ASTM B298-12

(Specification)Standard Specification for Silver-Coated Soft or Annealed Copper Wire

Standard Specification for Silver-Coated Soft or Annealed Copper Wire

ABSTRACT

This specification covers silver-coated, soft or annealed, round copper wire, intended for use in electrical equipment. The silver-coated wires are classified according to the total weight of the coated wires, namely; Class A, B, C, D, and E. Tensile strength test, resistivity test, weight of coating, and dimensional measurements shall be performed to conform to the requirements specified.

SCOPE

1.1 This specification covers silver-coated, soft or annealed, round copper wire, intended for use in electrical equipment, as follows:

1.1.1 Class A—Wire whose silver coating is at least 1.25 % of the total weight of the coated wire.

1.1.2 Class B—Wire whose silver coating is at least 2.50 % of the total weight of the coated wire.

1.1.3 Class C—Wire whose silver coating is at least 4.00 % of the total weight of the coated wire.

1.1.4 Class D—Wire whose silver coating is at least 6.10 % of the total weight of the coated wire.

1.1.5 Class E—Wire whose silver coating is at least 10.00 % of the total weight of the coated wire.

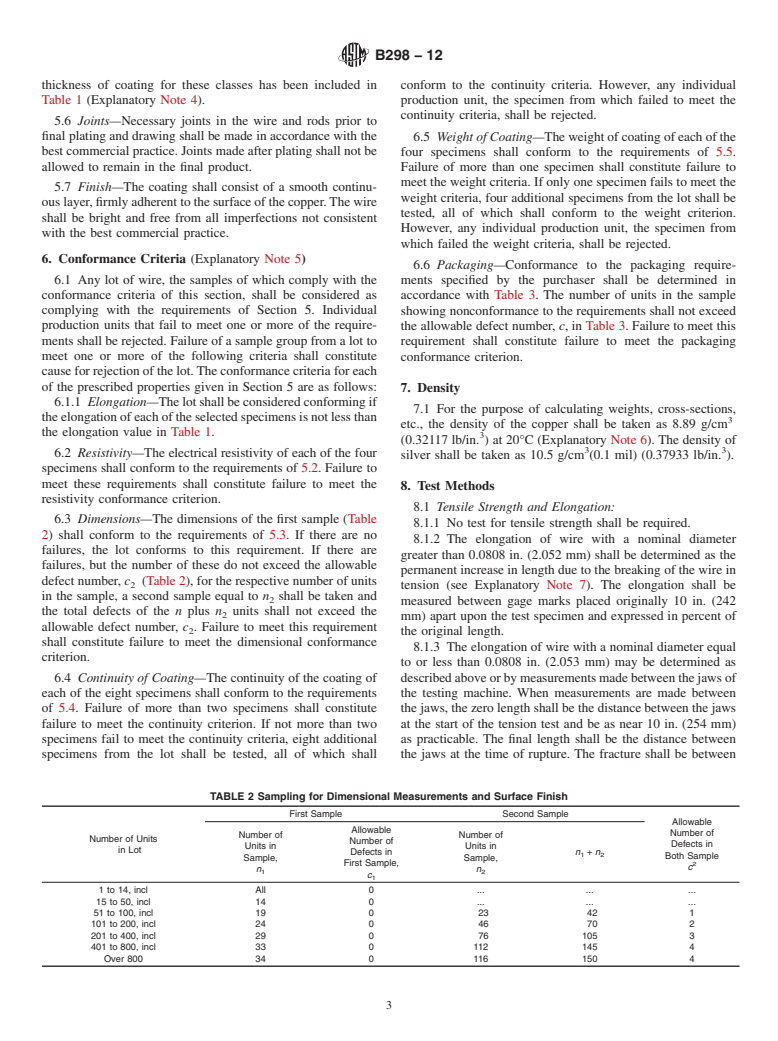

1.2 Silver-coated wire having different minimum percentages of silver by weight may be obtained by mutual agreement between the manufacturer and the purchaser. For information purposes the thickness of coating in microinches provided by the percentages listed above is shown in Table 1 (Explanatory Note 1).TABLE 1 Tensile Requirements

Diameter,

in.

