ASTM D4964-96(2008)e1

(Test Method)Standard Test Method for Tension and Elongation of Elastic Fabrics (Constant-Rate-of-Extension Type Tensile Testing Machine)

Standard Test Method for Tension and Elongation of Elastic Fabrics (Constant-Rate-of-Extension Type Tensile Testing Machine)

SIGNIFICANCE AND USE

This test method for testing loop tension and elongation of elastic fabrics is considered satisfactory for acceptance testing of commercial shipments of elastic fabrics because the test method is used in the trade for acceptance testing.

In case of a dispute arising from differences in reported test results when using this test method for acceptance testing of commercial shipments, the parties should conduct comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens that are as homogeneous as possible and that are from a lot of material of the type in question. The test specimens should then be randomly assigned in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using student's t-test for unpaired data and an acceptable probability level chosen by the two parties before the testing is begun. If bias is found, either its cause must be found and corrected or the purchaser and the supplier must agree to interpret future test results with consideration to the known bias.

This test method specifies the use of the CRE-type tensile testing machine. Users of this test method are cautioned that loop tension test data obtained using this method are not comparable to tension test data obtained using Test Method D 1775 because of the differences in testing machines. Test Method D 1775 uses a CRL-type tensile testing machine.

The loop tension and extension relationship of an elastic fabric is an important criterion for judging the suitability of the fabric for various end uses, such as: foundation garments, brassieres, and swimsuits.

Data from loop tension-recovery curves can be compared only if the tension testing machine, rate-of-extension, maximum loading (or extension), and specimen specifications are comparable. Since different m...

SCOPE

1.1 This test method covers the measurement of tension and elongation of wide or narrow elastic fabrics made from natural or man-made elastomers, either alone or in combination with other textile yarns, when tested with a constant-rate-of-extension (CRE) type tensile testing machine.

Note 1—For determination of similar testing using the constant-rate-of-load (CRL) type tensile testing machine, refer to Test Method D 1775.

1.2 The use of this test method requires the selection of, or mutual agreement upon, loop tension(s) and elongation(s) at which the test results will be determined.

1.3 Laundering procedures require mutual agreement on the selection of temperature and number of washing cycles and drying cycles to be used.

1.4 The values stated in SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore each system must be used independently of the other, without combining values in any way.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:D4964–96 (Reapproved 2008)

Standard Test Method for

Tension and Elongation of Elastic Fabrics (Constant-Rate-

of-Extension Type Tensile Testing Machine)

This standard is issued under the fixed designation D4964; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Minor editorial changes were made throughout in October 2008.

1. Scope D123 Terminology Relating to Textiles

D1775 Test Method for Tension and Elongation of Wide

1.1 This test method covers the measurement of tension and

Elastic Fabrics

elongation of wide or narrow elastic fabrics made from natural

D1776 Practice for Conditioning and Testing Textiles

or man-made elastomers, either alone or in combination with

other textile yarns, when tested with a constant-rate-of-

3. Terminology

extension (CRE) type tensile testing machine.

3.1 Definitions:

NOTE 1—For determination of similar testing using the constant-rate-

3.1.1 constant-rate-of-extension tensile testing machine

of-load (CRL) type tensile testing machine, refer to Test Method D1775.

(CRE), n—a testing machine in which the rate of increase of

1.2 The use of this test method requires the selection of, or

specimen length is uniform with time.

mutual agreement upon, loop tension(s) and elongation(s) at

3.1.2 constant-rate-of-load tensile testing machine (CRL),

which the test results will be determined.

n—a testing machine in which the rate of increase of the load

1.3 Laundering procedures require mutual agreement on the

being applied to the specimen is uniform with time after the

selection of temperature and number of washing cycles and

first 3 s.

drying cycles to be used.

3.1.3 elastic fabric, n—a textile fabric made from an elas-

1.4 The values stated in SI units or inch-pound units are to

tomer either alone or in combination with other textile mate-

be regarded separately as standard. The values stated in each

rials.

system may not be exact equivalents; therefore each system

3.1.4 elongation, n—the ratio of the extension of a material

must be used independently of the other, without combining

to the length of the material prior to stretching.

values in any way.

3.1.5 extension, n—the change in length of a material due to

1.5 This standard does not purport to address all of the

stretching.

safety concerns, if any, associated with its use. It is the

3.1.6 extension-recovery cycle, n—in tension testing, the

responsibility of the user of this standard to establish appro-

continuous extension of a specimen, with a momentary hold at

priate safety and health practices and determine the applica-

a specified extension, followed by a controlled rate of return to

bility of regulatory limitations prior to use.

zero extension.

