ASTM F2107-08(2020)

(Guide)Standard Guide for Construction and Maintenance of Skinned Areas on Baseball and Softball Fields

Standard Guide for Construction and Maintenance of Skinned Areas on Baseball and Softball Fields

SIGNIFICANCE AND USE

4.1 The skinned areas of baseball and softball fields should provide a uniform playing surface of high quality. Ball bounce should be true and predictable. Footing and sliding properties should favor optimum performance of players. Undulations, rough surface, hard or soft surfaces, weeds, stones, and wet spots detract from good play. Playing surface quality is largely affected by construction and maintenance procedures, and this standard guide addresses those procedures. While warning tracks are a type of skinned area found on baseball and softball fields, this standard does not apply to warning tracks. A separate standard, Guide F2270, presents information pertaining to warning tracks.

4.1.1 During construction, consideration should be given to factors such as the physical and chemical properties of materials used in the area, freedom from stones and other debris, and surface and internal drainage.

4.1.2 Maintenance practices that influence the playability of the surface include edging, dragging, rolling, watering, vegetation control, brushing or hosing to prevent buildup of a lip of mineral matter in turfgrass at the skinned/turfed edges, and removal of stones and debris that may adversely affect play and safety.

4.2 Those responsible for the design, construction, or maintenance, or a combination thereof, of skinned areas on baseball and softball fields will benefit from this guide.

4.3 This guide provides flexibility in choices of procedures and can be used to cover a variety of use and budget levels.

SCOPE

1.1 This guide covers techniques that are appropriate for the construction and maintenance of skinned areas on baseball and softball fields. This guide provides guidance for the selection of materials, such as soil, sand, gravel, crushed stone, crushed brick, calcined clay, calcined diatomaceous earth, vitrified clay, etc., for use in constructing or reconditioning skinned areas and for the selection of management practices that will maintain a safe and playable skinned surface. Although this guide is specific to baseball/softball, it has application to other sports where ball bounce, ball roll, or player footing, or a combination thereof, are of importance.

1.2 Decisions in selecting construction and maintenance techniques are influenced by existing soil types, climatic factors, level of play, intensity of use, equipment available, budget, and training and ability of management personnel.

1.3 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.4 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This guide offers an organized collection of information or a series of options and does not recommend a specific course of action. This document cannot replace education or experience and should be used in conjunction with professional judgment. Not all aspects of this guide may be applicable in all circumstances. The ASTM standard is not intended to represent or replace the standard of care by which the adequacy of a given professional service must be judged, nor should this document be applied without consideration of a project’s many unique aspects. The word “Standard” in the title of this document means only that the document has been approved through the ASTM consensus process.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Tra...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2107 − 08 (Reapproved 2020) An American National Standard

Standard Guide for

Construction and Maintenance of Skinned Areas on

Baseball and Softball Fields

This standard is issued under the fixed designation F2107; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope document means only that the document has been approved

through the ASTM consensus process.

1.1 This guide covers techniques that are appropriate for the

1.6 This international standard was developed in accor-

construction and maintenance of skinned areas on baseball and

dance with internationally recognized principles on standard-

softball fields. This guide provides guidance for the selection

ization established in the Decision on Principles for the

of materials, such as soil, sand, gravel, crushed stone, crushed

Development of International Standards, Guides and Recom-

brick,calcinedclay,calcineddiatomaceousearth,vitrifiedclay,

mendations issued by the World Trade Organization Technical

etc.,foruseinconstructingorreconditioningskinnedareasand

Barriers to Trade (TBT) Committee.

for the selection of management practices that will maintain a

safe and playable skinned surface. Although this guide is

2. Referenced Documents

specific to baseball/softball, it has application to other sports

2.1 ASTM Standards:

whereballbounce,ballroll,orplayerfooting,oracombination

C33 Specification for Concrete Aggregates

thereof, are of importance.

C242 Terminology of Ceramic Whitewares and Related

1.2 Decisions in selecting construction and maintenance

Products

techniques are influenced by existing soil types, climatic

D422 Test Method for Particle-SizeAnalysis of Soils (With-

factors, level of play, intensity of use, equipment available,

drawn 2016)

budget, and training and ability of management personnel.

D653 Terminology Relating to Soil, Rock, and Contained

1.3 The values stated in SI units are to be regarded as the

Fluids

standard. The values in parentheses are for information only.