Area at 20°C

Elongation

in 10 in.,

min, %

Thickness of Coating, μin. (For Information Only)

cmils

in.2

Class A, 1.25

% Silver

Class B, 2.50

% Silver

Class C, 4.00

% Silver

Class D, 6.10

% Silver

Class E, 10.00

% Silver

0.1285

16 510

0.01297

30

340

680

1 090

1 659

2 720

0.1144

13 090

0.01028

30

303

605

970

1 477

2 422

0.1019

10 380

0.008155

25

270

539

864

1 316

2 157

0.0907

8 230

0.00646

25

240

480

768

1 171

1 941

0.0808

6 530

0.00513

25

214

428

684

1 043

1 710

0.0720

5 180

0.00407

25

190

381

610

930

1 524

0.0641

4 110

0.00323

25

170

339

542

828

1 357

0.0571

3 260

0.00256

25

151

302

483

737

1 209

0.0508

2 580

0.00203

25

134

269

430

656

1 075

0.0453

2 050

0.00161

25

120

240

383

585

959

0.0403

1 620

0.00128

25

107

213

341

520

853

0.0359

1 290

0.00101

25

95

190

304

464

760

0.0320

1 020

0.000804

25

85

169

270

413

677

0.0285

812

0.000638

25

75

151

241

368

603

0.0253

640

0.000503

25

67

134

214

327

536

0.0226

511

0.000401

25

60

120

191

292

478

0.0201

404

0.00317

20

53

106

170

260

425

0.0179

320

0.000252

20

47

95

151

231

379

0.0159

253

0.000199

20

42

84

135

205

337

0.0142

202

0.000158

20

...

75

120

183

301

0.0126

159

0.000125

20

...

67

107

163

267

0.0113

128

0.000100

20

...

60

96

146

239

0.0100

100

0.0000785

20

...

53

85

129

212

0.0089

79.2

0.0000622

15

...

47

75

115

188

0.0080

64.0

0.0000503

15

...

42

68

103

169

0.0071

50.4

0.0000396

15

...

...

60

92

150

0.0063

39.7

0.0000312

15

...

...

53

81

133

0.0056

31.4

0.0000246

15

...

...

47

72

119

0.0050

25.0

0.0000196

15

...

...

42

65

106

0.0045

20.2

0.0000159

15

...

....

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B298 −12

Standard Specification for

1

Silver-Coated Soft or Annealed Copper Wire

This standard is issued under the fixed designation B298; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

2.1 The following documents of the issue in effect at the

1.1 Thisspecificationcoverssilver-coated,softorannealed,

round copper wire, intended for use in electrical equipment, as time of reference form a part of this specification to the extent

referenced herein:

follows:

2

1.1.1 Class A—Wire whose silver coating is at least 1.25%

2.2 ASTM Standards:

of the total weight of the coated wire.

B49Specification for Copper Rod Drawing Stock for Elec-

1.1.2 Class B—Wire whose silver coating is at least 2.50%

trical Purposes

of the total weight of the coated wire.

B193Test Method for Resistivity of Electrical Conductor

1.1.3 Class C—Wire whose silver coating is at least 4.00%

Materials

of the total weight of the coated wire.

B258 Specification for Nominal Diameters and Cross-

1.1.4 Class D—Wire whose silver coating is at least 6.10%

SectionalAreasofAWGSizesofSolidRoundWiresUsed

of the total weight of the coated wire.

as Electrical Conductors

1.1.5 Class E—Wirewhosesilvercoatingisatleast10.00%

E50Practices for Apparatus, Reagents, and Safety Consid-

of the total weight of the coated wire.

erations for Chemical Analysis of Metals, Ores, and

Related Materials

1.2 Silver-coated wire having different minimum percent-

agesofsilverbyweightmaybeobtainedbymutualagreement

3. Ordering Information

between the manufacturer and the purchaser. For information

3.1 Ordersformaterialunderthisspecificationshallinclude

purposes the thickness of coating in microinches provided by

the following information:

the percentages listed above is shown in Table 1 (Explanatory

3.1.1 Quantity of each size,

Note 1).

