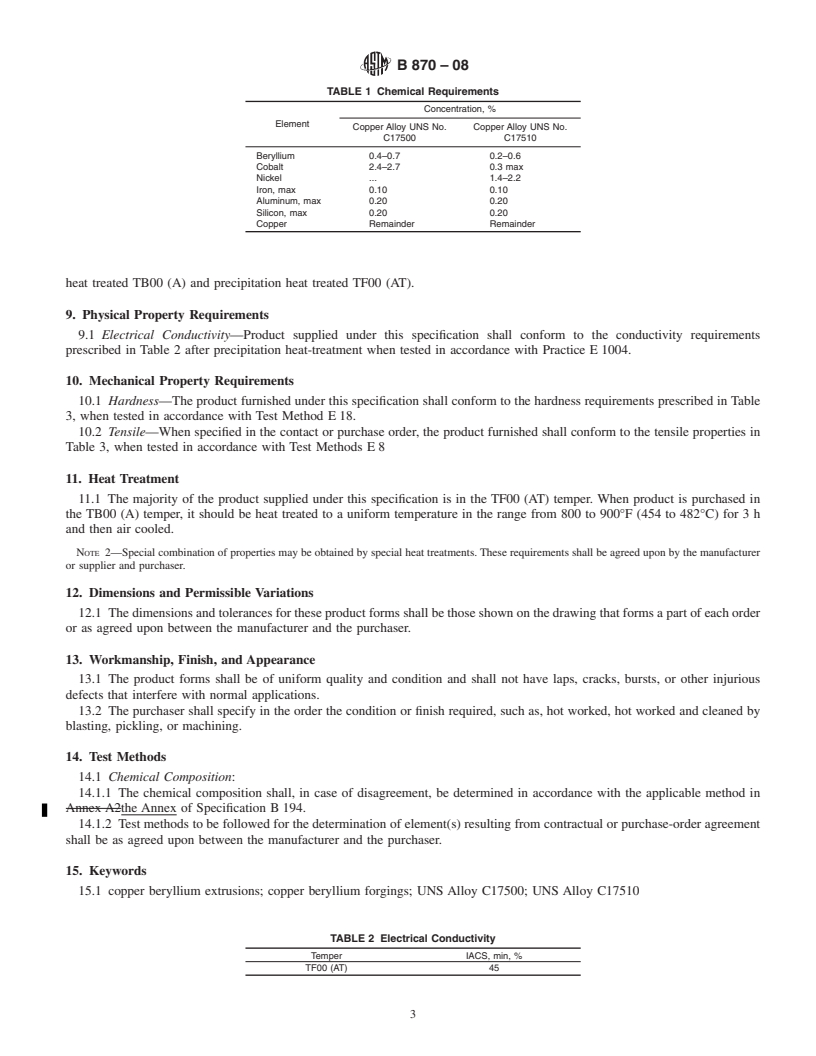

This specification establishes the requirements for copper-beryllium alloy forgings and extrusions. The following alloys are specified: UNS No. C17500 and C17510. The material of manufacture should be a cast billet conforming to the chemical composition requirements for the alloy specified. The product shall be manufactured by hot working or extrusion, solution heat-treating, precipitation hardening, and straightening. The material shall conform to the chemical composition for the alloy specified. The material shall conform to the electrical conductivity requirements specified. Hardness test and tensile test shall be made to conform to the requirements specified.

SCOPE

1.1 This specification establishes the requirements for copper-beryllium alloy forgings and extrusions. The following alloys are specified:

Copper Alloy

UNS No.Nominal Composition, % BerylliumCobaltNickel C175000.502.6 C175100.401.8

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazard caveat pertains to Sections 10 and 11 of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B870 −08

StandardSpecification for

Copper-Beryllium Alloy Forgings and Extrusions Alloys

1

(UNS Nos. C17500 and C17510)

This standard is issued under the fixed designation B870; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* B950 Guide for Editorial Procedures and Form of Product

Specifications for Copper and Copper Alloys

1.1 This specification establishes the requirements for

E8 Test Methods for Tension Testing of Metallic Materials

copper-beryllium alloy forgings and extrusions. The following

E18 Test Methods for Rockwell Hardness of Metallic Ma-

alloys are specified:

terials

Copper Alloy Nominal Composition, %

E527 Practice for Numbering Metals and Alloys in the

UNS No. Beryllium Cobalt Nickel

C17500 0.50 2.6 Unified Numbering System (UNS)

C17510 0.40 1.8

E1004 Test Method for Determining Electrical Conductivity

1.2 Units—The values stated in inch-pound units are to be

Using the Electromagnetic (Eddy-Current) Method

regarded as standard. The values given in parentheses are

mathematical conversions to SI units that are provided for

3. General Requirements

information only and are not considered standard.

3.1 The following sections of Specification B249/B249M

1.3 The following safety hazard caveat pertains to Sections

form a part of this specification:

10 and 11 of this specification: This standard does not purport

3.1.1 Material and Manufacture,

to address all of the safety concerns, if any, associated with its

3.1.2 Sampling,

use. It is the responsibility of the user of this standard to

3.1.3 Number of Tests and Retests,

establish appropriate safety and health practices and deter-

3.1.4 Specimen Preparation,

mine the applicability of regulatory limitations prior to use.

