ASTM B495-10(2017)

(Specification)Standard Specification for Zirconium and Zirconium Alloy Ingots

Standard Specification for Zirconium and Zirconium Alloy Ingots

ABSTRACT

This specification covers the six grades of zirconium and zirconium alloy ingots: Grade R60700, Grade R60702, Grade R60703, Grade R60704, Grade R60705, and Grade R60706. These materials shall be manufactured by electron beam, vacuum, or inert atmosphere melting in furnaces. The material shall form to the required chemical composition of zirconium, hafnium, iron, chromium, tin, hydrogen, nitrogen, carbon, niobium, and oxygen. Check analysis shall be performed. The following test methods shall be done: ultrasonic test and chemical test.

SCOPE

1.1 This specification covers six grades of zirconium ingots.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following precautionary caveat pertains only to the test method portion, Section 10, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B495 −10 (Reapproved 2017)

Standard Specification for

1

Zirconium and Zirconium Alloy Ingots

This standard is issued under the fixed designation B495; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Classification

1.1 This specification covers six grades of zirconium ingots. 4.1 The ingots are furnished in six grades as follows:

4.1.1 Grade R60700—Low oxygen unalloyed zirconium.

1.2 The values stated in inch-pound units are to be regarded

4.1.2 Grade R60702—Unalloyed zirconium.

as standard. The values given in parentheses are mathematical

4.1.3 Grade R60703—Unalloyed zirconium, metallurgical

conversions to SI units that are provided for information only

grade.

and are not considered standard.

4.1.4 Grade R60704—Zirconium-tin alloy.

1.3 The following precautionary caveat pertains only to the

4.1.5 Grade R60705—Zirconium-niobium alloy.

test method portion, Section 10, of this specification: This

4.1.6 Grade R60706—Zirconium-niobium alloy.

standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user

5. Ordering Information

of this standard to establish appropriate safety, health, and

5.1 Orders for materials under this specification shall in-

environmental practices and determine the applicability of

clude the following information:

regulatory limitations prior to use.

5.1.1 Quantity (weight),

1.4 This international standard was developed in accor-

5.1.2 Name of material (zirconium ingot),

dance with internationally recognized principles on standard-

5.1.3 Grade number (Section 4),

ization established in the Decision on Principles for the

5.1.4 ASTM designation and year of issue,

Development of International Standards, Guides and Recom-

5.1.5 Finish (Section 8), and

mendations issued by the World Trade Organization Technical

5.1.6 Additions to the specification and supplementary

Barriers to Trade (TBT) Committee.

requirements, if required.

2. Referenced Documents

NOTE 1—A typical ordering description is as follows: 10,000-lb

2

zirconium ingot, machine conditioned, ASTM B495, dated __, Grade

2.1 ASTM Standards:

R60702.

E114 Practice for Ultrasonic Pulse-Echo Straight-Beam

Contact Testing

6. Materials and Manufacture

E2626 Guide for Spectrometric Analysis of Reactive and

3

6.1 The ingots covered by this specification shall be manu-

Refractory Metals (Withdrawn 2017)

factured by electron beam, vacuum, or inert atmosphere

melting in furnaces conventionally used for reactive metals.

3. Terminology

3.1 Lot Definitions:

7. Chemical Composition

3.1.1 ingot, n—a quantity of metal cast into a shape suitable

for subsequent processing to various mill products. 7.1 The material shall conform to the requirements as to

chemical composition prescribed in Table 1.

7.2 When requested by the purchaser, a check analysis shall

1

This specification is under the jurisdiction of ASTM Committee B10 on

be performed for any elements listed in Table 1.

Reactive and Refractory Metals and Alloys and is the direct responsibility of

7.2.1 The manufacturer’s analysis shall be considered as

Subcommittee B10.02 on Zirconium and Hafnium.

verified if the check analysis confirms the manufacturer’s

Current edition approved Nov. 1, 2017. Published November 2017. Originally

approved in 1969. Last previous edition approved in 2010 as B495 – 10. DOI:

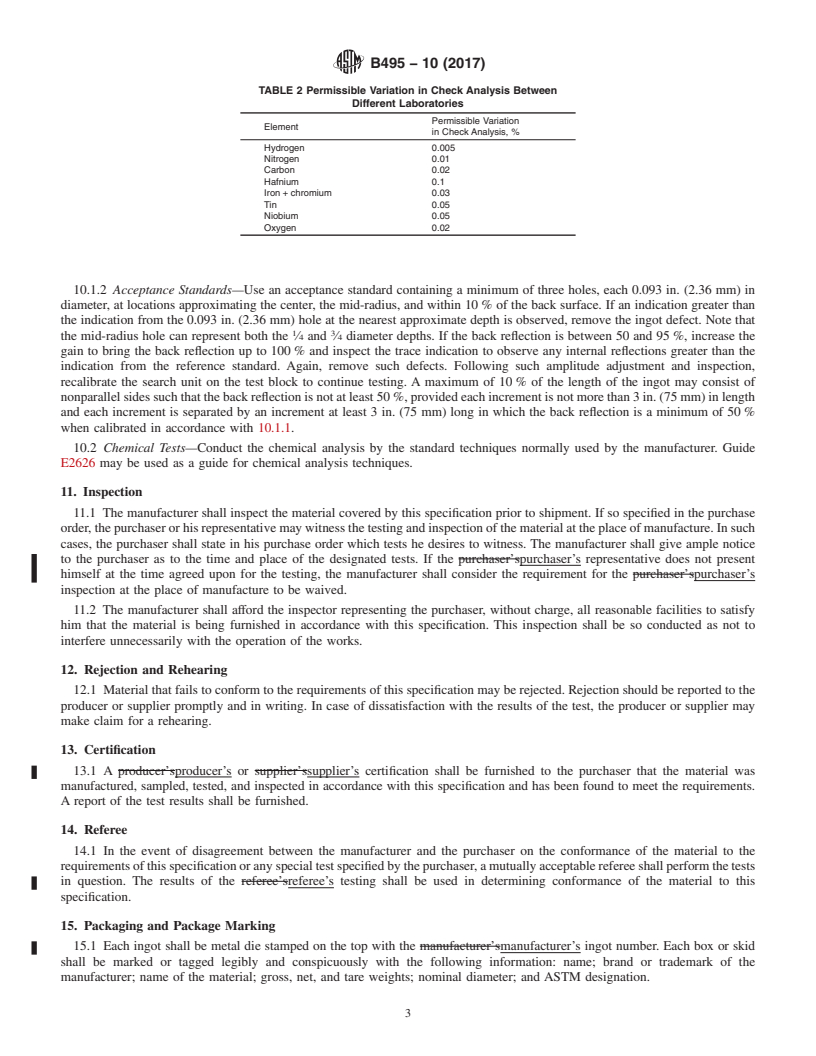

reported values within the tolerances prescribed in Table 2.

10.1520/B0495-10R17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

8. Workmanship, Finish, and Appearance

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

8.1 Ingots shall be conditioned by machining, grinding, or

the ASTM website.

3

surface fusion to remove gross surface and subsurface defects

The last approved version of this historical standard is referenced on

www.astm.org. detrimental to subsequent fabrication.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B495−10 (2017)

A

TABLE 1 Chemical Requirements

Composition, %

Element UNS Grade Designation

R60700 R60702 R60703 R60704 R60705 R60706

Zirconium + hafnium, 99.2 99.2 98.0 97.5 95.5 95.5

min

Hafnium, max 4.5 4.5 4.5 4.5 4.5 4.5

Iron + chromium 0.2 max 0.2 max . 0.2 to 0.4 0.2 max 0.2 max

Tin . . . 1.00 to 2.00 . .

Hydrogen, max 0.004 0.004 . 0.005 0.005 0.005

Nitrogen, max 0.020 0.020 . 0.025 0.025 0.025

Carbon, max 0.05 0.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B495 − 10 B495 − 10 (Reapproved 2017)

Standard Specification for

1

Zirconium and Zirconium Alloy Ingots

This standard is issued under the fixed designation B495; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers six grades of zirconium ingots.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 The following precautionary caveat pertains only to the test method portion, Section 10, of this specification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E114 Practice for Ultrasonic Pulse-Echo Straight-Beam Contact Testing

3

E2626 Guide for Spectrometric Analysis of Reactive and Refractory Metals (Withdrawn 2017)

3. Terminology

3.1 Lot Definitions:

3.1.1 ingot, n—a quantity of metal cast into a shape suitable for subsequent processing to various mill products.

4. Classification

4.1 The ingots are furnished in six grades as follows:

4.1.1 Grade R60700—Low oxygen unalloyed zirconium.

4.1.2 Grade R60702—Unalloyed zirconium.

4.1.3 Grade R60703—Unalloyed zirconium, metallurgical grade.

4.1.4 Grade R60704—Zirconium-tin alloy.

4.1.5 Grade R60705—Zirconium-niobium alloy.

4.1.6 Grade R60706—Zirconium-niobium alloy.

5. Ordering Information

5.1 Orders for materials under this specification shall include the following information:

5.1.1 Quantity (weight),

5.1.2 Name of material (zirconium ingot),

5.1.3 Grade number (Section 4),

5.1.4 ASTM designation and year of issue,

5.1.5 Finish (Section 8), and

1

This specification is under the jurisdiction of ASTM Committee B10 on Reactive and Refractory Metals and Alloys and is the direct responsibility of Subcommittee

B10.02 on Zirconium and Hafnium.

Current edition approved May 1, 2010Nov. 1, 2017. Published June 2010November 2017. Originally approved in 1969. Last previous edition approved in 20052010 as

B495 – 05.B495 – 10. DOI: 10.1520/B0495-10.10.1520/B0495-10R17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B495 − 10 (2017)

5.1.6 Additions to the specification and supplementary requirements, if required.

NOTE 1—A typical ordering description is as follows: 10,000-lb zirconium ingot, machine conditioned, ASTM B495, dated __, Grade R60702.

6. Materials and Manufacture

6.1 The ingots covered by this specification shall be manufactured by electron beam, vacuum, or inert atmosphere melting in

furnaces conventionally used for reactive metals.

7. Chemical Composition

7.1 The material shall conform to the requirements as to chemical composition prescribed in Table 1.

7.2 When requested by the purchaser, a check analysis shall be performed for any elements listed in Table 1.

7.2.1 The manufacturer’s analysis shall be considered as verified if the check analysis confirms the manufacturer’s reported

values within the tolerances prescribed in Table 2.

8. Workmanship, Finish, and Appearance

8.1 Ingots shall be conditioned by machining, grinding, or surface fusion to remove gross surface and subsurface defects

detrimental to subsequent fabrication.

8.2 After conditioning has been completed, no abrupt changes in diame

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.