D5883 Guide for Use of Rotary Kiln Produced Expanded

Shale, Clay or Slate (ESCS) as a Mineral Amendment in

1.4 This standard may involve hazardous materials,

Topsoil Used for Landscaping and Related Purposes

operations, and equipment. This standard does not purport to

E11 Specification for Woven Wire Test Sieve Cloth and Test

address all of the safety concerns, if any, associated with its

Sieves

use. It is the responsibility of the user of this standard to

F405 Specification for Corrugated Polyethylene (PE) Pipe

establish appropriate safety, health, and environmental prac-

and Fittings (Withdrawn 2015)

tices and determine the applicability of regulatory limitations

F1632 Test Method for Particle Size Analysis and Sand

prior to use.

Shape Grading of Golf Course Putting Green and Sports

1.5 This guide offers an organized collection of information

Field Rootzone Mixes

or a series of options and does not recommend a specific

F2270 Guide for Construction and Maintenance of Warning

course of action. This document cannot replace education or

Track Areas on Athletic Fields

experience and should be used in conjunction with professional

judgment. Not all aspects of this guide may be applicable in all

3. Terminology

circumstances. TheASTM standard is not intended to represent

or replace the standard of care by which the adequacy of a 3.1 Definitions—Except as noted, soil related definitions are

given professional service must be judged, nor should this

in accordance with Terminology D653.

document be applied without consideration of a project’s many 3.1.1 calcined clay—granular, lightweight material pro-

unique aspects. The word “Standard” in the title of this

duced by calcining clay minerals, such as montmorillonite and

1 2

This guide is under the jurisdiction of ASTM Committee F08 on Sports For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Equipment, Playing Surfaces, and Facilities and is the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee F08.64 on Natural Playing Surfaces. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved April 1, 2020. Published April 2020. Originally the ASTM website.

approved in 2001. Last previous edition approved in 2015 as F2107 – 08 (2015). The last approved version of this historical standard is referenced on

DOI: 10.1520/F2107-08R20. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2107 − 08 (2020)

attapulgite, at temperatures of about 700°C or higher. Those equivalent diameter. (2) as a textural class, soil material that

used as soil amendments should be hard, resistant to physical contains 85 % or more sand, and not more than 10 % clay. (3)

breakdown, and screened to appropriate sizes. Calcined clay is as a soil particle size class, soil material that contains 70 % or

a manufactured product that lacks the particle size and plas- more sand, and not more than 15 % clay (sandy soils). (4)asa

ticity properties that would allow it to be included in the soil textural group, soil material that falls within the textural

definition of clay. (1) classes of “sand” and “loamy sand” (sandy soils). (3,4)

3.1.6.1 Discussion—Although no mineralogy term is asso-

3.1.2 calcined diatomite—stable, lightweight granules pro-

ciated with the definition of sand, common usage often utilizes

duced by calcining diatomite (diatomaceous earth), a hydrated

the terms “quartz” or “silica” as synonyms for sand. While

silica mineral derived from the remains of diatoms. (1)

quartz is the most common silicate mineral in soils and in the

3.1.3 clay—clay can be defined in terms of a particular size

sand fractions in particular, quartz being a mineral highly

fraction of a soil, a soil textural class, a soil particle size class,

resistant to weathering, the synonymy with the term sand is

a soil textural group, soil mineralogy, or, in engineering terms,

incorrect. A proper mineralogy class for quartz is “siliceous,”

as materials that exhibit plastic soil properties when at appro-

defined as 90 % or more of the 0.2 to 2.0 mm fraction

priate water contents.

composed of silica minerals (quartz, chalcedony, or opal) and

3.1.3.1 Discussion—Ideally, the term “clay” should be ap-

other extremely durable minerals that are resistant to weather-

propriately defined when used to describe soils for skinned

ing. (4)

infield mixes. For example, a 60 % sand/40 % clay mixture

3.1.7 gravel—commonly used to denote spherical, cube-

could imply either 60 % sand/40 % clayey soil (or other soils

like, or equiaxial aggregate materials with an equivalent

with textures containing enough clay (<0.002 mm) to exhibit

diameter >2.0 mm and <7.6 mm. More correctly used, this

plasticity) or 60 % sand (2 to 0.05 mm)/40 % clay (<0.002

classificationrefersto“rockfragments”classifiedaspebblesin

mm).

the Glossary of Soil Science Terms (1997). (3,6)

3.1.3.1 clay—(1) as a particular size fraction of a soil, a soil

3.1.8 skinned area—area on sports fields that, by design, is

separate consisting of particles <0.002 mm (fine earth fraction)

devoid of turfgrasses or other vegetation; may be entire field or

in equivalent diameter. (2) as a textural class, soil material that

a portion of the field (for example, skinned infield in baseball

contains 40 % or more clay, <45 % sand and <40 % silt. (3)as

or softball; skinned base paths in otherwise turfed infield).

a soil particle size class, soil material that contains 35 % or

Pitching mounds and catcher’s and batter’s boxes are also

more clay, (clayey soils). (4) as a soil textural group, soil

considered skinned areas. Warning tracks (Guide F2270) can

material that falls within the textural classes of “sandy clay,”

be considered skinned areas as well.