3.1.5 Significance of Numerical Limits,

3.1.6 Inspection,

2. Referenced Documents

3.1.7 Rejection and Rehearing,

2

2.1 ASTM Standards:

3.1.8 Certification,

B194 Specification for Copper-BerylliumAlloy Plate, Sheet,

3.1.9 Test Reports, and

Strip, and Rolled Bar

3.1.10 Packaging and Package Marking.

B249/B249M Specification for General Requirements for

Wrought Copper and Copper-Alloy Rod, Bar, Shapes and

4. Terminology

Forgings

B441 Specification for Copper-Cobalt-Beryllium, Copper- 4.1 For definitions of terms related to copper and copper

Nickel-Beryllium, and Copper-Nickel-Lead-Beryllium alloys, see Terminology B846.

Rod and Bar (UNS Nos. C17500, C17510, and C17465)

4.2 Definitions of Terms Specific to This Standard:

B601 Classification forTemper Designations for Copper and

4.2.1 extrusion, n—a uniform metal shape, long in relation

Copper Alloys—Wrought and Cast

to its cross-sectional dimensions, produced by forcing a suit-

B846 Terminology for Copper and Copper Alloys

ably preheated billet or pre-formed shape through an orifice

(die) of the desired cross section.

4.2.2 forging, n—a metal part worked to a predetermined

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

shape by one or more such processes as hammering, upsetting,

and CopperAlloys and is the direct responsibility of Subcommittee B05.02 on Rod,

pressing, rolling, and so forth.

Bar, Wire, Shapes and Forgings.

Current edition approved April 1, 2008. Published April 2008. Originally

NOTE1—Forgedandextrudedshapesinthecontextofthisspecification

approved in 1996. Last previous edition approved in 2002 as B870 - 02. DOI:

are generally construed to be large section products; round, oval, half

10.1520/B0870-08.

2

round, geometric custom-ordered cross-sections, and asymmetrical metal

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

shapes. This is to generally differentiate products supplied according to

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on this document as opposed to forged and extruded “Rod and Bar” in

the ASTM website. Specification B441.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B870−08

5. Ordering Information 7.1.2 Copper, given as the remainder, is the difference

between the sum of results of all elements determined and

5.1 Include the following information when placing orders

100 %.

for product under this specification, as applicable:

7.1.3 When all elements listed in Table 1 for the alloy

5.1.1 ASTM designation and year of issue,

specifiedintheorderinginformationaredeterminedthesumof

5.1.2 Copper Alloy UNS No. (Secti

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B870–02 Designation: B 870 – 08

Standard Specification for

Copper-Beryllium Alloy Forgings and Extrusions Alloys

1

(UNS Nos. C17500 and C17510)

This standard is issued under the fixed designation B 870; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification establishes the requirements for copper-beryllium alloy forgings and extrusions. The following alloys are

specified:

Copper Alloy Nominal Composition, %

UNS No. Beryllium Cobalt Nickel

C17500 0.59 2.6

C17500 0.50 2.6

C17510 0.40 1.8

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are

mathematical conversions to SI units, whichunits that are provided for information only and are not considered standard.

1.3 The following safety hazard caveat pertains to Sections 10 and 11 of this specification: This standard does not purport to

address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish

appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B 194 Specification for Copper-Beryllium Alloy Plate, Sheet, Strip, and Rolled Bar

B 249/B 249M Specification for General Requirements for Wrought Copper and Copper-Alloy Rod, Bar, Shapes,Shapes and

Forgings

B 441SpecificationforCopper-Cobalt-Beryllium(UNSNo.C17500)andCopper-NickelBeryllium(UNSNo.C17510)Rodand

2

Bar SpecificationforCopper-Cobalt-Beryllium,Copper-Nickel-Beryllium,andCopper-Nickel-Lead-BerylliumRodandBar

(UNS Nos. C17500, C17510, and C17465)

2

B 601Classification for Temper Designations for Copper and Copper Alloys-Wrought and Cast

2

B846Terminology for Copper and Copper Alloys Classification for Temper Designations for Copper and Copper

AlloysWrought and Cast

B 846 Terminology for Copper and Copper Alloys

B 950 Guide for Editorial Procedures and Form of Product Specifications for Copper and Copper Alloys

E 8 Test Methods for Tension Testing of Metallic Materials

3

E 18Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials Test Methods for

Rockwell Hardness of Metallic Materials

E527Practice for Numbering Metals and Alloys (UNS) 527 Practice for Numbering Metals and Alloys in the Unified

Numbering System (UNS)

E 1004 Practice for Determining Electrical Conductivity Using the Electromagnetic (Eddy-Current) Method

3. General Requirements

3.1 The following sections of Specification B 249/B 249M form a part of this specification:

3.1.1 Material and Manufacture,

3.1.2 Sampling,

3.1.3 Number of Tests and Retests,

1

This specification is under the jurisdiction ofASTM Committee B05 on Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.02 on Rod, Bar,

Wire, Shapes and Forgings.

Current edition approved Oct. 10, 2002.April 1, 2008. Published December 2002.April 2008. Originally approved in 1996. Last previous edition approved in 19962002

as B 870 - 96.02.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 02.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B870–08

3.1.4 Specimen Preparation,

3.1.5 Significance of Numerical Limits,

3.1.6 Inspection,

3.1.7 Rejection and Rehearing,

3.1.8 Certification,

3.1.9 Test Reports, and

3.1.10 Packaging and Package Marking.

4. Terminology

4.1 4.1.1ForFor definitions of terms related to copper and copper alloys, see Terminology B 846.

4.2 Definitions of Terms Specific to This Standard:

4.2.1 extrusion, n—a uniform metal shape, long in relation to its cross-sectional dimensions, produced by forcing a suitably

preheated billet or pre-formed shape through an orifice (die) of the desired cross section.

4.2.2 forging, n—a metal part worked to a predetermined shape by one or more such processes as hammering, upsetting,

pressing, rolling, and so forth.

NOTE 1—Forged and extruded shapes in the context of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.