ASTM D5824-98(2017)

(Test Method)Standard Test Method for Determining Resistance to Delamination of Adhesive Bonds in Overlay-Wood Core Laminates Exposed to Heat and Water

Standard Test Method for Determining Resistance to Delamination of Adhesive Bonds in Overlay-Wood Core Laminates Exposed to Heat and Water

SIGNIFICANCE AND USE

4.1 This test method measures quantitatively the effects of water soaking and drying, and their associated swelling and shrinking stresses on adhesive bonds in overlay-laminated assemblies.

4.2 Adhesive bond performance is based on the ability of the adhesive and adhesive bonds to resist delamination during accelerated exposure to water and heat.

4.3 Resistance to delamination when subjected to environmental factors is critical to the performance of the laminated assembly in service.

4.4 This test method is to be used to determine the quality of adhesive bonds in overlay-wood core laminates after the adhesive has been certified by a specification appropriate for the product, class, and end use.

SCOPE

1.1 This test method provides a procedure to determine the quality of bond between an overlay and a wood core in an adhesively bonded laminate. The quality of bond is determined by measuring the resistance to delamination of the adhesively bonded laminate when tested under specific conditions of preparation, conditioning, and testing. Such products include, but are not limited to, window and door components, such as stiles and rails, and other overlaid panels. Typical wood-based cores are finger-jointed lumber, particleboard, oriented strand board, and hardboard. Typical overlays would be veneer, high-pressure laminate, high-density polyethylene, and fiberglass-reinforced plastic.

1.2 Adhesive bond performance as measured by resistance to delamination in this test method is suitable for use in adhesive product development, manufacturing quality control, and monitoring bonding processes.

1.3 This test method does not provide guidance for determining bond line performance for plywood products.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5824 − 98 (Reapproved 2017)

Standard Test Method for

Determining Resistance to Delamination of Adhesive Bonds

in Overlay-Wood Core Laminates Exposed to Heat and

1

Water

This standard is issued under the fixed designation D5824; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This test method provides a procedure to determine the

quality of bond between an overlay and a wood core in an

2. Referenced Documents

adhesively bonded laminate. The quality of bond is determined

2

2.1 ASTM Standards:

by measuring the resistance to delamination of the adhesively

D907 Terminology of Adhesives

bonded laminate when tested under specific conditions of

D4442 Test Methods for Direct Moisture Content Measure-

preparation, conditioning, and testing. Such products include,

ment of Wood and Wood-Based Materials

but are not limited to, window and door components, such as

D5266 Practice for Estimating the Percentage of Wood

stiles and rails, and other overlaid panels. Typical wood-based

Failure in Adhesive Bonded Joints

cores are finger-jointed lumber, particleboard, oriented strand

E6 Terminology Relating to Methods of Mechanical Testing

board, and hardboard. Typical overlays would be veneer,

E41 Terminology Relating To Conditioning

high-pressure laminate, high-density polyethylene, and

E177 Practice for Use of the Terms Precision and Bias in

fiberglass-reinforced plastic.

ASTM Test Methods

1.2 Adhesive bond performance as measured by resistance

E691 Practice for Conducting an Interlaboratory Study to

to delamination in this test method is suitable for use in

Determine the Precision of a Test Method

adhesive product development, manufacturing quality control,

3. Terminology

and monitoring bonding processes.

3.1 Definitions:

1.3 This test method does not provide guidance for deter-

3.1.1 Certain terms in this test method are defined in

mining bond line performance for plywood products.

Terminologies D907, E6, and E41.

1.4 The values stated in inch-pound units are to be regarded

3.1.2 delamination, n—the separation of layers in a laminate

as standard. The values given in parentheses are mathematical

because of failure of the adhesive, either in the adhesive itself

conversions to SI units that are provided for information only

or at the interface between the adhesive and the adherend. (See

and are not considered standard.

Terminology D907.)

1.5 This standard does not purport to address all of the

3.1.3 overlay, n—a uniform layer of material, usually in the

safety concerns, if any, associated with its use. It is the

form of a sheet, adhesively bonded to an adherend with the

responsibility of the user of this standard to establish appro-

purpose of improving the appearance or physical properties of

priate safety, health and environmental practices and deter-

the laminate.

mine the applicability of regulatory limitations prior to use.

3.2 Definitions of Terms Specific to This Standard:

1.6 This international standard was developed in accor-

3.2.1 edge, n—in an adhesively bonded laminate, the di-

dance with internationally recognized principles on standard-

mension along its length [and parallel to the grain] where the

ization established in the Decision on Principles for the

overlay is bonded to the core.