3.1.7 force, n—a physical influence exerted by one body on

2. Referenced Documents

another which produces acceleration of bodies that are free to

2.1 ASTM Standards:

move and deformation of bodies that are not free to move.

D76 Specification for Tensile Testing Machines for Textiles

3.1.8 loop tension, n— in elastic material testing, the total

tension at any specified extension that is exerted on a specimen

1 in a loop formation.

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

3.1.9 narrow elastic fabric, n—an elastic fabric that is less

and is the direct responsibility of Subcommittee D13.59 on Fabric Test Methods,

General.

than 150 mm or 6 in. wide.

Current edition approved July 1, 2008. Published October 2005. Originally

3.1.10 tension, n—a uniaxial force tending to cause the

approved in 1989. Last previous edition approved in 2004 as D4964 – 96(2004).

stretching of a material.

DOI: 10.1520/D4964-96R08E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Withdrawn. The last approved version of this historical standard is referenced

the ASTM website. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D4964–96 (2008)

3.1.11 tension-recovery chart, n— in tension testing,a D1775 because of the differences in testing machines. Test

continuously plotted graph of tension versus extension result- Method D1775 uses a CRL-type tensile testing machine.

ing from a tension-recovery cycle. 5.3 The loop tension and extension relationship of an elastic

3.1.12 tension test, n— in textiles, a test designed to fabric is an important criterion for judging the suitability of the

fabric for various end uses, such as: foundation garments,

measure the tautness in a textile strand or fabric.

3.1.13 wide elastic fabric, n—anelasticfabricthatisatleast brassieres, and swimsuits.

5.4 Data from loop tension-recovery curves can be com-

150 mm or 6 in. wide.

pared only if the tension testing machine, rate-of-extension,

3.1.14 For definitions of other textile terms used in this test

maximum loading (or extension), and specimen specifications

method, refer to Terminology D123.

are comparable. Since different machine set-ups will cause

different results on the same fabric, machine set-ups must

4. Summary of Test Method

always be specified before making a test and be reported with

4.1 Loop Tension at Specified Elongation(s)—A condi-

the test results.

tioned loop specimen is mounted in a CRE-type tensile testing

5.5 The test for measuring loop tension at specified elonga-

machine. The specimen is then extended at a specified rate to

tion(s) is used to determine the tension of an elastic fabric

a specified loop tension, and returned at a specified rate to zero

when subjected to a specified elongation which is less than the

tension. The cycle is repeated two more times to give a total of

elongation required to rupture the fabric. The test prescribes

threecycles.Duringthetest,extension-recoverycurvesmaybe

points of measurement on the extending (outgoing) cycle only.

plotted by an automatic recorder for all or only the third cycle.

5.6 The test for measuring elongation at specified tension(s)

The tension at specified percent elongation(s) is calculated

is used to determine the elongation of an elastic fabric when

from the graph of the third cycle or obtained from the

subjected to a specified loop tension which is less than the

instrument.

tensionrequiredtorupturethefabric.Thetestprescribespoints

4.2 Elongation at Specified Loop Tension—A conditioned

of measurement on the loading (outgoing) cycle only.

loop specimen is mounted in a CRE-type tensile testing

machine. The specimen is then loaded at a specified rate to a

6. Apparatus

specified loop tension, and unloaded at a specified rate to zero

6.1 Tensile Testing Machine, CRE-Type, conforming to

loop tension. The cycle is repeated two more times to give a

Specification D76, equipped with an automatic recording

total of three cycles. During the test, tension-recovery curves

device and cycling controls.

maybeplottedbyanautomaticrecorderforalloronlythethird

6.2 Band Clamps, to hold loop specimen during testing.The

cycle. The elongation at a specified loop tension is calculated

diameter of the anvils will be 13.06 0.25 mm (0.5 6 0.01 in.)

from the graph of the third cycle or obtained from the

or 6.56 0.25 mm (0.25 6 0.01 in.).The length of the anvil will

instrument.

not be less than 76 mm (3.0 in.).

