ASTM F405-97

(Specification)Standard Specification for Corrugated Polyethylene (PE) Tubing and Fittings

Standard Specification for Corrugated Polyethylene (PE) Tubing and Fittings

SCOPE

1.1 This specification covers requirements and test methods for materials, marking dimensions, workmanship, elongation, brittleness, pipe stiffness, and perforations for corrugated polyethylene (PE) tubing and fittings in nominal sizes of 3 to 6 in., inclusive.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only. Note 1-Sizes 8 to 15 in. are described in Specification F667.

1.3 The text of this specification references notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.4 The following precautionary caveat pertains only to the test methods portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 405 – 97

Standard Specification for

1

Corrugated Polyethylene (PE) Pipe and Fittings

This standard is issued under the fixed designation F 405; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

3

1. Scope F412 Terminology Relating to Plastic Piping Systems

F667 Specification for Large Diameter Corrugated Poly-

1.1 This specification covers requirements and test methods

3

ethylene Pipe and Fittings

for materials, marking dimensions, workmanship, elongation,

brittleness, pipe stiffness, and perforations for corrugated

3. Terminology

polyethylene (PE) pipe and fittings in nominal sizes of 3 to 6

3.1 Definitions— Definitions are in accordance with Termi-

in., inclusive.

nology F412, and abbreviations are in accordance with Ter-

1.2 The values stated in inch-pound units are to be regarded

minologyD1600,unlessotherwisespecified.Theabbreviation

as the standard. The values given in parentheses are for

for polyethylene is PE.

information only.

3.2 Definitions of Terms Specific to This Standard:

NOTE 1—Sizes 8 to 15 in. are described in Specification F667.

3.2.1 crack—any break or split that extends through the

1.3 The text of this specification references notes and wall.

3.2.2 crease—a deformation that cannot be removed like a

footnotes that provide explanatory material. These notes and

footnotes (excluding those in tables and figures) shall not be dent; generally associated with wall buckling.

considered as requirements of the specification.

4. Significance and Use

1.4 The following precautionary caveat pertains only to the

4.1 Corrugated PE pipe and fittings are intended for under-

test methods portion, Section 8, of this specification: This

ground applications where soil support is given to the flexible

standard does not purport to address all of the safety concerns,

walls. Their major uses are in soil drainage and septic field

if any, associated with its use. It is the responsibility of the user

leach beds (see appendix for installation guidelines).

of this standard to establish appropriate safety and health

4.2 Corrugated fittings complying with the requirements of

practices and determine the applicability of regulatory limita-

this specification may be used with either standard or heavy-

tions prior to use.

duty pipe as defined by the requirements of Table 1.

2. Referenced Documents

5. Materials

2.1 ASTM Standards:

5.1 General—Compounds used in the manufacture of cor-

D618 Practice for Conditioning Plastics and Electrical

2

rugated PE drainage pipe and fittings shall conform with the

Insulating Materials for Testing

requirementsofGradeP14ClassC,GradeP23ClassC,Grade

D1248 SpecificationforPolyethylenePlasticsMoldingand

2

P33 Class C, or Grade P34 Class C, as defined and described

Extrusion Materials

in Specification D1248.

D1600 Terminology for Abbreviated Terms Relating to

2

Plastics

NOTE 2—Class B pigments may be substituted for Class C provided

D2122 Test Method for Determining Dimensions of Ther-

that ultraviolet protection is acceptable to the purchaser as satisfactory for

3

moplastic Pipe and Fittings

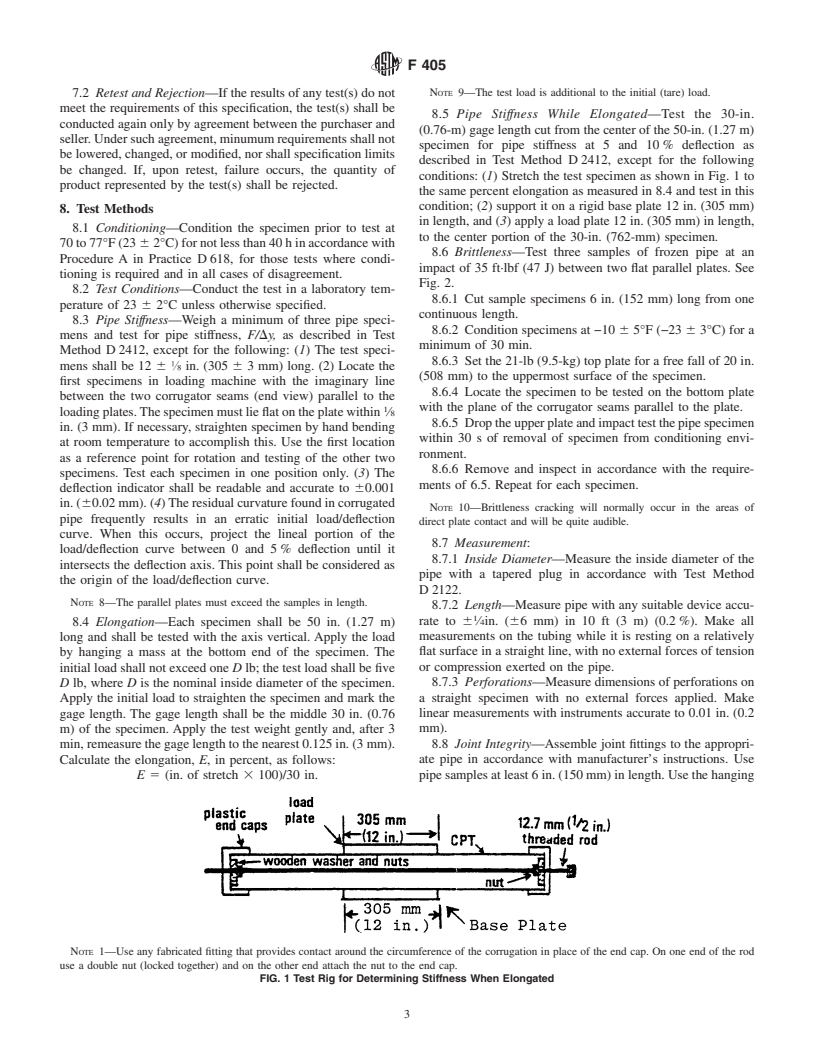

the intended use.

D2412 TestMethodforDeterminationofExternalLoading

5.2 Rework Material—The manufacturer shall use only his

3

Characteristics of Plastic Pipe by Parallel-Plate Loading

own clean pipe or fitting rework material; the pipe and fittings

produced shall meet all the requirements of this specification.

1

ThisspecificationisunderthejurisdictionofASTMCommitteeF-17onPlastic

6. Requirements

Piping Systems and is the direct responsibility of Subcommittee F17.65 on Land

Drainage.

6.1 The pipe and fittings shall be homogeneous throughout

Current edition approved Jan. 10, 1997. Published November 1997. Originally

and free of foreign inclusions or visible defects. The pipe and

published as F405–74. Last previous edition F405–96a.

2 fittings shall be as uniform as commercially practicable in

Annual Book of ASTM Standards, Vol 08.01.

3

Annual Book of ASTM Standards, Vol 08.04. color, opacity, density, and other physical properties. The ends

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 405

TABLE 1 Physical Test Requirements for Corrugated Plastic and sewer pipe are measured and reported as pipe stiffness which is

Pipe

determined in accordance with Test Method D2412. The term “crush

strength”isnotapplicabletoplasticpipingbecause(1)thevaluesobtained

can be significantly different, depe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.