Development of International Standards, Guides and Recom-

3.2.2 end, n—in an adhesively bonded laminate, the dimen-

sion which is perpendicular to the length of the laminate where

the overlay is bonded to the core.

1

This test method is under the jurisdiction of ASTM Committee D14 on

Adhesives and is the direct responsibility of Subcommittee D14.30 on Wood

2

Adhesives. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Aug. 1, 2017. Published August 2017. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1995. Last previous edition approved in 2011 as D5824 – 98 (2011). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D5824-98R17. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5824 − 98 (2017)

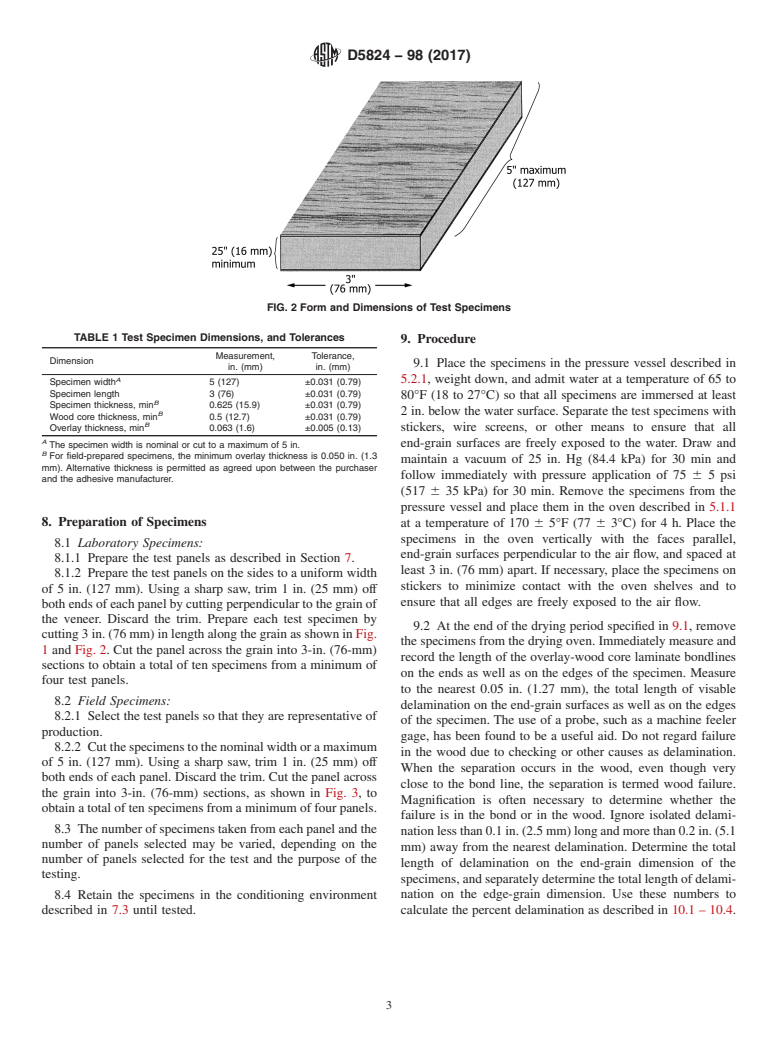

4. Significance and Use 6.2 Cut field specimens from test panels (see Fig. 3) to the

form and dimensions shown in Fig. 2 and Table 1. When the

4.1 This test method measures quantitatively the effects of

nominal width of the panel is us

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5824 − 98 (Reapproved 2011) D5824 − 98 (Reapproved 2017)

Standard Test Method for

Determining Resistance to Delamination of Adhesive Bonds

in Overlay-Wood Core Laminates Exposed to Heat and

1

Water

This standard is issued under the fixed designation D5824; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method provides a procedure to determine the quality of bond between an overlay and a wood core in an adhesively

bonded laminate. The quality of bond is determined by measuring the resistance to delamination of the adhesively bonded laminate

when tested under specific conditions of preparation, conditioning, and testing. Such products include, but are not limited to,

window and door components, such as stiles and rails, and other overlaid panels. Typical wood-based cores are finger-jointed

lumber, particleboard, oriented strand board, and hardboard. Typical overlays would be veneer, high-pressure laminate,

high-density polyethylene, and fiberglass-reinforced plastic.

