ASTM C25-99

(Test Method)Standard Test Methods for Chemical Analysis of Limestone, Quicklime, and Hydrated Lime

Standard Test Methods for Chemical Analysis of Limestone, Quicklime, and Hydrated Lime

SCOPE

1.1 These test methods cover the chemical analysis of high-calcium and dolomitic limestone, quicklime, and hydrated lime. These test methods are classified as either standard (preferred) or alternative (optional).

1.2 The standard test methods are those that employ classical gravimetric or volumetric analytical procedures and are typically those required for referee analyses where chemical specification requirements are an essential part of contractual agreement between buyer and seller.

1.3 Alternative or optional test methods are provided for those who wish to use procedures shorter or more convenient than the standard methods for the routine determinations of certain constituents. Optional test methods may sometimes be preferred to the standard test methods, but frequently the use of modern and expensive instrumentation is indicated which may not be accessible to everyone. Therefore, the use of these test methods must be left to the discretion of each laboratory.

1.4 The analytical procedures appear in the following order: Section Aluminum Oxide 15 Available Lime Index 28 Calcium and Magnesium Oxide: Alternative EDTA Titration Method 31 Calcium Carbonate Equivalent 33 Calcium Oxide: Gravimetric Method 16 Volumetric Method 17 Carbon Dioxide by Standard Method 22 Combined Oxides of Iron and Aluminum 12 Ferrous Iron X5 Free Calcium Oxide X6 Free Moisture in Hydrated Lime 21 Free Moisture in Limestone 20 Free Silica 29 Insoluble Matter Including Silicon Dioxide: Standard Method 8 Optional Perchloric Acid Method 9 Insoluble Matter Other Than Silicon Dioxide 11 Loss on Ignition 19 Magnesium Oxide 18 Manganese: Bismuthate Method X4 Periodate (Photometric) Method 27 pH Determination of Alkaline Earth Solutions 34 1a Phosphorus: Titrimetric Method X3 Molybdovanadate Method 26 Silicon Dioxide 10 Strontium Oxide X2 Sulfur Trioxide 23 Total Carbon: Direct Combustion-Thermal Conductivity Cell Method 32 Total Iron: Standard Method, Potassium Dichromate Titration 13 Potassium Permanganate Titration Method X1 Ortho-Phenanthroline, Photometric Method 14 Total Sulfur: Sodium Carbonate Fusion 24 Combustion-Iodate Titration Method 25 Unhydrated Oxides 30

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Notes 11, 13, 27, 47, X2.1, and X5.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C 25–99

Standard Test Methods for

Chemical Analysis of Limestone, Quicklime, and Hydrated

Lime

ThisstandardisissuedunderthefixeddesignationC25;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

Manganese:

Bismuthate Method Appendix X4

1.1 These test methods cover the chemical analysis of

Periodate (Photometric) Method 27

high-calcium and dolomitic limestone, quicklime, and hy-

pH Determination of Alkaline Earth Solu- 34

tions

dratedlime.Thesetestmethodsareclassifiedaseitherstandard

Phosphorus:

(preferred) or alternative (optional).

Titrimetric Method Appendix X3

1.2 The standard test methods are those that employ classi-

Molybdovanadate Method 26

Silicon Dioxide 10

cal gravimetric or volumetric analytical procedures and are

Strontium Oxide Appendix X2

typically those required for referee analyses where chemical

Sulfur Trioxide 23

specification requirements are an essential part of contractual Total Carbon:

Direct Combustion-Thermal Conductiv- 32

agreement between buyer and seller.

ity Cell Method

1.3 Alternative or optional test methods are provided for

Total Carbon and Sulfur:

those who wish to use procedures shorter or more convenient Combustion/Infrared Detection Method 35

Total Iron:

than the standard methods for the routine determinations of

Standard Method, Potassium Dichro- 13

certain constituents. Optional test methods may sometimes be

mate Titration

Potassium Permanganate Titration Appendix X1

preferredtothestandardtestmethods,butfrequentlytheuseof

Method

modern and expensive instrumentation is indicated which may

Ortho-Phenanthroline, Photometric 14

not be accessible to everyone. Therefore, the use of these test

Method

Total Sulfur:

methods must be left to the discretion of each laboratory.

Sodium Carbonate Fusion 24

1.4 The analytical procedures appear in the following order:

Combustion-Iodate Titration Method 25

Section

Unhydrated Oxides 30

Aluminum Oxide 15

Available Lime Index 28 1.5 This standard does not purport to address all of the

Calcium and Magnesium Oxide:

safety concerns, if any, associated with its use. It is the

Alternative EDTATitration Method 31

responsibility of the user of this standard to establish appro-

Calcium Carbonate Equivalent 33

Calcium Oxide: priate safety and health practices and determine the applica-

Gravimetric Method 16

bility of regulatory limitations prior to use. For specific

Volumetric Method 17

precautionary statements, see Note 11, Note 13, Note 27, Note

Carbon Dioxide by Standard Method 22

Combined Oxides of Iron and Aluminum 12 51, Note X2.1, and Note X5.1.

