ASTM E252-05

(Test Method)Standard Test Method for Thickness of Thin Foil, Sheet, and Film by Mass Measurement

Standard Test Method for Thickness of Thin Foil, Sheet, and Film by Mass Measurement

SCOPE

1.1 This test method covers the determination of the thickness of metallic foil and sheet 0.015 in. (0.38 mm) and less in thickness by measuring the mass of a specimen of known area and density. The test method is applicable to other sheet, foil, and film as indicated in Annex A3.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical conversions to SI units, which are provided for information and only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 252 – 05

Standard Test Method for

Thickness of Thin Foil, Sheet, and Film by Mass

1

Measurement

This standard is issued under the fixed designation E 252; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* selection of other specimen sizes and the resulting change in

accuracy of the test method.

1.1 This test method covers the determination of the thick-

3.2 Balance—capable of measuring to the nearest 0.1 mg of

ness of metallic foil and sheet 0.015 in. (0.38 mm) and less in

2 2

thickness for the 8.000-in. (51.613-cm ) circle.

thickness by measuring the mass of a specimen of known area

and density. The test method is applicable to other sheet, foil,

4. Procedure

and film as indicated in Annex A3.

2 2

4.1 Blank an 8.000 6 0.008-in. (51.613 6 0.051-cm )

1.2 The values stated in inch-pound units are to be regarded

circle representative of the foil or sheet, swab with acetone or

asthestandard.Thevaluesgiveninparenthesesaremathemati-

other suitable solvent to ensure a surface free of soil, and

cal conversions to SI units, which are provided for information

determine the mass of the clean, dry specimen to the nearest

and only and are not considered standard.

0.1 mg. Use a suitable solvent to remove any coating known to

1.3 This standard does not purport to address all of the

2 2

exceed 0.005 mg/ft (4.645 mg/cm ) of surface area.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Calculation

priate safety and health practices and determine the applica-

5.1 Determine the thickness from the relationship:

bility of regulatory limitations prior to use.

T 5 W/AD

2. Referenced Documents

where:

2.1 The following documents of the issue in effect on the

T = thickness of the foil, sheet, or film, in. (or cm),

date of material purchase, unless otherwise noted, form a part

W = mass of the circle, g,

of this specification to the extent referenced herein:

2 2

A = area of the circle, in. (or cm ), and

2

2.2 ASTM Standards: 3 3

D = density of the foil, sheet, or film, g/in. (or Mg/m ).

D 1505 Test Method for Density of Plastics by the Density-

5.2 Densities of Aluminum Alloys:

Gradient Technique

5.2.1 Calculate the density of aluminum foil or sheet from

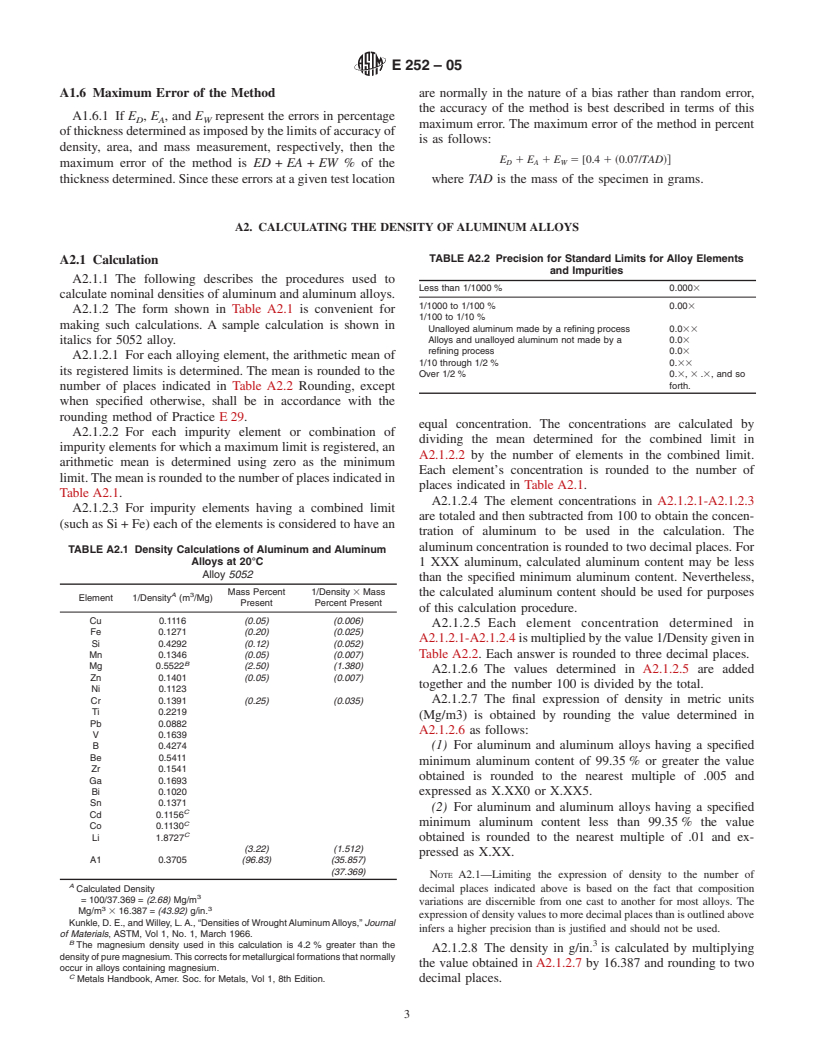

E29 Practice for Using Significant Digits in Test Data to

chemical composition limits of the alloy by the method

Determine Conformance with Specifications

described in Annex A2. The densities of foil or sheet alloys

determined in this manner are accurate to within 6 0.3 %.

3. Apparatus

5.2.2 Table 1 lists densities computed for some of the

3.1 Precision Blanking Press—to cut foil or sheet circles

common foil or sheet alloys. A column headed “Mils/g for

2 2

that are 8.000 6 0.008 in. (51.613 6 0.051 cm ) in area or

2

8.000-in. Area” is added for convenience in determining

3.1915 60.0015in.(81.06 60.04mm)indiameter.Othersize 2 2

thickness of the 8.000-in. (51.613-cm ) specimens. The mass

specimens may be used with the recognition that the accuracy

of the specimen in grams multiplied by this factor is equal to

stated in 6.1 is no longer applicable. See Annex A1 for the

the thickness of the foil or sheet in mils.

6. Precision and Bias

1

This test method is under the jurisdiction of ASTM Committee B07 on Light

6.1 Following the procedure outlined in this test method,

Metals and Alloys and is the direct responsibility of Subcommittee B07.05 on

repeatedmassmeasurementsofthesamespecimenondifferent

Testing.

balances should result in agreement within 1 mg. It is outside

Current edition approved June 1, 2005. Published June 2005. Originally

approved in 1964. Last previous edition approved in 2004 as E 252 – 04.

of the scope of this test method to describe maintenance and

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

calibration procedures for balances, but disagreement larger

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

than 1 mg warrants attention to maintenance or recalibration of

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. the balance.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E252–05

TABLE 1 Densities of Aluminum Foil or Sheet Alloys Applicable

to the Determination of Thickness by the Mass Measurement

M

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.