ASTM D1652-04

(Test Method)Standard Test Method for Epoxy Content of Epoxy Resins

Standard Test Method for Epoxy Content of Epoxy Resins

SIGNIFICANCE AND USE

The epoxy content of epoxy resins is an important variable in determining their reactivity and the properties of coatings made from them. These test methods may be used to determine the epoxy content of manufactured epoxy resins and confirm the stated epoxy content of purchased epoxy resins.

SCOPE

1.1 This test method covers the procedure for manual and automatic titration of epoxy resins for the quantitative determination of the percent epoxide content from 0.1 - 26 % epoxide.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1652–04

Standard Test Method for

1

Epoxy Content of Epoxy Resins

This standard is issued under the fixed designation D1652; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

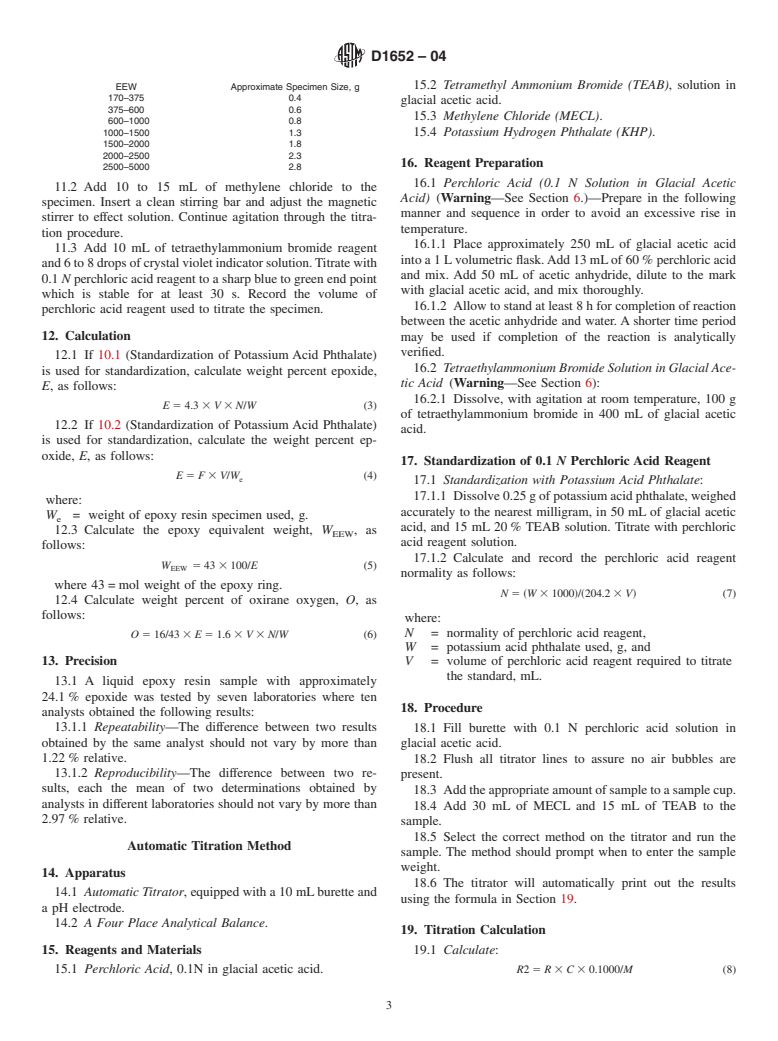

1. Scope* situ by the addition of perchloric acid to the quaternary

ammonium halide rapidly opens the oxirane ring.

1.1 This test method covers the procedure for manual and

3.1.2 In the Automatic Titration Method, the reaction is

automatic titration of epoxy resins for the quantitative deter-

measuring the millivolt (MV) potential as perchloric acid is

mination of the percent epoxide content from 0.1 – 26 %

added, which combines with the bromide to form the hydro-

epoxide.

bromic acid, which reacts with the epoxide group. As the

1.2 The values stated in SI units are to be regarded as the

reaction progresses, the potential will gradually increase until

standard. The values given in parentheses are for information

the reaction nears completion at which point the potential

only.

increases very quickly. The titrator measures the rate of the

1.3 This standard does not purport to address all of the

reaction by calculating the change in potential between per-

safety concerns, if any, associated with its use. It is the

chloric acid addition increments. When the change in potential

responsibility of the user of this standard to establish appro-

begins to decrease, the titrator determines that the titration is

priate safety and health practices and determine the applica-

complete. The epoxide content is calculated using the reagent

bility of regulatory limitations prior to use. For specific hazard

factor entered by the user during standardization, the weight of

statements, see Section 6.

the sample, and the volume of perchloric acid added during

2. Referenced Documents titration.

2

2.1 ASTM Standards:

4. Significance and Use

D1193 Specification for Reagent Water

4.1 The epoxy content of epoxy resins is an important

2.2 Other Documents:

variable in determining their reactivity and the properties of

OSHA Regulations, 29 CFR, paragraphs 1910.1000 and

3

coatings made from them. These test methods may be used to

1910.1200

determine the epoxy content of manufactured epoxy resins and

3. Summary of Test Method

confirm the stated epoxy content of purchased epoxy resins.

3.1 The resin is dissolved in a suitable solvent and the

5. Reagents

resulting solution is titrated with hydrogen bromide either

5.1 Purity of Reagents—Reagent grade chemicals shall be

directly or in situ. The hydrogen bromide reacts stoichiometri-

used in all tests. Unless otherwise indicated, it is intended that

cally with epoxy groups to form bromohydrins; therefore, the

all reagents shall conform to the specifications of the Commit-

quantity of acid consumed is a measure of the epoxy content.

tee onAnalytical Reagents of theAmerican Chemical Society,

3.1.1 In the Manual Titration Method, the titration is with

4

where such specifications are available. Other grades may be

standard perchloric acid in the presence of an excess of

used, provided it is first ascertained that the reagent is of

tetraethylammonium bromide. Hydrogen bromide generated in

sufficiently high purity to permit its use without lessening the

accuracy of the determination.

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

5.2 Purity of Water—Unless otherwise indicated, references

and Related Coatings, Materials, andApplications and is the direct responsibility of

to water shall be understood to mean reagent water as defined

Subcommittee D01.33 on Polymers and Resins.

by Type II of Specification D1193.

Current edition approved November 1, 2004. Published December 2004.

Originallyapprovedin1969.Lastpreviouseditionapprovedin1997asD1652 – 97.

DOI: 10.1520/D1652-04.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Reagent Chemicals, American Chemical Society Specifications, American

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Chemical Society, Washington, DC. For suggestions on the testing of reagents not

Standards volume information, refer to the standard’s Document Summary page on listed by the American Chemical Society, see Analar Standards for Laboratory

the ASTM website. Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

3

AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments, and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.