“silty clay” and “clay” (clayey soils). (5) in terms of

mineralogy, soil particulates that are commonly occurring but 3.1.9 soil—sediments or other unconsolidated accumula-

not restricted to the <0.002 mm fraction (clay minerals). tions of solid particles produced by the physical and chemical

Commonly occurring in soil mineralogy classes as smectitic, disintegration of rocks, and which may or may not contain

kaolinitic, illitic (micaceous), gibbsitic, ferritic, or mixed. Soil organic matter.

mineralogy classes are defined predominantly by the type of

3.1.10 soil profile—vertical section of a soil, showing the

soil mineral dominating (40 % or more) the fine earth fraction.

nature and sequence of the various layers, as developed by

(6) in engineering terms, soils containing enough soil material

deposition or weathering or both or as developed by construc-

in the less than 0.4 mm fractions such that when moist they

tion procedures.

exhibit consistence characteristics of “moderately plastic” or

3.1.11 soil texture (gradation) (grain-size distribution) —the

“very plastic” forming a roll 4 cm or longer and 4 mm or

proportions by mass of a soil or fragmented rock distributed in

thinner that supports its own weight. (2-7)

specified particle size ranges.

3.1.4 vitrified clay—clay that has been manufactured

3.1.11.1 soil textural class—texture designation based on

through vitrification, which is the progressive reduction and

relative proportions of the various soil separates: sand (2.0 to

elimination of porosity of a ceramic composition, with the

0.05 mm in diameter), silt (0.05 to 0.002 mm), and clay

formationofaglassphase,asaresultofaheattreatment. C242

(<0.002 mm). (2-7)

3.1.5 expanded shale, clay, or slate (ESCS)—a rotary kiln

NOTE1—Particlesizerangesforsand,silt,andclayaslistedabovevary

producedvesicularamorphoussilicateparticulatematerial.Itis

somewhat from ranges given in Test Method D422 and Terminology

a highly porous, low density material with an apparent specific

D653.

gravityofapproximately0.8to2.4,andadry/looseunitweight

3 3

of approximately 35 to 70 lb/ft (561 to 1121 kg/m ). D5883

4. Significance and Use

3.1.6 sand—sand can be defined in terms of a particular size

4.1 The skinned areas of baseball and softball fields should

fraction of soil, a soil textural class, a soil particle size class,

provide a uniform playing surface of high quality. Ball bounce

and a soil textural group.

should be true and predictable. Footing and sliding properties

3.1.6.1 sand—(1) as a particular size fraction of soil, a soil should favor optimum performance of players. Undulations,

separate consisting of particles >0.05 mm and <2.0 mm in

rough surface, hard or soft surfaces, weeds, stones, and wet

spots detract from good play. Playing surface quality is largely

affected by construction and maintenance procedures, and this

The boldface numbers in parentheses refer to the list of references at the end of

this standard. standard guide addresses those procedures. While warning

F2107 − 08 (2020)

tracks are a type of skinned area found on baseball and softball diameter from the surface 1.5 cm. The settled depth of the

fields, this standard does not apply to warning tracks. A modified soil should be about 10 cm.

separate standard, Guide F2270, presents information pertain-

(2) Modification of an existing soil should be done during

ing to warning tracks.

construction of the facility. In some recreational baseball/

4.1.1 During construction, consideration should be given to

softball situations, consideration of skinned areas occurs only

factors such as the physical and chemical properties of mate-

after a turfgrass stand is worn down to the soil surface. Layout

rials used in the area, freedom from stones and other debris,

and modification of skinned areas can take place at that time

and surface and internal drainage.

and will require taking the field out of play unless the work is

4.1.2 Maintenance practices that influence the playability of

done after the playing season.

the surface include edging, dragging, rolling, watering, vegeta-

5.1.2.2 Artificial (Man-made) Skinned Areas:

tion control, brushing or hosing to prevent buildup of a lip of

(1) Artificial (man-made) profiles are sometimes con-

mineral matter in turfgrass at the skinned/turfed edges, and

structed to create the skinned area. In situations where profiles

removalofstonesanddebristhatmayadverselyaffectplayand

contain more than 85 % sand and exhibit high internal perme-

safety.

ability under heavy compaction, the skinned infield mix can be

4.2 Those responsible for the design, construction, or

placed on a drainage blanket of gravel, which provides

maintenance, or a combination thereof, of skinned areas on

subsurface drainage. In situations where profiles contain less

baseball and softball fields will benefit from this guide.

than 85 % sand and exhibit limited internal permeability under

4.3 This guide provides flexibility in choices of procedures

heavy compaction, a drainage blanket of gravel is not required,

and can be used to cover a variety of use and budget levels.

as subsurface drainage will be minimal. Skinned infield mixes

of this nature may be placed directly on top of the subsoil.