Ferrous Iron Appendix X5

Free Calcium Oxide Appendix X6

2. Referenced Documents

Free Moisture in Hydrated Lime 21

Free Moisture in Limestone 20 2.1 ASTM Standards:

Free Silica 29

C 50 Practice for Sampling, Inspection, Packing, and Mark-

Insoluble Matter Including Silicon Dioxide:

ing of Lime and Limestone Products

Standard Method 8

Optional Perchloric Acid Method 9 C51 Terminology Relating to Lime and Limestone (as

Insoluble Matter Other Than Silicon Diox- 11

Used by the Industry)

ide

C911 Specification for Quicklime, Hydrated Lime, and

Loss on Ignition 19

Magnesium Oxide 18

Limestone for Chemical Uses

D 1193 Specification for Reagent Water

E29 Practice for Using Significant Digits in Test Data to

ThesetestmethodsareunderthejurisdictionofASTMCommitteeC-7onLime

and are the direct responsibility of Subcommittee C07.05 on Chemical Tests.

Current edition approved Aug. 10, 1999. Published September 1999. Originally Annual Book of ASTM Standards, Vol 04.01.

published as C 25–19T. Last previous edition C 25–98. Annual Book of ASTM Standards, Vol 11.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C25–99

Determine Conformance with Specifications alloy not requiring protective coating and shall meet the

E 50 Practices for Apparatus, Reagents, and Safety Precau- density requirements for Class S.

tions for Chemical Analysis of Metals 5.1.3 Glassware and Laboratory Containers—Standard

E70 Test Method for pH of Aqueous Solutions with the volumetric flasks, burets, pipets, dispensers, etc., shall be

Glass Electrode carefully selected precision grade or better and shall be

E 173 Practice for Conducting Interlaboratory Studies of calibrated, if necessary, to meet the requirements of each

Methods for Chemical Analysis of Metals operation. Standard-type interchangeable ground glass orTFE-

E 200 Practice for Preparation, Standardization, and Stor- fluorocarbon joints are recommended for all volumetric glass-

age of Standard and Reagent Solutions for Chemical ware. Polyethylene containers are recommended for all aque-

Analysis ous solutions of alkalies and for standard solutions where the

E 691 Practice for Conducting an Interlaboratory Study to presence of dissolved silica or alkali from the glass would be

Determine the Precision of a Test Method objectionable.

E 832 Specification for Laboratory Filter Papers 5.1.4 Desiccators—Desiccators shall be provided with a

good desiccant such as anhydrous magnesium perchlorate,

3. Terminology

activated alumina, sulfuric acid, or phosphoric anhydride.

3.1 Definitions—Unless otherwise specified, for definitions Anhydrous calcium sulfate may also be used provided it has

of terms used in these test methods refer to TerminologyC51. been treated with a color-changing indicator to show when the

desiccant has lost its effectiveness. Calcium chloride and silica

4. Significance and Use

gel are not satisfactory desiccants for this type of analysis.

4.1 These test methods provide accurate and reliable ana- 5.1.5 Filter Paper—Filter paper shall conform to the re-

lytical procedures to determine the chemical constituents of

quirements of SpecificationE 832,Type II (quantitative). Class

limestone, quicklime, and hydrated lime (Note 1).The percent- E shall be used for coarse and gelatinous precipitates. When

ages of specific constituents which determine a material’s

medium-textured paper is required, Class F filter paper shall be

qualityorfitnessforuseareofsignificancedependinguponthe used. When a retentive paper is needed, Class G shall be used.

purpose or end use of the material. Results obtained may be

Recommendations: Filter Pore Size Filter Speed

Class (microns)

used in relation to specification requirements.

E 20 to 25 fast speed

4.2 Because quicklime and hydrated lime quickly absorb

F 8 medium speed

water and carbon dioxide from the air, precision and bias are

G 2.5 slow speed

extremely dependent upon precautions taken during sample

5.1.6 Crucibles—Platinum crucibles and tight fitting lids

preparation and analysis to minimize excessive exposure to

should preferably be made of pure unalloyed platinum and be

ambient conditions.

of 25 to 35-mL capacity. Where alloyed platinum is used for

NOTE 1—These test methods can be applied to other calcareous

greater stiffness or to obviate sticking of fused material to

materials if provisions are made to compensate for known interferences.

crucible or lid, the alloyed platinum should not decrease in

weight by more than 0.2 mg when heated at 1200°C for 1 h.