3.1.2 Wire size, diameter in inches (see 5.3 and Table 1),

1.3 The values stated in inch-pound units are to be regarded

3.1.3 Class of coating (Section 1 and Table 1),

as standard. The values given in parentheses are mathematical

3.1.4 Type of copper, if special (see 4.2),

conversions to SI units that are provided for information only

3.1.5 Place of inspection (see 9.1), and

and are not considered standard.

3.1.6 Packaging and Package Marking (Section 10).

1.3.1 Exceptions—The SI values for density, resistivity, and

3.1.7 In addition supplementary requirements shall apply

volume are to be regarded as standard.

onlywhenspecifiedbythepurchaserintheinquiry,contract,or

1.4 The following precautionary caveat pertains only to the

purchase order for direct procurement by agencies of the U.S.

testmethodsectionofthisspecification: This standard does not Government (see S1, S2, and S3).

purport to address all of the safety concerns, if any, associated

4. Materials and Manufacture

with its use. It is the responsibility of the user of this standard

to establish appropriate safety and health practices and

4.1 The material shall be silver-coated copper wire (Ex-

determine the applicability of regulatory limitations prior to

planatory Note 2), of such quality and purity that the finished

use. For specific precautionary statements see 8.4.1.2 and

product shall have the properties and characteristics prescribed

Explanatory Note 2.

in this specification.

NOTE 1—The following specifications define copper suitable for use:

Specification B49.

1

This specification is under the jurisdiction of ASTM Committee B01 on

Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on

2

Conductors of Copper and Copper Alloys. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 15, 2012. Published November 2012. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1955. Last previous edition approved in 2007 as B298–07. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/B0298-12. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B298−12

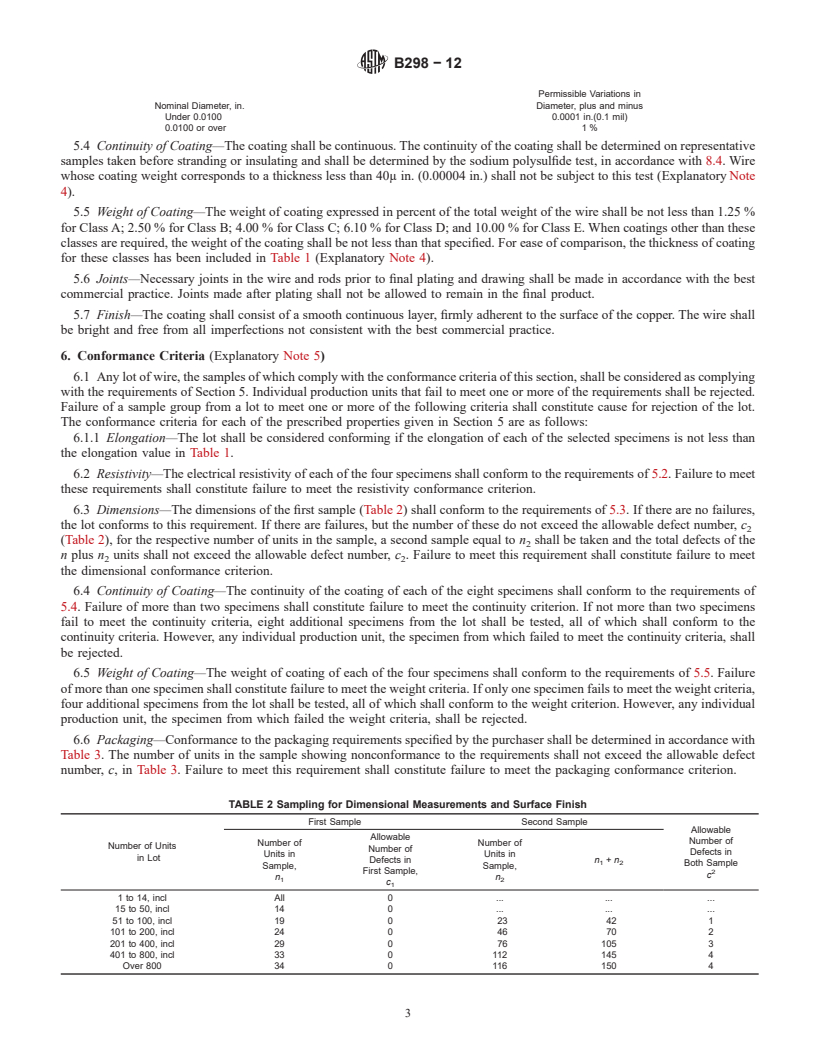

TABLE 1 Tensile Requirements

Area at 20°C Thickness of Coating, µin. (For Information Only)