6.3 Sewing Machine Single-Needle.

5. Significance and Use

5.1 This test method for testing loop tension and elongation

7. Sampling

of elastic fabrics is considered satisfactory for acceptance

7.1 Lot Sample—As a lot sample for acceptance testing,

testing of commercial shipments of elastic fabrics because the

take at random the number of rolls of fabric as directed in an

test method is used in the trade for acceptance testing.

applicable material specification or other agreement between

5.1.1 In case of a dispute arising from differences in

thepurchaserandthesupplier.Considerrollsoffabrictobethe

reported test results when using this test method for acceptance

primary sampling units.

testing of commercial shipments, the parties should conduct

NOTE 2—An adequate specification or other agreement between the

comparative tests to determine if there is a statistical bias

purchaser and the supplier requires taking into account the variability

between their laboratories. Competent statistical assistance is

between rolls of fabric, and the variability between specimens from a

recommended for the investigation of bias.As a minimum, the

swatch from a roll of fabric, to provide a sampling plan with a meaningful

two parties should take a group of test specimens that are as

producer’s risk, consumer’s risk, acceptable quality level, and limiting

homogeneous as possible and that are from a lot of material of

quality level.

the type in question. The test specimens should then be

7.2 Laboratory Sample—As a laboratory sample for accep-

randomly assigned in equal numbers to each laboratory for

tance testing, take a full width swatch,2m(2yd) long, from

testing.Theaverageresultsfromthetwolaboratoriesshouldbe

the end of each roll of fabric in the lot sample, after first

compared using student’s t-test for unpaired data and an

discarding a minimum of1m(1yd)of fabric from the very

acceptable probability level chosen by the two parties before

outside of the roll.

the testing is begun. If bias is found, either its cause must be

7.3 Test Specimens—Take test specimens as follows:

found and corrected or the purchaser and the supplier must

7.3.1 Wide Elastic Fabrics—If the purchaser and the sup-

agree to interpret future test results with consideration to the

plier agree to test the fabric in only one direction, cut five

known bias.

5.2 This test method specifies the use of the CRE-type

tensile testing machine. Users of this test method are cautioned

For additional information on obtaining apparatus, equipment, or supplies that

that loop tension test data obtained using this method are not

may be suitable for use in this standard, please visit the ASTM Manufacturers’

comparable to tension test data obtained using Test Method Equipment Directory at www.astm.org.

´1

D4964–96 (2008)

specimens from each swatch in the laboratory sample with the 9.2.1 Use one of the procedures described in 9.2.2 through

long dimension of the specimens parallel to the direction of 10.2.4 to verify or set the position of the clamps.

test. If the purchaser and the supplier agree to test the fabric in

9.2.2 Use the gage supplied by tensile testing machine

both directions, from each full-width swatch in the laboratory manufacturer.

sample, cut five specimens parallel to the long dimension and

9.2.3 Make and use a paper gage as directed below.

five specimens perpendicular to the long dimension. Speci-

9.2.3.1 Cut a strip of flexible paper that measures 275 6 2

mens should be spaced along a diagonal to allow for represen-

mm by 106 2 mm, or 11.0 6 0.05 in. by 0.5 6 0.05 in.

tation in each specimen of different warp and filling areas, or

9.2.3.2 From one end of paper strip, measure a distance of

waleandcourseareas.Takenospecimensnearerthanonetenth

250 6 2 mm, or 10.0 6 0.05 in., and draw a line perpendicular

of the fabric width from the selvage.

to the long axis.

7.3.2 Narrow Elastic Fabric—Cut five specimens from

9.2.3.3 Place a strip of double-faced tape across the strip,

each swatch in the laboratory sample. For narrow knitted or

and on the short end, coincident with the line.

woven elastic fabrics that are more than 75 mm (3 in.) wide,

9.2.3.4 Curl the untaped end of the strip to form a loop,

the purchaser and the supplier may agree to (1) use specimens

aligning the end with the 250 mm, or 10 in., line. Press down

of the widths specified in 8.1.1 for wide elastic fabrics of

on the strip, fastening it to the double-faced tape.

comparable construction, or (2) if wide clamps are available,

9.2.3.5 Place the paper loop around the testing machine

use full-width specimens.

