ASTM D1442-93

(Test Method)Standard Test Method for Maturity of Cotton Fibers (Sodium Hydroxide Swelling and Polarized Light Procedures)

Standard Test Method for Maturity of Cotton Fibers (Sodium Hydroxide Swelling and Polarized Light Procedures)

SCOPE

1.1 This test method covers the determination of the percentage of mature fibers in a sample of loose, chemically untreated cotton fibers, whether taken before processing or unravelled from a textile product.

1.2 This test method gives two optional procedures for determining maturity, as follows:

1.2.1 Procedure 1--Sodium Hydroxide Swelling.

1.2.2 Procedure 2--Polarized Light.

Note 1--For other test methods for the determination of maturity of cotton fibers refer to Test Methods D1464 and D2480.

1.3 The values stated in SI units are to be regarded as standard. No other units of measure are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 1442 – 93 An American National Standard

Standard Test Method for

Maturity of Cotton Fibers (Sodium Hydroxide Swelling and

Polarized Light Procedures)

This standard is issued under the fixed designation D 1442; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.3 micronaire reading, n—a relative measurement of

fiber fineness derived from the porous plug air-flow method.

1.1 This test method covers the determination of the per-

3.1.4 For definitions of other terms used in this method,

centage of mature fibers in a sample of loose, chemically

refer to Terminology D 123.

untreated cotton fibers, whether taken before processing or

3.2 Definitions of Terms Specific to This Standard:

unravelled from a textile product.

3.2.1 immature fibers, n—in testing with sodium hydroxide

1.2 This test method gives two optional procedures for

solutions, fibers that have either swollen and assumed a spiral

determining maturity, as follows:

form similar to that shown in Fig. 1, or remained flat, thinly

1.2.1 Procedure 1—Sodium Hydroxide Swelling.

outlined, and almost transparent as shown in Fig. 2, with total

1.2.2 Procedure 2—Polarized Light.

wall width less than the lumen width.

NOTE 1—For other test methods for the determination of maturity of

3.2.2 immature fiber, n—observed under polarized light,

cotton fibers refer to Test Methods D 1464 and D 2480.

fibers that appear purple, indigo, or blue that turn orange or

yellow-orange upon rotation to the subtractive position and

2. Referenced Documents

show parallel extinction upon removal of the selenite plate (see

2.1 ASTM Standards:

Table 1).

D 123 Terminology Relating to Textiles

D 1440 Test Method for Length and Length Distribution of

A

TABLE 1 Colors of Cotton Fibers Viewed with Polarized Light

Cotton Fibers (Array Method)

Without Selenite Plate With Selentite Plate

D 1442 Test Method for Maturity of Cotton Fibers (Sodium

Fiber Subtractive

2 Additive Colors

Hydroxide Swelling and Polarized Light Procedures)

Classification First Order Colors

Second Order First Order

D 1447 Test Method for Length and Length Uniformity of

Mature light yellow yellow light yellow

Cotton Fibers by Fibrograph Measurement

white green yellow

D 1464 Test Method for Differential Dyeing Behavior of Immature gray-blue blue orange-yellow

gray purple orange

Cotton

A

Classified according to Mary Anna Grimes, “Polarized Light Preferred for

D 1769 Test Method for Linear Density of Cotton Fibers

2 Maturity Tests,” Textile World, February, 1945.

(Array Sample)