5. General Apparatus and Materials and Reagents

5.1.7 Muffle Furnace—The electric muffle furnace should

5.1 General Apparatus and Materials:

be capable of continuous operation up to 1000°C and be

5.1.1 Balance—The balance shall be of an analytical type

capable of intermittent operation at higher temperatures if

with a capacity not to exceed 200 g. It may be of conventional

required. It should have an indicating pyrometer accurate to

design or it may be a constant-load, direct-reading type. It shall

625°C.

be capable of reproducing weighings within 0.0002 g with an

5.2 Reagents:

accuracy of 60.0002 g. Rapid weighing devices that may be

5.2.1 Purity of Reagents—Reagent grade chemicals shall be

provided such as a chain, damper, or heavy riders shall not

used in all tests. Unless otherwise indicated, it is intended that

increase the basic inaccuracy by more than 0.0001 g at any

all reagents shall conform to the specifications of the Commit-

reading and with any load within the rated capacity of the

tee onAnalytical Reagents of theAmerican Chemical Society

balance.

where such specifications are available. Other grades may be

5.1.2 Weights—Weights used for analysis shall conform to

used provided it is first ascertained that the reagent is of

Class S-1 requirements of the National Institute of Standards

sufficiently high purity to permit its use without lessening the

andTechnologyasdescribedinNISTCircular547. Theyshall

accuracy of the determination. In addition to this, it is desirable

be checked at least once a year or when questioned, and

in many cases for the analyst to ensure the accuracy of his

adjusted to within allowable tolerances for Class S-1 weights.

results by running blanks or checking against a comparable

All new sets of weights purchased shall have the weights of 1

sample of known composition.

g and larger made of stainless steel or other corrosion-resistant

4 9

Annual Book of ASTM Standards, Vol 14.02. Reagent Chemicals, American Chemical Society Specifications, American

Annual Book of ASTM Standards, Vol 03.05. Chemical Society, Washington, DC. For suggestions on the testing of reagents not

Discontinued 1997; see 1997 Annual Book of ASTM Standards, Vol 03.05. listed by the American Chemical Society, see Analar Standards for Laboratory

Annual Book of ASTM Standards, Vol 15.05. Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Available from National Institute of Standards and Technology, Gaithersburg, and National Formulary, U.S. Pharmacopeia Convention, Inc. (USPC), Rockville,

MD 20899. MD.

C25–99

5.2.2 Purity of Water—Unless otherwise indicated, refer- 6.4.1 The calculations included in the individual procedures

ences to water are understood to mean distilled water or other sometimes assume that the exact weight specified has been

water of equivalent purity. Water conforming to Specification used. Accurately weighed samples which are approximately

D 1193 meets these requirements. but not exactly equal to the weight specified may be used

provided appropriate corrections are made in the calculation.

5.2.3 Concentration of Reagents:

Unless otherwise stated, weights of all samples and residues

5.2.3.1 Concentrated Acids and Ammonium Hydroxide—

should be recorded to the nearest 0.0001 g.

When acids and ammonium hydroxide are specified by name

6.4.2 In all mathematical operations on a set of observed

or chemical formula only, it shall be understood that concen-

values, the equivalent of two more places of figures than in the

trated reagents approximating the following specific gravities

single observed values shall be retained. For example, if

or concentrations are intended:

observed values are read or determined to the nearest 0.1 mg,

Acetic acid (HC H O ) 99.5 %

2 3 2

Hydrochloric acid (HCl) sp gr 1.19 carry numbers to the nearest 0.001 mg in calculation.

Hydrofluoric acid (HF) 48 %

6.5 Rounding Figures—Rounding figures to the nearest

Nitric acid (HNO ) sp gr 1.42

significant place required in the report should be done after the

Perchloric acid (HClO)70%

Phosphoric acid (H PO)85% calculations are completed, in order to keep the final results

3 4

Sulfuric acid (H SO ) sp gr 1.84

2 4

free from calculation errors. The rounding procedure should

Ammonium hydroxide (NH OH) sp gr 0.90

follow the principle outlined in PracticeE29.

5.2.3.2 Dilute Reagents—The concentration of dilute acids

7. Performance Requirements for Test Methods

and NH OH except when standardized, are specified as a ratio

stating the number of measured volumes of the concentrated

7.1 Referee Analyses—The reference test methods that ap-

reagenttobedilutedwithagivennumberofmeasuredvolumes

pear in Sections 8 through 32, or any other test methods

of water. In conformance with international practice, new and

qualified in accordance with 7.3, are required for referee

revised methods will use the “plus” designation instead of the

analysis in those cases where conformance to the requirements

ratio (:) symbol as the specified designation of dilution; for

of a chemical specification are questioned. In these cases a

example, H SO (5 + 95) means 5 volumes of concentrated

2 4 limestone, quicklime, or hydrated lime shall not be rejected for

H SO (sp gr 1.84) diluted with 95 volumes of water.