1.2 Adhesive bond performance as measured by resistance to delamination in this test method is suitable for use in adhesive

product development, manufacturing quality control, and monitoring bonding processes.

1.3 This test method does not provide guidance for determining bond line performance for plywood products.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D907 Terminology of Adhesives

D4442 Test Methods for Direct Moisture Content Measurement of Wood and Wood-Based Materials

D5266 Practice for Estimating the Percentage of Wood Failure in Adhesive Bonded Joints

E6 Terminology Relating to Methods of Mechanical Testing

E41 Terminology Relating To Conditioning

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions:

3.1.1 Certain terms in this test method are defined in Terminologies D907, E6, and E41.

3.1.2 delamination, n—the separation of layers in a laminate because of failure of the adhesive, either in the adhesive itself or

at the interface between the adhesive and the adherend. (See Terminology D907.)

1

This test method is under the jurisdiction of ASTM Committee D14 on Adhesives and is the direct responsibility of Subcommittee D14.30 on Wood Adhesives.

Current edition approved April 1, 2011Aug. 1, 2017. Published April 2011August 2017. Originally approved in 1995. Last previous edition approved in 20032011 as

D5824 – 98 (2003).(2011). DOI: 10.1520/D5824-98R11.10.1520/D5824-98R17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

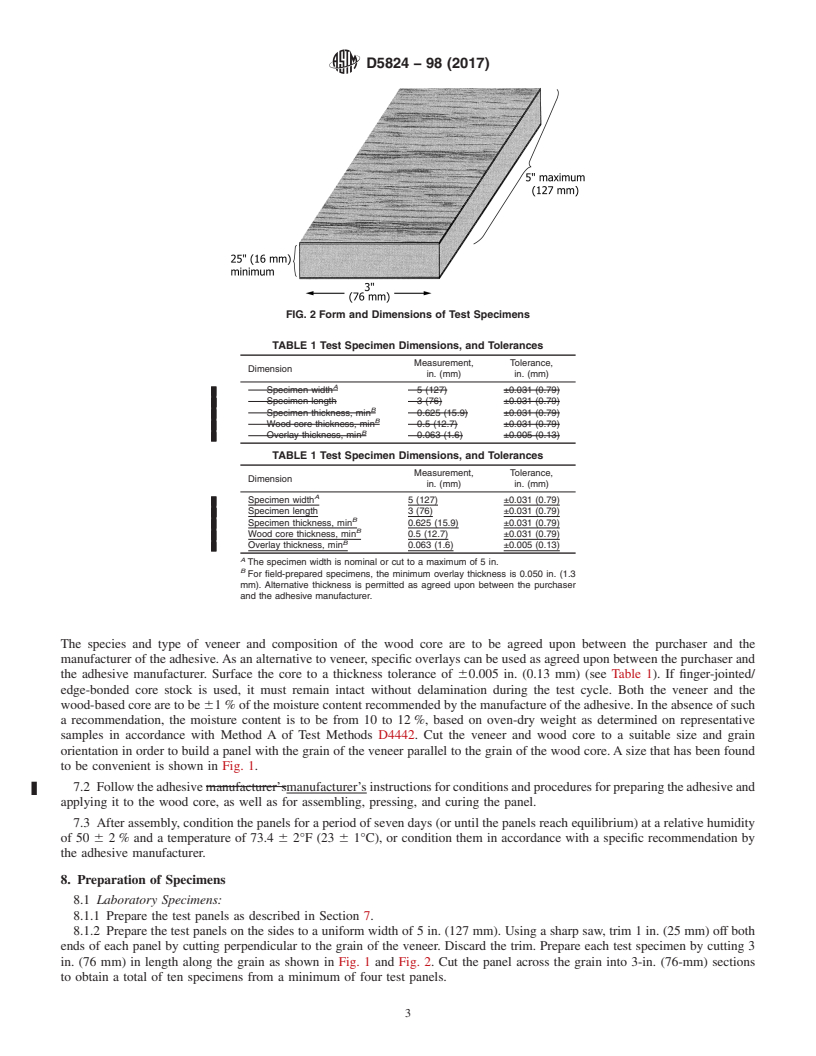

D5824 − 98 (2017)

3.1.3 overlay, n—a uniform layer of material, usually in the form of a sheet, adhesively bonded to an adherend with the purpose

of improving the appearance or physical properties of the laminate.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 edge, n—in an adhesively bonded laminate, the dimension along its length [and parallel to the grain] where the overlay

is bonded to the core.

3.2.2 end, n—in an adhesively bonded lami

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.