5. Construction

Additional information regarding the construction of skinned

5.1 Skinned Infield and Basepath Areas:

infield areas with subsurface drainage systems is found in the

5.1.1 Skinned Infield Mix—Materials used to provide the

appendix.

skinned surface should be relatively inert mineral matter,

(2) Skinned Infield Mix—Askinned infield mix can be used

which will resist chemical and physical degradation. This soil

to bring the surface to final grade.Add approximately 10 to 15

or mixture is sometimes referred to as “dirt,” for example,

cm (4 to 6 in.) of skinned infield mix and finish to final grade.

infield dirt. It is used in constructing skinned infields and

Skinned infield mix materials should meet the following

basepath areas.

particle size specifications. Quartz sands are recommended; if

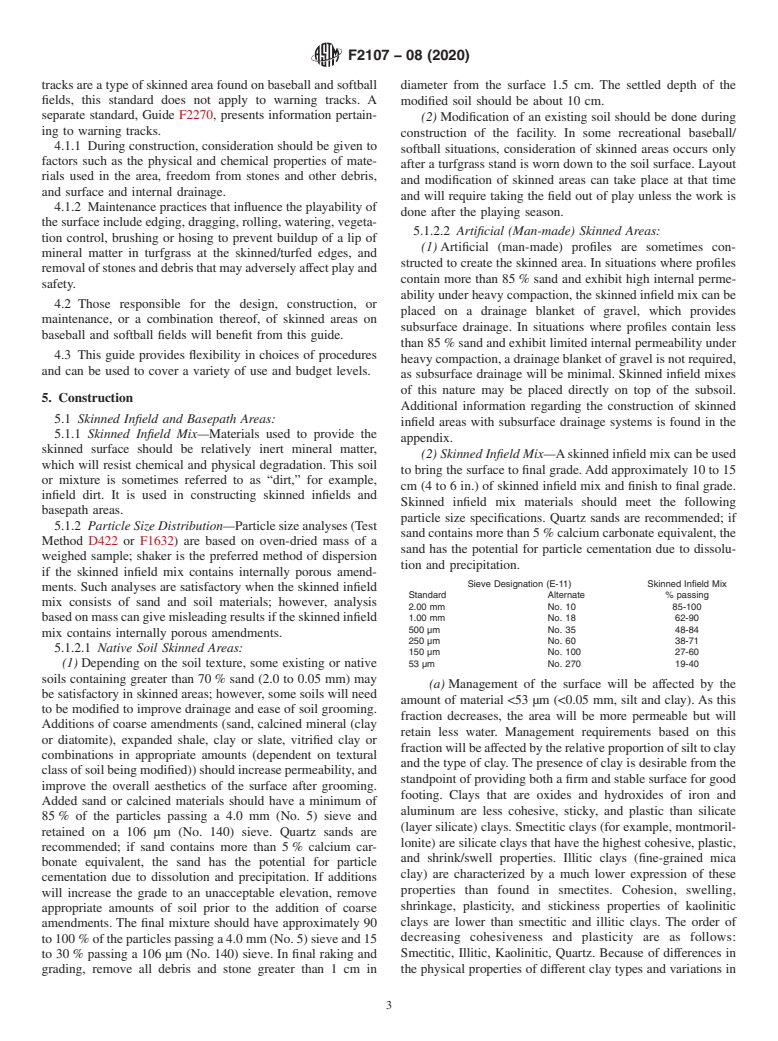

5.1.2 Particle Size Distribution—Particlesizeanalyses(Test

sand contains more than 5 % calcium carbonate equivalent, the

Method D422 or F1632) are based on oven-dried mass of a

sand has the potential for particle cementation due to dissolu-

weighed sample; shaker is the preferred method of dispersion

tion and precipitation.

if the skinned infield mix contains internally porous amend-

Sieve Designation (E-11) Skinned Infield Mix

ments. Such analyses are satisfactory whe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.