Elongation

Diameter,

in 10 in.,

Class A, 1.25 Class B, 2.50 Class C, 4.00 Class D, 6.10 Class E, 10.00

2

in.

cmils in.

min, %

% Silver % Silver % Silver % Silver % Silver

0.1285 16 510 0.01297 30 340 680 1 090 1 659 2 720

0.1144 13 090 0.01028 30 303 60

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B298 − 07 B298 − 12

Standard Specification for

1

Silver-Coated Soft or Annealed Copper Wire

This standard is issued under the fixed designation B298; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers silver-coated, soft or annealed, round copper wire, intended for use in electrical equipment, as

follows:

1.1.1 Class A—Wire whose silver coating is at least 1.25 % of the total weight of the coated wire.

1.1.2 Class B—Wire whose silver coating is at least 2.50 % of the total weight of the coated wire.

1.1.3 Class C—Wire whose silver coating is at least 4.00 % of the total weight of the coated wire.

1.1.4 Class D—Wire whose silver coating is at least 6.10 % of the total weight of the coated wire.

1.1.5 Class E—Wire whose silver coating is at least 10.00 % of the total weight of the coated wire.

1.2 Silver-coated wire having different minimum percentages of silver by weight may be obtained by mutual agreement between

the manufacturer and the purchaser. For information purposes the thickness of coating in microinches provided by the percentages

listed above is shown in Table 1 (Explanatory Note 1).

1.3 The SI values of resistance and density are to be regarded as standard. For all other properties values values stated in

inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical conversions to SI units that

are provided for information purposes only.only and are not considered standard.

1.3.1 Exceptions—The SI values for density, resistivity, and volume are to be regarded as standard.

1.4 The following precautionary caveat pertains only to the test method section of this specification:This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific

precautionary statements see 8.4.1.2 and Explanatory Note 2.

2. Referenced Documents

2.1 The following documents of the issue in effect at the time of reference form a part of this specification to the extent

referenced herein:

2

2.2 ASTM Standards:

B4B49 Specification Tough-Pitch Lake Copper-Refinery Shapesfor Copper Rod Drawing Stock for Electrical Purposes

(Withdrawn 1981)

B5 Specification for High Conductivity Tough-Pitch Copper Refinery Shapes

B193 Test Method for Resistivity of Electrical Conductor Materials

B258 Specification for Nominal Diameters and Cross-Sectional Areas of AWG Sizes of Solid Round Wires Used as Electrical

Conductors

E50 Practices for Apparatus, Reagents, and Safety Considerations for Chemical Analysis of Metals, Ores, and Related Materials

3. Ordering Information

3.1 Orders for material under this specification shall include the following information:

3.1.1 Quantity of each size,

3.1.2 Wire size, diameter in inches (see 5.3 and Table 1),

1

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on Conductors

of Copper and Copper Alloys.

Current edition approved May 15, 2007Nov. 15, 2012. Published June 2007November 2012. Originally approved in 1955. Last previous edition approved in 19992007

ε1

as B298 – 99B298 – 07. . DOI: 10.1520/B0298-07.10.1520/B0298-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B298 − 12

TABLE 1 Tensile Requirements

Area at 20°C Thickness of Coating, μin. (For Information Only)

Elongation

Diameter,

in 10 in.,

Class A, 1.25 Class B, 2.50 Class C, 4.00 Class D, 6.10 Class E, 10.00

2

in.

cmils in.

min, %

% Silver % Silver % Silver % Silver % Silver

0.1285 16 510 0.01297 30 340 680 1 090 1 659 2 720

0.1144 13 090 0.01028 30 303 605 970 1 477 2 422

0.1019 10 380 0.008155 25 270 539 864 1 316 2 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.