2 4 failure to conform to chemical requirements unless all sample

5.2.3.3 Standard Solutions—Concentrations of standard so-

preparationandanalysisofanyoneconstituentismadeentirely

lutions shall be expressed as normalities (N) or as equivalents

byreferencetestmethodsprescribedintheappropriatesections

in grams per millilitre of the component to be determined, for

of this test method or by other qualified test methods. Excep-

example: 0.1 N K Cr O solution (1 mL = 0.004 g Fe O ).The

tion can be made when specific test methods are prescribed in

2 2 7 2 3

average of at least three determinations shall be used for all

the standard specification for the limestone, quicklime, or

standardizations. The standardization used to determine the

hydrated lime in question. The test methods actually used for

strength of the standard solutions is described in the text under

the analysis shall be designated.

each of the appropriate procedures.

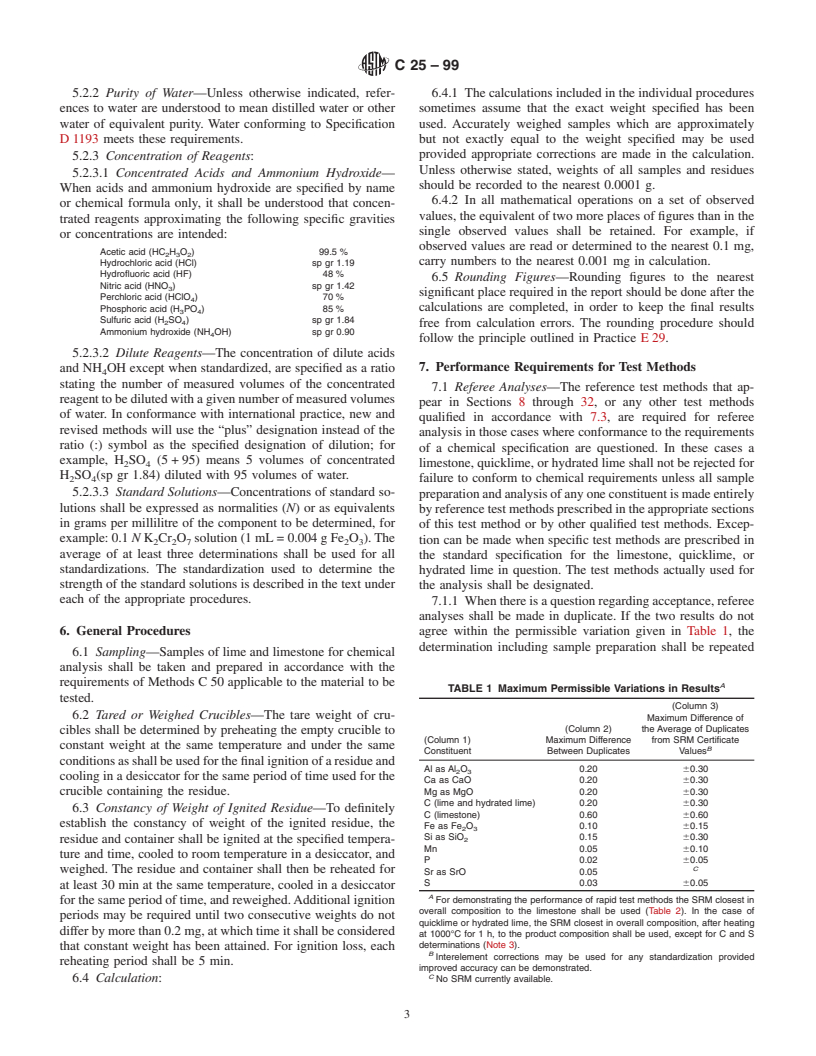

7.1.1 Whenthereisaquestionregardingacceptance,referee

analyses shall be made in duplicate. If the two results do not

6. General Procedures agree within the permissible variation given in Table 1, the

determination including sample preparation shall be repeated

6.1 Sampling—Samples of lime and limestone for chemical

analysis shall be taken and prepared in accordance with the

requirements of Methods C 50 applicable to the material to be

A

TABLE 1 Maximum Permissible Variations in Results

tested.

(Column 3)

6.2 Tared or Weighed Crucibles—The tare weight of cru-

Maximum Difference of

(Column 2) the Average of Duplicates

cibles shall be determined by preheating the empty crucible to

(Column 1) Maximum Difference from SRM Certificate

constant weight at the same temperature and under the same

B

Constituent Between Duplicates Values

conditionsasshallbeusedforthefinalignitionofaresidueand

Al as Al O 0.20 60.30

2 3

cooling in a desiccator for the same period of time used for the

Ca as CaO 0.20 60.30

crucible containing the residue. Mg as M

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.