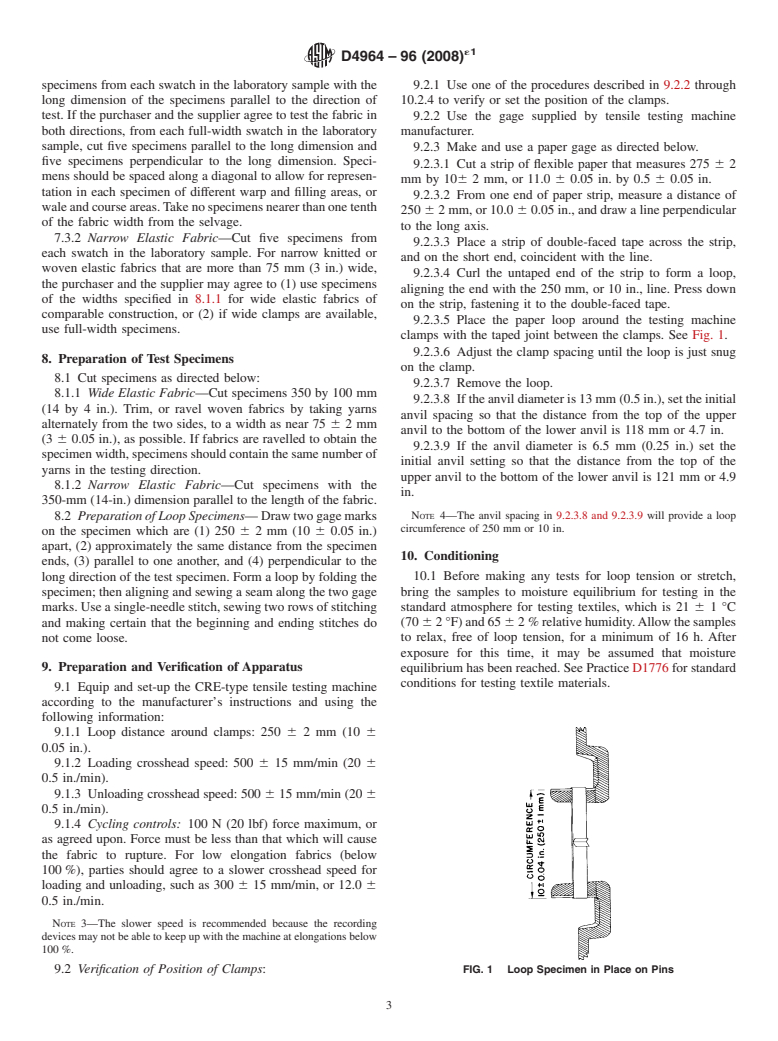

clamps with the taped joint between the clamps. See Fig. 1.

9.2.3.6 Adjust the clamp spacing until the loop is just snug

8. Preparation of Test Specimens

on the clamp.

8.1 Cut specimens as directed below:

9.2.3.7 Remove the loop.

8.1.1 Wide Elastic Fabric—Cut specimens 350 by 100 mm

9.2.3.8 Iftheanvildiameteris13mm(0.5in.),settheinitial

(14 by 4 in.). Trim, or ravel woven fabrics by taking yarns

anvil spacing so that the distance from the top of the upper

alternately from the two sides, to a width as near 75 62mm

anvil to the bottom of the lower anvil is 118 mm or 4.7 in.

(3 6 0.05 in.), as possible. If fabrics are ravelled to obtain the

9.2.3.9 If the anvil diameter is 6.5 mm (0.25 in.) set the

specimen width, specimens should contain the same number of

initial anvil setting so that the distance from the top of the

yarns in the testing direction.

upper anvil to the bottom of the lower anvil is 121 mm or 4.9

8.1.2 Narrow Elastic Fabric—Cut specimens with the

in.

350-mm (14-in.) dimension parallel to the length of the fabric.

NOTE 4—The anvil spacing in 9.2.3.8 and 9.2.3.9 will provide a loop

8.2 Preparation of Loop Specimens—Drawtwogagemarks

circumference of 250 mm or 10 in.

on the specimen which are (1) 250 62mm(10 6 0.05 in.)

apart, (2) approximately the same distance from the specimen

10. Conditioning

ends, (3) parallel to one another, and (4) perpendicular to the

10.1 Before making any tests for loop tension or stretch,

long direction of the test specimen. Form a loop by folding the

specimen; then aligning and sewing a seam along the two gage bring the samples to moisture equilibrium for testing in the

standard atmosphere for testing textiles, which is 21 61°C

marks. Use a single-needle stitch, sewing two rows of stitching

and making certain that the beginning and ending stitches do (70 62°F)and65 62 %relativehumidity.Allowthesamples

to relax, free of loop tension, for a minimum of 16 h. After

not come loose.

exposure for this time, it may be assumed that moisture

9. Preparation and Verification of Apparatus equilibrium has been reached. See Practice D1776 for standard

conditions for testing textile materials.

9.1 Equip and set-up the CRE-type tensile testing machine

according to the manufacturer’s instructions and using the

following information:

9.1.1 Loop distance around clamps: 250 62mm(10 6

0.05 in.).

9.1.2 Loading crosshead speed: 500 6 15 mm/min (20 6

0.5 in./min).

9.1.3 Unloading crosshead speed: 500 6 15 mm/min (20 6

0.5 in./min).

9.1.4 Cycling controls: 100 N

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.