D 2480 Test Method for Maturity Index and Linear Density

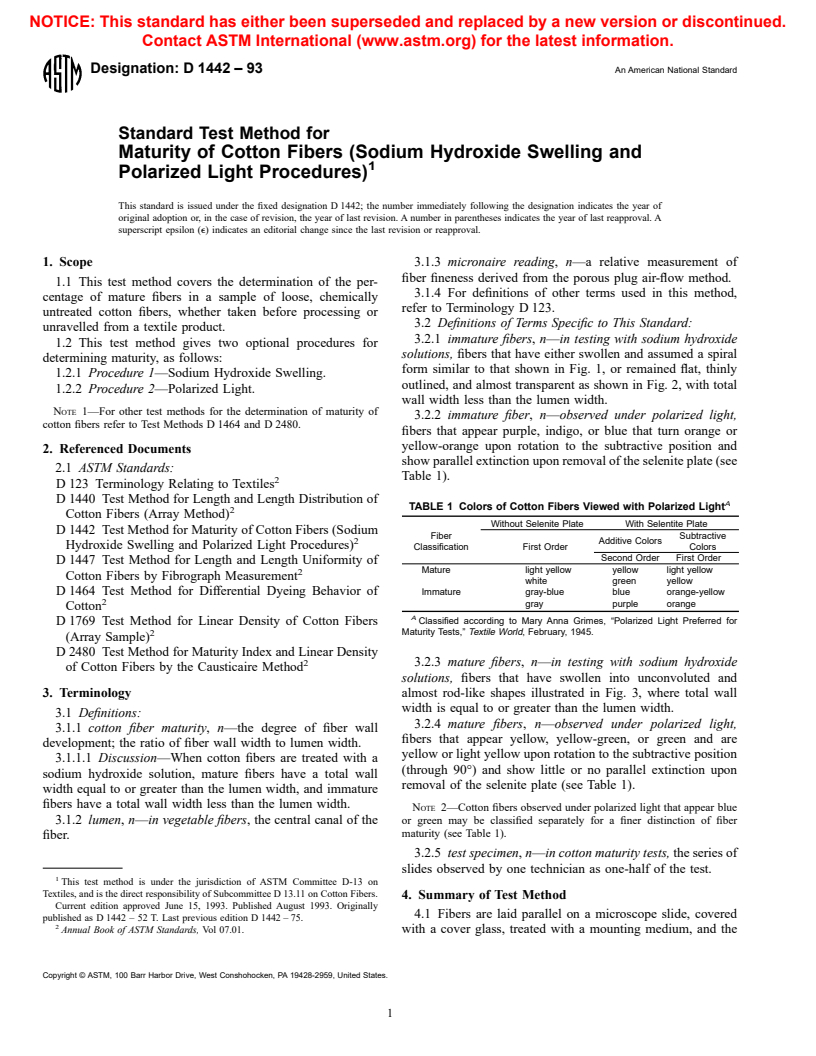

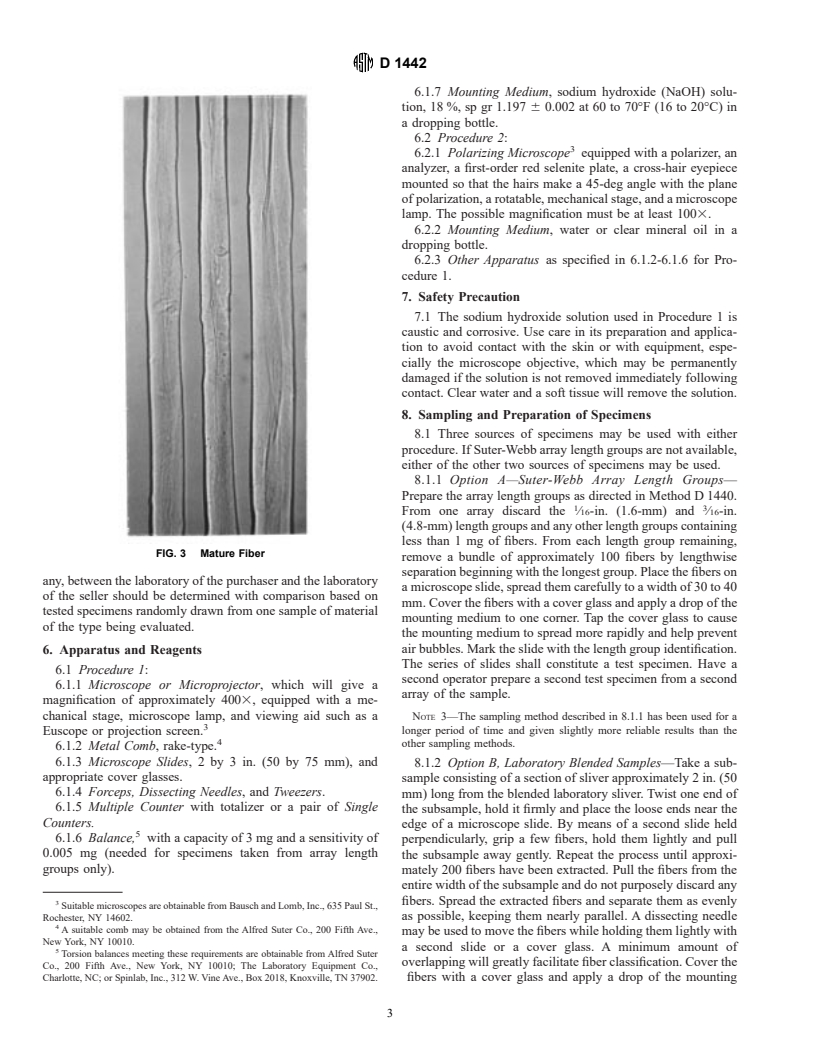

2 3.2.3 mature fibers, n—in testing with sodium hydroxide

of Cotton Fibers by the Causticaire Method

solutions, fibers that have swollen into unconvoluted and

3. Terminology almost rod-like shapes illustrated in Fig. 3, where total wall

width is equal to or greater than the lumen width.

3.1 Definitions:

3.2.4 mature fibers, n—observed under polarized light,

3.1.1 cotton fiber maturity, n—the degree of fiber wall

fibers that appear yellow, yellow-green, or green and are

development; the ratio of fiber wall width to lumen width.

yellow or light yellow upon rotation to the subtractive position

3.1.1.1 Discussion—When cotton fibers are treated with a

(through 90°) and show little or no parallel extinction upon

sodium hydroxide solution, mature fibers have a total wall

removal of the selenite plate (see Table 1).

width equal to or greater than the lumen width, and immature

fibers have a total wall width less than the lumen width.

NOTE 2—Cotton fibers observed under polarized light that appear blue

3.1.2 lumen, n—in vegetable fibers, the central canal of the

or green may be classified separately for a finer distinction of fiber

maturity (see Table 1).

fiber.

3.2.5 test specimen, n—in cotton maturity tests, the series of

slides observed by one technician as one-half of the test.

This test method is under the jurisdiction of ASTM Committee D-13 on

Textiles, and is the direct responsibility of Subcommittee D 13.11 on Cotton Fibers.

4. Summary of Test Method

Current edition approved June 15, 1993. Published August 1993. Originally

4.1 Fibers are laid parallel on a microscope slide, covered

published as D 1442 – 52 T. Last previous edition D 1442 – 75.

Annual Book of ASTM Standards, Vol 07.01. with a cover glass, treated with a mounting medium, and the

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 1442

FIG. 2 Immature Fiber (Type B)

the growing season interfere with this relationship. Thus two

cottons having the same linear density, or having the same

average wall thickness as indicated by air-flow instruments,

may vary greatly in maturity, that is, a cotton having extremely

FIG. 1 Immature Fiber (Type A)

variable wall thickness may contain more immature fibers than

another cotton of the same Micronaire reading composed of

magnified images are then classified as mature or immature

fibers having very uniform wall thickness.

fibers.

5.3 The Sodium Hydroxide Swelling (Procedure 1) has been

4.2 The method offers two procedures for classifying the

used in judging other maturity tests such as the Causticaire and

fibers as mature or immature:

the differential dye methods, in which the individual fibers are

4.2.1 Procedure 1, Sodium Hydroxide Swelling, which uses

not examined.

an 18 % solution of sodium hydroxide as the mounting

5.4 Finer distinctions between different degrees of fiber wall

medium and a laboratory microscope for viewing the fibers at

development can be made with the Polarized Light procedure

a magnification of 4003.

than with the Sodium Hydroxide Swelling procedure. The

4.2.2 Procedure 2, Polarized Light, which uses water or

Polarized Light procedure gives a view of the fiber in its

clear mineral oil as the mounting medium and requires a

natural state so that fibrillar structure, striations, reversals, etc.,

polarizing microscope giving a magnification of 1003. Fibers

are clearly visible as are growth abnormalities and variations in

are classified according to their second-order interference

wall thickness. This method may be preferred by botanists,

colors, using a first-order red selenite plate (Table 1).

geneticists, and plant physiologists, while the Sodium Hydrox-

ide Swelling procedure may be preferred for routine testing of

5. Significance and Use

large numbers of samples. Technicians are more easily trained

5.1 Information regarding the percentage of immature fibers

for the latter method. Arbitrary classification as to maturity

is desirable because immature fibers: (1) break easily during must be made with both methods.

processing; (2) have a tendency to form neps; (3) have a

5.5 This method is not considered satisfactory for accep-

tendency to become entangled around particles of trash and tance testing because between laboratory precision can be poor.

leaf, thus making cleaning more difficult and increasing the In some cases the purchaser and seller may have to test a

amount of fiber removed with foreign matter; (4) adversely commercial shipment of one or more specific material by an

affect yarn and fabric appearance; and (5) may appear differ- appropriate method even though the method has not been

ently after dyeing. recommended for acceptance testing of commercial shipments.

5.2 Maturity has a high positive correlation with linear In such a case, if there is a disagreement arising from

density, but genetic differences and differences in wall thick- differences in values reported by the purchaser and seller in

ness caused by plant diseases, soil, and water conditions during using this method for acceptance testing, the statistical bias, if

D 1442

6.1.7 Mounting Medium, sodium hydroxide (NaOH) solu-

tion, 18 %, sp gr 1.197 6 0.002 at 60 to 70°F (16 to 20°C) in

a dropping bottle.

6.2 Procedure 2:

6.2.1 Polarizing Microscope equipped with a polarizer, an

analyzer, a first-order red selenite plate, a cross-hair eyepiece

mounted so that the hairs make a 45-deg angle with the plane

of polarization, a rotatable, mechanical stage, and a microscope

lamp. The possible magnification must be at least 1003.

6.2.2 Mounting Medium, water or clear mineral oil in a

dropping bottle.

6.2.3 Other Apparatus as specified in 6.1.2-6.1.6 for Pro-

cedure 1.

7. Safety Precaution

7.1 The sodium hydroxide solution used in Procedure 1 is

caustic and corrosive. Use care in its preparation and applica-

tion to avoid contact with the skin or with equipment, espe-

cially the microscope objective, which may be permanently

damaged if the solution is not removed immediately following

contact. Clear water and a soft tissue will remove the solution.

8. Sampling and Preparation of Specimens

8.1 Three sources of specimens may be used with either

procedure. If Suter-Webb array length groups are not available,

either of the other two sources of specimens may be used.

8.1.1 Option A—Suter-Webb Array Length Groups—

Prepare the array length groups as directed in Method D 1440.

1 3

From one array discard the ⁄16-in. (1.6-mm) and ⁄16-in.

(4.8-mm) length groups and any other length groups containing

less than 1 mg of fibers. From each length group remaining,

FIG. 3 Mature Fiber

remove a bundle of approximately 100 fibers by lengthwise

separation beginning with the longest group. Place the fibers on

any, between the laboratory of the purchaser and the laboratory

a microscope slide, spread them carefully to a width of 30 to 40

of the seller should be determined with comparison based on

mm. Cover the fibers with a cover glass and apply a drop of the

tested specimens randomly drawn from one sample of material

mounting medium to one corner. Tap the cover glass to cause

of the type being evaluated.

the mounting medium to spread more rapidly and help prevent

air bubbles. Mark the slide with the length group identification.

6. Apparatus and Reagents

The series of slides shall constitute a test specimen. Have a

6.1 Procedure 1:

second operator prepare a second test specimen from a second

6.1.1 Microscope or Microprojector, which will give a

array of the sample.

magnification of approximately 4003, equipped with a me-

chanical stage, microscope lamp, and viewing aid such as a

NOTE 3—The sampling method described in 8.1.1 has been used for a

longer period of time and given slightly more reliable results than the

Euscope or projection screen.

other sampling methods.

6.1.2 Metal Comb, rake-type.

6.1.3 Microscope Slides, 2 by 3 in. (50 by 75 mm), and

8.1.2 Option B, Laboratory Blended Samples—Take a sub-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.